Velvex Industrial Oil - Nandan Petrochem Ltd

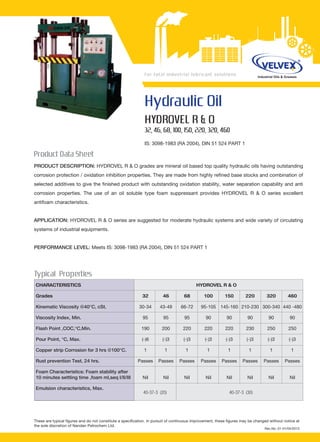

- 1. Hydraulic Oil HYDROVEL R & O 32, 46, 68, 100, 150, 220, 320, 460 IS: 3098-1983 (RA 2004), DIN 51 524 PART 1 PRODUCT DESCRIPTION: HYDROVEL R & O grades are mineral oil based top quality hydraulic oils having outstanding corrosion protection / oxidation inhibition properties. They are made from highly refined base stocks and combination of selected additives to give the finished product with outstanding oxidation stability, water separation capability and anti corrosion properties. The use of an oil soluble type foam suppressant provides HYDROVEL R & O series excellent antifoam characteristics. APPLICATION: HYDROVEL R & O series are suggested for moderate hydraulic systems and wide variety of circulating systems of industrial equipments. PERFORMANCE LEVEL: Meets IS: 3098-1983 (RA 2004), DIN 51 524 PART 1 These are typical figures and do not constitute a specification. In pursuit of continuous improvement, these figures may be changed without notice at the sole discretion of Nandan Petrochem Ltd. 200 Product Data Sheet Typical Properties 40-37-3 (30)40-37-3 (20) CHARACTERISTICS HYDROVEL R & O Grades 32 46 68 100 150 220 320 460 Kinematic Viscosity @40°C, cSt. 30-34 43-49 66-72 95-105 145-160 210-230 300-340 440 -480 Viscosity Index, Min. 95 95 95 90 90 90 90 90 Flash Point ,COC,°C,Min. 190 200 220 220 220 230 250 250 Pour Point, °C, Max. (-)6 (-)3 (-)3 (-)3 (-)3 (-)3 (-)3 (-)3 Copper strip Corrosion for 3 hrs @100°C. 1 1 1 1 1 1 1 1 Rust prevention Test, 24 hrs. Passes Passes Passes Passes Passes Passes Passes Passes Foam Characteristics: Foam stability after 10 minutes settling time ,foam ml,seq I/II/III Nil Nil Nil Nil Nil Nil Nil Nil Emulsion characteristics, Max. Rev.No. 01-01/04/2013

- 2. These are typical figures and do not constitute a specification. In pursuit of continuous improvement, these figures may be changed without notice at the sole discretion of Nandan Petrochem Ltd. PRODUCT DESCRIPTION : HYDROVEL AW grades are blends of high viscosity index, chemically stable base oils and specially selected anti-wear, anti-oxidation, anti-rust and anti-foam additives. These oils have good demulsibility characteristics. They meet the requirements of very high pressure systems (1000 psi and above) and also of systems where high speed actuations are desired. APPLICATION : HYDROVEL AW grades are extensively used to actuate various mechanisms of special purpose machines, positive displacement pumps such as axial, piston, vane and gear types etc. They can also be used in enclosed gear boxes, compressors, chain drives, machine tools, circulation oiling systems, etc. PERFORMANCE LEVEL : HYDROVEL AW 32 TO AW 150 grades Meet IS 10522 – 1983 (RA 1998), DIN 51 524 PART 1. Product Data Sheet Hydraulic Oil HYDROVEL AW 32, 46, 68, 100, 150, 220, 320, 460 IS: 10522-1983(RA 1998), DIN 51 524 PART 1. Typical Properties CHARACTERISTICS HYDROVEL AW Grades 32 46 68 100 150 220 320 460 Kinematic Viscosity @40°C, cSt. 30-34 43-49 66-72 95-105 145-160 210-230 300-340 440 -480 Viscosity Index, Min. 95 95 95 90 90 90 90 90 Flash Point ,COC,°C,Min. 200 200 220 220 230 240 250 250 Pour Point, °C, Max. (-)6 (-)6 (-)6 (-)6 (-)6 (-)6 (-)6 (-)6 Copper strip Corrosion for 3 hrs @100°C. 1 1 1 1 1 1 1 1 Rust prevention Test, 24 hrs. Passes Passes Passes Passes Passes Passes Passes Passes Foam Characteristics: Foam stability after 10 minutes settling time ,foam ml,seq I/II/III Nil Nil Nil Nil Nil Nil Nil Nil Emulsion characteristics, Max. 200 40-37-3 (20) 40-37-3 (30) Rev.No. 01-01/04/2013

- 3. 100 These are typical figures and do not constitute a specification. In pursuit of continuous improvement, these figures may be changed without notice at the sole discretion of Nandan Petrochem Ltd. Hydraulic Oil HYDROVEL HLP 32, 46, 68, 100, 150 IS: 11656-1986 (RA 2002),DIN 51524 PART II,HLP Type PRODUCT DESCRIPTION: HYDROVEL HLP oils are premium grade extra heavy duty antiwear hydraulic oils (HLP Type) with outstanding thermal & oxidation stability and have exceptional load carrying capacity as indicated by high FZG rating (11 Stage Pass). These oils are blended from highly refined selected base stocks fortified with high quality antioxidant, antiwear additives to satisfy the increased demands of thermal and oxidation stability of modern fluids. These oils have excellent hydrolytic stability, demulsibility, air release characteristic and have good filterability. APPLICATION: HYDROVEL HLP are recommended for high pressure hydraulic systems, especially for sophisticated high performance electro hydraulic or numerically controlled system, in hydraulic couplings and drive motor bearings. These oils can also be used in screw compressor and enclosed gear boxes due to their outstanding thermal and oxidation stability. PERFORMANCE LEVEL: Meets IS: 11656 -1986 (RA 2002), DIN 51 524 Part II, HLP Type Product Data Sheet Typical Properties CHARACTERISTICS HYDROVEL HLP Grades 32 46 68 100 150 Kinematic Viscosity @40°C, cSt. 30-34 44-48 68-74 95-105 145-160 Viscosity Index, Min. 105 100 100 100 95 Flash Point ,COC,°C,Min. 200 200 220 250 250 Pour Point, °C, Max. (-)9 (-)9 (-)9 (-)6 (-)6 Copper strip Corrosion for 3 hrs @100°C. 1 1 1 1 1 Rust prevention Test, 24 hrs. Passes Passes Passes Passes Passes Total Acidity (mg of KOH/g of oil) 1 1 1 1 1 Foam Characteristics: Foam stability after 10 minutes settling time ,foam ml,seq I/II/III Nil Nil Nil Nil Nil Emulsion characteristics, Max. 40-37-3 (20) 40-37-3 (20) 40-37-3 (20) 40-37-3 (30) 40-37-3 (30) Rev.No. 01-01/04/2013

- 4. IS: 11656-1986 (RA 2002),DIN 51524 PART III Rev.No. 01-01/04/2013

- 5. 100 These are typical figures and do not constitute a specification. In pursuit of continuous improvement, these figures may be changed without notice at the sole discretion of Nandan Petrochem Ltd. Spindle Oil SPINVEL 5, 12, 22 IS: 493 , PART II - 1981 ( RA 2004) PRODUCT DESCRIPTION: SPINVEL Grades are blended from highly refined hydrotreated oils and have been incorporated with antioxidant, antirust additives to meet the requirements of Textile Machineries particularly. They have low pour point, high viscosity index and have good demulsibility characteristic also. They reduce the rate of wear, lower the power consumption, eliminate spindle sticking and protects against corrosion. APPLICATION: SPINVEL Grades are suitable for high speed spindles in textile machineries operating at very high speeds and other machine tools where high speed and moderate loads are encountered. PERFORMANCE LEVEL: Meets IS: 493 PART II-1981 (RA 2004). Product Data Sheet Typical Properties CHARACTERISTICS SPINVEL Grades 5 12 22 Kinematic Viscosity @40°C, cSt. 4.5-5.5 11-13 20-24 Viscosity Index, Min. 90 90 90 Flash Point ,PMCC**/COC,°C,Min. **90 160 180 Pour Point, °C, Max. (-)6 (-)6 (-)6 Copper strip Corrosion for 3 hrs @100°C. 1 1 1 Rev.No. 01-01/04/2013

- 6. These are typical figures and do not constitute a specification. In pursuit of continuous improvement, these figures may be changed without notice at the sole discretion of Nandan Petrochem Ltd. Machine Oil MACHINEVEL 32, 46, 68, 100, 150, 220, 320, 460 IS: 493, PART I -1981 (RA 2004) PRODUCT DESCRIPTION: MACHINEVEL grades blended from high viscosity index base stocks. They have good inherent oxidation and thermal stability with excellent ability to separate from water. MACHINEVEL oils are specially formulated with additives to improve adhesiveness and film strength characteristics. APPLICATION: MACHINEVEL grades recommended preferably for non-critical all loss lubrication systems and other applications such as lubrication of bearings, open gears, light loaded slides and guide ways of machine tools. They are also recommended for lubrication of looms in the textile mills and other applications which do not require additive containing lubricants. These oils can also be used for flushing of inaccessible internal surfaces of various automotive and industrial equipment. PERFORMANCELEVEL: MeetsIS:493(Part1):1981[RA2004] Product Data Sheet Typical Properties CHARACTERISTICS MACHINEVEL Grades 32 46 68 100 150 220 320 460 Kinematic Viscosity @40°C, cSt. 30-34 44-48 66-72 95-105 145-155 216-224 315-325 450-470 Viscosity Index, Min. 90 90 90 90 90 90 90 90 Flash Point ,COC,°C,Min. 200 200 220 220 220 240 250 250 Pour Point, °C, Max. (-)6 (-)6 (-)6 (-)6 (-)6 (-)6 (-)3 (-)3 Copper strip Corrosion for 3 hrs @100°C. 1 1 1 1 1 1 1 1 50 Rev.No. 01-01/04/2013

- 7. 200 These are typical figures and do not constitute a specification. In pursuit of continuous improvement, these figures may be changed without notice at the sole discretion of Nandan Petrochem Ltd. Industrial Gear Oil GEARVEL 68, 100, 150, 220, 320, 460 IS: 8406-1993(RA 2006), DIN 51517 Part 3 PRODUCT DESCRIPTION: GEARVEL grades are premium quality lubricants fortified with sulphur-phosphorous type of EP additives. They have excellent anti-foam, anti-rust, anti-oxidation and demulsification characteristics making them ideal for systems subjected to heavy shock loads. GEARVEL grades are marketed over a wide viscosity ranges to take care of the variety of speed-load conditions encountered by the industries. These oils contain chemically active additives, which react with the metals of the gear’s teeth to form an anti-welding film between them. APPLICATION: GEARVEL grades are recommended for all heavy duty enclosed gear drives with circulation or splash lubrication system operating under heavy or shock load conditions up to a temperature of 100°C. PERFORMANCE LEVEL: Meets IS: 8406 – 1993 (RA 2006), DIN 51517 Part 3. Product Data Sheet Typical Properties CHARACTERISTICS GEARVEL Grades 68 100 150 220 320 460 Kinematic Viscosity @40°C, cSt. 66-74 95-105 145-160 210-230 310-335 440-480 Viscosity Index, Min. 95 95 95 90 90 90 Flash Point ,COC,°C,Min. 200 210 220 220 220 230 Pour Point, °C, Max. (-)6 (-)6 (-)6 (-)3 (-)3 (-)3 Copper strip Corrosion for 3 hrs @100°C. 1 1 1 1 1 1 Rust prevention Test, 24 hrs. Passes Passes Passes Passes Passes Passes Foam Characteristics: Foam stability after 10 minutes settling time ,foam ml,seq I/II/III Nil Nil Nil Nil Nil Nil Rev.No. 01-01/04/2013

- 8. 200 These are typical figures and do not constitute a specification. In pursuit of continuous improvement, these figures may be changed without notice at the sole discretion of Nandan Petrochem Ltd. GEARVEL PLUS Industrial Gear Oil 68,100,150,220,320,460 IS:8406-1993 ( RA 2006) DIN -51517 Part 3 Typical Properties DESCRIPTION: GEARVEL PLUS range of oils are Extra Premium quality lubricants fortified with sulphur-phosphorous type of EP additives. They have excellent anti-foam, anti-rust, anti-oxidation and demulsification characteristics making them ideal for systems subjected to heavy shock loads. GEARVEL PLUS Oils are marketed over a wide viscosity ranges to take care of the variety of speed-load conditions encountered by the industries. These oils contain chemically active additives, which react with the metals of the gears's teeth to form an anti-welding film between them. Specialty Grade EP additives provides high tenacity and very high load withstand features, with extremely low evaporation loss. APPLICATION: GEARVEL PLUS ranges are recommended for all heavy duty enclosed gear drives with circulation or splash lubrication system operating under heavy or shock load conditions up to a temperature of 100°C. Gearvel Plus 460 specially recommended for crane gear boxes & Worm Gear boxes with extended oil change intervals and minimum oil top up. PERFORMANCE LEVEL: Meet IS: 8406 - 1993 (RA 2006), DIN 51517 Part 3 specifications. Product Data Sheet CHARACTERISTICS GEARVEL PLUS Grades 68 100 150 220 320 460 Kinematic Viscosity @40°C, cSt. 66-74 95-105 145-160 210-230 310-330 440-480 Viscosity Index, Min. 135 135 135 125 115 110 Flash Point ,COC,°C,Min. 200 210 220 220 220 230 Pour Point, °C, Max. (-)6 (-)6 (-)6 (-)3 (-)3 (-)3 Copper strip Corrosion for 3 hrs @100°C. 1 1 1 1 1 1 Rust prevention Test, 24 hrs. Passes Passes Passes Passes Passes Passes Foam Characteristics: Foam stability after 10 minutes settling time ,foam ml,seq I/II/III Nil Nil Nil Nil Nil Nil Rev.No. 01-01/04/2013

- 9. TRANSVEL C-4 SAE 30 Product Data Sheet Typical Properties These are typical figures and do not constitute a specification. In pursuit of continuous improvement, these figures may be changed without notice at the sole discretion of Nandan Petrochem Ltd. Transmission OIL Characteristics Test Method Specification Colour Visual Red K.Viscosity @100 °C IS 1448 P: 25 9.3-12.5 Viscosity Index, Min. IS 1448 P: 56 90 Flash Point ,°C,Min. IS 1448 P: 69 160 Pour Point,°C, Max. IS 1448 P: 10 (-)18 Product Description : TRANSVEL C-4 SAE 30 Oil is blended using highly refined virgin base stocks with special additives to impart high oxidation stability, anti-wear, anti-rust, anti-foam and the desired frictional characteristics in service. It is compatible with the seal material used in hydraulic transmissions systems. TRANSVEL C-4 SAE 30 is hydraulic transmission to meet General Motors Detroit Diesl ALLISON type C-4 specifications. Application : TRANSVEL C-4 SAE 30 oil is recommended for commercial power transmissions, industrial torque converters and automatic transmissions manufactured by AVTEC Ltd.,Hosur,erstwhile power products division of Hindustan Motors Ltd,under License from General Motors USA.Such hauling and cycling transmissions are fitted on a wide variety of Allison heavy duty automatic Transmissions fitted to On-highway and off-highway equipments e.g.Dumpers,scrappers,Shovel loaders,Excavators,Crawler-Tractors,etc.,used in Mines, cement quarries and Dam construction sites etc. BENEFITS: • Smooth operation of precision hydraulic control systems. • Smoother engagement / disengagement of clutch, because of desired friction properties to provide a ‘‘soft shift feel’’. • Provides Protection against wear, rust and corrosion. • Provide excellent seal life. PERFORMANCE LEVEL: TES-228 for Hhydraulic transmission fluid type C-4 of Detroit Diesl ALLISON Division of General Grade: TES 228 Rev.No. 01-01/04/2013

- 10. Transmission OIL TRANSVEL SAE 10 W Characteristics Test Method Specification K.Viscosity @100 °C, cSt IS 1448 P: 25 5.6 Viscosity Index, Min. IS 1448 P: 56 100 Flash Point,°C,Min. IS 1448 P: 69 200 Pour Point,°C,Max. IS 1448 P: 10 (-)27 TBN mg KOH/gm, Min. IS 1448 P:86 8.0 Sulphated Ash, mass % Max. IS 1448 P:4 1.50 Product Data Sheet Typical Properties These are typical figures and do not constitute a specification. In pursuit of continuous improvement, these figures may be changed without notice at the sole discretion of Nandan Petrochem Ltd. Product Description : TRANSVEL SAE 10W is formulated with highly refined base oils combined with ash less dispersant, metallo-organic detergent and effective corrosion and oxidation inhibitor to meet the performance standards. Application: TRANSVEL SAE 10W oil is recommended for all classes of supercharged diesel engines of high speed output such as Heavy Duty Diesel Vehicles / Tractors, Earthmoving/off Highway equipments, Transmission systems of caterpillar Equipment and large generating sets. TRANSVEL SAE 10W meets the requirements of Hydraulic fluid type C2 specification of Detroit Diesel Allision, Division of General Motors Corporation, USA. BENEFITS • Minimizes deposits & wear • Prevent Rust and Corrosion • Maintain excellent engine cleanliness • Minimize deposits resulting from high output, low speed, and low temperature operations. • Excellent control of cold sludge and corrosive wear • Possess excellent oxidation stability to ensure long service life especially in Transmission systems. PERFORMANCE LEVEL: API CD, US MIL-L-45199B, IS: 13656-2002 E-DL2, Caterpillar Series 3 API CD, MIL-L-45199B, IS: 13656-2002 E-DL2, Caterpillar Series 3 Rev.No. 01-01/04/2013

- 11. These are typical figures and do not constitute a specification. In pursuit of continuous improvement, these figures may be changed without notice at the sole discretion of Nandan Petrochem Ltd. Compressor Oil COMPRESSVEL 68, 100, 150 IS: 13256-1992(RA 2004) TYPE DAA, DIN 51506 VD -L PRODUCT DESCRIPTION: COMPRESSVEL grades are manufactured from highly refined base stocks with oxidation, rust, corrosion and foam inhibitors. They provide excellent lubrication under high temperature and high load conditions with low carbon-forming tendency and protection against entrained air. COMPRESSSVEL grades are designed to provide superior thermal and oxidation stability and rust protection. APPLICATION: COMPRESSVEL are recommended for use in the cylinder lubrication of reciprocating and rotary air compressors operating up to 220°C air discharge temperature. PERFORMANCE LEVEL: Meets IS 13256 – 1992 (RA 2004) TYPE DAA, DIN 51506 VD – L Product Data Sheet Typical Properties CHARACTERISTICS COMPRESSVEL 68 100 150 Kinematic Viscosity @40°C, cSt. 66-70 95-105 145-160 Viscosity Index, Min. 100 100 100 Flash Point ,COC,°C,Min. 230 230 240 Pour Point, °C, Max. (-)12 (-)9 (-)6 Copper strip Corrosion for 3 hrs @100°C. 1 1 1 Emulsion characteristic ,Max 40-40- 40-40- 40-40- 0(10) 0(10) 0(20) Rust Preventing characteristic Passes Passes Passes 200 Rev.No. 01-01/04/2013

- 12. These are typical figures and do not constitute a specification. In pursuit of continuous improvement, these figures may be changed without notice at the sole discretion of Nandan Petrochem Ltd. Machine Tool Way Oil WAYVEL 32, 68, 220 PROPERITORY GRADE PRODUCT DESCRIPTION: WAYVEL grades are manufactured from highly refined base stocks with high oxidation stability and are formulated with oiliness, extreme pressure, anti - foam and tackiness additives. These oils provides smooth, chatter free operations by carrying out higher load of machine tools with minimum stick-slip and improved surface finish of the work piece APPLICATION: WAYVEL grades are recommended for the lubrication of horizontal and vertical machine tool slide ways and guides, planers, grinders, shapers etc. PERFORMANCE LEVEL: Proprietary Grade Product Data Sheet Typical Properties CHARACTERISTICS WAYVEL 32 68 220 Kinematic Viscosity @40°C, cSt. 30-34 64-72 210-230 Viscosity Index, Min. 95 95 95 Flash Point ,COC,°C,Min. 190 210 240 Pour Point, °C, Max. (-)3 (-)3 (-)3 50 Rev.No. 01-01/04/2013

- 13. 100 These are typical figures and do not constitute a specification. In pursuit of continuous improvement, these figures may be changed without notice at the sole discretion of Nandan Petrochem Ltd. Heat Transfer Oil THERMVEL 32, 100 PROPERITORY GRADE PRODUCT DESCRIPTION: THERMVEL grades are highly refined mineral oils with exceptional inherent oxidation stability, strong thermal stability and good heat transfer properties for use as Industrial Heat transfer Fluids .These Oils also possess low Volatility to minimize evaporation loss in the open systems and low vapour pressure to eliminate vapour lock in the circulating pumps for long and trouble free service life in heat transfer systems. APPLICATION: THERMVEL grades are recommended for use as heat transfer fluids in well-designed open heat transfer systems operating up to 260°C and up to 300°C for closed system. The products find extensive applications in Textile, Pharmaceuticals, Chemicals and other processing Industries. PERFORMANCE LEVEL: Proprietary Grade Product Data Sheet Typical Properties CHARACTERISTICS THERMVEL Grade 32 100 Kinematic Viscosity @40°C, cSt. 30-34 95-105 Viscosity Index, Min. 95 95 Flash Point ,COC,°C,Min. 190 210 Pour Point, °C, Max. (-)3 (-)3 Operating Temperature Range,°C 260-300 Rev.No. 01-01/04/2013

- 14. Heat Transfer Oil THERMVEL SPECIAL 32, 100 PROPERITORY GRADE PRODUCT DESCRIPTION: THERMVEL SPECIAL grades are blended from light coloured high viscosity index base stocks having good oxidation and thermal stability with specially selected antioxidants for extra long service life of these Industrial Heat Transfer fluids. These Industrial Heat Transfer fluids have also very low level of volatility, vapour pressure, sulphur content and CCR value to provide superior performance. APPLICATION: THERMVEL SPECIAL grades are recommended for use as heat transfer fluids in well-designed open heat transfer systems operating up to 280°C and up to 315°C for closed system. The products find extensive applications in Textile, Pharmaceuticals, Chemical and other processing Industries PERFORMANCE LEVEL: Proprietary Grade Product Data Sheet Typical Properties CHARACTERISTICS THERMVEL SPECIAL 32 100 Kinematic Viscosity @40°C, cSt. 30-34 95-105 Viscosity Index, Min. 110 100 Flash Point ,COC,°C,Min. 200 230 Pour Point, °C, Max. (-)9 (-)9 Operating Temperature Range,°C 280-315 These are typical figures and do not constitute a specification. In pursuit of continuous improvement, these figures may be changed without notice at the sole discretion of Nandan Petrochem Ltd. 100 Rev.No. 01-01/04/2013

- 15. 200 Soluble Cutting Oil CUTVEL S IS:1115 - 1986 (RA 2002) PRODUCT DESCRIPTION: CUTVEL S is a MULTI-PURPOSE SOLUBLE CUTTING OIL manufactured from carefully selected paraffinic base oils and proprietary emulsifiers which have a bearing on the stability of the emulsion even with water of 400 ppm hardness. A stable milky white emulsion is prepared by adding the oil to water with continuous stirring. CUTVEL S gives the desired cooling characteristics, provides rust protection, lubricity for the cutting operation with good finish of work piece and longer life for tools. CUTVEL S is also fortified with appropriate biocides to keep control of bacterial growth. APPLICATION: CUTVEL S is recommended for a variety of cutting operations on both ferrous and non-ferrous metals. For general machining operations the emulsion is normally prepared with 5% oil and for grinding operation the emulsion has 2% of oil. CAUTION : Not recommended for machining of magnesium as fine chips of magnesium is a fire hazard when moistened with water. PERFORMANCE LEVEL: Meets IS 1115-1986 (RA 2002). Product Data Sheet Typical Properties CHARACTERISTICS CUTVEL S Water, % mass, Max. 10.0 Copper strip corrosion at 100°C for 3 Hrs, Max. 1 (a) Emulsion Stability Test ,5:1 and 20:1 ratio in water of 400 ppm hardness Passes Thermal stability Test Passes Ash, % by mass, Max. 3.5 Frothing Test , 5:1 and 20:1 ratio in water of 200 ppm Passes Flash Point,COC,°C, Min. 150 Cast Iron corrosion test 0/1-1 These are typical figures and do not constitute a specification. In pursuit of continuous improvement, these figures may be changed without notice at the sole discretion of Nandan Petrochem Ltd. Rev.No. 01-01/04/2013

- 16. 200 DESCRIPTION: CUTVEL S PLUS is a PREMIUM SOLUBLE CUTTING OIL manufactured from carefully selected paraffinic base oils and proprietary emulsifiers which have a bearing on the stability of long lasting emulsion even with water of 400 ppm hardness. CUTVEL S PLUS gives the desired cooling characteristics and effective foam control, provides rust and corrosion protections with required lubricity for the cutting operations with good finish of work pieces and longer life for tools. CUTVEL S PLUS is also fortified with appropriate biocides to keep control of bacterial growth even during machine shutdown period. A stable milky white emulsion is prepared by adding the oil to water, with continuous stirring APPLICATION: CUTVEL S PLUS is recommended for a variety of cutting operations on both ferrous and non-ferrous metals. For general machining operations the emulsion is normally prepared with 5 % oil and for grinding operation the emulsion has 2% of oil. CAUTION : Not recommended for machining of magnesium as fine chips of magnesium is a fire hazard when moistened with water. PERFORMANCE LEVEL: Meets IS 1115-1986 (RA 2002) performance requirements. Product Data Sheet Typical Properties CHARACTERISTICS CUTVEL S PLUS Emulsion Stability & Frothing Passes Copper Strip Corrosion at 100°C for 3 hours 1a Cast Iron Corrosion Test 0/1-1 Thermal stability Test Passes Flash Point,COC,°C, Min. 150 pH of 5% emulsion 9.2 (Typical) Cutvel S Plus Soluble Cutting Oil IS: 1115-1986 (RA 2002) These are typical figures and do not constitute a specification. In pursuit of continuous improvement, these figures may be changed without notice at the sole discretion of Nandan Petrochem Ltd. Rev.No. 01-01/04/2013

- 17. CHARACTERISTICS CUTVEL N 12 Kinematic Viscosity @40°C,cSt 11-13 Flash Point,COC,°C, Min. 150 Copper strip corrosion @ 100°C for 3 Hrs, Min 4 Sap Value, mg KOH/gm, Min 5 PRODUCT DESCRIPTION: CUTVEL N 12 contains active and non-active sulphur, fatty oil and chlorinated additives to give better surface finish and longer life of cutting tools over a wide range of operating temperatures by providing an excellent lubricating film which resists cutting stresses. APPLICATION: CUTVEL N 12 is recommended for severe machining operations of gear cutting, broaching and threading of alloys and stainless steels, where low viscosity oil is required. The product is NOT recommended for use on non-ferrous metals. PERFORMANCE LEVEL: Proprietary Grade Product Data Sheet Typical Properties Neat Cutting Oil CUTVEL N 12 Proprietary Grade These are typical figures and do not constitute a specification. In pursuit of continuous improvement, these figures may be changed without notice at the sole discretion of Nandan Petrochem Ltd. 50 Rev.No. 01-01/04/2013

- 18. Neat Cutting Oil CUTVEL N 102 IS: 3065 -1985(RA 2002) TYPE 1 GRADE II PRODUCT DESCRIPTION: CUTVEL N 102 is blended from highly refined base stocks with fatty oils and chlorinated additives for a wide range of machining operations with good surface finish without discolouration of the work piece. It minimizes the tools from excessive wear during use. APPLICATION: CUTVEL N 102 is recommended for multipurpose machining operations of ferrous and non-ferrous metals including different grinding and milling operations. PERFORMANCE LEVEL: Meets IS: 3065-1985 (RA 2002), TYPE 1, Grade II Product Data Sheet Typical Properties CHARACTERISTICS CUTVEL N 102 Kinematic Viscosity @40°C,cSt 20-24 Flash Point,COC,°C, Min. 160 Copper strip corrosion at 100°C for 3 Hrs, Max. 1 Sap Value, mg KOH/gm 9-11 These are typical figures and do not constitute a specification. In pursuit of continuous improvement, these figures may be changed without notice at the sole discretion of Nandan Petrochem Ltd. 100 Rev.No. 01-01/04/2013

- 19. Neat Cutting Oil CUTVEL N 203 IS:3065-1985 (RA 2002) TYPE 2 GRADE III PRODUCT DESCRIPTION: CUTVEL N 203 contains highly refined base oils with inactive sulphurised fatty oil. It can be used for a wide range of machining operations with good surface finish without discolouration of the work piece. It minimizes the tools from excessive wear during use. APPLICATION: CUTVEL N 203 is recommended for multipurpose machining operations of ferrous and non-ferrous metals where severity of machining is not encountered. PERFORMANCE LEVEL: Meets IS: 3065-1985 (RA 2002), TYPE 2, Grade III Product Data Sheet Typical Properties CHARACTERISTICS CUTVEL N 203 Kinematic Viscosity @40°C,cSt 32-36 Flash Point,COC,°C, Min. 160 Copper strip corrosion at 100°C for 3 Hrs, Max. 1 Sap Value, mg KOH/gm 9-11 These are typical figures and do not constitute a specification. In pursuit of continuous improvement, these figures may be changed without notice at the sole discretion of Nandan Petrochem Ltd. 100 Rev.No. 01-01/04/2013

- 20. Neat Cutting Oil CUTVEL N 15 GRADE: IS: 3065-1985 (RA 2002), TYPE 3, Grade I CHARACTERISTICS CUTVEL N 15 Kinematic Viscosity @40°C,cSt 15-20 Flash Point,COC,°C, Min. 160 Copper strip corrosion @ 100°C for 3 Hrs, Min. 4 Sap Value, mg KOH/gm, Min 5 PRODUCT DESCRIPTION: CUTVEL N 15 contains active and non-active sulphur, fatty oil and chlorinated additives to give better surface finish and longer life of cutting tools over a wide range of operating temperatures by providing an excellent lubricating film which resists cutting stresses. APPLICATION: CUTVEL N 15 is recommended for severe machining operations of gear cutting, broaching and threading of alloys and stainless steels, where moderate viscosity oil is required. The product is NOT recommended for use on non-ferrous metals. PERFORMANCE LEVEL: CUTVEL N 15 meets the requirement of IS: 3065-1985 (RA 2002), TYPE 3, Grade I Product Data Sheet Typical Properties These are typical figures and do not constitute a specification. In pursuit of continuous improvement, these figures may be changed without notice at the sole discretion of Nandan Petrochem Ltd. 50 Rev.No. 01-01/04/2013

- 21. 100 Neat Cutting Oil CUTVEL N 302 IS: 3065 -1985 (RA 2002) TYPE 3 GRADE II PRODUCT DESCRIPTION: CUTVEL N 302 contains active and non-active sulphur, fatty oil and chlorinated additives to give better surface finish and longer life of cutting tools over a wide range of operating temperatures by providing excellent lubricating film which resists cutting stresses. APPLICATION: CUTVEL N 302 is recommended for machining operations of gear cutting, broaching and threading of alloys and stainless steels, where moderate viscosity oil is required. The product is NOT recommended for use on non-ferrous metals. PERFORMANCE LEVEL: Meets IS: 3065-1985 (RA 2002), TYPE 3, Grade II Product Data Sheet Typical Properties CHARACTERISTICS CUTVEL N 302 Kinematic Viscosity @40°C,cSt 34-40 Flash Point,COC,°C, Min. 160 Copper strip corrosion at 100°C for 3 Hrs, Min. 4 Sap Value, mg KOH/gm, Min 10 These are typical figures and do not constitute a specification. In pursuit of continuous improvement, these figures may be changed without notice at the sole discretion of Nandan Petrochem Ltd. Rev.No. 01-01/04/2013

- 22. These are typical figures and do not constitute a specification. In pursuit of continuous improvement, these figures may be changed without notice at the sole discretion of Nandan Petrochem Ltd. CHARACTERISTICS EDMVEL 2 Colour, ASTM, Max. 1.0 Kinematic Viscosity at 40°C, cSt 2.0-3.0 Flash Point, COC, °C, Min. 90 Copper Strip Corrosion for 3 Hrs. at 100°C. 1 PRODUCT DESCRIPTION: EDMVEL 2 is highly refined oil, recommended for submerged ram-type electrical discharge machining of dies and other complex recessed shapes. This is a low viscosity oil with high flash point, slight odor and has natural resistance to oxidation. Its low level of volatility provides dependable safety and minimal loss from evaporation during use. The high dielectric constant promotes an efficient energy -to-work ratio. The electric spark is concentrated between the electrode and work piece for maximum metal removal and minimum scattering and energy loss that may lead to overheating and premature oxidation. As a result EDMVEL 2 provides extended service life with minimum power consumption. APPLICATION: In all electrical discharge machines working by penetration especially for roughing, finishing and super finishing work where a high removal rate is required For submerged ram-type electrical discharge machining of dies and other complex recessed shapes. The requirements for insulation and controlled dielectric discharge during electric discharge machining operations. BENEFITS: • Highly refined, bright and light colored low viscosity product with low odour • Good heat transfer with high oxidation resistance to degradation for extended product life • Quick chip removal properties for efficient EDM operation and better surface finish. • Relating high flash point ensures no generation of fume and safety from fire hazards • Optimum setting action and excellent filterability through cartridge eliminates clogging of fine orifices and valves. • High wetability ensures liquid /metal contact with low electrode wear and uniform insulation • Non-corrosive and requires least topping up quantity • Low skin sensitivity in normal use for non-toxicity of the product. PERFORMANCE LEVEL: proprietary grade Product Data Sheet Typical Properties Spark Errossion Oil EDMVEL 2 Grade: Proprietry Grade 50 Rev.No. 01-01/04/2013

- 23. 100 Honing Oil HONEVEL 7, 10 PROPERIOTORY GRADE PRODUCT DESCRIPTION: HONEVEL grades are inactive type low viscosity honing oils based on mineral oils fortified with specially selected additives to impart good lubricity characteristics and low temperature fluidity for honing and lapping operations of all ferrous and non-ferrous metals with good surface finish. These products have very light colour for better visibility of work-pieces and tools to the operators, excellent chip flushing, good heat carrying capacity and provide long service life to the honing stone. APPLICATIONS: HONEVEL grades are recommended for machining operations, like honing, lapping, turning, drilling, tapping etc. of all ferrous and non-ferrous metals and their alloys except Titanium alloys, for super finishing of work- pieces. PERFORMANCE LEVEL: Proprietary Grade Product Data Sheet Typical Properties CHARACTERISTICS HONEVEL 7 HONEVEL 10 Kinematic Viscosity @40°C,cSt 4-6 9-10 Flash Point,COC,°C, Min. 130 150 Copper strip corrosion @ 100°C for 3 Hrs, Max. 1 1 Pour Point, °C, Max. (-)9 (-)9 These are typical figures and do not constitute a specification. In pursuit of continuous improvement, these figures may be changed without notice at the sole discretion of Nandan Petrochem Ltd. Rev.No. 01-01/04/2013

- 24. Synthetic Grinding Fluid SYNTHVEL WSP IS:11186-1985 ( RA 2002 ) 2, 5, 12 PRODUCT DESCRIPTION: SYNTHVEL WSP grades are water based synthetic grinding fluid supplied in concentrated form and are to be diluted with water in suitable ratios before use. These grinding fluids are free from mineral oil, fatty matter and nitrite. These grinding fluids are economical with excellent cooling and anti - rust properties when applied in grinding and other high speed machining operations of iron and steel with longer service life to grinding wheels and good surface finish. The solution maintains the clarity throughout the service period and is not attacked by bacteria. The oil removes grinding debris quickly and keeps the wheel exceptionally clean. APPLICATION: SYNTHVEL WSP grades are recommended for grinding operations of Iron, Steel, Non-alloyed Steels, Nickel Chromium Steels, High Nickel and Titanium alloys. It must not be used for grinding operations of aluminum, zinc, copper or magnesium alloys, tin or cadmium coated parts. Dilution range for the products varies from 1:40 min. to 1:100 max. PERFORMANCE LEVEL: Meet IS: 11186 -1985 (RA 2002) These are typical figures and do not constitute a specification. In pursuit of continuous improvement, these figures may be changed without notice at the sole discretion of Nandan Petrochem Ltd. 50 Product Data Sheet Typical Properties Clear liquid with Green Fluorescence Clear liquid with Green Fluorescence Clear liquid with Green Fluorescence CHARACTERISTICS SYNTHVEL Grades WSP 2 WSP 5 WSP 12 Appearance of 10% Volume in Distilled Water Specific Gravity at 15.6°C 1.200 1.220 1.260 pH of 2 % Fluid in Distilled Water, Min 9.0 9.0 9.0 Cast iron corrosion test in 50:1 Distilled water Passes Passes Passes Rev.No. 01-01/04/2013

- 25. Quenching Oil QUENCHVEL IS: 2664-1980(RA 2004) 22, 32,68 PRODUCT DESCRIPTION: QUENCHVEL oils are blended from premium quality solvent refined paraffinic base stocks which have high flash and fire points, and low volatility characteristics with specially selected additives for heat treatment of work piece for improved safety and long service life of the products. These products provide proper and controlled cooling with outstanding chemical and oxidation stability. APPLICATION: Different quenching oils with wide range of quenching speeds are used for different types of quenching operations to cover the ranges of quenching need on wide variety metallic parts. QUENCHVEL 22, QUENCVEL 32 and QUENCHVEL 68 are straight mineral oil type quenching oils, where as QUENCHVEL 22C, QUENCVEL 32C and QUENCHVEL 68C are compounded type quenching oils. PERFORMANCE LEVEL: Meets IS: 2664 – 1980 (RA 2004) Product Data Sheet Typical Properties CHARACTERISTICS QUENCHVEL Grades 22/22C 32/32C 68/68C Kinematic Viscosity @40°C, cSt. 20-24 30-34 64-72 Viscosity Index, Min. 90 90 90 Flash Point ,COC,°C,Min. 190 200 200 Pour Point, °C, Max. (-)6 (-)6 (-)3 These are typical figures and do not constitute a specification. In pursuit of continuous improvement, these figures may be changed without notice at the sole discretion of Nandan Petrochem Ltd. 50 Rev.No. 01-01/04/2013

- 26. Rust Preventive Oil (Solvent Based) RUSTVEL WD S Proprietary Grade 60, 90, 120 PRODUCT DESCRIPTION: RUSTVEL WD S (SOLVENT BASED-WATER DISPLACING TYPE) are light bodied solvent Cut Back type, water displacing rust preventive oils. They form very thin, soft and powerful protective film on evaporation of the solvent present in the rust preventive oils. RUSTVEL WD S are very good water displacing characteristic and excellent finger print corrosion prevention property. APPLICATION: RUSTVEL WD S can be applied by dipping, brushing, swabbing or spraying at ambient temperature for the protection of the iron sheets, metal stacks, ball and roller bearings etc. from corrosion and rust. PERFORMANCE LEVEL: Proprietary Grade. Product Data Sheet Typical Properties CHARACTERISTICS RUSTVEL WDS Grades 60 90 120 Flash Point ,Abel ** /PMCC °C,Min. 32** 60 70 Copper Strip Corrosion Test @50°C for 3 hrs 1 1 1 Film Thickness , Micron, in. 3.5 4.5 6.0 Water Displacement Properties Passes Passes Passes These are typical figures and do not constitute a specification. In pursuit of continuous improvement, these figures may be changed without notice at the sole discretion of Nandan Petrochem Ltd. 200 Rev.No. 01-01/04/2013

- 27. PRODUCT DESCRIPTION: RUSTVEL WD M are non-solvent type oily film forming type rust preventive oils with different viscosities and film thickness. RUSTVEL WD M are blended from selected base stocks and special additives to ensure excellent protection of metal components against rusting for longer and shorter duration in indoor and outdoor applications respectively. Because of its non-drying characteristics, the removal of RUSTVEL WD M from the metal components is easier by treating with petroleum solvents, alkaline cleaning or vapour degreasing agents and do not require any special precautions during storage, handling and applications as they are free from any solvent. APPLICATION: RUSTVEL WD M can be applied by immersion, brush, swab or spray for protecting metal components from rusting. PERFORMANCE LEVEL: Proprietary Grade. Product Data Sheet Typical Properties CHARACTERISTICS RUSTVEL WD M Grades 105 115 125 Kinematic Viscosity @40°C, cSt. (Typical) 15 24 450 Film Thickness , Micron, Min. 2 2 25 Flash Point ,COC °C,Min. 130 160 230 Copper Strip Corrosion Test @100°C for 3 hrs 1 1 1 Rust Preventive Oil RUSTVEL WD M Proprietary Grade 105, 115, 125 (Oil Based) These are typical figures and do not constitute a specification. In pursuit of continuous improvement, these figures may be changed without notice at the sole discretion of Nandan Petrochem Ltd. 200 Rev.No. 01-01/04/2013