Rt Acceptance

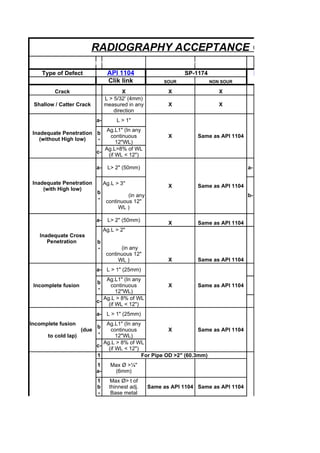

- 1. RADIOGRAPHY ACCEPTANCE CRITERIA Prepared by: Mathew.N.Samuel- OSE311M (Marmul) Type of Defect API 1104 SP-1174 B31.3 (Normal) Clik link SOUR NON SOUR Clik link Crack X X X L > 5/32' (4mm) Shallow / Catter Crack measured in any X X direction a- L > 1" Ag.L1" (In any Inadequate Penetration b continuous X Same as API 1104 (without High low) - 12"WL) Ag.L>8% of WL c- (if WL < 12") a- L> 2" (50mm) a- Inadequate Penetration Ag.L > 3" X Same as API 1104 (with High low) b (in any b- - continuous 12" WL ) a- L> 2" (50mm) X Same as API 1104 Ag.L > 2" Inadequate Cross Penetration b - (in any continuous 12" WL ) X Same as API 1104 a- L > 1" (25mm) Ag.L1" (In any b Incomplete fusion continuous X Same as API 1104 - 12"WL) Ag.L > 8% of WL c- (if WL < 12") a- L > 1" (25mm) Incomplete fusion Ag.L1" (In any b (due continuous X Same as API 1104 - to cold lap) 12"WL) Ag.L > 8% of WL c- (if WL < 12") 1 For Pipe OD >2" (60.3mm) 1 Max Ø >¼" a- (6mm) 1 Max Ø> t of b thinnest adj. Same as API 1104 Same as API 1104 - Base metal Burn Through (BT)

- 2. Ag L> ½" (13mm) in any continuous 1 12" weld or total Same as API 1104 Same as API 1104 c- WL (whichever is Burn Through (BT) less) 2 For Pipe OD <2 3/8" 2 Max Ø >¼" a- (6mm) 2 Max Ø> t of b thinnest adj. Same as API 1104 Same as API 1104 - Base metal More than one 2 Burn through of c- any size If Density of the Radiographic Image of the a- Weld Metal exceeds that of thinnest adj.Base Metal Internal Concavity (The areas that Same as API 1104 Same as API 1104 exceeds the Density of the b thinnest adjcent - parent metal,The criteria for Burn Through are applicable) Under Cutting EU-External Under cutting a- EU + IU > 2" Same as API 1104 Same as API 1104 b EU + IU > 1/6th IU-Internal Under cutting - of WL For Pipe OD> 2" (60.3 mm) L > 2" Width a- a- >1/16" (1.6mm) Ag.L>2" (in any Elongated Slag Incl b continuous 12" Same as API 1104 Same as API 1104 & b- (only in - & Tungsten and Tungsten and WL) fussion zone) copper inclusiions copper inclusiions continuous/brocken/ Ag.L of ESI + ISI shall be treated as shall be treated as c- c- wagontracks - ESI- > 8% of WL slag inclussion for slag inclussion for Elongated Slag Inclussion the purposes of the purposes of assessment assessment Elongated Slag Incl For Pipe OD< 2" (60.3 mm) a- L > 3t b Width of ESI > Same as API 1104 Same as API 1104 - 1.6mm Ag.L of ESI + ISI c- > 8% of WL Isolated Slag Inclusion For pipe > 2" (60.3mm)

- 3. Ag.L>½" 13mm (Other locations leaving a- (in any a- fusion Zone) continous 12" WL) b Width of ISI > Same as API 1104 Same as API 1104 b- - 3.mm Ag.L of ESI + ISI c- c- > 8% of WL For pipe < 2" (60.3mm) If Width > 0.5t & a- L > 2t Same as API 1104 Same as API 1104 b Ag.L of ESI + ISI - > 8% of WL Porosity a- Size >1/8" (3mm) a- b Size > ¼t b- - Same as API 1104 Same as API 1104 Scattered Por c- c- (refer fig) Ø of Cluster > ½" Cluster Porosity a- a- (13mm) Ag.L > ½" b (13mm) in any b- - continuous 12" WL Same as API 1104 Same as API 1104 Single Ø of Pore c- in Cluster Pore > 1/16" (2mm) Hollow Bead a- L > ½ (13mm) a- Ag.L > 2" (50mm) b in any continuous - 12" WL L > ¼" (6mm) but Same as API 1104 Same as API 1104 separated by c- <50mm between them d Ag.L > 8% of WL - Excess Reinforcement Wall Thickness External Weld Reinforcement (mm) Wall Thickness and Penetration (mm) 6.4 and under 1.6 mm ≤ 6 mm (1/4") > 6 mm (1/4"),≤ 13 mm 6.4 -12.7 2.5 Excess Reinforcement > 13 mm (1/2"), 25 mm and Penetration Over 12.7 3 > 25 mm (1")

- 4. ANCE CRITERIA B31.3 (Normal) B31.3 (Severe) Sec IX Clik link Clik link Clik link X X X X X X X X X Depth > 1/32 " (0.78mm) & 0.2t (whichever is Less) X X Ag.L > 1.5" (38mm) in any 6" WL (150mm) Not specified Not specified X X X Not specified Not specified X

- 5. Wj shall never be Wj shall never be less than the base less than the base metal thickness metal Not specified Wj = Total Joint Wj = Total Joint Thick + Thick + reinforcement reinforcement Depth > 1/32" (1mm) X Not specified & ≤ t/4 L > 1/8" (3 mm) t upto 3/8" L > 2t a- L > t/3 a- (10 mm) W > 3.125mm & t/2 W > 2.34mm & t/3 L=1/3 t for t > 3/8" (10 mm) b- b- (whichever is less) (whichever is less) upto 57 mm Inclusive L = 3/4" (19 mm) Ag.L > 4t in any 6" Ag.L > 4t in any 6" c- c- for t > 57 WL WL Ag.L > t in mm a length of 12t & distance between d- indication exceeds 6L where "L" is the longest indication

- 6. 20% of t or 1/8" (3 mm) L > 2t a- L > t/3 a- whichever is less W > 3/32" (2.5mm) No.of indication shall not W > 1/8" & t/2 b- & t/3 (whichever is b- be 12 in any 6" WL if t < (whichever is less) less) 1/8" (3 mm) Ag.L > 4t in any 6" Ag.L < t in any 12" for t >1/8" (3 mm) refer c- c- WL WL chart in Appendix I Same as >2" Same as >2" (60.3mm) (60.3mm) Max Ø>¼ t or For t≤ 6mm same as 20% of t or 1/8" (3 mm) a- 3.90mm a- Sec.VIII Division D whichever is less (whichever is less) Ø>1/3t or 6mm if No.of indication shall not t> 6mm 1.5 times indication b- b- be 12 in any 6" WL if t < Sec.VIII Division D separated by more 1/8" (3 mm) than 1" Ø > 9.5mm if t > for t >1/8" (3 mm) refer c- c- 2" chart in Appendix I For t≤ 6mm same as Size > 1" or 2t a- B31.3(S) (whichever is less) t> 6mm 1.5 times of Ag.L > 1" in any 6" b- a- Refer chart in Appendix I B31.3 (S) WL Max Ø>¼ t or For t≤ 6mm same as 20% of t or 1/8" (3 mm) a- 3.90mm a- B31.3(S) whichever is less (whichever is less) Ø>1/3t or 6mm if No.of indication shall not t> 6mm 1.5 times of indication b- b- be 12 in any 6" WL if t < B31.3 (S) separated by more 1/8" (3 mm) than 1" Ag.L > 1" in any 6" for t >1/8" (3 mm) refer c- c- WL chart in Appendix I External Weld Wall Thickness reinforcement ≤ 6 mm (1/4") ≤ 1.6 mm (1/16") > 6 mm (1/4"),≤ 13 mm ≤ 3 mm (1/8") (1/2") > 13 mm (1/2"), 25 mm ≤ 4 mm (5/32") (1") > 25 mm (1") ≤ 5 mm (3/16")

- 15. HOME

- 26. HOME

- 46. HOME