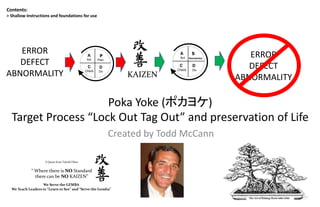

POKA YOKE for Lock Out Tag Out LOTO

- 1. Poka Yoke (ポカヨケ) Target Process “Lock Out Tag Out” and preservation of Life Created by Todd McCann Contents: > Shallow Instructions and foundations for use A Quote from Taiichi Ohno “ Where there is NO Standard there can be NO KAIZEN” We Serve the GEMBA We Teach Leaders to “Learn to See” and “Serve the Gemba” ERROR DEFECT ABNORMALITY S D Do A Act C Check Standardize S D Do A Act C Check Standardize P Plan D Do A Act C Check P Plan D Do A Act C Check KAIZEN ERROR DEFECT ABNORMALITY

- 2. Technique: POKA YOKE (Originally BAKA Yoke Idiot Proofing) GOAL: Creates ideal state of 100% inspection. ZERO based thinking > prevention of recurrence Defined: The technique of installing countermeasures and standards to create an environment in work processes that focuses on early detection and prevention of process abnormalities errors and defects in process. Target is ZERO. Focus and Aim is to eliminate all known sources of process errors/defects. Behaviors are changed in the worker. (Eliminating Warusa Kagen > related to use of Poka Yoke) 2 Categories: Prevention and Detection Detection Poka Yoke: are placed as close to where errors occur, providing early /quick feedback to the worker that an error/mistake is about to occur, so the error/mistake can be immediately corrected. (You can install andons, visual and/or audible devices as well as check list addressing steps that are error likely ) Prevention Poka Yoke: (JIDOKA) Engineered into production devices to make it impossible to perform an error. GO / NO GO devices Selected Error Types: -Processing error > Process operation missed or not performed to a step in standard work. -Setup error > Using the incorrect materials tooling or setting machine adjustments incorrect to specification. -Missing part > Not all parts are available when required to perform standard work. -Improper part/item > Incorrect part is used in the process. -Operations error > Carrying out an operation incorrectly; having the incorrect version of documentation, specification, necessary requirement to complete standard work -Measurement error > Errors in machine adjustment, human error in test measurement or dimensions of a part, location, and installation. How to Create Poka Yoke: • Identify and expose area where error occurs •Determine Root Cause of error: 5Whys/Ishikawa /FMEA/Cause and Effect matrix, 5W+1H, etc •Determine Poka Yoke type: ShutOut <> Control type (preventing an error GO / NO GO /Attention type (highlighting that an error has been made , is occurring and requires attention for correction) •Determine method type (human factoring): Contact, Work Sequence, Constant # •Change Standardized Work Ex: Check sheet •Train to new condition •Perform Equipment improvement (JIDOKA or install audible and/or visual andon/controls) (ポカヨケ) Poka Yoke> Evaluation, Creation and Installation Process TARGET: LOTO Correction required /error has occurred Analysis: Genchi Genbutsu for Genjitsu PDCA Go to Gemba and Genchi GO SEE what happened at the Point of Origin Seek out Point of Origin of Error Use A3 to document condition and environment > create “Hoken” Have individuals involved with error discovery present as well as observers to re-create error/abnormal conditions Query individuals for their knowledge of the error Thoroughly understand current condition at point of origin. Differentiate Symptom from Cause Move downstream, understand and record effects of error Move upstream and understand conditions that may be contributing causal factors to error Potential Data to collect: Facts and data at point of origin regarding error causes Occurrence, frequency & rate of error over time intervals (when, where and how often) Upstream & downstream cause and effects) Skills required to perform task Applied Measurement systems Tolerances Form Fit Function requirements Standardized Work Potential Outputs of Activities: Comprehensive set of facts and data regarding error 5W’s 1H Ishikawa (4M or other as required) Process Flow Diagram Material & Information Flow Diagram Pareto Histogram 80/20 Run Chart / Control Chart FMEA Cause and Effect Matrix Materials Required: Blank A3 and pencil Documentation, standard work procedures, regulatory requirements Skills, Foundational Knowledge and Mindsets Required: Tacit and Intrinsic knowledge and demonstrated proficiency of and Mastery of these skills: POKA YOKE Scientific Thinking Method (STM) for solving problems Prevention of recurrence mindset. Zero Based Thinking Open mindedness not looking for Right and Wrong only looking for condition of Good<>No Good to Target Condition Socratic Method Fault/Decision Tree Analysis 5 Why’s/ 5Why’s and 1 How A3 and Hoken Development Direct observation 3GEN Event recreation 3M Muda Mura Muri 5S KAIZEN Spirit Challenge Spirit Jidoka 7 Tools of Quality 1. Ishikawa diagram 2. Check sheet 3. Control chart 4. Pareto chart 5. Histogram 6. Scatter diagram 7. Stratification flow chart or run chart) Failure Modes & Effects Analysis (FMEA) Factors /tolerances related to Critical to Form Fit and Function Factors /tolerances related to Critical to Quality (CTQ) Use of Standard Worksheets Nemawashi Yokoten Warusa Kagen Generic Error Modeling System (GEMS > James Reasons) Behavior Shaping Constraint identification Created by: Todd McCann Date: 1-1-1999 Subject: (ポカヨケ) Poka Yoke Thinking Analysis: Create Hypothesis > Determine Root Cause of Error PDCA Determine , Create and Plan appropriate Countermeasure Select Type of POKA YOKE to install, WHY and HOW PDCA Perform Test and Trial of Poka Yoke at origin of error PDCA Permanently Install Poka Yoke PDCA Use Facts and Data > Determine what SHOULD be happening versus what IS happening in current condition Use A3 to document condition and environment > continue to create “Hoken” Share work outputs & conditions discovered with those involved with error so Learning takes place Thoroughly understand current condition & causal/contributing factors Create Hypothesis’ (Null and Alternative) Potential Data to collect: Collect additional , at point of origin of error, data and facts regarding error during hypothesis creation as required Potential Outputs of Activities: Null and Alternate hypothesis Comprehensive set of facts and data regarding error at point of origin Clear and concise understanding of what SHOULD be happening in current condition not What is Happening! Install Poka Yoke Install Poka Yoke(s) Install Measurement System Remember to Measure Process Performance > NOT PEOPLE performance Document process and approve new ways of working Instruct LOTO workers in use of Poka Yoke System Instruct LOTO workers of Target Condition of Poka Yoke System and Target Condition of LOTO Poka Yoke(s) Measure to new standard Record learning and improve again Use Facts and Data > Create 3 countermeasures for Trial application and measurement at Origin of error. Create 3 A3’s to document hypothesis and 3 trials for application of Poka Yoke(s) continue to record your thinking and create “Hoken” Share 3 alternatives with those involved with error so Learning takes place (Nemawashi & Yokoten) Decide on type of Poke Yoke Shut Out <>Attention !Decide on Method!: CONTACT - use of shape, size or other physical attributes for early detection of Non-Standard Installation of LOTO SEQUENCE > MOTION STEP - use of a checklist to ensure completion of all installation process step are completed to standard Potential Data to collect: Collect additional data and facts regarding error during hypothesis creation as required Potential Outputs of Activities: 3 Countermeasure Alternatives 3 A3’s documenting Alternatives Determine duration of Trial Measurement system for implementation of 3 Trials Select 1 of 3 trials Perform Trial 1 at Origin of error. Use A3 to document results of Poka Yoke Test and Trial Continue to record your thinking and create “Hoken” Share results of Trail 1 with those involved with error so Learning takes place and sharing of new learning must occur (Yokoten) Potential Data to collect: Collect additional data and facts regarding effectiveness of new condition(s) created and cause and effect during trial at point of origin Potential Outputs of Activities: Results of Test and Trial to Eliminate known source (s) of error Definable, Predictable and Repeatable process to Prevent recurrence of errors Development of measurement system to check effectiveness of Poka Yoke at point of origin and for measuring effectiveness of overall Poka Yoke system Development of Training activities for use of Poka Yoke and new ways of working with Poka Yoke in Target Condition S D Do A Act C Check Standardize S D Do A Act C Check Standardize ERROR DEFECT ABNORMALITY S D Do A Act C Check Standardize S D Do A Act C Check Standardize P Plan D Do A Act C Check P Plan D Do A Act C Check KAIZEN ERROR DEFECT ABNORMALITY P Plan D Do A Act C Check P Plan D Do A Act C Check P Plan D Do A Act C Check P Plan D Do A Act C Check P Plan D Do A Act C Check P Plan D Do A Act C Check P Plan D Do A Act C Check P Plan D Do A Act C Check P Plan D Do A Act C Check P Plan D Do A Act C Check