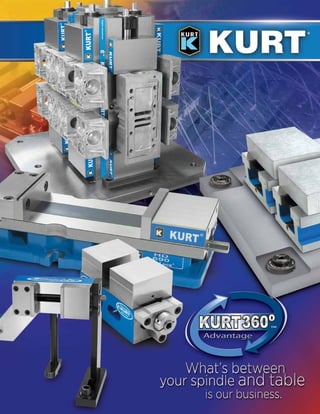

Kurt Catalog 2014

- 2. KURT KURT ® PH 763.574.8309 email workholding@kurt.com www.kurtworkholding.com Introduction..................................2 Application Chart..........................3 NEW SideWinder....................... 4-5 NEW PinLock Mounting System and Receiver Bushings............. 6-7 NEW MaxLock 350 Multi-Axis Vise..............................8 NEW MaxLock SCMX425 & SCMX250 Multi-Axis Vise.............9 NEW HD690 Vise.........................10 NEW HD691 Vise.........................11 HDL AngLock Vises............... 12-13 HD CarvLock Short Vises...... 14-15 HDL CarvLock Towers .......... 16-17 HD CarvLock Towers............ 18-21 Rotary Table Workholding..........22 HD/HDL Vise How To Order.........23 HD/HDL Jaws Kits and Fixture Plates........................ 24-27 DoubleLock Vises................. 28-29 ClusterLock Cluster Tower.........30 ClusterLock.................................31 SeraLock Foundations................32 WedgeLock Clamping Modules......................................33 Modular ToolBlox........................34 ToolBlox......................................35 VersatileLock Vises (3600)... 36-39 MaxLock Multi-Axis Vise page 9 VersatileLock Vises (3400) pages 40-41 2 VersatileLock Vises (3400)... 40-41 AngLock PT-Series Vises...... 42-43 Custom Workholding............ 44-45 Back to Back Vises............... 46-47 MoveLock Modular System.. 48-49 MiniLock............................... 50-51 Self-Centering Vise............... 52-53 Extra Capacity 6" XL Vises... 54-55 Extra Capacity 8" XL Vises... 56-57 AngLock D-Series Vises........ 58-59 Repair Kits............................ 60-61 DLU CarvLock Vise Jaw Kits.......62 3-In-One System Jaw Plates......63 Grid Plates..................................64 InnerLock Jaw Plates.................65 Machinable Jaw Plate................65 Standard Jaw Plates...................65 Groove Lock................................66 Magnetic Jaw Plate and Parallel Set.................................66 6" Magnetic Jaw Plates.............66 NEW Sine Plates.........................67 8" Parallel Sets...........................67 2MWS Magnetic Workstop.........68 AngLock Workstop......................68 6AWS Workstop..........................68 Parallel Keeper...........................68 Kurt Speed Handle......................69 HDM690 Vise page 10 SideWinder pages 4-5 Kurt Torque Handle TH6.............69 Replacement Vise Handles.........69 Handle Hanger............................69 Vise Screw Hex Extensions........69 Spanner Wrench.........................69 Swivel Base................................70 Sine Keys (Non-Expandable O-Ring Style)...............................70 Vise Keys....................................70 PowerLock Drawbar...................71 NEW KHP5000PF and KHP500PH Pneumatic/Hydraulic Pumps......72 KHP5000 Hydraulic Pump...........73 New Products from Kurt....... 74-75 HD CarvLock Towers pages 18-21

- 3. Find the best solution for your application Surface Grinders Double Vise VISE TYPES • • • Modular Vise Pallet Vise Self Centering • Tower Vise General Purpose Machining High Horsepower Machining High Precision Machining • • • • • Single Vise TYPE OF WORK • • • Edge Clamp • • • • • • • • • • • • • • • • • • Large Parts Small Parts “Pull-Type” Jaw Clamping • 80,000 PSI Ductile Iron Base Air Operated Clamps Dissimilar Size Parts FEATURES • Hydraulic Operation (Hand or Foot Actuated) Internal Hex Available Machinable Jaw Available Manual Operation Metric Version Available Quick Change Jaw • • • • Reverse Screw Available • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 1.5" • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 2.5" 3" 3.5" • 4" 5" • • • 6" 8" 10" 200 • • • • • • • • • • • Power Drawbar • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 2" JAW WIDTH • • • • • • • • • • • • • • • • • • • • • • • ToolBlox Tombstones • • • WedgeLock • • • MiniLock • • • 5 Axis • • • • • • • MoveLock • • • Specialty ClusterLock • • • • • HD Series • • • • • HD Series Cluster Tower • DoubleLock • • Pallet Changers For VMC’s • • • • • • • • • • 3600 Series Pallet Changers for HMC’s • • • • • 3400 Series Knee Type Mills Manual Mills • Multi Station SCD Series CNC, Vertical Machining Center • • • • • XL Series CNC, Horizontal Machining Center/FMS PT Series MACHINERY TYPES CNC Mills HD Series 5 Axis Single Station “D” Series Workholding Application Chart • • • APPROXIMATE CLAMPING RANGE (LBS FORCE) 300 350 700 900 1,000 1,400 1,500 2,600 N/A 3,000 5,700 6,900 7,400 7,800 9,400 12,600 20,000 26,000 MAXIMUM JAW OPENING IN STANDARD JAW POSITION (INCHES) Custom Workholding pages 44-45 Rotary Table Workholding page 22 10 9 7.375 21 PinLock Mounting System pages 6-7 8 6 6 6x2 4x8 4x2 N/A N/A Swing Clamps Request Catalog N/A N/A N/A N/A N/A Pneumatic/Hydraulic Pumps page 72 3

- 4. SideWinder™ PATENT PENDING Model: SDW25 SideWinder The Kurt SideWinder is a vise that mounts vertically to the back of any Kurt 6" vise. The SideWinder includes a stabilization leg that will mount to the table on the movable end of the vise and a workstop to position the height of the part. Purpose: For doing 2nd op work holding the part vertically rather than horizontally. Advantage: • Saves set up time for 2nd op vertical work • Machining can be done on both vises in the same setup • Vise is at an elevated position which is more conducive to longer reach machining • Has a stabilizer foot for vibration control • Can be mounted to any Kurt industry standard 6 vise • Has a round nut which controls deflection to a greater degree • Does not interfere with the host vise • Pull type vise • AngLock design 4 Features: • aw Width: 2.500 J • aw Height: 1.063 J • ax Opening: 2.500 M • ax Clamping Force: 2,450 Lbs. M • djustment Range of Workstop: A 0- 4.313 • ex Size: 0.375 H • verall Bracket Width: 14.000 O • ex Length: 0.453 H • eight: 19lbs W • atent Pending P Torque-Ft. Lbs. Clamping Force-Lbs. 4 580 6 880 8 1,120 10 1,540 12 2,450 www.kurtworkholding.com | Toll Free Phone 1-877-226-7823 | Toll Free Fax 1-877-226-7828 | Phone 763-574-8309 | Fax 763-574-8313

- 5. SideWinder™ 14.45 3.2 0.0 / 2.50 STROKE 1.75 2.19 1.06 JAW HEIGHT 3/8 DRIVE HEX .45 2.500 JAW WIDTH 6.00 3.875 1/2-13 SHCS 8. / 8.31 3.000 SLOT WIDTH 0.940 88 / 3.19 1.063 ADJUSTABLE PART STOP 5.0 OF ADJUSTMENT. MACHINE TABLE/ BOTTOM OF VISE URFACE FOR EPEATABLILITY. 0.531 ADJUSTABLE SUPPORT FOOT. 1.5 13.750 14.45 3.2 0.0 / 2.50 STROKE 1.75 2.19 1.06 JAW HEIGHT 3/8 DRIVE HEX .45 2.500 JAW WIDTH 1/2-13 SHCS 8. / 8.31 LOCATING PIN FOR FASTER SETUP'S 3/8 DRIVE HEX 3.000 SLOT WIDTH 0.940 1.063 ADJUSTABLE PART STOP 5.0 OF ADJUSTMENT. MACHINE TABLE/ BOTTOM OF VISE ADJUSTABLE PART STOP 5.0 OF ADJUSTMENT. 0.531 1.5 ADJUSTABLE SUPPORT FOOT. ADJUSTABLE SUPPORT FOOT. 13.750 14.45 14.45 3.2 3.2 1.75 1.75 0.0 / 2.50 0.0 / 2.50 STROKE STROKE 2.19 2.19 .45 .45 2.500 2.500 JAW JAW WIDTH WIDTH 6.00 6.00 3.875 3.875 LOCATING PIN FOR FASTER SETUP'S 3/8 DRIVE HEX 2.88 // 3.19 2.88 3.19 1.06 1.06 JAW HEIGHT JAW HEIGHT 3/8 DRIVE HEX 3/8 DRIVE HEX 8. // 8.31 8. 8.31 3.000 3.000 SLOT SLOT WIDTH WIDTH 0.940 0.940 ADJUSTABLE PART STOP 5.0 OF ADJUSTMENT. PRECISION SURFACE FOR PRECISION SURFACE FOR LOCATION REPEATABLILITY. LOCATION REPEATABLILITY. MACHINE TABLE/ MACHINE TABLE/ ADJUSTABLE SUPPORT FOOT. BOTTOM OF VISE BOTTOM OF VISE 0.531 0.531 ADJUSTAB ADJUSTA 1.5 1.5 www.kurtworkholding.com | Toll Free Phone 1-877-226-7823 | Toll Free Fax 1-877-226-7828 | Phone 763-574-8309 | Fax 763-574-8313 5

- 6. PinLock™ Mounting System PATENT PENDING B Locating and Clamping Shanks: .03 RAD Max PinLock pin assembly engages and creates a locking force with line contact as opposed to other competitive systems that use point contact The PinLock system is designed to reduce time spent accurately positioning and D clamping fixture plates and subplates. A system requires a minimum of two PinLock locators, a primary and a secondary locator. Or two primary bushings can be used to Drill Tap Per Design Table achieve higher accuracy. Liner bushings Listed Below are used to reduce wear on fixture plates. Receiver bushings are used with the PinLock for locating and clamping. For larger subplates additional PinLocks may be used where higher holding force is required. Additional clearance is required on these PinLocks so as not to influence the primary and secondary locators. C A D Max Corner Radius .03 PinLock features a helical extraction design. This feature aids in overcoming binding in side load conditions and enhances the removal of the PinLock in any application. Features • xtraction assist for side load conditions. E • ins provide stronger holding forces. P • ompatible with existing systems. C C • aterial : hank/Bushing, high strength M S alloy steel B • Finish: Black Oxide • Heat Treat: Shanks, RC 46-50 Bushings, RC 46-50 Liners, RC 46-50 Pins, RC 56-60 D • Operating Temperature Range -49° to 400°F A • Patent Pending Locating and Clamping Shank Dimensions Part Number PL13-050 PL13-075 PL16-050 PL16-075 PL20-075 PL20-100 PL25-075 PL25-100 PL30-075 PL30-100 Shank Diameter (mm) A 13 16 20 25 30 Fixture Plate Thickness ±0.005 0.50 0.75 0.50 0.75 0.75 1.00 0.75 1.00 0.75 1.00 PL35-075 1.00 Diameter C 0.25 1.06 0.31 1.38 0.38 1.75 0.38 2.00 0.44 2.13 0.75 PL35-100 Head of Shank Height B PL35-150 35 1.50 Length Under Head D 1.08 1.33 1.15 1.40 1.53 1.78 1.70 1.95 1.88 2.13 Hex Wrench Size for Removal Screw Torque (In/Lbs) Hold-Down Force (lbs) 3/32 1/4 12 750 5/32 3/8 24 1,200 5/32 3/8 55 2,250 5/32 3/8 200 5,444 5/32 3/8 200 8,000 1/4 9/16 400 11,780 1/4 9/16 700 15,200 1.97 0.50 2.25 2.22 2.72 PL35-200 2.00 3.22 PL50-075 0.75 2.45 PL50-100 1.00 PL50-150 PL50-200 6 Recommended Hex Wrench Size for Set Screw 50 1.50 2.00 0.63 3.00 2.70 3.20 3.70 www.kurtworkholding.com | Toll Free Phone 1-877-226-7823 | Toll Free Fax 1-877-226-7828 | Phone 763-574-8309 | Fax 763-574-8313

- 7. PinLock™ Receiver Bushings Back Mount and Face Mount styles of receiver bushings are available. Generally, the Face Mount receiver bushing is utilized in blind hole applications (Slip Fit). The Back Mount receiver bushing is used in applications for through hole (Light Press Fit). B Back Mount B Face Mount C C A Drill Drill Tap Per Tap Per Design TableDesign Table Listed BelowListed Below A A .03 A .03 RAD Max RAD Max D D Note: Both type of bushings should be installed approximately 0.012 below subplate surface. C C Max Corner Max Corner Radius .03 Radius .03 B B D D Back Mount Bushing Installation Instructions Face Mount Bushing Installation Instructions Installation Dimension Face Mount Part Number Back Mount Shank Dia. (mm) Actual Clearance Bore O.D. Drill +0.0005 +0.0000 Diameter -0.0000 -0.0004 A B Depth +0.002 -0.000 C Tap Size Depth1 H Bolt Circle Min. Diameter Subplate 3 PL Thickness Equally D Spaced Part Number Shank Dia. (mm) Actual O.D. +0.0000 -0.0004 A Depth +0.000 -0.002 B C-Bore ±0.006 C Min. Subplate Thickness D PL13RBF 13 1.3750 11/16 1.3750 0.467 8-32x5/16 0.984 13/16 PL13RBB 13 0.7870 0.270 1.000 3/4 PL16RBF 16 1.4370 13/16 1.4370 0.470 8-32x5/16 1.125 13/16 PL16RBB 16 0.8760 0.281 1.156 3/4 PL20RBF 20 1.6873 13/16 1.6873 0.637 10-32x3/8 B 1.362 B 1-1/8 PL20RBB 20 1.0950 0.345 1.280 7/8 PL25RBF 25 2.0623 1 2.0623 0.799 1/4-28x1/2 1.644 1-1/4 PL25RBB 25 1.3763 0.416 1.593 1 PL30RBF 30 2.2654 1 3/16 2.2654 0.871 1/4-28x3/4 1.876 1-3/8 PL30RBB 30 1.6264 0.432 1.906 1-1/4 2.178 1-1/2 PL35RBB 35 1.8764 0.493 2.155 1-5/16 2.916 2 PL50RBB 50 2.6269 0.621 2.988 1-3/4 PL35RBF 35 2.6873 1 9/16 D 2.6873 PL50RBF 50 3.4998 2 5/32 3.4998 Liner Bushings C C D 0.904 5/16-24x7/8 1.239 3/8-24x1 NOTE ON INSTALLATION OF PRESS FIT LINERS BACK MOUNT STYLE RECEIVER BUSHINGS: To alleviate the possibility of binding the shank in the bore, the maximum interference fit between bore bushing O.D. should not exceed 0.0005. PinLock Repair Kits Shank Diameter PL13-Kit 16mm PL16-Kit 20mm PL20-Kit 25mm PL25-Kit 30mm 0.50 13 PL13LBP-050 PL13LBS-050 0.7518 0.75 13 PL13LBP-075 PL13LBS-075 0.7518 0.50 16 PL16LBP-050 PL16LBS-050 1.0018 0.75 16 PL16LBP-075 PL16LBS-075 1.0018 0.75 20 PL20LBP-075 PL20LBS-075 1.3772 1.00 20 PL20LBP-100 PL20LBS-100 1.3772 0.75 25 PL25LBP-075 PL25LBS-075 1.3772 1.00 25 PL25LBP-100 PL25LBS-100 1.3772 0.75 30 PL30LBP-075 PL30LBS-075 1.7523 1.00 30 PL30LBP-100 PL30LBS-100 1.7523 0.75 35 PL35LBP-075 PL35LBS-075 1.7523 1.00 35 PL35LBP-100 PL35LBS-100 1.7523 1.50 35 PL35LBP-150 PL35LBS-150 1.7523 35 PL35LBP-200 PL35LBS-200 1.7523 50 PL50LBP-075 PL50LBS-075 2.5025 50 PL50LBP-100 PL50LBS-100 2.5025 1.50 50 PL50LBP-150 PL50LBS-150 2.5025 2.00 50 PL50LBP-200 PL50LBS-200 2.5025 PL35-Kit 50mm Liner O.D. +0.0000 -0.0004 PL30-Kit 35mm Secondary Liner Part Number Kurt Part Number 13mm Primary Liner Part Number 1.00 Determining if one primary and one secondary or two primary liners are needed will depend on the locating repeatability. With two primary liners, repeatability of ±0.0005 will be maintained if the two holes for receiver bushings are held to a centerline distance of ±0.0002 tolerance. Shank Diameter (mm) 0.75 A Fixture Plate Thickness ±0.005 2.00 A PL50-Kit PLHT2 PinLock hex tool Fold up hex key set for all 20-50mm PinLock Clamping Assemblies www.kurtworkholding.com | Toll Free Phone 1-877-226-7823 | Toll Free Fax 1-877-226-7828 | Phone 763-574-8309 | Fax 763-574-8313 7

- 8. MaxLock™ 350 Multi-Axis AngLock® Vise Model: MX350 • urt AngLock Design pulls the part down. K • Pull Type feature decreases stationary deflection. • 0.625 stroke – Allows for wider range of clamping before having to change setup. C-Bore for 1/2 SHCS • Modular Design – Mounts on two inch grid patterns when 5/8-11 Thread C-Bore for 1/2 SHCS removed from the riser and “T” slots or center hole grids 100mm and under. 5/8-11 Thread • When mounted in a two inch grid the vise comes with locator bolts for quick alignment. • When mounted on the risers, precision 5/8 holes have been added so Kurt sine keys can be used for quick alignment. Screw Selection Chart • Auxiliary clamping slots – allows the customer more flexibility in mounting the vise. Screw Minimum Maximum Part Number Length Jaw Opening Jaw Opening T • he customer will finish machine the horizontal surface of the jaw plate for higher accuracy, eliminating the need for parallels MX350-5-8 MX350-5-8 8.00 0.15 3.5 is the standard MX350-5-12 12.00 3.5 7.5 • ptional jaws: O C-Bore for 1/2 SHCS screw that is MX350-5-18 18.00 7.5 11.5 D • ouble step 40 RC jaws with CDN coating on the vertical 5/8-11 Thread supplied with MX350-5-24 24.00 11.5 15.5 position of the step Part No. MX350-236-1 the vise See Screw 5/16-18 UNC Thread M • achinable semi-hard steel jaws available in 3 lengths Removable Cap 3.500 Chart (2X) See Screw C • hip guard – the fully chip guarded design allows for faster load SIDE VIEW 5/16-18 UNC Thread Removable Cap 3.500 Chart (2X) times and a smoother operating vise. -B- -B• he screw is easily manufactured and changed, by the T customer, to allow a broad range of part sizes. 4.625 K • urt workstop is an available option (Part No. 6AWS-Kit) 4.625 R.328 R.328 4.780 • Maximum of 40 Ft. Lbs. provides up to 7,000 Lbs. clamping force 4.6253.625 4.625 0.563 • Ship Weight: 31lbs. 5.000 5.000 4.780 2.375 0.13 3.625 2.375 R.500 R.500 OPTIONAL RISERS Part No MX350RL and MX350RS SIDE VIEW -A- -A- Removable Cap 3.500 2.688 2.688 0.750 0.750 0.250 0.250 BOTTOM VIEW 3.500 3.500 3.000 3.000 0.625 0.625 4.625 0.313 0.313 0.132 See Screw Chart 0.132 END VIEW R.328 5.000 2.000 1.6 2.000 1.6 0.100 4.150 1.155 1.250 1.750 3.813 1.750 1.155 1.250 1.000 B A 1.005 R.500 1.750 0.13 0.188 0.132 0.188 B OPTIONS: See Screw MX350-236 3.500 Part Number Chart Double Step Jawplate THRU ALL MX350-235-35 2X Ø .265 Cap Ø.390 .281 MX350-235-45 BOTH SIDES MX350-236-1 Double Step Jawplate 3.040 A w/CBN Coating 4.625 3.625 2.375 8 0.132 MX350-235-55 A 0.230 0.730 1.230 1.000 4.780 0.13 5/16-18 UNC Thread (2X)B 3.50 4.50 Removable 5.50 1.250 3.813 0.625 (4X) 4.625 0.625 (4X) 0.563 1.750 0.250 3.500 0.250 END VIEWS Cap 1.000 1.000 0.250 1.000 1.000 0.531 0.531 (2X) (4X) 0.531 0.531 (2X) (4X) 4.625 0.563 9/16 HEX 2.000 0.625 (4X) 2.000 0.625 (4X) 0.500 (2X) 1.750 0.500 (2X) 1.750 C-Bore for 1/2 SHCS Removable Cap 3.500 3.500 2.000 1.750 2.000 1.750 0.045 1.005 Jaw Plate 1.000 2.95 2.000 Dimensions Clearance Required to 2.000 MX350RS 4.625 0.045 C-Bore for 1/2 SHCS Insert 1.750 MX350RL Plate Dimensions 5.650 Jaw 1.750 3.97 0.625 (4X) Bolt Under Rail. Clearance Required to 5/8-11 Thread -AInsert Bolt Under Rail. 2.688 MACHINABLE JAW 0.750 MX350-236 JAWPLATE 3.500 SEMI-HARD STEEL 0.563 5/8-11 Thread 0.250 2.000 2.000 TOP VIEW 3.000 0.100 2X Ø .265 THRU ALL 0.625 (4X) 0.313 0.188 1.000 1.000 0.625 Ø.390 .281 BOTH SIDES 0.500 (2X) 1.155 1.250 3.040 0.531 1.750 0.531 1.000 1.750 A (2X) (4X) 1.005 1.000 2.000 0.045 Jaw Plate Dimensions Clearance Required to 1.250 Insert Bolt Under Rail. .500 Part Number 1.6 3.813 See Screw Chart 5/16-18 UNC Thread (2X) 4.625 9/16 4.625 HEX 4.780 3.625 1.6 1.6 0.563 2.375 0.250 www.kurtworkholding.com | Toll Free Phone 1-877-226-7823 | Toll Free Fax 1-877-226-7828 | 0.13 Phone 763-574-8309 | Fax 763-574-8313 3.813 4.150 B .500 9/1 HE 9/ HE 2.000 BOTTOM VIEW 4.780 0.100 1.6 5/16-18 UNC Thread 1.6 4.150(2X) 4.150 0.563 0.563 3.625 2.375 -B- 1.6 0.563 0.13 4.625 3.625 2.37 0.132 9/1 HEX

- 9. MaxLock™ SCMX425 and SCMX250 Models: SCMX425 and SCMX250 Features: • elf-centering vise for five axis machining S ± • 0.0002 repeatability • djustable Center Line A • achinable Jaws M • he customer will machine in a step for T higher accuracy eliminating the need for parallels H • old up to a 6-1/2 long parts with model SCMX425 • lamp both OD and ID C • urt AngLock design pulls the part down K 2 • -1/2 4 jaw widths • all jaws for increased spindle clearance T • aws are reversible J • lexible mounting options F • ex keys required for jaw removal: H SCMX250: 5/64, 3/32 SCMX425: 3/32, 1/8 K K K SCMX425 CLAMPING FORCE LBS. B TOP VIEW K Ft. Lbs B 10 B Lbs Force 500 20 30 N MIN SIDE VIEW TO P MAX N MIN TO P MAX E 50 E L L G HEX F D F M G HEX G HEX M N MIN TO P MAX D C Z F Q (4X) C'BORED FOR LHSHCS (4X) C Q (4X) 4.000 2.500 E 0.69 0.69 F 1.12 1.11 G 3/8 5/16 H 2.25 1.50 J 2.75 2.00 K 9.12 6.11 1.625 1.344 1.125 0.940 0.000 0.000 1,800 P 2.500 1.000 Q 0.531 Ø 0.406 Ø S 1.000 1.000 T 1.250 - U1 3.000 - U2 3.000 2.000 U3 1.500 - U4 1.500 - V 0.625 0.375 W 0.688 0.500 X 0.375 - Y 0.500 - 1.750 - Est Ship Weight 30 lbs 10 lbs H Y X A X Z W V W TYP 5.000 D N Z Y Q (4X) C'BORED FOR LHSHCS (4X) 8.000 1,300 A X Z D V C C'BORED FOR LHSHCS TYP (4X) V W Q (4X)TYP 2.500 C 30 BOTTOM VIEW G HEX 4.000 Z H X Y L D 2.000 B 40 C C'BORED FORFLHSHCS (4X) SCMX250 2.313 L HATCHING DENOTES 750 CARVABLE AREA M HATCHING DENOTES CARVABLE AREA A Y J L SCMX425 A 350 20 H E Lbs Force 10 M M 3,000 Ft. Lbs HATCHING DENOTES N MIN TO CARVABLE AREA J P MAX H EJ 2,500 SCMX250 CLAMPING FORCE LBS. HATCHING DENOTES CARVABLE AREA J 2,000 60 FRONT VIEW 1,500 40 B 1,000 DIMENSIONAL DATA U3 U3 U4 V W TYP A U3 U4 U4 S S T T U3 U2S U1 S S S T T T T U2 U1 U1 U4 www.kurtworkholding.com | Toll Free Phone 1-877-226-7823 | Toll Free Fax 1-877-226-7828 U2 | Phone 763-574-8309 | Fax 763-574-8313 9

- 10. HD690 Vises HD690 Vise Features: • full 9 inch opening between jaws when using A standard hard jaw plates. L • ess deflection of stationary jaw. Wider more stable stationary jaw equals less deflection. • tationary jaw bolts down from top. No need to remove S from table to disassemble vise. Bolting the stationary from the top reduces the stress in the body and will stay flatter after assembly. • arrower body width allows more vises in the same N work envelope. • aller body design equals less deflection under T clamping loads. • olts and locates directly on standard grid plates: B 40mm, 50mm or 2 inch. P • ull type body design reduces stress in the body resulting in more accurate clamping. • uick change movable jaw. The HD platform movable Q JAW POSITIONS jaw allows for quick change and carvability to hold that JAW POSITIONS odd shaped part. • roove Lock jaw and workstop included. AA G AA U • ses sine keys for alignment. • wivel base available. Part No. D50-4-SA S • ed height matched ±0.0005 B • hip weight: HD690/HDM690 (75lbs.), HDH690 (80lbs.) S Model: HDH690 Model: HD690 SIDE VIEW HDM690 VIEW SIDE G HYDRAULIC UNIT HYDRAULIC UNIT Manual Torque Ft.-Lbs. HD690 HDM690 10 975 20 HYDRAULIC HYDRAULIC UNIT CC UNIT CC JAW POSITION AA AA END OF VISE J CC CC G DRAULIC C HYDRAULIC FF END OF END OF T UNIT UNIT VISE VISE FF G J END OF VISE J J H H EE FF EE 9,450 80 5,250 3,200 12,600 X X K K K E X HH X R R R R R R C E HH X M Z M Z GG HEX Z Y (4X) Y (4X) Z Z M N M N T T T Q Q X W S Q Q V S P P METRIC Q I A 0.330 0.940 S U S WU W 3.875 I T HD690 ALUMINUM S T S MACHINABLE KIT V U V U Part No. HD690AL-JAWKIT W W M12 T T V GG HEX V GG HEX 2.000 2.986 50 MM T 200 MM 80 MM Q Q 10.000 W Q Q 4.000 X 16 MM X 0.625 X Y Z 0.992 AA 9.062 BB 12.099 13.787 DD GG HEX T (4X) R I Y (4X) 1/2-13 Y CC Q Z 2.000 R BOTTOM VIEW B B P (TYP) P (TYP)N P (TYP) BOTTOM VIEW O O O 16.824 Jaw # Used EE 2.250 XJAB6A-318 HD6AL-2 STATIONARY JAW MOVABLE JAW FF 3.375 GG 3/4 HH N N Z 4.000 B Y (4X) A A HH U Q S 1.735 M R P (TYP) K C END END VIEW B VIEWEND VIEW C L O END VIEW R M I Y (4X) L L 0.725 R Q S H V R R 2.312 M J HH Q GG HEXGG HEX U 10 HH C 3.375 S L C F 0.6600 BOTTOM VIEW F 1.485 BOTTOM VIEW G X BOTTOM VIEW C C C Z M BOTTOM VIEW VIEW BOTTOM BOTTOM VIEW X M L A R R 16.810 F X R R BOTTOM VIEW X A D X X FL 6.000 K K HH 7.338 O X F X N X I K F E END E Hydraulic VIEW Displacement E 1.18 D cu. D In. N A D E 11,025 L D 7,875 X D 2,800 X D 6,300 2,400 E EE 1,600 4,700 D EE C 4,275 H DD DD B 3,700 EE EE AA 3,150 3.125 E D A AA 4,725 AA H H 2,000 J J 3,250 F AA 800 2,400 H AA 1,575 70 SIDE VIEW G 400 60 SIDE SIDE VIEW VIEWSIDE VIEW AA HD690/HDM690 HDH690 E SIDE VIEW 1,200 1,625 G G DIMENSIONAL DATA HDH690 SIDE VIEW 50 DD SIDE VIEW DD G EE AA H H 30 END OF END OF VISE 40 VISE FF FF BB BB Hydraulic EE PSI AA J J VISE CLAMPING FORCE-LBS. FF VISE CLAMPING FORCE-LBS. BB JAW POSITIONS JAW POSITIONS G END OF VISE END OF VISE FF BB DRAULIC UNIT FF PATENT PENDING 1.508 www.kurtworkholding.com | Toll FreeVPhone 1-877-226-7823 | Toll Free Fax 1-877-226-7828 | Phone 763-574-8309 | Fax 763-574-8313 X X X V V U U U

- 11. 8 HD691 Vises PATENT PENDING HD691 Vise Features: • asier programming in the “Y” axis positive direction E • Reduces “reach-over” distance making part loading safer and easier • A full 9 inch opening between jaws when using standard hard jaw plates. • Less deflection of stationary jaw. Wider more stable stationary jaw equals less deflection. • Stationary jaw bolts down from top. No need to remove from table to disassemble vise. Bolting the stationary from the top reduces the stress in the body and will stay flatter after assembly. • Narrower body width allows more vises in the same work envelope. • Taller body design equals less deflection under clamping loads. • Bolts and locates directly on standard grid plates: 40mm, 50mm or 2 inch. • Pull type body design reduces stress in theJAW POSITIONS body JAW POSITIONS resulting in more accurate clamping. • Quick change movable jaw. The HD platform movable AA jaw allows for quick change and carvability to hold that AA odd shaped part. • Groove Lock jaw and workstop included. • Uses sine keys for alignment. • Swivel base available. Part No. D50-4-SA BB BB • Bed height matched ±0.0005 • Ship weight: HD691 (75lbs.), HDH691 (80lbs.) Model: HDH691 Model: HD691 G G VISE CLAMPING FORCE-LBS. Manual Torque Ft.-Lbs. HD691 10 975 20 1,625 JAW POSITIONS 1,600 50 EE 1.493 G CC EE EE 5/8 1.493 G END OF VISE HYDRAULIC HYDRAULIC UNIT ONLY UNIT ONLY 2,800 11,025 G 3,200 12,600 5,250 L Hydraulic HH Displacement cu. In. H J H K H K F F F A A A N FN L L P P METRIC N E HH X D E D X HYDRAULIC UNIT ONLY I R E X C C BOTTOM VIEW R GG HEX X M (3X) M M Z Y (4X) Z Z R Y (4X) Q R R T S U GG HEX GG HEX S U I U T S U V U W 2.986 50 MM T 200 MM 80 MM V W X T 10.000 V 4.000 16 MM Y Y (4X) Q Y (4X) QQ Q Q Q 0.625 Z 0.992 AA 9.062 BB 12.099 CC 13.787 DD 16.824 EE 2.250 3.375 GG T T V 3/4 HH V S W GG HEX 2.000 FF Q R GG HEX I S Z M BOTTOM VIEW BOTTOM VIEW BOTTOM VIEW X (3X) I C BOTTOM VIEW X (3X) R M12 R D C X X (3X) 3.875 P (TYP) Z GG HEX 1/2-13 GG HEX U E HH 0.330 0.940 Q A D HH HYDRAULIC UNIT 2.000 S L HH 4.000 P (TYP) O P (TYP) O M R FF R O X (3X) 0.725 R END VIEW M P (TYP) BOTTOM VIEW N B B O N 7.338 C L R O M M 1.735 K END VIEW END END VIEW B VIEW L R D K 1.485 H 1.18 X X X 2.312 X (3X) (3X) EI R J R X END VIEW K D D 0.6600 F K AA 3.375 E SIDE VIEW AA 16.810 AA 9,450 B AA C D 2,400 G H J END OF VISE FF HYDRAULIC 5/8 UNIT 5/8 1.493 1.493 1.493 HYDRAULIC HYDRAULIC HYDRAULIC UNIT UNIT ONLY UNIT G 4,725 J 6,300 7,875 H HYDRAULIC UNIT AA J J END OF END OF EE EE VISE VISE FF DD FF SIDE VIEW SIDE VIEW SIDE VIEW HH HH 3.125 6.000 2,000 HYDRAULIC UNIT ONLY SIDE VIEW HD691 HDH691 B 4,700 FF 80 5/8 SIDE A VIEW 4,275 70 DD DD HYDRAULIC 1,575 HYDRAULIC UNIT UNIT 3,150 400 800 HYDRAULIC G HYDRAULIC UNIT ONLY 1,200 UNIT ONLY 60 BB 1.493 1.493 END OF VISE 3,700 L L HDH691 3,250 40 CC CC Hydraulic PSI H H DIMENSIONAL DATA FF 2,400 30 JAW POSITION AA VISE CLAMPING FORCE-LBS. FF 5/8 5/8 J J END OF END OF VISE VISE EE EE 1.575 V W www.kurtworkholding.com | Toll Free PhoneW 1-877-226-7823W| Toll Free Fax 1-877-226-7828 | Phone 763-574-8309 | Fax 763-574-8313 11 W W U U S S

- 12. HDL AngLock® Vises (46 Inch) Manual Hydraulic 4 Inch Models: HDL4 Manual English – PATENTED HDHL4 Hydraulic – PATENTED HDLM4 Manual Metric – PATENTED HDHLM4 Hydraulic – PATENTED 6 Inch Models: HDL6 Manual English – PATENTED HDHL6 Hydraulic – PATENTED HDLM6 Manual Metric – PATENTED HDHLM6 Hydraulic – PATENTED H G For specific model numbers see page 23. * L B K The HDL AngLock Vises are high density long vises with two clamping stations. They provide repeatable clamping to 0.0002 and combine high density with heavy duty features. Designed on a rugged 80,000 PSI ductile iron body with steel components, both models provide strength, rigidity and long term F accuracy while absorbing machining Preload P ( 2X ) M Y vibration. E Both jaws ( HYD Only) Features: s oad h jaws D Only) * J Optional Int Hex AA X U N TOP VIEW H W * SAE Straight T Thread O-Ring Port This End HYD Only G * L B K * * J Optional Int Hex AA BOTTOM VIEW (Mounting hole pattern is designated by color code) X LL NN MM D V A ±0.001 Movement Location For OOØ SCHS ( 4X ) KK GG A ±0.001 ( 3X ) KK FF HH Location For PPØ SCHS ( 4X ) MM SAE Straight T Thread O-Ring Port This End HYD Only W GG HH JJ U V FF N ( 2X ) QQØ ( 4X ) 12 * Movement • wo clamping stations – repeatable T clamping to 0.0002. • 3 and 4 inch opening in each Full station with standard hard jaw system. • aws are indexable 180 degrees. J • Manual and hydraulic modelsD available. • ast easyC F conversion between manual and hydraulic models. Part #HDHLM4-3-SA-KIT (4 inch) #HDHLM6-3-SA-KIT (6 inch) • aximizes the number of parts in the M work envelope. • djustable pre-load feature allows A you to minimize pre-load range thus reducing the turns of the handle to open or close the vise (manual version). • olding block features the ability to H clamp same or dissimilar sized parts and provides pre-loading ability in the front or back jaw (manual version). F • Lifetime Iron Clad Warranty. P ( 2X ) • E height tolerance ±0.001. M Bed C * JJ LL NN ( 3X ) ( 2X ) RRØ ( 2X ) www.kurtworkholding.com | Toll Free Phone 1-877-226-7823 | Toll Free Fax 1-877-226-7828 | Phone 763-574-8309 | Fax 763-574-8313

- 13. Both jaws ( HYD Only) N R HDL AngLock® Vises (46 Inch) FRONT VIEW Clearance Above SHCS Head S HDLM4 / HDL4 Movement Z Both Directions MM Inch Manual Only 60.325 A 2.375 O G N * * L SS * K * ( EXT HEX ) This End Manual Only AA Optional INT HEX AA ( INT HEX HYD ) T Hex AA T REAR VIEW OF STANDARD HEIGHT JAW U V W X Y Z X U DD EEØ 4-Holes 2-Sides DD CC CC V AA BB CC DD EE FF BB SAE Straight T Thread O-Ring Port This End HYD Only W TT Clearance OPTIONAL JAW KIT Above SHCS 1.9 Head HEIGHT JAW (4 Inch) or 2.5 HEIGHT JAW (6 Inch) SS Clearance Above TT SHCS Head Clearance S Above SHCS Head Location ForN OOØ SCHS ( 4X ) SIDE VIEW LL FF GG KK Q Preload Y Both jaws ( HYD Only) KK O O Location For PPØ SCHS ( 4X ) F E P ( 2X ) Movement GG HH JJ KK LL MM NN OO PP QQ RR SS TT HDHLM4 / HDHL4 MM 60.325 101.600 4.000 101.600 415.925 16.375 415.925 200.025 7.875 200.025 63.500 2.500 63.500 418.287 16.468 418.287 209.144 8.234 209.144 33.680 1.326 – 9.855 0.388 – 41.275 1.625 41.275 82.550 TT 3.250 82.550 101.600 4.000 101.600 Clearance 35.560 SHCS 35.560 Above 1.400 Head 4.000 101.600 101.600 75.794 2.984 75.794 65.075 2.562 65.075 20.625 0.812 20.625 7.722 0.304 7.722 14.275 0.562 7/16 – 20 UNF EXT HEX EXT HEX O-RING PORT 9.525 0.375 9.525 42.875 1.688 42.875 63.500 2.500 63.500 M8 x 1.25 M8 x 1.25 M8 x 1.25 – – 3.175 3.048 0.120 – 11.099 0.437 11.900 INT HEX INT HEX INT HEX 9.525 0.375 9.525 Q 34.325 1.375 34.325 65.100 2.563 65.100 M8 x 1.25 R x 1.25 M8 M8 x 1.25 0.750 H 20.000 100.000 HDLM6 / HDL6 5.250 5.250 HDHLM6 / HDHL6 MM Inch MM Inch 25.000 75.000 5.250 * 5.250 5.000 7.000 Movement Z Both Directions Manual Only C 20 30 40 50 60 P 70 2,125 3,140 4,040 4,980 5,870 ( 2X ) Movement 1,500 2,000 2,500 3,000 3,500 4,000 4,500 M 1,450 1,900 2,550 3,100 3,700 4,200 4,800 Hyd. Displacement 0.414 cubic inches KK 5.000 7.000 * D 175.000 2.000 50.000 H M12 SHCS – – 1/2 SHCS – 0.625 16.000 – 60.960 2.400 30.328 1.194 31.75 kgs/70 lbs CLAMPING FORCE LBS. J Hydraulic HDHLM6 Torque- HDLM4 Hydraulic HDHLM4 X HDLM6 Ft. Lbs. HDL4 PSI HDHL4 PSI HDHL6 Optional Int Hex 10 1,040 1,000 775 1,540 500 875 M LL G 25.000 75.000 100.000 100.000 175.000 C – 1.500 – 1.500 2.000 Movement 40.000 – Z 40.000 – 50.000 Both Directions M8 SHCS – M8 SHCS – M12 SHCS – Manual Only * – 5/16 SHCS – 5/16 SHCS – 1/2 SHCS – 0.625 – 0.625 – 0.625 16.000 – – 16.000 – J 16.000 48.260 1.900 48.260 60.960 2.400 Optional Int Hex1.900 AA 20.422 0.804 20.422 0.804 30.328 1.194 34 lbs/15.42 kgs 33 lbs/14.96 kgs 32.21 kgs/71 lbs Estimated Shipping Weight of Vise Body Only BB Inch 2.375 79.375 3.125 79.375 3.125 4.000 152.400 6.000 152.400 6.000 16.375 533.400 21.000 533.400 21.000 7.875 258.877 10.192 258.877 10.192 2.500 82.550 3.250 82.550 3.250 16.468 539.750 21.250 539.750 21.250 8.234 269.875 10.625 269.875 10.625 – 36.830 1.450 – – – 21.844 0.860 – – 1.625 63.500 2.500 63.500 2.500 3.250 127.000 5.000 127.000 5.000 4.000 127.000 5.000 127.000 5.000 1.400 43.891 1.728 43.891 1.728 4.000 152.400 6.000 152.400 6.000 2.984 101.600 4.000 101.600 4.000 2.562 84.125 3.312 84.125 3.312 0.812 24.613 0.969 24.613 0.969 0.304 13.259 0.522 13.259 0.522 ( 2X ) 7/16-20 UNF 7/16-20 UNF 7/16 – 20 UNF 19.050NN 0.750 O-RING PORT EXT HEX EXT HEX O-RING PORT O-RING PORT 0.375 11.125 0.438 11.125 0.438 1.688 53.975 53.975 2.125 MM 2.125 ( 3X 2.500 98.425 3.875 ) 98.425 3.875 M8 x 1.25 M10 x 1.5 M10 x 1.5 M10 x 1.5 M10 x 1.5 0.125 – – 3.175 0.125 – 3.962 0.156 – – 0.437 15.875 0.625 15.875 0.625 F INT HEX QQØHEX INTPreload INT HEX HEX INT INT HEX 4X 0.375Y 11.125 E 0.438 P (( 2X )) 11.125 0.438 M 1.375 jaws28.575 1.125Movement 28.575 1.125 Both 2.563 Only) 79.375 3.125 79.375 3.125 ( HYD M8 x 1.25 M8 x 1.25 M8 x 1.25 M8 x 1.25 M8 x 1.25 0.750 1.000 1.000 20.000 100.000 N ( EXT HEX ) ( 3XThis End Manual Only ) AA Optional NN INT HEX F ( 2XAA ( INT HEX HYD ) Preload A ±0.001 ) E Q Y Both jaws D ( HYD Only) C R RRØ ( 2X ) DD EEØ DD 4-Holes CC CC 2-Sides FF HH Movement JJ Z Both Directions LL Manual Only A ±0.001 Dimensional Data D High Density 4 6 Full OpenVise HDL Manual Hydraulic C MM T R GG HH JJ B C D E F G H J B K L M N O P Q R S Manual Hydraulic 2,520 3,350 4,310 5,750 6,860 7,460 1,000 1,500 2,000 2,500 3,000 3,500 4,000 4,500 * * AA U 1,600 2,330 3,130 3,950 4,750 ( 5,475 NN 6,350 T 7,100 2X ) SAE S W Thread MM Port Th N Hyd. Displacement ( HYD O 3X ) 1.08 cubic inches A ±0.001 D V HD HDL J aw K its F ixture P lates SEE PAGES 24-27 Clearance Above SHCS Head www.kurtworkholding.com | Toll Free Phone 1-877-226-7823 | Toll Free Fax 1-877-226-7828 | Phone 763-574-8309 | Fax 763-574-8313 O S + 13

- 14. a HD CarvLock® Short Vises Manual Hydraulic Model: HDM6 Manual For specific model numbers see page 23. The HD CarvLock Vises are High-Density and Heavy-Duty. The overall vise is very compact, making possible maximum density workholding across the full range of today’s machining centers. The HD Vise can be equipped with quick change jaws in aluminum, cast iron or with a fixture plate. Features: • ompact size. Overall length of just 13.750 and overall width of C only 6. • lamping power/accuracy - produces up to 7,800 lbs of clamping C force with repeatable clamping to 0.0002. D • urability - 80,000 PSI ductile iron vise body for rugged strength, rigidity and long-term accuracy while absorbing machining vibration. • nclosed vise body keeps out chips and contaminants - makes E cleanup fast and easy. •F ast, easy conversion from manual to hydraulic. Easy to switch between both styles. Part No. HDHM6-3-SA-KIT. • Jaws are indexable 180 degrees. • Lifetime Iron Clad Warranty. (shown with optional machinable aluminum jaws) The HDM6 Manual vise body has optional jaw systems which include a set of 7075 T-6 aluminum jaw blocks or a set of ductile iron jaw blocks (1.73SS standard thickness, 2.40 optional thickness) or fixture plate. Screw and nut assemblies are reversible with the vise body. TT One jaw kit will handle two different parts.Clearance Above SHCS Head Accessory Jaw Plate Shown Model: HDHM6-DA Double Acting Hydraulic With Optional 2.5 Height Jaw Double acting hydraulic vise uses hydraulic pressure to clamp and unclamp. Extremely reliable operation compared to other vises using mechanical operation for unclamping. Designed for automated systems. (shown with optional machinable aluminum jaws) Non-Carvable Area Typical VIEW TOP R Features: • ell suited for automation. W • ast, positive open/close cycle. F C • ompact size - overall length of just 13.750 and overall width Clearance Above SHCS Head of only 6. S • lamping power/accuracy - produces up to 7,800 lbs C O clamping force @ 5,000 PSI of hydraulic pressure with repeatable clamping to 0.0002. N • urability - 80,000 PSI ductile iron vise body for rugged D strength, rigidity and long-term accuracy while absorbing machining vibration. • nclosed vise body keeps out chips and contaminants E T (INT HEX) F makes cleanup fast and easy. Preload P (2X) (SAE STRAIGHT THREAD UU • aws are indexable 180 degrees. O-RING PORT) J Movement Both•Jaws Iron Clad Warranty. L ifetime E Q M The HDHM6 Hydraulic vise body has optional jaw systems which include a set of 7075 T-6 aluminum jaw blocks orN set of ductile a iron jaw blocks (1.73 standard thickness, 2.40 optional thickness) or fixture plate. Screw and nut assemblies are reversible with the vise body. One jaw kit will handle two different parts. A R H 14 D C F Preload UU Both Jaws Q P (2X) Movement E M H G N A * L D H C B K J BOTTOM VIEW (Mounting hole pattern is designated by color code) Location For HHØ SHCS (2X) AA Z EE (2X) DD DD EE (2X) U JJØ (4X) AA V BB CC X (4X) KKØ (2X) Z BB Location For GGØ SHCS (2X) CC W www.kurtworkholding.com | Toll Free Phone 1-877-226-7823 | Toll Free Fax 1-877-226-7828 | Phone 763-574-8309 | Fax 763-574-8313

- 15. H HD CarvL ock® G Short Vises * REAR VIEW H B Dimensional Data High Density 6 HD Vise Manual Hydraulic HDM6 K MM SS TT Clearance Above SHCS Head J V X (4X) W Accessory Jaw Plate Shown With Optional 2.5 Height Jaw SIDE VIEW F Preload UU U Both Jaws Q V N RR MAX QQ MIN L FRONT VIEW U A Manual Hydraulic Non-Carvable Area Typical Remove Locating Pins For Convertible Use R MM MAX LL MIN PP P (2X) Movement E M H SS S A B C D E F G H J K L M N O P Q R S MM J Non-Carvable Area Typical A O D C TT N Number HDM6-CONVKIT Clearance Convertible Kits for Optional Machinable Jaws – Part Above SHCS Head RR MAX OO Convertible Option SIDE VIEW QQ MIN Remove Locating Pins For Convertible Use Accessory Jaw Plate Shown MM MAX With Optional 2.5 Height Jaw LL MIN T (INT HEX) Location ForSTRAIGHT THREAD NN (SAE PP AA Z HHØ SHCS (2X)PORT) O-RING Non-Carvable Area Typical EE (2X) DD VV D T THREAD E (2X) Ø cation For GØ SHCS (2X) DD FRONT VIEW VV JJØ (4X) Convertible Option AA Z Clearance Above SHCS Head BB BB S CC CC O Inch 79.375 3.125 79.375 3.125 152.400 6.000 152.400 6.000 339.725 13.375 339.725 13.375 169.875 6.688 169.875 6.688 82.550 3.250 82.550 3.250 349.250 13.750 349.250 13.750 174.625 6.875 174.625 6.875 177.800 7.000 174.630 6.875 182.040 7.167 – – 63.500 2.500 63.500 2.500 127.000 5.000 127.000 5.000 127.000 5.000 127.000 5.000 43.891 1.728 43.891 1.728 152.400 6.000 152.400 6.000 6.350 0.250 6.350 0.250 84.120 3.312 84.120 3.312 24.610 0.969 24.610 0.969 13.260 0.522 13.260 0.522 15.875 0.625 7/16-20 UNF 7/16-20 UNF T INT. HEX INT. HEX O-RING PORT O-RING PORT U 11.125 0.438 11.125 0.438 V 53.975 2.125 53.975 2.125 W 98.43 3.875 98.43 3.875 X M10 x 1.5 M10 x 1.5 M10 x 1.5 M10 x 1.5 Z – 1.000 – 1.000 AA 25.000 – 25.000 – BB 75.000 2.953 75.000 2.953 CC 127.000 5.000 127.000 5.000 DD 50.000 – 50.000 – EE – 2.000 – 2.000 GG – 1/2 – 1/2 HH M12 – M12 – JJ 15.875 0.625 15.875 0.625 KK 16.000 0.630 16.000 0.630 LL 77.770 3.062 82.550 3.250 MM 90.470 3.562 95.250 3.750 NN 23.830 0.938 23.830 0.938 OO 18.540 0.730 18.540 0.730 PP 30.630 1.206 30.630 1.206 QQ 331.770 13.062 336.550 13.250 RR 344.470 13.562 349.250 13.750 SS 60.960 2.400 60.960 2.400 TT 30.330 1.190 30.330 1.190 UU – – 3.180 0.125 VV 7.92 0.312 4.78 0.188 Estimated Shipping Weight of Vise Body Only 21.8 Kgs (48 lbs) Prelo U Both J Q R N X (4X) W NNClearance Above SHCS Head HDHM6 Inch EE (2X) OO KKØ (2X) Location For GGØ SHCS (2X) R Torque-Ft. Lbs. V X (4 F RR MAX Preload QQ MIN UU Both Jaws E EE (2X) Q DD Clamping Force LBS. HDM6 10 883 20 1,684 Hydraulic PSI HDHM6 1,000 1,600 JJØ 500 (4X) 30 2,503 1,500 40 3,187 2,000 50 3,963 2,500 60 4,837 3,000 70 5,556 3,500 N U 875 2,330 H 3,130 3,950 VV 4,750 Con C 5,475 4,000 6,350 4,500 7,100 5,000 7,800 Hyd. Displacement 1.08 cubic inches T (INT HEX) (SAE STRAIGHT THREAD O-RING PORT) HD HDL J aw K its F ixture Z P lates SEE PAGES 24-27 + www.kurtworkholding.com | Toll Free Phone 1-877-226-7823 | Toll Free Fax 1-877-226-7828 | Phone 763-574-8309 | Fax 763-574-8313 EE (2X) 15 A

- 16. Hex) ard aws te HDL CarvLock® Towers (46 Inch) 4 Inch Models: CTHDL443 English CTHDL444 English CTHDL445 English CTHDLM443 Metric CTHDLM444 Metric CTHDLM445 Metric 6 Inch Models: CTHDL644 English CTHDL645 English CTHDL646 English CTHDLM644 Metric CTHDLM645 Metric CTHDLM646 Metric J Manual Hydraulic K Holes H K Holes G L Holes F L Holes DR C'BORED For L SHCS (4X) D TYP E TYP For specific model numbers see page 23. Manually or Hydraulically operated, eight station HDL Cluster Tower system features a ductile iron integral vise tower. Designed for use on mid-size and larger AA Movement machining External including horizontal and vertical centers Internal BB machining centers with a fourthBoth Directions axis and indexable CC HEX HEXtables. This workholding system achieves workpiece immobility while damping cutter induced vibration. Features: • High density vise tower system. Hold multiple parts in eight clamping stations. Increase part volume. • epeatable clamping to 0.0002. 4 inch model R X delivers up to 5,870 lbs. each station at 60 ft lbs of torque. 6 inch model delivers up to 7,460 lbs. of V clamping force at 70 ft lbs of torque. • elf-adjusting holding block of either front or back jaw S Z for clamping the same or dissimilar sized parts. To further enhance fast operation, an adjustable pre-load feature reduces handle turns for opening and closing clamping stations. • uctile iron column insures strength, rigidity and long D term accuracy. Carvable • aw options available to fit your application. Select J Jaws from Hard jaws, Machinable aluminum jaws, Machinable ductile Iron jaws. See page 27. Y • aws are indexable 180 degrees. J • luminum fixture plate available. See page 26. A • levated column makes clearing chips and E J contaminants fast and easy. K Holes H Lifetime G Clad Warranty. Iron K Holes • L Holes F L Holes P C'BORED For K H SHCS (4X) Holes K F L DR Holes C'BORED For L SHCS (4X) FF EE EE D TYP E TYP DD DD A (Square) 1/2 of A±0.001 GG X .50 DP 4-Holes 8-Sides N 16 B DR U P (3X) J K Holes G L Holes 1/2 of A ±0.001 (shown with optional hard jaws) (shown with optional aluminum jaws) A (Square) EDGE LOCATING HOLES ON BASE PLATE N P (3X) 300MM Base Plate Only O M (3X) S Q 400MM 500MM Base Plates Only P (5X) R T Internal CC HEX M (5X) External BB HEX AA Movement Both Directions Internal CC HEX W (Internal Hex) External BB HEX X DR C'BORED For K SHCS (4X) 1/2 of A ±0.001 C X 45ø (4X) C X 45ø (4X) 1/2 of A±0.001 W (Internal Hex) DR C'BORED For L SHCS (4X) 1/2 of A ±0.001 DR C'BORED For K SHCS (4X) V Z Carvable Jaws Hard Jaws Y Hard Jaws A (Square) 1/2 of A±0.001 C X 45ø (4X) U P B www.kurtworkholding.com | Toll Free Phone 1-877-226-7823 | Toll Free Fax 1-877-226-7828 | Phone 763-574-8309 | Fax 763-574-8313 O

- 17. HDL CarvLock® Towers (46 Inch) Manual Hydraulic Base Dimensional Data HDL Long Cluster Tower CTHDL(M)44 MM Inch CTHDL(M)64 MM Inch A B C D E F G H J K L M N O P Q R S T U V 300MM Base MM Inch 400MM Base MM Inch 500MM Base MM Inch 630MM Base MM Inch 300 11.811 400 15.748 500 19.685 630 24.803 25.4 1 31.75 1.25 31.75 1.25 38.1 1.5 20 0.79 50 1.97 60 2.36 70 2.76 158.75 6.25 158.75 6.25 158.75 6.25 215.9 8.5 101.6 4 101.6 4 101.6 4 152.4 6 – – 158.75 6.25 203.2 8 254 10 – – 317.5 12.5 406.4 16 508 20 127 5 160 6.299 200 7.874 250 9.842 254 10 320 12.598 400 15.748 500 19.685 M12 SHCS – M16 SHCS – M16 SHCS – M16 SHCS – – 1/2 SHCS 1/2 SHCS – 1/2 SHCS – 1/2 SHCS 15 0.59 18 0.709 18 0.709 18 0.790 40 1.575 – – – – 200 3.937 80 3.15 – – – – 100 7.874 M12 x 1.75 – M16 x 2.0 – M16 x 2.0 – M16 x 2.0 – – – 55 2.165 55 2.165 – – – – 110 4.33 110 4.33 – – – – 75 2.953 75 2.953 – – – – 150 5.906 150 5.906 – – – – 25 0.984 25 0.984 25 0.984 449.6 17.701 570.23 22.45 W X Y Z AA BB CC DD EE FF GG 425.78 16.763 548.38 415.92 16.375 533.4 200.03 7.875 258.88 15 0.59 19.05 3.05 0.12 3.95 14.28 0.562 19.05 11.1 0.437 15.87 34.92 1.375 28.58 65.1 2.563 79.38 9.53 0.375 9.53 M8 x 1.25 M8 x 1.25 M8 x 1.25 21.59 21 10.192 0.75 0.156 0.750 0.625 1.125 3.125 0.375 M8 x 1.25 Base Weight 119 lbs 270 lbs 39 lbs CLAMPING FORCE LBS. TorqueHDL(M)4 HDL(M)6 Ft. Lbs. Hydraulic HDHL(M)4 HDHL(M)6 PSI 10 1,040 1,540 500 20 30 40 50 60 70 2,125 3,140 4,040 4,980 5,870 2,520 3,350 4,310 5,750 6,860 7,460 1,000 1,500 2,000 2,500 3,000 3,500 4,000 4,500 Hyd. Displacement .414 cubic inches 85 lbs 133 lbs 255 lbs Ask about our 12 Station HD CarvLock Towers 875 775 1,600 1,450 2,330 1,900 3,130 2,550 3,950 3,100 4,750 3,700 5,475 4,200 6,350 4,800 7,100 Hyd. Displacement 1.08 cubic inches 6AWS and 6AWSM Workstop, p.68 Spanner Wrench, p.69 Model No. DL430-307-SA – 4 Model No. DL640-307A-SA – 6 HD HDL J aw K its F ixture P lates SEE PAGES 24-27 + www.kurtworkholding.com | Toll Free Phone 1-877-226-7823 | Toll Free Fax 1-877-226-7828 | Phone 763-574-8309 | Fax 763-574-8313 17

- 18. HD CarvLock® Towers Manual Hydraulic Model: CTHDM64 For specific model numbers see page 23. This manually operated, eight station HD Cluster Tower system features a cast iron integral vise tower. Ideal for horizontal machining centers or vertical machining centers with indexable tables. This workholding system achieves workpiece immobility while damping cutter induced vibration. Features: • ost compact, high density vise tower system in the M industry. • old multiple parts in eight clamping stations. Increase H part volume. • mall footprint which reduces spindle travel, part to part, S maximizing throughput without compromising holding accuracy. • uctile iron column insures strength, rigidity and long D term accuracy. • aw options available to fit your application. Select from J Machinable aluminum jaws, Machinable ductile Iron jaws and Aluminum fixture plate. J • aws are indexable 180 degrees. • ase sizes available include: 300mm, 400mm, B 500mm, 630mm. • Elevated column makes clearing chips and contaminants fast and easy. • Lifetime Iron Clad Warranty. (shown with optional machinable aluminum jaws) Model: CTHDHM64 For specific model numbers see page 23. Identical in capacity and features as the manual HD CarvLock Tower system, this system is actuated hydraulically. Hydraulic piston is an integral part of the vise nut within the vise and tower body to conserve valuable space on the machine table. This hydraulic version also shares all of the jaw options and other accessories which are available in the manual version. Hydraulic pump and hose not included. Features: • p to 7,100 pounds of clamping force. U • aw options available to fit your application. Select J from Machinable aluminum jaws, Machinable ductile Iron jaws and Aluminum fixture plate. • aws are indexable 180 degrees. J • levated column makes clearing chips and E contaminants fast and easy. • ase sizes available include: 300mm, 400mm, B 500mm, 630mm. • Lifetime Iron Clad Warranty. CTHDHM64 S pecifications SEE PAGE 20 18 + (shown with optional machinable aluminum jaws) www.kurtworkholding.com | Toll Free Phone 1-877-226-7823 | Toll Free Fax 1-877-226-7828 | Phone 763-574-8309 | Fax 763-574-8313

- 19. HD CarvLock® Towers Manual Hydraulic CLAMPING FORCE LBS. TorqueFt. Lbs. 10 20 30 40 50 60 70 S Q Inch MM Inch MM Inch 300.000 11.811 400.000 15.748 500.000 19.685 630.000 24.803 25.400 1.000 31.750 1.250 31.750 1.250 38.100 1.500 C 20.000 0.787 50.000 1.969 60.000 2.362 70.100 2.760 D 215.900 8.500 215.900 8.500 215.900 8.500 215.900 8.500 E 152.400 6.000 152.400 6.000 152.400 6.000 152.400 6.000 F – – 158.750 6.250 203.200 8.000 254.000 10.000 20.000 G – – 317.500 12.500 406.400 16.000 508.000 H 127.000 5.000 160.000 6.299 200.000 7.874 250.000 9.843 J 254.000 10.000 320.000 12.598 400.000 15.748 500.000 19.685 K M12 M12 M16 M16 M16 M16 M16 M16 L – – M12 M12 M12 M12 M12 M12 M G F CTHDM646 MM B J H CTHDM645 Inch A M (5X) 400 500 Base Plate Only CTHDM644 MM 883 1,684 U 2,503 (5X) 3,187 3,963 4,837 5,556 R T HD MANUAL TOWER DIMENSIONS CTHDM643 HDM6 15.000 0.591 18.000 0.709 18.000 0.709 18.000 0.709 – – – – 100.000 3.937 – – – – 200.000 7.874 – – – – M16 x 2.0 M16 x 2.0 DR 40.000 For1.575 C'BORED K SHCS (4X) 80.000 3.150 N O P M12 x 1.75 M12 x 1.75 Q – 55.000 2.165 55.000 2.165 – – – – 110.000 4.331 110.000 4.331 – – S – – 75.000 2.953 75.000 2.953 – – T – – 150.000 5.906 150.000 5.906 – – U N – R P (3X) – – M16 x 2.0 M16 x 2.0 M16 x 2.0 M16 x 2.0 – – 0.984 25.000 0.984 25.000 0.984 15.875 403.230 15.875 403.230 15.875 403.230 15.875 390.520 15.375 390.520 15.375 390.520 15.375 390.520 15.375 220.680 8.688 220.680 8.688 220.680 8.688 220.680 8.688 Z 111.130 4.375 111.130 4.375 111.130 4.375 111.130 4.375 AA U (5X) Q 25.000 Y S – X M (3X) O 300 630 Base Plate Only 1/2 of A ±0.001 D – E TYP W TYP 403.230 398.480 15.688 398.480 15.688 398.480 15.688 398.480 15.688 V DR 47.625C'BORED For 1.875 1.875 47.625 1.875 47.625 1.875 174.625 6.875 174.625 6.875 174.625 6.875 DD 82.550 3.250 82.550 3.250 82.550 3.250 82.550 3.250 EE M (5X) A (Square) L SHCS 6.875 174.625 (4X) 47.625 CC 1/2 of A ±0.001 R T BB 92.080 3.625 92.080 3.625 92.080 3.625 92.080 3.625 0.625 INT. HEX 15.875 INT. HEX 0.625 INT. HEX 15.875 INT. HEX 308 161.0 355 183.7 C X 45 15.875 INT. (4X) HEX FF Approx. Ship weight Kgs/ Lbs without jaw sets 400 500 Base Plate Only 139.7 0.625 S 15.875 INT. HEX Q INT. HEX 405 0.625 INT. HEX 239.5 528 M (5X) R T SIDE VIEW P (3X) N AA Remove Locating Pins For Convertible Use O 300 630 Base Plate Only FF (INT HEX) (SAE Straight Thread O-Ring Port) TOP VIEW 500 Base Plate Only 400 H F M (3X) U (5X) J G DR C'BORED For K SHCS (4X) P (3X) N Z EE MAX DD MIN W Z D M (3X) O E TYP TYP 300 630 Base Plate Only X Y 1/2 of A ±0.001 CC DR C'BORED For L SHCS (4X) BB Convertible Option Shown CTHDM6-CONVKIT B P300 Base Plate Only V P or U REF 1/2 of A ±0.001 A (Square) C X 45 (4X) M HD HDL J aw K its F ixture P lates SEE PAGES 24-27 FF (INT HEX) (SAE Straight Thread O-Ring Port) www.kurtworkholding.com | Toll Free Phone 1-877-226-7823 | Toll Free Fax 1-877-226-7828 | Phone 763-574-8309 | Fax 763-574-8313 + 19

- 20. HD CarvLock® Towers Hydraulic CTHDHM64 Specifications CLAMPING FORCE LBS. Hydraulic HDHM6 PSI 500 875 HD HYDRAULIC TOWER DIMENSIONS CTHDHM643 CTHDHM644 CTHDHM645 CTHDHM646 MM Inch MM Inch MM Inch MM Inch A 300.000 11.811 400.000 15.748 500.000 19.685 630.000 24.803 B 25.400 1.000 31.750 1.250 31.750 1.250 38.100 1.500 C 20.000 0.787 50.000 1.969 60.000 2.362 70.100 D 215.900 8.500 215.900 8.500 215.900 8.500 E 152.400 6.000 152.400 6.000 152.400 F – – 158.750 6.250 203.200 G – – 317.500 12.500 H 127.000 5.000 160.000 J 254.000 10.000 320.000 K M12 M12 M16 H 12.598 K Holes 6.299 – – 0.591 2,000 3,130 215.900 8.500 2,500 3,950 6.000 152.400 6.000 3,000 4,750 8.000 254.000 10.000 3,500 5,475 4,000 6,350 4,500 7,100 5,000 7,800 Hyd. Displacement cu. in. 1.08 508.000 20.000 250.000 9.843 400.000 500.000 19.685 M16 M16 M12 DR C'BORED For K SHCS 3.937 (4X) 15.748 M16G M16 L HolesM12 M12 M12 15.000 2,330 2.760 J 16.000 K Holes7.874 200.000 F M12 L Holes0.709 L 1,600 1,500 406.400 M16 M 1,000 18.000 18.000 0.709 18.000 N 40.000 1.575 – – – – 100.000 O 80.000 3.150 – – – – 200.000 – – – – P M12 x 1.75 M12 x 1.75 M12 J Remove Locating K Holes Pins For G Convertible Use L Holes F Accumulator L Holes (Inside Tower)EE MAX M16 x 2.0 M16 x 2.0 – – 55.000 2.165 55.000 2.165 – – 110.000 4.331 110.000 4.331 – – – – 75.000 2.953 75.000 2.953 150.000 5.906 150.000 5.906 H K Holes – – S T – – – – V G L Holes TOP VIEW 7.874 Q U – – W X Y Z AA 25.000 0.984 25.000 0.984 DR19.180 487.170 C'BORED 390.520 For K SHCS 15.375 390.520 220.680 (4X) 8.688 220.680 A/2 127.000 5.000 127.000 ±0.001 0.250 6.350 6.350 19.180 487.170 19.180 15.375 390.520 8.688 220.680 5.000 127.000 0.250 6.350 1.875 47.625 487.170 BB 47.625 1.875 47.625 CC DD 174.625 6.875 174.625 6.875 174.625 82.550 3.250 82.550 3.250 82.550 3.750 95.250 D 3.250 82.550 E TYP A/2±0.001 TYP 487.170 15.375 390.520 220.680 8.688 5.000 127.000 5.000 95.250 3.750 95.250 3.750 82.550 3.250 82.550 3.250 Approx. Ship weight Kgs/ Lbs without jaw sets 148.8 170.1 A (Square) X 192.8 375 EE MAX3.750 95.250 DD 82.550MIN3.250 425 248.6 DR C'BORED H S For L SHCS K Holes Q F (4X) (5X) G L Holes 548 L Holes S Q A/2 ±0.001 P (3X) N A/2±0.001 O M (5X) M (3X) A (Square) 300MM 630MM Base Plate Only 20 Accumulator (Inside Tower) N P (3X) T 400MM 500MM Base Plate Only B M 300MM 630MM Base Plate Only Z FF Y Z CC DR C'BORED For L SHCS (4X) AA W BB B C X 45 (4X) P 300MM Base Convertible Plate Only Option Shown P/N CTHDM6-CONVKIT Does Not Include Jaws V P or U M (5X) P www.kurtworkholding.com | Toll Free Phone 1-877-226-7823 | Toll Free Fax 1-877-226-7828 | Phone 763-574-8309 | Fax 763-574-8313 Q N (3X) V Conv Optio P/N C Does P (3X O M (5X) X U S (5X) Remove P 300MM Base PinsOFor Locating M V Plate Only Convertible Use P or U (3X) P/N CTHDM6-CONVKIT 300MM 630MM Base Plate Only EE MAX D DD MIN Does Not Include Jaws E TYP TYP U (5X) Hydraulic Disconnect Convertible M Option Shown (5X) R T 400MM 500MM Base Plate Only DR C'BORED For L SHCS (4X) C X 45 FF (4X) P 300MM Base Convertible A (Square) Plate Only Option Shown W P/N CTHDM6-CONVKIT AA Jaws Does Not Include U Z Hydraulic Valve (4X)R N For K SHCS (4X) C X 45 (4X) re) SIDE VIEW BB C'BORED DR Y BB A/2±0.001 CC X CC Z C X 45 (4X) Y J K Holes U D E TYP TYP Y Remove Locating0.250 0.250 6.350 Pins For 47.625 1.875 DR C'BORED A/2 1.875 ±0.001 Convertible Use 6.875 For L SHCS 6.875 174.625 3.250 82.550 3.250 (4X) FF Re Pin Co X 15.375 8.688 DR C'BORED For K SHCS (4X) DD MIN 19.180 EE 328 Hydraulic – Disconnect – – D – Hydraulic –E TYP 25.000 0.984 Valve (4X) TYP – M16 x 2.0 M16 x 2.0 M16 x 2.0 M16 x 2.0 Hydraulic Valve (4X) 0.709 R J K Holes Hydraulic Disconnect (3

- 21. HD CarvLock® Towers CTHDHL64 Hydraulic Tower – English CTHDHLM64 Hydraulic Tower – Metric This hydraulically operated eight station tower features all-new design for fast loading of parts. All internalized hydraulic piston/nut saves valuable space. Includes all original KURT AngLock precision clamping and iron clad rigid construction for damping vibration. Features: • ydraulically operated eight station H CTHDHLM64 Cluster Tower. • tilizes an all internal hydraulic piston nut to U 12.500 (SQUARE) conserve space. Pressure is maintained until 6.250 1.97 X 45° (4X) released by operator or triggering device. Easy disconnect for pallet shuttle. R • epeatable clamping to 0.0002. Each station DR C'BORED delivers up to 7,100 lbs. of clamping force at FOR 5/8 SHCS (4X) 4,500 PSI. 6.299 [160mm] face is controlled separately for • Each convenient part loading and removal. J 12.598• aw opening is 4 per station. [320mm] ach face has a maximum total stroke of 1/4 •E (SQUARE) .984 [25mm] (1/8 per station). DR J • aw options available: Hard jaws, machinable C'BORED FOR aluminum. machinable ductile iron. See pg.27 1/2 SHCS (4X) B • ase sizes available: 400mm, 500mm, 630mm. • ifetime Iron Clad Warranty L (shown with optional hard jaws) 7.874 [200mm] 15.748 [400mm] (SQUARE) SIDE VIEW TOP VIEW 12.500 (SQUARE) 6.250 1.75 24.61 1.97 X 45° (4X) DR C'BORED FOR 5/8 SHCS (4X) 6.299 [160mm] 20.85 12.598 [320mm] (SQUARE) .984 [25mm] DR C'BORED FOR 1/2 SHCS (4X) 9.492 7.874 [200mm] 15.748 [400mm] (SQUARE) 18mm 55mm (2X) (5X) 75mm (2X) M16 x 2 (5X) 1.250 HD HDL J aw K its F ixture P lates SEE PAGES 24-27 www.kurtworkholding.com | Toll Free Phone 1-877-226-7823 | Toll Free Fax 1-877-226-7828 | Phone 763-574-8309 | Fax 763-574-8313 + 21

- 22. Kurt Rotary Table Workholding Systems What comes with the kit: Features: • Four-sided column with jaw kits • End Support Assembly • Indexer Locator • T-Nuts • Face Plate Locating Pin • • Screws * ub-plates not included. S Can be quoted separately. • igh density vise tower system. Hold multiple H parts in eight clamping stations. Increase part volume. • epeatable clamping to 0.0002. Each station R delivers up to 7,460 lbs. of clamping force at 70 ft lbs of torque. • elf-adjusting holding block of either front S or back jaw for clamping the same or dissimilar sized parts. To further enhance fast operation, an adjustable pre-load feature reduces handle turns for opening and closing clamping stations. D • uctile iron column insures strength, rigidity and long term accuracy. • aw options available to fit your application. J Select from hard jaws, machinable aluminum jaws, machinable ductile iron jaws and aluminum fixture plate. J • aws are indexable 180 degrees. • ifetime Iron Clad Warranty. L O • ptional single-station convertible kit available for machinable jaws (CTHDLM4-CONVKIT) and hard jaws (CTHDLM4J-CONVKIT). Add this tower to your indexer or have Kurt provide a turnkey solution. Kits are available for the following models: CENTROID (GOLDEN SUN) HAAS RT-150 (CNC-151R) HRT210 RT-200 (CNC-201R) HRT310 NIKKEN CNC180 CNC302 CNC180B CNC302B SMW TROYKE TSUDAKOMA YUASA YUKIWA RT-225 DL-9 RN-150 (FP) RNCM-301 DMNC-220 JNC170 (FP) RT-275 DL-10 RN-200 (FP) RNCM-401 DMNC-280 JNC200 (FP) DL-12 RT-250 (CNC-251R) CNC202 CNC320 RN-250 RB-250 DMNC-320 JNC250 (FP) RT-320 (CNC-321R) CNC202B CNC321 RN-300 RB-300 DRFT-220 YNC170 (FP) CNC200 CNC321B RNCV-401 RZ-160 (FP) DRFT-280 YNC200 (FP) HARDINGE CNC250 CNC400 RNCM-251 RZ-200 (FP) DRFT-320 YNC250 (FP) GD160 CNC260 CNC401 GD210 CNC260B CNC401B Available jaw and fixture options: • luminum, cast iron, steel, and fixture plate. A See pages 24-27 22 www.kurtworkholding.com | Toll Free Phone 1-877-226-7823 | Toll Free Fax 1-877-226-7828 | Phone 763-574-8309 | Fax 763-574-8313

- 23. HD/HDL Vise How To Order, Special Options, Fewer Components HDM6AL (Manual 6 vise with standard aluminum jaws.) HDHM6AL2.5 (Hydraulic vise with optional height aluminum jaws.) HDLM6J (Manual 6 vise with hard jaws.) HDLHM6AL2.5 (Hydraulic vise with optional height aluminum jaws.) HDL Double Station Vise Examples: HD H M L Long Heavy Duty, High Density AL 6 “M” if Metric. Nothing Width if English “H” if Hydraulic. Nothing if Manual HD Double Station Vise Examples: Jaw material AL= Aluminum C= Cast Iron J= Hard Jaws 2.5 HD Optional Aluminum Jaw height if not standard H Cluster Tower Heavy Duty, High Density L Long M 6 “M” if Metric. Nothing Width if English “H” if Hydraulic. Nothing if Manual Note: Hard Jaws for HDL bodies only Back-to-back mounting option. HD vises mount easily back-to-back, providing a new way to achieve a multiple clamping station tower. Contact factory for details. Estimated shipping weight: 88.9Kgs/196Lbs 4 6 AL 2.5 Metric Width “H” if Hydraulic. Nothing if Manual Jaw material AL= Aluminum C= Cast Iron Optional Aluminum Jaw height if not standard THDM63AL (Manual 6 short back-to-back vise, 300mm base with standard height aluminum jaws.) THDHM66AL2.5 (Hydraulic 6 short back-to-back vise, 630mm base with optional height aluminum jaws.) HD Back-To-Back Vises Examples: HD and HDL Cluster Tower Examples: HD M Heavy Duty, High Density CTHDM643AL (Manual 6 short tower with 4 sides, 300mm base with standard height aluminum jaws.) CTHDHM645AL2.5 (Hydraulic 6 tower with 4 sides, 500mm base with optional height aluminum jaws.) CT H 3 Base size 300, 400, 500, Number 630mm of Sides AL 2.5 Jaw material AL= Aluminum C= Cast Iron J= Hard Jaws Optional Aluminum Jaw height if not standard T HD H Tombstone Heavy Duty, High Density L M Long 6 3 Metric Width Base size 300, 400, 500, 630mm “H” if Hydraulic. Nothing if Manual Fixture Plate (HD6ALP620-239) For HD Short Body Ultra high density loads of small parts can be accommodated in a single setup by mounting various off-the-shelf clamping modules to this fixture plate. AL 2.5 Optional Aluminum Jaw height if not standard Jaw material AL= Aluminum C= Cast Iron J= Hard Jaws HD Vise design utilizes fewer working components. Faster changeovers. Fewer problems. To utilize this system’s components, the movable and stationary vise jaws are removed and the fixture plate is positioned and then clamped by normal actuation of the vise. HD HDL J aw K its F ixture P lates SEE PAGES 24-27 www.kurtworkholding.com | Toll Free Phone 1-877-226-7823 | Toll Free Fax 1-877-226-7828 | Phone 763-574-8309 | Fax 763-574-8313 + 23

- 24. HD HDL Jaw Kits B Non-Useable Area (2X) ALUMINUM AND CAST IRON MACHINABLE JAWS K E Jaw Kit Dimensional Data for High Density 6 HD HDL Vises A HD6AL Jaw Kit F MM A HD6AL2.5 Jaw Kit HD6C Jaw Kit Inch MM Inch MM Inch 1.728 43.891 60.960 2.400 43.891 1.728 152.400 6.000 B 152.400 6.000 152.400 6.000 C 127.000 5.000 127.000 5.000 Accessory Pallet Plate 127.000 5.000 D 82.550 3.250 82.550 3.250 82.550 3.250 E 84.120 3.312 84.120 3.312 84.120 3.312 F 24.160 0.951 24.160 0.951 24.160 0.951 G 13.260 0.522 30.330 1.190 13.260 0.522 H 349.250 13.750 349.250 13.750 349.250 13.750 Est Ship Wt.Kgs/Lbs. 5.4 12 8.6 19 17.7 39 H Non-Carvable Area Typical E F D Clearance Above SHCS Head G C A B 24 www.kurtworkholding.com | Toll Free Phone 1-877-226-7823 | Toll Free Fax 1-877-226-7828 | Phone 763-574-8309 | Fax 763-574-8313

- 25. HD HDL Jaw Kits N J MAX K MIN N F B B B H M N N N B B B B F G HARDENED JAW POSITIONS (MANUAL VISE SHOWN) L MAX M MIN O C F B B N HARD JAW OPTION – DIMENSIONAL DATA J MAX K MIN M N D 4 H MANUAL HYDRAULIC G E MM 59.538 2.344 B 76.200 C 73.812 D 6 D MANUAL O HYDRAULIC A MM Inch Inch A N O B B H L MAXMAX L N M Hard Jaw KitM MIN MIN Part Numbers M J MAXMAX J K MINLBS K MIN PART NO. DESCRIPTION HDL4J-JAWKIT B INCH J STYLE HARD JAW KIT HDL6J-JAWKIT O N M MINM MIN J MAXJ MAX K MIN K MIN M N N H H Preload Both Jaws H ( HYD Only ) O G D G N N B 5 O 5 27 13 O B D C N O B A H H G D G N D C 37.719 101.600 4.000 152.400 6.000 13.894 0.547 18.415 0.725 31.369 D 1.235 F C A MAX 44.069 1.735 2.500 98.425 0.687 23.876 D B B O 63.500 K 17.450 L M10 x 1.50 N E Preload Both Jaws H F ( HYD Only ) F O 0.940 1/2 – 13 B MIN 151.511 121.844 4.797 N 163.906 6.453 C O 209.550 8.250 5.965 221.615 8.725 271.526 O B 10.690 P B E A FRONT VIEW DA MAX B MIN N E J L TYP D E J C P N E J L TYP K K A MAX B MIN L TYP P A K C CONVERTIBLE OPTIONS – DIMENSIONAL DATA L TYP FOR HARD AND CARVABLE JAWS E J 4 F K MANUAL HYDRAULIC B DA MAX MM Inch B MIN F G E B B F MM Inch G N D Machinable Jaw Kit Part Numbers DESCRIPTION HDLM4AL-JAWKIT LBS N N 289.941 11.415 299.644 11.797 391.541 239.725 9.438 308.356 87.325 3.438 P 105.156 73.431 2.891 86.741 147.244 A 5.797 188.341 7.415 205.968 8.109 274.574 10.810 E K J L KGS A MAXMAX A 1.40 HIGH ALUMINUM JAW KIT B MIN MIN 3 6 B J 68.326 8.891 H E 2.344 10.690 L TYP J B 225.831 D C 59.538 C A 8.344 N 271.526 E G A 211.938 6 MANUAL HYDRAULIC F B A PART NO. 55.880L TYP 2.200 77.775 3.062 409.168 16.109 528.574 20.810 259.080 10.200 331.775 13.062 Hard Jaws Only 0.812 18.542 0.730 2.690 K 15.415 12.140 4.140 3.415 B A A E B M A 1.40 HIGH IRON JAW KIT 14 7 N 20.625 1.73 HIGH ALUMINUM JAW KIT 14 7 HD6AL2.5-JAWKIT B 4 HD6AL-JAWKIT Preload Preload BothBoth Jaws Jaws H H ( HYDHYD Only ) ( Only ) 8 HDLM4C-JAWKIT E 1.90 HIGH ALUMINUM JAW KIT 2.4 HIGH ALUMINUM JAW KIT 19 9 O 18.262 0.719 23.825 0.938 P 15.240 N Hard Soft Jaws 0.600 15.367 0.605 HDLM4AL1.9-JAWKIT A E B HD6C-JAWKIT C 1.73 HIGH IRON JAW KIT A C A F CONVERTIBLE OPTION FOR HARD JAWS F HDLM4J-CONVKIT HDLM6J-CONVKIT (MANUAL VISE) A MAX B MIN G G Preload Both Jaws H ( HYD Only ) B N D D B A MAX A EC E B B MIN B A MAXA MAX B MIN B MIN J N J F G N N B 33 15 K A MAX B MIN P P CONVERTIBLE OPTION FOR CARVABLE JAWS (MANUAL VISE SHOWN) HDLM4-CONVKIT AND HDLM6-CONVKIT L MAX M MIN P L TYP TYP L J MAX K MIN K K D O E J P P C L TYP K P www.kurtworkholding.com | Toll Free Phone 1-877-226-7823 | P Toll Free Fax 1-877-226-7828 | Phone 763-574-8309 | Fax 763-574-8313 L TYP C EC J N E B N A J MAX M K MIN B B A MAX 3.875 B MIN A 3/8 – 16MAX M12 x 1.75 B F O 1.485 B A B A A 3.175 0.125 3.175 0.125 N B MIN Hydraulic Only Hydraulic Only Hydraulic Only Hydraulic Only A F E 3.000 B E H ( HYD Only ) C 1.115 D F HARDENED JAW POSITIONS Preload (MANUAL VISE SHOWN) Both Jaws 28.321 G C FN F N G C B H 4.000 J O E L MAX M MIN G 101.600 H KGS 10 INCH J STYLE HARD JAW KIT N G L MAX HDLM6J-JAWKIT METRIC J STYLE HARD JAW KIT 27 13 M MIN B B J MAX N N PreloadK MIN B B Preload C A Both Jaws B B A Both Jaws H F F H O F ( HYD Only ) ( HYD Only HARD JAWS (MANUAL VISE )SHOWN) N B O N G H H G D D D Preload C C G A G B B C Both Jaws O H F N ( L MAXL MAX HYD Only ) J MAX K MIN M M N B 10 HDLM4J-JAWKIT METRIC J STYLE HARD JAW KIT L MAX M MIN E 4.000 2.906 N G N N N B O B C 2.690 F N 68.326 101.600 E F E B B N 25

- 26. HD HDL Fixture Plates C C B B B J C HD6ALP620-239 Fixture Plate MM A B C E F J K L Est Ship Wt.Kgs/ Lbs. B e Inch 50.290 152.400 355.600 84.120 24.610 177.800 62.710 82.550 1.980 6.000 14.000 3.312 0.969 7.000 2.469 3.250 6.4 14 J J K Non-Useable Area (2X) E Non-Useable Area (2X) K L Non-Useable Area (2X) Accessory Pallet Plate A F L Accessory Pallet Plate C Aluminum Fixture Plate Accessory for HDLM Vise CTHDLM Tower 4 Non-Useable Area (2X) HDLM4ALP419 MM A B C D E H J K L L H A D C Non-Useable Area (2X) H G (4 X) (4X) A D F (4X) 26 48.26 101.60 393.70 196.85 40.54 20.57 65.07 100.84 65.02 1.900 4.00 15.500 7.750 1.596 0.810 2.562 3.970 2.560 HDL6ALP619 Inch MM A B C D E F G H J Inch 48.260 152.400 508.000 254.000 30.988 24.613 138.938 84.125 82.550 1.900 6.000 20.000 10.000 1.220 0.969 5.470 3.312 3.250 B A E Above Screw Head (2X) Aluminum Fixture Plate Accessory for HDLM Vise CTHDLM Tower 6 J (2X) Non-Useable Area (2X) H G (4 X) (4X) F (4X) www.kurtworkholding.com | Toll Free Phone 1-877-226-7823 | Toll Free Fax 1-877-226-7828 | Phone 763-574-8309 | Fax 763-574-8313

- 27. D E HD HDL CarvLock® Towers (4/6 Inch) K TYP J D HARD JAWS D MACHINABLE JAWS Q HDLM4J-Jaw Kit R MM Centered CxE A 6 inch Jaw Accessories 4 Inch Jaw Accessories H B Inch CxE G F CxE 2.500 2.625 4.000 1.400 4.000 – – – – – – – – – 0.304 0.812 2.562 HDLM4AL1.9-Jaw Kit MM 63.500 66.675 101.600 48.260 P 101.600 – – – Clearance – Above SHCS – Head – – – – 20.422 20.625 65.075 D E Q P G A Clearance Above SHCS B Head M CxE K TYP J H D B – – – – – – – – – – 0.547 4.547 6.656 2.250 – – – G P F B Non-Carvable Area Typ. All Cx MovableEJaws B N MAX O MIN A X E Clearance B Above SHCS Head M HARD JAWS TYP. D E B A X A E Clearance Clearance Above Above B SHCSB SHCS Head Head CxE L L B CONVERTIBLE OPTION SHOWN HARD JAWS DOES NOT INCLUDE JAWS 82.550 90.630 127.000 43.890 152.400 – – – – – – – – – 13.260 24.610 84.120 3.250 3.568 5.000 1.728 6.000 – – – – – – – – – 0.522 0.969 3.312 HD6AL2.5-Jaw Kit MM 82.550 90.630 127.000 60.960 152.400 – – – – – – – – – 30.330 24.610 84.120 3.250 3.568 5.000 2.400 6.000 – – – – – – – – – 1.194 0.969 3.312 C Inch N MAX O MIN M L HARD JAWS CARVABLE JAWS CTHDLM6J-CONVKIT CTHDLM6-CONVKIT MM Inch MM Inch K TYP J C R x E C X Centered E P MACHINABLE JAWS HD6AL-Jaw Kit HD6C-Jaw Kit MM Inch 6 Inch Jaw Accessories Convertible Option D Q D D C X E F AxE A B – – – – – – – – – – 13.874 115.494 169.060 57.150 – – – – – – – – – – – – – 0.547 4.000 7.750 2.250 – – – D C x EC x E B – – – – – – – – – – 13.894 101.600 196.850 57.150 – – – Inch A 2.690 B 103.170 4.062 C 101.600 4.000 D 37.719 1.485 B P E 151.610 5.968 F 18.415 A 0.725 G 44.069 X 1.735 E 0.940 H 23.876 Clearance J 98.425 3.875 Above B K Head SHCSM12 x 1.75 1/2 – 13 L – – M – – N – – O – – P – – Q – – R – – 2.625 4.000 B 1.900 4.000 A – X – E – – B – – – – – 0.804 0.812 2.562 CARVABLE JAWS CTHDLM4-CONVKIT MM Inch H D R Cx Centered E B E J D D K TYP A B C D E F G H J K L M N O P Q R HDLM6J-Jaw Kit C MM X 68.326 E C Inch X E2.500 4 Inch Jaw Accessories Convertible Option HARD JAWS CTHDLM4J-CONVKIT MM Inch HARD JAWS D D HDLM4AL-Jaw Kit HDLM4C-Jaw Kit MM Inch A 59.538 2.344 63.500 B 76.200 3.000 66.675 C 73.812 2.906 101.600 B D 28.321 1.115 35.560 P E 101.600 4.000 101.600 F 13.894 0.547 – AxE G 31.369 1.235 – Clearance H 17.450 0.687 – JAbove 63.500 2.500 – B SHCS K Head x 1.50 3/8 – 16 M10 – L – – – Non-Carvable M – – – Area Typ. – All N – – Movable Jaws O – – – P – – 7.722 Q – – 20.625 R – – 65.075 B MAX MIN Manual Hydraulic – A – B C – – D E – – F G – H – J – K – L 21.590 M 141.605 N 254.640 O 68.326 P – – Q R – H Q – – – – – – – – – – 18.415 145.415 256.540 79.760 – – – D R CxE Centered P G – – – – – – – – – – 0.850 5.575 10.025 2.690 – – – – – – – – – – – – – 0.725 5.725 10.100 3.140 – – – D D C X E CxE C D C X E B C R Cent X E B B P P N MAX F AO MIN A A AxE AxE X X X E E Cleara E Clearance Clearance Abo Clearance Clearance Above B Above Above B SHC B B B Above SHCS SHCS SHCS Head SHCS Head Head Hea Head M Non-Carvable Non-Carvable Area Typ. All Area Typ. All Movable Jaws Movable Jaws L B ALUM. OR DUCTILE CARVABLE JAWS SHOWN TYP. P B P CONVERTIBLE OPTION SHOWN CARVABLE JAWS www.kurtworkholding.com | Toll Free Phone 1-877-226-7823 | Toll Free Fax 1-877-226-7828 | Phone 763-574-8309 | Fax 763-574-8313 27

- 28. DoubleLock® Vises PATENTED Manual Hydraulic Models: DL800 Model: DLH800 DL800 Features: nt Movable Set • arge Capacity L -DL800 8 wide x 6 opening each station. • roductivity – multiple part workholding for better P spindle utilization, reduced tool change time, and reduced machine travel from part to part. • ccuracy – repeatable clamping A to 0.0002. • urability – 80,000-PSI ductile iron body D and steel components provide strength, rigidity and long term accuracy while absorbing machining vibration. • elf-adjusting holding block over the entire S clamping range. M • etric version available. • Optional internal hex screw available. • re-load is adjustable from 0.010 to 0.150. P • ew holding block features the ability to clamp N Front Movable Front Movable Rear Jaw Setprovides preloading Movable dissimilar sized Jaw Setand Set parts Jaw A AB Aability in the front or back jaw. Conversion Kit Plate Shown with optional convertible kit. Use your DoubleLock vise to it’s full capacity with the DoubleLock convertible kit. The kit is available for the DL800 vise. DLC800-KIT OPTIONAL CONVERTIBLE KIT – JAW POSITIONS Front Movable Front Movable JawJaw Set Set Rear MovableMovable RearFront Movable JawJaw Jaw Set Set Set Conversion Kit Kit Conversion Plate Plate A A Rear Movable Rear Movable Jaw Set Jaw Set E B B E Conversion Conversion KitKit C F F D Plate Plate Rear Movable C C Jaw Set Conversion Kit D Plate B B A C C E D G G D F DLH800 Features: • epeatable clamping (0.0002) for high accuracy R E E E F F machining and handles a higher horsepower cut G F than the manual version. • ompact design features a wide range of C clamping forces up to 9,450 lbs. 1/4 stroke 1/8 per side. • roductivity – multiple part workholding for better P spindle utilization, reduced tool change time, and reduced machine travel from part to part. • urability – 80,000-PSI ductile iron body and D steel components provide strength, rigidity and long term accuracy while absorbing machining vibration. G G H H H OPTIONAL CONVERTIBLE KIT - JAW OPENING POSITIONS Part # A B C D KHP5000PF Pneumatic/ Hydraulic Pump, p.72 28 E F G H Ship Wt. Lbs DLC800 - KIT 16.000 12.000 23.000 17.000 19.000 13.000 18.000 14.000 20 KHP5000 Hydraulic Pump, p.73 www.kurtworkholding.com | Toll Free Phone 1-877-226-7823 | Toll Free Fax 1-877-226-7828 | Phone 763-574-8309 | Fax 763-574-8313

- 29. DoubleLock® Vises Manual Hydraulic PATENTED TOP VIEW VISE CLAMPING FORCE-LBS Manual torque Ft.-lbs. VISE CLAMPING FORCE-LBS. 400 1,575 2,023 – 800 3,150 40 3,578 1,200 4,725 50 – 1,600 6,300 5,136 2,000 7,875 – 2,400 9,450 80 6,883 100 B B – 20 LLØ LLØ DLH800 10 E E Hydraulic PSI Max. 70 C C DL800 30 KK KK F F 8,997 60 1/8 NPT HYD PORT 1/8 NPT HYD PORT SIDE VIEW P (TYP) P (TYP) M M G HEX G HEX FF MAX FF L MAX L D D FF MAX FF MAX K K DIMENSIONAL DATA S1(2X) DLH800 Q S1(2X) DL800 Q 3.750 A 3.750 J J A A B 8.060 R 30.000 R C D H Movement in Both Directions H Movement in Both Directions E F 4.000 4.250 - 3/4 - H (Mounting hole pattern is designated by color code) EEØ EEØ DD U DD KK CC U F CC 0.190 0.190 J BOTTOM VIEW DD U DD CC U CC 4.000 O 15.000 O S(4X) 15.000 S(4X) G EEØ EEØ 8.060 30.000 1.965 1.965 K C E 6.000 6.000 L 2.200 2.200 M 1.075 1.075 N 1.220 1.220 O V V FRONT VIEW O Q 1/2-13 1/2-13 5/8-11 5/8-11 7.250 7.250 U FF 2.375 T JAW POSITIONS 0.750 R V 1/8 NPT V HYD PORT 5/8-11 7.000 7.000 V WØ (2X) WØ (2X) 4.750 5/8-11 S1 AA AA LLØ BB BB 4.750 P S T T 8.000 8.000 0.750 B 2.375 W FF 0.750 0.750 AA 2.500 2.500 HH G HEX GG H Movement in Both Directions 8.500 8.500 1/2 6.000 8.925 8.925 HH L N 5.000 FF FF MAX 1.000 EE D 5.000 DD FF MAX M 1.000 GG P (TYP) BB 13.075 13.075 CC K J 1/2 6.000 A S1(2X) Q JJ R S(4X) EEØ HH DD U CC CC U DD 16.000 – 6.49 Ship wt FF HH 16.000 250 360 Hyd Displacement cu. In. REAR VIEW JJ KK - 2.36 EEØ O BB T AA www.kurtworkholding.com | Toll Free Phone 1-877-226-7823 | Toll Free Fax 1-877-226-7828 | Phone 763-574-8309 | Fax 763-574-8313 29

- 30. ClusterLock Cluster Tower® Model: CT2DC4B Features: • ade from ductile iron and steel, a stiffness of 2.5 times M aluminum is achieved. Vibration damping of ductile iron is 20 times higher than aluminum. Includes hardened bed and jaws. • our double vises with 50mm (1.968) wide jaw and F 50mm (2) opening. • ilot (0.8768) in both ends. Four and six bolt mounting hole P pattern fits all indexers. Has 60° center in outboard end. • onvertible to single station large opening vise. C • ptions include machinable jaws, tail support, workstops, and O conversion kit. • hip guards included. C • 5 lbs. 4 SIDE VIEW 6.000 MAX 2.000 4.464 14.360 3,000 Maximum Force 3,000 Holes For 3/8ø On 6.250 B.C. 6.000 MAX 40 0.940 40 2.000 0.6875 • ade from ductile iron and steel, a stiffness of 2.5 times M aluminum is achieved. Vibration damping of ductile iron is 20 times higher than aluminum. Includes hardened bed and jaws. • our single vises with 50mm (1.968) jaws and F 50mm (2) opening. • ilot (0.8768) in both ends. Four and six bolt mounting hole P pattern fits all indexers. Has 60° center in outboard end. • ptions include machinable jaws, tail support, workstops. O • oes not require tail support. D • Chip guards included. I • nternal hex screw standard. • 25 lbs. TOP VIEW 1.969 4.350 Optional Step Jaws 3.000 40 0.327 0.940 6 10 1,000 15 1,500 20 2,000 25 3,000 Maximum Force 3,000 Holes F On 6.25 2.000 5.000 0.427 2.000 0. lbs. 7.980 4.464 6.579 TorqueFt. Lbs. 1.969 0.687 5.000 CT2SH4A CLUSTER TOWER SINGLE MANUAL VISE CLAMPING FORCE SIDE VIEW 7.000ø 0 .427 0.940 Optional Conversion Kit Optional Conversion Kit Features: Holes For 3/8ø CAP Screw On 6.250 B.C. 2.000 7.00 6 0.500 7.000ø 6 0.500 2.000 0. 5.867 SPACER 0.6875 3 14.360 SPACER 0. 5.867 30 2,000 25 2.000 TYP 3.000 2.000 TYP 2.000 1,500 10.750 MAX 2.000 10.750 MAX 0.740 1.367 1,000 19 0.740 0.427 0.740 9 14 0.427 Holes For 3/8ø CAP Screw On 6.250 B.C. 2.000 2.000 lbs. 2.000 TOP VIEW 0.687 TorqueFt. Lbs. 1.969 1.969 Model: CT2SH4A CT2DC4B CLUSTER TOWER DOUBLE MANUAL VISE CLAMPING FORCE 4.350 Optional Step Jaws 0.740 6.579 0. 40 1.367 6 0.327 2.000 0.940 www.kurtworkholding.com | Toll Free Phone 1-877-226-7823 | Toll Free Fax 1-877-226-7828 | Phone 763-574-8309 | Fax 763-574-8313

- 31. 20 (CL2D10) ClusterLock 16 (CL2D8) 12 (CL2D6) 8 (CL2D4) 4 (CL2D2) Model: CL2D2-2A 2 (CL2D1) ClusterLock is a precision double vise, configured from 1 to 10 units in a common base. By using the famous AngLock principle assures that the movable jaw will not lift. Features: • 0,000-PSI ductile iron construction. 8 H • ardened bed ways and hardened steel jaw plates. • tandard spacing is 1.968 (50mm). Consult the S factory for other spacing. • ise bed surface is ground parallel to within 0.001. V • deal for small VMC’s with pallet changers. I • uitable for tombstone mounting on HMC’s. S • an be converted to single opening (6 maximum) C with the optional convertible kit. 12 Part # CLUSTERLOCK MANUAL VISE CLAMPING FORCE Ship Wt. Lbs. 2CL2D1-2A 12 CL2D2-2A 24 CL2D4-2A 48 CL2D6-2A Torque- Ft. Lbs. lbs. 9 1,000 72 14 1,500 CL2D8-2A 96 19 2,000 CL2D10-2A 120 25 0.680 3,000 TOP VIEW 2.625 2 2.000 2 2.000 3/8 HEX SIDE VIEW 20 (CL2D10) 16 (CL2D8) 12 (CL2D6) 8 (CL2D4) 4 (CL2D2) 2 (CL2D1) 12 0.680 2 www.kurtworkholding.com | Toll Free Phone 1-877-226-7823 | Toll Free Fax 1-877-226-7828 | Phone 763-574-8309 | Fax 763-574-8313 31

- 32. SeraLock® Foundations SeraLock Tower Options 400 or 500 mm The SeraLock Towers, SeraLock Pallets, WedgeLock Module system and MoveLock Modular System are the latest innovation for achieving high density, highly repeatable part clamping. SeraLock Towers and SeraLock Pallets are designed with interlocking “V” shaped serrated surfaces for precise and repeatable alignment of WedgeLock and MoveLock clamping modules. 400 or 500 mm SeraLock Towers are available in400 or 500 mm four sided, two sided and single sided towers with a base that will mount to your HMC or an indexer for VMC applications. SeraLock pallets are available in sizes that will accommodate most vertical machining centers. A custom, high density workholding system can be configured quickly when our WedgeLock modular system of single and double sided clamping jaws are used with the SeraLock Tower or SeraLock Pallet. 6 2.000 Max column height = 27 400 or 500 mm 1.25 Standard 6 6 400 or 500 mm 2.000 2.000 SeraLock features: Tower Base Options 2.000 2-Sided Bolted Tower 4-Sided Cast Tower With Base Matched To Machine 4-Sided Bolted Tower Max column height = 27 Max column height = 27 • ultiple components may be used at M the same time. • ike and unlike workpieces may be L machined all in the same setup. Max column height = 27 • elf-aligning. S 400 or 500 mm • llows creation of the equivalent of a A custom fixture in less time than the custom fixture can be designed. 2.000 • ery economical. V 2-Sided Bolted Tower 2-Sided Bolted Tower 4-Sided Cast Tower With Base Matched To To Machine 4-Sided Cast Tower With Base Matched Machine Pallet length options Single Row Block SSRB124 Multi-Row Plate 32 2.000 0.50 24 1.25 Standard 18 Max column height = 27 Single Row Block SSRB112 4-Sided Cast Tower With 6 Matched To Machine Base 4-Sided Bolted Tower 4-Sided Bolted Tower 0.50 Single Row Block SSRB118 1.25 Standard 2-Sided B 0.688 Pallet T-slot options 2.000 0.688 1.250 1.969 2.000 1.250 1.969 2.000 2.000 4-Sided Cast Tower With Base Matched To Machine 12 6 1.25 Standard 1.25 • odular components can be used over M 1.25 Standard and over again. Standard Max column height = 27 • ix and match components. M 2.000 2.000 2.000 2-Sided Bolted Tower 2.000 4-Sided Bolted Tower 2.000 Width in increments of (2) T-Slots Or 4 (Custom Ordered) Length Custom Ordered 2-SidedWidth inTower Bolted increments of 4-Sided Bolted Tower 4-Sided Cast Tower With Base Matched To Machine (2) T-Slots Or 4 www.kurtworkholding.com | Toll Free Phone 1-877-226-7823 | Toll Free Fax 1-877-226-7828 (Custom Ordered) | Phone 763-574-8309 | Fax 763-574-8313 2.000