Strategic Sourcing Process

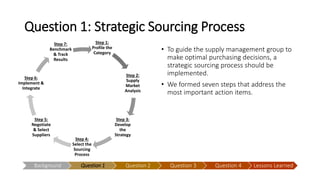

- 1. Question 1: Strategic Sourcing Process Step 1: Profile the Category Step 2: Supply Market Analysis Step 3: Develop the Strategy Step 4: Select the Sourcing Process Step 5: Negotiate & Select Suppliers Step 6: Implement & Integrate Step 7: Benchmark & Track Results Background Question 1 Question 2 Question 3 Question 4 Lessons Learned • To guide the supply management group to make optimal purchasing decisions, a strategic sourcing process should be implemented. • We formed seven steps that address the most important action items.

- 2. Step 1: Profile the Category Background Question 1 Question 2 Question 3 Question 4 Lessons Learned 1 • Define the category and commodities in it. 2 • Quantity used? Types? Sizes? Who are users? Locations? Processes? 3 • Data must be documented in detail.

- 3. Step 2: Supply Market Analysis Background Question 1 Question 2 Question 3 Question 4 Lessons Learned 1 • Identify local and global suppliers. 2 • Analyze them for potential risks and opportunities. 3 • Calculate raw material prices, labor, and transportation.

- 4. Step 3: Develop the Strategy Background Question 1 Question 2 Question 3 Question 4 Lessons Learned 1 • Decide where to buy while minimizing risk and cost. 2 • Assemble cross-functional team. 3 • Alternatives to current suppliers? How competitive is marketplace? How open are users to new suppliers?

- 5. Step 4: Select the Sourcing Process Background Question 1 Question 2 Question 3 Question 4 Lessons Learned 1 • RFP to solicit bids. 2 • Specifications, delivery, and service requirements. 3 • Pricing breakdown, legal and financial terms and conditions.

- 6. Step 5: Negotiate & Select Suppliers Background Question 1 Question 2 Question 3 Question 4 Lessons Learned 1 • Reduce bids to valid ones. Ask for clarifications if needed. 2 • Multiple rounds of negotiations. Establish a short-list. 3 • Approval and sign-off by team.

- 7. Step 6: Implement & Integrate Background Question 1 Question 2 Question 3 Question 4 Lessons Learned 1 • Notify selected bidder. 2 • Include bidder in implementation process. 3 • Communicate improvements, processes, changes in delivery, service requirements, and pricing.

- 8. Step 7: Benchmark &Track Results Background Question 1 Question 2 Question 3 Question 4 Lessons Learned 1 • Start of continuous cycle moving forward. 2 • Benchmark categories, monitor results, ensure full value is achieved. 3 • Back to Step 1 to re-assess constantly evolving markets.

Editor's Notes

- In our case, categories could be transportation, packaging, etc. Commodities include carboard, tape, etc.

- Cross functional team is very important to incorporate diverse opinion. How open are users to new suppliers? This will be difficult and I expect pushback on this one. No one who has a prefered vendor likes to change it b/c someone in procurement is telling you to. Therefore, you need to relate to them the value that the change will bring for them and not just cost cutting.

- This is the paperwork aspect of the process. Putting your ideas and knowhow into the actually procurement process and getting the contract worked up.