New holland cx840 combine service repair manual

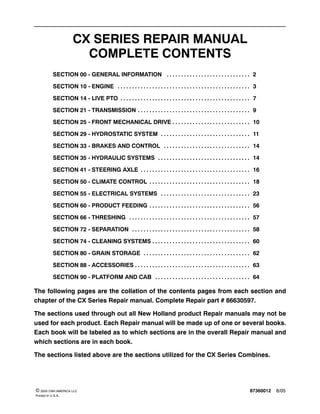

- 1. 87360012 8/05© 2005 CNH AMERICA LLC Printed In U.S.A. CX SERIES REPAIR MANUAL COMPLETE CONTENTS SECTION 00 - GENERAL INFORMATION 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . SECTION 10 - ENGINE 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SECTION 14 - LIVE PTO 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SECTION 21 - TRANSMISSION 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SECTION 25 - FRONT MECHANICAL DRIVE 10. . . . . . . . . . . . . . . . . . . . . . . . . . . SECTION 29 - HYDROSTATIC SYSTEM 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SECTION 33 - BRAKES AND CONTROL 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SECTION 35 - HYDRAULIC SYSTEMS 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SECTION 41 - STEERING AXLE 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SECTION 50 - CLIMATE CONTROL 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SECTION 55 - ELECTRICAL SYSTEMS 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SECTION 60 - PRODUCT FEEDING 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SECTION 66 - THRESHING 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SECTION 72 - SEPARATION 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SECTION 74 - CLEANING SYSTEMS 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SECTION 80 - GRAIN STORAGE 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SECTION 88 - ACCESSORIES 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SECTION 90 - PLATFORM AND CAB 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . The following pages are the collation of the contents pages from each section and chapter of the CX Series Repair manual. Complete Repair part # 86630597. The sections used through out all New Holland product Repair manuals may not be used for each product. Each Repair manual will be made up of one or several books. Each book will be labeled as to which sections are in the overall Repair manual and which sections are in each book. The sections listed above are the sections utilized for the CX Series Combines.

- 2. SECTION 00 -- GENERAL INFORMATION 00-1 SECTION 00 -- GENERAL INFORMATION CONTENTS Section Description Page Introduction 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Important information 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . General instructions 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Shimming 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Rotating shaft seals 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . O--ring seals 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Sealing compounds 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Cotter pins 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Spare parts 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Tools 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Safety regulations 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Accident prevention 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Safety rules 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . General guidelines 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Start-up 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hydraulic systems 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Wheels and Tyres 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Removal and Re-fitting 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Explanation of machine serial numbers 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Units of measure -- Conversion chart 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Minimum hardware tightening torques 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Drives 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Main output shaft 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Unloading output shaft 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- 3. SECTION 00 -- GENERAL INFORMATION 00-2 INTRODUCTION This manual is subdivided in sections marked by two-digit numbers, with independent page numbering within each section. For a quick reference, these sections have the same identification number and the same descrip- tion of the relevant Flat Time Rate Manual. The dealt matters and the information can be easily detected by index on the previous pages. At the bottom of each page there is the manual print number and the relevant publication/up-dating date. The pages of further up-datings shall have the same print number, followed by a two-digit number (for example: 1st Up-dating 604.62.501.01; 2nd Up-dating 604.62.501.02; etc.) and the relevant publication date. These pages shall be completed by the new print of the index, duly revised. The information of this manual are up-dated at the date of the publication. As NEW HOLLAND continuously im- proves its product range, some information could be not up-dated due to modifications of technical or commercial type, as well as for suiting the law regulations of the different countries. In case of disagreement, refer to NEW HOLLAND Sales and Service networks. IMPORTANT INFORMATION All repair and maintenance works listed in this manual must be carried out only by staff belonging to the NEW HOLLAND Service network, strictly complying with the instructions given and using, whenever required, the special tools. Anyone who carries out the above operations without complying with the prescriptions shall be responsible for the subsequent damages. The manufacturer and all the organizations of its distribution chain, including -- without limitation -- national, re- gional or local dealers, reject any responsibility for damages due to the anomalous behaviour of parts and/or components not approved by the manufacturer himself, including those used for the servicing or repair of the product manufactures or marketed by the Manufacturer. In any case, no warranty is given or attributed on the product manufactures of marketed by the Manufacturer in case of damages due to an anomalous behaviour of parts and/or components not approved by the Manufac- turer. No reproduction, though partial of text and illustrations allowed

- 4. SECTION 00 -- GENERAL INFORMATION 00-3 GENERAL INSTRUCTIONS SHIMMING For each adjustment operation, select adjusting shims and measure individually using a micrometer, then add up the recorder values. Do not rely on measuring the entire shimming set, which may be in- correct, or the rated value indicated for each on shim. ROTATING SHAFT SEALS For correct rotating shaft seal installation, proceed as follows: -- before assembly, allow the seal to soak in the oil it will be sealing for at least thirty minutes -- thoroughly clean the shaft and check that the working surface on the shaft is not damaged -- position the sealing lip facing the fluid; with hydrodynamic lips, take into consideration the shaft rotation direction and position the grooves so that they will deviate the fluid towards the inner side of the seal -- coat the sealing lip with a thin layer of lubricant (use oil rather than grease) and fill the gap between the sealing lip and the dust lip on double lip seals with grease -- insert the seal in its seat and press down using a flat punch, do not tap the seal with a hammer or mallet -- whilst inserting the seal, check that it is perpendicular to the seat; once settled, make sure that it makes contact with the thrust element, if required -- to prevent damaging the seal lip on the shaft, position a protective guard during installation operations O--RING SEALS Lubricate the O--RING seals before inserting them in the seats, this will prevent them from overturning and twisting, which would jeopardise sealing efficiency. SEALING COMPOUNDS Apply one of the following sealing compounds on the mating surfaces marked with an X: RTV SILMATE, RHODORSIL CAF 1 or LOCTITE PLASTIC GASKET. Before applying the sealing compound, prepare the surfaces as follows: -- remove any incrustations using a metal brush; -- thoroughly de--grease the surfaces using one of the following cleaning agents: trichlorethylene, petrol or a water and soda solution. COTTER PINS When fitting split cotter pins, ensure that the pin notch is positioned in the direction of the force required to stress the pin. Spiral cotter pins do not require special positioning.

- 5. SECTION 00 -- GENERAL INFORMATION 00-4 PROTECTING THE ELECTRONIC/ ELECTRICAL SYSTEMS DURING CHARGING OR WELDING To avoid damage to the electronic/electrical systems, always observe the following: 1. Never make or break any of the charging circuit connections, including the battery connections, when the engine is running. 2. Never short any of the charging components to ground. 3. Always disconnect the ground cable from the battery before arc welding on the combine or on any header attached to the combine. • Position the welder ground clamp as close to the welding area as possible. • If welding in close proximity to a computer module, then the module should be removed from the combine. • Never allow welding cables to lay on, near or across any electrical wiring or electronic component while welding is in progress. IMPORTANT: If welding must be performed on the unit, either the combine or the header (if it is attached), the battery ground cable must be disconnected from the combine battery. The electronic monitoring system and charging system will be damaged if this is not done. Remove the battery ground cable. Reconnect the cable when welding is completed. 4. Always disconnect the negative cable from the battery when charging the battery in the combine with a battery charger. WARNING Batteries contain sulfuric acid. In case of contact with skin, flush the affected area with water for five minutes. Seek medical attention immediately. Avoid contact with the skin, eyes or clothing. Wear eye protection when working near batteries.

- 6. SECTION 10 -- ENGINE -- CHAPTER 1 10-1 SECTION 10 -- ENGINE Chapter 1 -- 7.5L New Holland Engine CONTENTS Section Description Page 10 000 Specifications 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Tightening Torques 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Special Tools 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Greases and Sealants 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fault Finding 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Description and Operation 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 001 Engine Overhaul--Introduction 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Injection Pump Timing Check 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 100 Engine Disassembly and Overhaul:-- 10 101 Cylinder Head, Valves and Related parts 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 106 Front Cover and Timing Gears 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 102 Oil Pan 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 103 Flywheel 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 102 Rear cover plate 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 102 Oil pump 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 102 Oil Pressure Relief Valve 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 106 Camshaft, tappets and camshaft bearings 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 105 Pistons and Cylinder Block 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 103 Crankshaft 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 001 Engine compression test 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- 7. SECTION 10 -- ENGINE -- CHAPTER 1 10-17 DESCRIPTION AND OPERATION 2 The New Holland 7.5 Litre engine is a 6-cylinder turbocharged and aftercooled, having a bore of 111.8 mm (4.4″) and a stroke of 127 mm (5.0″) which generates a displacement of 7.5L (456 in3). The engine uses a mechanical or electronically controlled in line injection pump depending on model and has been designed to meet current emission regulations and must only be serviced by an authorised service agent. For a detailed Description and Operation of the fuel system reference must be made to the Fuel System Chapter in this Section of the manual. All engines feature cross flow cylinder heads, with the inlet and exhaust manifolds on opposite sides of the cylinder head. The fuel and air combustion process, takes place in the specially designed bowl in the crown of the pistons. CYLINDER BLOCK ASSEMBLY The cylinder block is an alloy cast iron with deep cylinder skirts, and water jackets for cooling the cylinders. The cylinder bores are machined integral with the cylinder block, during the manufacturing process. Cylinders are in line and vertical and numbered 1 to 6 from the front to the rear of the engine. They can be bored oversize for the fitment of sleeves, which are available in service. The oil pan is the reservoir for the engine oil lubrication system and a cast iron front cover on the front of the engine covers the timing gear assembly.

- 8. SECTION 10 -- ENGINE -- CHAPTER 1 10-18 CYLINDER HEAD ASSEMBLY The cylinder head incorporates an inlet and exhaust valve per cylinder with the valve rocker arm shaft assembly bolted to the cylinder block through the cylinder head. Cylinder head retaining bolts are evenly spaced with a six point pattern around each cylinder, this ensures an even clamping load across the cylinder head area. The intake and exhaust manifolds are bolted to the head, the intake manifold is mounted on the right hand side of the engine, with the diesel injectors mounted outside the rocker cover. The exhaust manifold is mounted on the left hand side of the engine. Water outlet connections and thermostats being attached to the front of the cylinder block. Valve guides are integral in the cylinder head, and valves with oversize stems are available in service. Special replaceable sintered iron valve seats are pressed into each valve port during manufacture and oversize valve seats also available in service. All valves are fitted with positive valve rotators and valve stem oil seals. Valve clearance is maintained by adjustment of the self locking adjusting screw, mounted in each of the rocker arms. 3 CAMSHAFT ASSEMBLY The camshaft runs in 5 replaceable bearings. The camshaft drive gear is in mesh with and driven by the camshaft idler gear which is driven by the crankshaft timing gear. Camshaft end thrust is controlled by a thrust plate bolted to the block, and located between the camshaft gear and the front camshaft journal. A helical gear is mounted on the rear of the camshaft, and drives the engine oil lubrication pump mounted forward of the flywheel. 396--E--16 TI 4 CRANKSHAFT ASSEMBLY The crankshaft is supported in the cylinder block by 7 main bearings. The crankshaft is manufactured from steel with machined finished crank webs End thrust is controlled by a thrust bearing incorporated in the centre main bearing of the crankshaft. An external damper is fitted to the crankshaft pulley to ensure smooth running operation. Front and rear crankshaft oil sealing is effected by cassette type seals that are designed for long and durable service life. 5

- 9. SECTION 10 -- ENGINE -- CHAPTER 1 10-19 CONNECTING RODS Connecting rods ‘‘Teepee” (wedge) shaped at the small end have been designed to reduce the reciprocating weight at the piston end. The connecting rods are of a heavy beam construction and are assembled as a matched set to each engine. They are retained in position by the connecting rod big end cap and secured by two bolts per rod. The small end of the connecting rod is fitted with a replaceable bronze bushing, through which the free floating piston pin is fitted. The steel pin being held in place within the piston by two snap rings. 6 PISTONS Pistons are constructed of an aluminium silicon alloy with an iron insert for the top ring. The combustion chamber being recessed into the piston crowns. Each piston has two compression rings and one oil control ring, to reduce friction and increase positive sealing. All rings are located above the piston pin. A Engines with Electronically Controlled Injection Pump B Engines with Mechanically Controlled Injection Pump 7 MANIFOLDS The cross flow design aluminium intake, and cast iron exhaust manifolds, are on opposite sides of the cylinder head. This is designed to maintain balanced heat distribution within the cylinder head. The configuration of the manifolds also ensures minimum heat transfer to the intake manifold. A grid heater is fitted to the intake manifold to assist in cold starting of the engine when coolant water temperature is below 30°C. 8 TIMING GEARS The crankshaft timing gear is heated and press fitted on to the front of the crankshaft, to a high degree of accuracy during manufacturing. This enables precise timing being maintained during the life of the engine. The crankshaft gear, 2, drives the idler gear, 3, which is attached to the front of the cylinder block. The idler gear then drives the camshaft gear, 1, and the injection pump gear, 4. The camshaft gear is bolted to the front of the camshaft, and is keyed to maintain position of the gear on the camshaft. P396--E--36 . ... . 23 4 1 9

- 10. SECTION 10 -- ENGINE -- CHAPTER 1 10-20 LUBRICATION SYSTEM 10 Engine Lubrication System Lubrication of the engine, Fig. 10, is maintained by a rotor type oil pump mounted in the rear of the engine block, forward of the flywheel on the left hand side of the engine. TA6010058 11 The oil pump is driven from the rear of the camshaft and draws oil from the engine oil pan through a tube and screen assembly. 12

- 11. SECTION 10 -- ENGINE -- CHAPTER 1 10-21 A spring loaded relief valve is integral with the dummy oil filter head mounted on the left hand side of the engine block and prevents over pressurisation of the system. 396--E--18 TI 3 13 The spin on type oil filter is mounted at the rear of the engine. 14 Oil flows from the filter to the main oil gallery, which runs the length of the cylinder block and also intersects the camshaft follower chamber. The main gallery supplies oil to the crankshaft main bearings, connecting rods and both big and small ends. The underside of the pistons and pins, are lubricated by oil pressure jets mounted adjacent to each main journal housing. The camshaft drive gear bushing is pressure lubricated through a drilled passage from the front main bearing. The gear has small oil passages machined on both sides allowing excess oil to escape. 396--E--26 TI 15 An intermittent flow of oil is directed to the valve rocker arm shaft assembly via a drilled passage in the cylinder block. This is located vertically above No.1 camshaft bearing, 1, and aligns to a hole in the cylinder head. The rotation of the camshaft allows a controlled intermediate flow of lubrication. 396--E--16 TI 1 16

- 12. SECTION 10 -- ENGINE -- CHAPTER 1 10-22 Timing gears are lubricated by splashed oil from the cam follower chamber, and the pressure lubricated camshaft drive gear bushing. P396--E--36 17 The turbocharger is supplied with oil from the oil filter support housing, 1, mounted on the left hand side of the engine. 18 The fuel injection pump is pressure lubricated from a port, 1, on the right hand side of the engine block. The fuel pump is either electronically controlled using an electronic control unit 19 or Mechanically controlled depending on model build 20

- 13. SECTION 10 -- ENGINE -- CHAPTER 1 10-23 ENGINE OVERHAUL--INTRODUCTION In the following procedures and illustrations the engine is shown removed from the vehicle however there are certain operations that can be performed with the engine installed. Where it is necessary to remove the engine use a suitable hoist or overhead gantry and standard engineering procedures. Removal of the engine is described in Chapter 3 of Section 10 of this manual. Dismantle the engine following conventional techniques and by referring to the appropriate overhaul sections of this chapter. Always refer to the specification section as necessary. NOTE: Where it is necessary to remove additional items to gain access to the components on the engine Refer to Chapter 3 “Remove and Replace, 7.5L NH Engine”. NOTE: All gaskets, seals, and ‘O’ rings must be replaced during re-assembly. Where new sealant is to be applied refer to ‘‘Engine Specifications”. For concerns relating to the fuel system refer to the fuel system Chapter in this manual. On engines fitted with the electronically controlled fuel injection pump refer to the “Engine Fault Codes” chapter in the electrical section of the manual. Operations or repairs that can be performed with the engine still in the vehicle. 1. Front timing cover, Pump drive gear and idler gear. Removal of engine is required in order to remove and replace the camshaft timing gear. 2. Front pulley and damper assembly. 3. Cylinder head and associated inlet and exhaust components. 4. Fuel injection pump removal and timing. 5. Water pump, thermostat, and associated components . 6. Oil pump relief valve. 7. Turbocharger.

- 14. SECTION 10 -- ENGINE -- CHAPTER 1 10-24 INJECTION PUMP TIMING CHECK If a fuel related concern is identified check the injection pump timing before proceeding with any other disassembly. NOTE: Where it is necessary to remove additional items to gain access to the components on the engine Refer to Chapter 3 “Engine Removal and Replacement”. 1. Remove engine drive belts. 21 1. Remove injection pump timing cover. 22 2. Using 29mm socket (1--1/8 inch) socket rotate crankshaft to top dead centre (TDC) with number 1 cylinder firing. 0 23 3. When engine is at TDC the threaded hole in the injection pump drive flange aligns with the pump timing plate. 24

- 15. SECTION 10 -- ENGINE -- CHAPTER 1 10-25 4. To ensure the crankshaft is accurately positioned at TDC remove the crankshaft timing plug, 1, from the side of the engine block. IMPORTANT: DO NOT disturb the timing pin bush, 2. This has been accurately set during original manufacture. If the bush is moved then pump timing CAN NOT be accurately set. 25 5. insert the crankshaft timing pin 297672 into the side of the block. 26 6. If necessary gently turn the crankshaft to engage the rounded end of the timing pin in the slot of the crankshaft. This is not visible and must be performed by ‘feel’. 27 7. When the timing pin is located in the slot of the crankshaft the pin is fully seated. Do Not attempt to rotate the crankshaft when timing pin is fully inserted as damage will occur. 28

- 16. SECTION 10 -- ENGINE -- CHAPTER 1 10-26 8. Check that the injection pump go/no-go timing pin Tool No 295005 (NA-FNH00536-2) will screw into the pump hub. IMPORTANT: The engine must never be rotated while the timing pin is installed. 9. If the pin engages in the pump timing plate (inset, Figure 30) when the crankshaft is at TDC the pump timing is correct. 29 10. If pump timing is incorrect and timing pin can not be screwed into pump, remove pump timing gear, install rigid timing pin 295005 (NA-FNH00536-1) into pump and refit timing gear. 30 NOTE: This injection pump timing check assumes that the crankshaft and camshaft timing gears were correctly positioned during engine assembly. To check the position of these timing gears it is necessary to remove the engine front cover.

- 17. SECTION 10 -- ENGINE -- CHAPTER 1 10-27 OVERHAUL Op. 10 101 CYLINDER HEAD, VALVES, AND RELATED PARTS Cylinder Head Removal NOTE: The cylinder head can be removed with the engine installed in the combine. 1. Drain the engine coolant by placing a suitable container,1, below the coolant drain hose, 2. 10013105 1 2 31 2. Drain the coolant from the engine block using drain tap, 1, on left hand side of the radiator, 2. 10013106 1 2 32 3. Remove all necessary hardware and components in order to gain access to the cylinder head. Refer to Chapter 3 “Remove and Replace, 7.5L NH Engine” for further details. 33 4. Remove the fan belt. 34

- 18. SECTION 10 -- ENGINE -- CHAPTER 1 10-28 5. Clean the area surrounding the fuel injectors. Disconnect and remove injector lines, 1, and leak off lines, 2, from the fuel injectors and injection pump. Cap all exposed openings. 2 1 35 6. Remove injectors from the cylinder head. 36 7. Remove the turbocharger assembly, ensuring all openings are capped to prevent dirt ingress. 37 8. Remove the thermostat housing, 1, and water pump housing, 2. 38

- 19. SECTION 10 -- ENGINE -- CHAPTER 1 10-29 9. Remove the rocker cover and gasket. 39 10. Loosen the rocker shaft retaining bolts (which also serve as head bolts) evenly and alternately and remove the rocker shaft assembly. 40 NOTE: Leave bolts in the rocker shaft supports during removal, as they retain the support on the shaft. 11. Remove pushrods in turn and place in a numbered rack to maintain the same position for reassembly. 41 12. Remove remaining cylinder head bolts by working progressively from each end of the cylinder head towards the centre. 13. Carefully lift the cylinder head assembly away from the engine block. 42

- 20. Thank you very much for your reading. Please Click Here. Then Get COMPLETE MANUAL. NO WAITING NOTE: If there is no response to click on the link above, please download the PDF document first and then click on it.

- 21. SECTION 10 -- ENGINE -- CHAPTER 1 10-30 Cylinder Head Disassembly 1. Using a valve spring compressor, tool No.291050, 1, remove the retainer locks, 2, and place in a numbered rack. 2. Clean the cylinder head, and remove carbon deposits from around the valve heads. TA6010011 1 2 43 44 Inlet and Exhaust Valves 1. Keepers 2. Spring Retainer 3. Seal 4. Spring 5. Inlet Valve 6. Exhaust Valve 7. Spring 8. Seal 9. Spring Rotator 10. Spring Rotator 11. Keepers

- 22. SECTION 10 -- ENGINE -- CHAPTER 1 10-31 Inspection and Repair, Cylinder Head 1. Replace cylinder head core plugs if discoloured (rusty), or leaking. Before fitting new plugs remove all old sealer from the cylinder head. Apply sealant G, see ‘‘SPECIFICATIONS”, to the new plug mating faces, and drive the new plugs into location. The core plugs fitted to the Cylinder Head are:-- 6 off, In the top, and 1 off, in the rearof the cylinder head. 5 off, in the intake face. 2. Scrape all gasket surfaces clean, wash cylinder head in a suitable solvent and clean valve guide bores. NOTE: Ensure injector washers have been removed prior to cleaning. TA6010008 45 3. Inspect cylinder head for nicks and burrs on mating face, Remove using a suitable abrasive and ensure faces are clean after repair. 4. Using a straight edge and feeler gauges, check that the flatness of the cylinder head in all directions does not exceed, 0.03mm (0.001 in) in any (25.4mm (1 in), or 0.127mm (0.005 in), overall limit. 5. If the cylinder head has been resurfaced, determine that all head bolt faces will seat by placing the cylinder head less gasket, on the cylinder block and installing bolts hand tight. TA6010012 2 3 4 5 6 6 7 8 46 6. Ensure rocker shaft supports are fitted with long bolts. Using a feeler gauge, check clearance between underside of bolt heads and cylinder head or rocker shaft support. 7. If a 0.25mm (0.010 in) feeler gauge can be inserted under the bolt head the bolt has bottomed. Therefore the cylinder block thread must be increased using a 9/16--13 UNC--2A Thread tap. Identify each head bolt to ensure they are reinstalled in the bolt holes they werechecked in. 47

- 23. SECTION 10 -- ENGINE -- CHAPTER 1 10-32 Valve Inserts Insert Oversize Counter Bore in Cylinder Head Insert Oversize Exhaust valve insert Intake valve insert 0.25mm (0.010 in) 44.17--44.20mm (1.739--1.740 in) 50.01--50.04mm (1.969--1.970 in) 0.58mm (0.020 in) 44.42--44.45mm (1.749--1.750 in) 50.27--50.29mm (1.979--1.980 in) 0.76mm (0.030 in) 44.68--44.70mm (1.759--1.760 in) 50.52--50.55mm (1.989--1.990 in) NOTE: Refacing the valve seat should always be co-- ordinated with refacing of the valve to ensure a com- pression tight fit. 1. Examine the valve seat inserts and reface if pitted, renew if loose or damaged. 2. To install a new valve insert, the cylinder head must be counter bored, as described in the above chart. The new insert must be chilled in dry ice prior to installation. Valve Seat Specifications, Fig. 48. 1. Valve seat angle Intake 30.0°--30.30° Exhaust 45.0°--45.30° 2. Valve seat width Intake 1.9--2.4mm (0.078--0.098 in) Exhaust 1.8--2.3mm (0.072--0.092 in) 3. Valve Head Face to Cylinder Head Face Depth Intake 0.89--1.29mm (0.035--0.051 in) Exhaust 1.2--1.6mm (0.048--0.064 in) NOTE: Valve inserts of 0.010 in (0.25mm) and 0.020 in (0.5mm) oversize on diameter are sometimes installed during manufacture. Cylinder Heads with oversize inserts are stamped so10/os, so20/os, on the exhaust manifold side in line with the valve seat concerned. 3. Check the width of the valve seat inserts, and as required reface by grinding to dimensions detailed above. TA6010013 1 2 3 48 4. Measure the concentricity of valve seats, using a dial indicator and measure concentricity of seat to the valve guide bore. Total Indicator Reading should not exceed 0.051mm (0.002 in), Fig. 49. 49