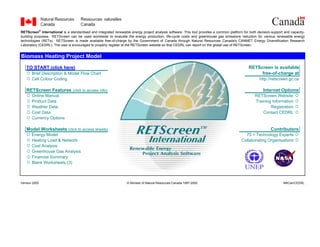

More Related Content Similar to Biomass heating project Similar to Biomass heating project (20) More from Hartono Prayitno More from Hartono Prayitno (15) 1. RETScreen® International is a standardised and integrated renewable energy project analysis software. This tool provides a common platform for both decision-support and capacity-

building purposes. RETScreen can be used worldwide to evaluate the energy production, life-cycle costs and greenhouse gas emissions reduction for various renewable energy

technologies (RETs). RETScreen is made available free-of-charge by the Government of Canada through Natural Resources Canada's CANMET Energy Diversification Research

Laboratory (CEDRL). The user is encouraged to properly register at the RETScreen website so that CEDRL can report on the global use of RETScreen.

Biomass Heating Project Model

TO START (click here) RETScreen is available

Brief Description & Model Flow Chart free-of-charge at

Cell Colour Coding http://retscreen.gc.ca

RETScreen Features (click to access info) Internet Options

Online Manual RETScreen Website

Product Data Training Information

Weather Data Registration

Cost Data Contact CEDRL

Currency Options

Model Worksheets (click to access sheets) Contributors

Energy Model 70 + Technology Experts

Heating Load & Network Collaborating Organisations

Cost Analysis

Greenhouse Gas Analysis

Financial Summary

Blank Worksheets (3)

Version 2000 © Minister of Natural Resources Canada 1997-2000. NRCan/CEDRL

2. ®

RETScreen Energy Model - Biomass Heating Project

Site Conditions Estimate Notes/Range

Project name Local / District Heating

Project location Ontario, Canada

Nearest location for weather data Kapuskasing A, ON Complete HL and Network sheet

Number of buildings buildings 5

Total pipe length m 1,337

Heating energy demand MWh 5,230

GJ 18828

Peak heating load kW 1,747

million Btu/h 5.962

System Characteristics Estimate Notes/Range

System type - Biomass

Biomass Heating System System Design Graph

Biomass fuel type - Wood medium HV WHR Biomass Peak

Moisture content on wet basis of biomass % 50% 200% 0% to 55%

As-fired calorific value of biomass MJ/t 8,111 150% 10,800 to 15,900

Biomass boiler(s) capacity (1 boiler) kW 1,500 See Product Database

Biomass boiler(s) manufacturer Sylva Energy Systems 100%

Biomass boiler(s) model Not specified 50%

Biomass boiler(s) seasonal efficiency % 75% 60% to 90%

Biomass energy delivered MWh 5,201 0%

Percentage of peak heating load % 85.8% Load Demand

Percentage of total heating energy demand % 99.4% (Power) (Energy)

Peak Load Heating System

Peak load fuel type - Natural gas

Peak load system steady-state efficiency % 100% 50% to 350%

Suggested peak load system capacity kW 247 75 to 3,000

Peak load system capacity kW 1,500 75 to 3,000

Peak load system seasonal efficiency % 75% 50% to 350%

Peak energy delivered MWh 30

Percentage of peak heating load % 85.8%

Percentage of total heating energy demand % 0.6%

Back-up Heating System (optional)

Suggested back-up boiler capacity kW 1,500 75 to 3,000

Back-up boiler capacity kW 0 75 to 3,000

Annual Energy Production WHR Biomass Peak Total Notes/Range

Percentage of peak heating load % 0.0% 85.8% 85.8% 171.7%

Heating capacity kW 0 1,500 1,500 3,000

million Btu/h 0 5.118 5.118 10.236

Equivalent full output hours h 0 3,467 20 -

Capacity factor % 0.0% 39.6% 0.2% -

Percentage of total heating energy demand % 0.0% 99.4% 0.6% 100.0%

Heating energy delivered MWh 0 5,201 30 5,231

million Btu 0 17745 101 17847

Biomass requirement t - 3,078 - 3,078

Heating fuel requirement m³ - - 3,858 3,858

Complete Cost Analysis sheet

Version 2000 © Minister of Natural Resources Canada 1997 - 2000. NRCan/CEDRL

03/09/2003; BIOH06-B.xls

3. RETScreen ® Heating Load Calculation & District Heating Network Design - Biomass Heating Project

Site Conditions Estimate Notes/Range Monthly Inputs Notes/Range

Nearest location for weather data Kapuskasing A, ON See Weather Database Month °C-d Month °C-d Month °C-d

Heating design temperature °C -31.4 -40.0 to 15.0 (<18°C) (<18°C) (<18°C)

Annual heating degree days below 18°C °C-d 6,454 Complete Monthly Inputs January 1,136 May 297 September 244 See

Domestic hot water heating base load % 21% 0% to 25% February 969 June 143 October 428 Weather

Equivalent degree-days for DHW heating °C-d/d 4.7 0.0 to 10.0 March 839 July 67 November 679 Database

Equivalent full load hours h 2,993 April 526 August 104 December 1,023

Base Case Heating System and Heating Load Estimate/Total

See Technical Note on Network Design

Building clusters

Base Case Heating System 1 2 3 4 5 6 7 8 9 10 11 12 13 14

Heated floor area per building cluster m² 16,100 3,700 2,700 8,500 1,000 200

Number of buildings in building cluster buildings 5 1 1 1 1 1

Heating fuel type(s) - - Natural gas Natural gas Natural gas Natural gas Natural gas

Heating system seasonal efficiency % - 68% 68% 68% 68% 68%

Heating Load Calculation

Heating load for building cluster W/m² - 201 78 75 147 50

Heating energy demand MWh 5,230 2,230 630 1,900 440 30 - - - - - - - - -

Total peak heating load kW 1,747 745 210 635 147 10 - - - - - - - - -

Fuel consumption - units - - m³ m³ m³ m³ m³ - - - - - - - - -

Fuel consumption - annual - - 317,465 89,687 270,486 62,639 4,271 - - - - - - - - -

Cost of fuel - units - - $/m³ $/m³ $/m³ $/m³ $/m³ - - - - - - - - -

Unit cost of fuel - - 0.330 0.330 0.330 0.330 0.330

Total fuel cost - $ 245,701 $ 104,763 $ 29,597 $ 89,260 $ 20,671 $ 1,409 - - - - - - - - -

District Heating Network Design Estimate/Total

Design Criteria

Design supply temperature °C 120

Design return temperature °C 80

Differential temperature °C 40

Main Distribution Line

Main pipe network oversizing % 20%

Pipe sections Load Length Pipe size Is the Building cluster supplied by this pipe section? (yes/no)

(kW) (m) (mm) 1 2 3 4 5 6 7 8 9 10 11 12 13 14

Section 1 1,737 472 DN 125 Yes Yes Yes Yes No

Section 2 992 170 DN 100 No Yes Yes Yes No

Section 3 782 65 DN 80 No No Yes Yes No

Section 4 -

Section 5 -

Section 6 -

Section 7 -

Section 8 -

Section 9 -

Section 10 -

Section 11 -

Section 12 -

Section 13 -

Total pipe length for main distribution line m 707

Secondary Distribution Lines

Secondary pipe network oversizing % 0% Secondary distribution pipes length per building cluster (m)

Length of pipe section m 630 122 207 46 241 14

Pipe size mm DN 80 DN 50 DN 80 DN 50 DN 32 - - - - - - - - -

District Heating Network Costs

Total pipe length m 1,337

Costing method - Formula

Energy transfer station(s) connection type - Indirect

Energy transfer station(s) cost factor - 1.00

Main distribution line pipe cost factor - 0.50

Secondary distribution line pipe cost factor - 0.50

Exchange rate $/CAD 1.00

ETS and secondary distribution pipes costs per building cluster ($)

Energy transfer station(s) cost - $ 248,637 $ 88,664 $ 45,337 $ 75,543 $ 36,287 $ 2,807 - - - - - - - - -

Secondary distribution line pipe cost - $ 103,396 $ 23,302 $ 32,085 $ 8,786 $ 37,355 $ 1,868 - - - - - - - - -

Total building cluster connection cost - $ 352,033 $ 111,966 $ 77,422 $ 84,329 $ 73,642 $ 4,674 - - - - - - - - -

Main Distribution Line Pipe Cost by Pipe Size Categories

Summary of main distribution line pipe size mm DN 32 DN 40 DN 50 DN 65 DN 80 DN 100 DN 125 DN 150

Summary of main distribution line pipe length m - - - - 65 170 472 -

Summary of main distribution line pipe cost - $ 164,605 - - - - $ 12,415 $ 36,550 $ 115,640 -

Total district heating network costs - $ 516,638 Return to

Energy Model sheet

Version 2000 © Minister of Natural Resources Canada 1997 - 2000. NRCan/CEDRL

03/09/2003; BIOH06-B.xls

4. RETScreen® Cost Analysis - Biomass Heating Project

Type of project: Standard Currency: $ $ Cost references: Canada - 2000

Second currency: United States USD Rate: $/USD 0.67800

Relative Quantity Unit Cost

Initial Costs (Credits) Unit Quantity Unit Cost Amount Costs Range Range

Feasibility Study

Feasibility study Cost 1 $ 5,000 $ 5,000

Sub-total: $ 5,000 0.4%

Development

Project development Cost 1 $ 5,000 $ 5,000

Sub-total: $ 5,000 0.4%

Engineering

Engineering Cost 1 $ 15,000 $ 15,000

Sub-total: $ 15,000 1.1%

Renewable Energy (RE) Equipment

Biomass heating system (1 boiler) kW 1,500 $ 200 $ 300,000 75 - 3,000 $125 - $250

Biomass equipment installation kW 1,500 $ 70 $ 105,000 75 - 3,000 $20 - $140

Transportation project 1 $ 2,000 $ 2,000

$ - $ -

$ - $ -

Sub-total: $ 407,000 29.0%

Balance of Plant

Peak load heating system kW 1,500 $ 85 $ 127,500 75 - 1,000 $85 - $133

Energy transfer station(s) building 5 - $ 248,637

Secondary distribution line pipe m 630 - $ 103,396

Main distribution line pipe m 707 - $ 164,605

Building and yard construction m² 300 $ 350 $ 105,000 20 - 300 $220 -$470

Equipment installation p-h 2,000 $ 40 $ 80,000 500 - 700 $25 - $50

Transportation project 1 $ 3,000 $ 3,000

$ -

$ -

Sub-total: $ 832,138 59.3%

Miscellaneous

Overhead p-h 200 $ 50 $ 10,000 36 - 120 $50 - $100

Training p-h 40 $ 60 $ 2,400 8 - 30 $40 - $100

Contingencies % 10% $ 1,264,138 $ 126,414 5% - 40%

Sub-total: $ 138,814 9.9%

Initial Costs - Total $ 1,402,952 100.0%

Relative Quantity Unit Cost

Annual Costs (Credits) Unit Quantity Unit Cost Amount Costs Range Range

O&M

Property taxes/Insurance project 1 $ 1,000 $ 1,000

Spare parts burner 1 $ 15,000 $ 15,000 1-3 $200 - $600

O&M labour p-h 400 $ 20 $ 8,000 96 - 700 $15 - $30

Travel and accommodation p-trip $ -

General and administrative project 1 $ 1,200 $ 1,200

$ -

$ - $ -

Contingencies % 10% $ 24,000 $ 2,400

Sub-total: $ 27,600 55.7%

Fuel/Electricity

Biomass t 3,078 $ 5.0 $ 15,390 $0 - $85

Natural gas m³ 3,858 $ 0.330 $ 1,273

Parasitic electricity kWh 53,000 $ 0.100 $ 5,300

Sub-total: $ 21,963 44.3%

Annual Costs - Total $ 49,563 100.0%

Unit Cost

Periodic Costs (Credits) Period Unit Cost Amount Interval Range Range

Refractory insulation Cost 5 yr $ 5,000 $ 5,000

$ -

$ -

End of project life - $ - Go to GHG Analysis sheet

Version 2000 © Minister of Natural Resources Canada 1997 - 2000. NRCan/CEDRL

03/09/2003; BIOH06-B.xls

5. ®

RETScreen Greenhouse Gas (GHG) Emission Reduction Analysis - Biomass Heating Project

Use GHG analysis sheet? Yes Type of analysis Standard Complete Financial Summary sheet

Background Information

Project Information Global Warming Potential of GHG

Project name Local / District Heating 1 ton CH4 = 21 tons CO2 (IPCC 1996)

Project location Ontario, Canada 1 ton N2O = 310 tons CO2 (IPCC 1996)

Base Case Electricity System (Reference)

Fuel type Fuel mix CO2 emission CH4 emission N2O emission Fuel conversion T&D GHG emission

factor factor factor efficiency losses factor

(%) (kg/GJ) (kg/GJ) (kg/GJ) (%) (%) (tCO2/MWh)

Natural gas 100.0% 56.1 0.0030 0.0010 45.0% 8.0% 0.491

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

Electricity mix 100% 135.5 0.0072 0.0024 8.0% 0.491

Base Case Heating System (Reference)

Fuel type Fuel mix CO2 emission CH4 emission N2O emission Fuel conversion Transport or GHG emission

factor factor factor efficiency transfer losses factor

(%) (kg/GJ) (kg/GJ) (kg/GJ) (%) (%) (tCO2/MWh)

Heating system

1 Natural gas 42.6% 56.1 0.0030 0.0010 68.0% 0.0% 0.299

2 Natural gas 12.0% 56.1 0.0030 0.0010 68.0% 0.0% 0.299

3 Natural gas 36.3% 56.1 0.0030 0.0010 68.0% 0.0% 0.299

4 Natural gas 8.4% 56.1 0.0030 0.0010 68.0% 0.0% 0.299

5 Natural gas 0.6% 56.1 0.0030 0.0010 68.0% 0.0% 0.299

6 0 0.0% #N/A #N/A #N/A 0.0% 0.0% 0.000

7 0 0.0% #N/A #N/A #N/A 0.0% 0.0% 0.000

8 0 0.0% #N/A #N/A #N/A 0.0% 0.0% 0.000

9 0 0.0% #N/A #N/A #N/A 0.0% 0.0% 0.000

10 0 0.0% #N/A #N/A #N/A 0.0% 0.0% 0.000

11 0 0.0% #N/A #N/A #N/A 0.0% 0.0% 0.000

12 0 0.0% #N/A #N/A #N/A 0.0% 0.0% 0.000

13 0 0.0% #N/A #N/A #N/A 0.0% 0.0% 0.000

14 0 0.0% #N/A #N/A #N/A 0.0% 0.0% 0.000

Heating energy mix 100.0% 82.5 0.0044 0.0015 0.0% 0.299

Proposed Case Heating System (Mitigation)

Fuel type Fuel mix CO2 emission CH4 emission N2O emission Fuel conversion Transport or GHG emission

factor factor factor efficiency transfer losses factor

(%) (kg/GJ) (kg/GJ) (kg/GJ) (%) (%) (tCO2/MWh)

Heating system

Waste heat 0.0% 0.0 0.0000 0.0000 100.0% 0.0% 0.000

Biomass 99.4% 0.0 0.0320 0.0040 75.0% 0.0% 0.009

NPeak - Natural gas 0.6% 56.1 0.0030 0.0010 75.0% 0.271

Parasitic electricity 1.0% 135.5 0.0072 0.0024 100.0% 0.0% 0.491

Heating energy mix 101.0% 1.8 0.0425 0.0053 0.0% 0.016

GHG Emission Reduction Summary

Base case GHG Proposed case GHG End-use annual Annual GHG

emission factor emission factor energy delivered emission reduction

(tCO2/MWh) (tCO2/MWh) (MWh) (tCO2)

Heating system 0.299 0.016 5,231 1,482.0

Net GHG emission reduction tCO2/yr 1,482.0

Complete Financial Summary sheet

Version 2000 © United Nations Environment Programme & Minister of Natural Resources Canada 2000. UNEP/DTIE and NRCan/CEDRL

03/09/2003; BIOH06-B.xls

6. RETScreen® Financial Summary - Biomass Heating Project

Annual Energy Balance Yearly Cash Flows

Year Pre-tax After-tax Cumulative

Project name Local / District Heating Electricity required MWh 53.0 # $ $ $

Project location Ontario, Canada Incremental electricity demand kW - 0 (350,738) (350,738) (350,738)

Renewable energy delivered MWh 5,201 GHG analysis sheet used? yes/no Yes 1 84,533 84,533 (266,205)

Heating energy delivered MWh 5,231 Net GHG emission reduction tCO2/yr 1,482.0 2 88,534 88,534 (177,670)

Cooling energy delivered MWh - Net GHG emission reduction - 25 yrs tCO2 37,051 3 92,616 92,616 (85,055)

Heating fuel displaced See HL and Network sheet 4 96,779 96,779 11,724

5 95,504 95,504 107,228

Financial Parameters 6 105,356 105,356 212,584

7 109,773 109,773 322,357

Avoided cost of heating energy $/MWh 47.0 Debt ratio % 75.0% 8 114,279 114,279 436,636

RE production credit $/kWh - Debt interest rate % 7.0% 9 118,875 118,875 555,512

RE production credit duration yr 15 Debt term yr 15 10 117,469 117,469 672,980

RE credit escalation rate % 2.0% 11 128,345 128,345 801,326

GHG emission reduction credit $/tCO2 - Income tax analysis? yes/no No 12 133,223 133,223 934,549

GHG reduction credit duration yr 10 Effective income tax rate % 38.0% 13 138,198 138,198 1,072,746

GHG credit escalation rate % 2.0% Loss carryforward? yes/no Yes 14 143,272 143,272 1,216,019

Retail price of electricity $/kWh 0.100 Depreciation method - Declining balance 15 141,719 141,719 1,357,738

Demand charge $/kW - Depreciation tax basis % 80.0% 16 269,255 269,255 1,626,993

Energy cost escalation rate % 2.0% Depreciation rate % 20.0% 17 274,640 274,640 1,901,633

Inflation % 2.0% Depreciation period yr 15 18 280,133 280,133 2,181,766

Discount rate % 9.0% Tax holiday available? yes/no No 19 285,736 285,736 2,467,502

Project life yr 25 Tax holiday duration yr 5 20 284,021 284,021 2,751,523

21 297,280 297,280 3,048,803

Project Costs and Savings 22 303,225 303,225 3,352,028

23 309,290 309,290 3,661,317

Initial Costs Annual Costs and Debt 24 315,475 315,475 3,976,793

Feasibility study 0.4% $ 5,000 O&M $ 27,600 25 313,582 313,582 4,290,375

Development 0.4% $ 5,000 Fuel/Electricity $ 21,963 26 - - 4,290,375

Engineering 1.1% $ 15,000 Debt payments - 15 yrs $ 115,527 27 - - 4,290,375

RE equipment 29.0% $ 407,000 Annual Costs - Total $ 165,090 28 - - 4,290,375

Balance of plant 59.3% $ 832,138 29 - - 4,290,375

Miscellaneous 9.9% $ 138,814 Annual Savings or Income 30 - - 4,290,375

Initial Costs - Total 100.0% $ 1,402,952 Heating energy savings/income $ 245,701 31 - - 4,290,375

Cooling energy savings/income $ - 32 - - 4,290,375

Incentives/Grants $ - RE production credit income - 15 yrs $ - 33 - - 4,290,375

GHG reduction income - 10 yrs $ - 34 - - 4,290,375

Annual Savings - Total $ 245,701 35 - - 4,290,375

Periodic Costs (Credits) 36 - - 4,290,375

# Refractory insulation $ 5,000 Schedule yr # 5,10,15,20,25 37 - - 4,290,375

# $ - Schedule yr # 0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0 38 - - 4,290,375

# $ - Schedule yr # 0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0 39 - - 4,290,375

End of project life - $ - Schedule yr # 25 40 - - 4,290,375

41 - - 4,290,375

Financial Feasibility 42 - - 4,290,375

43 - - 4,290,375

Pre-tax IRR and ROI % 28.7% Calculate GHG reduction cost? yes/no No 44 - - 4,290,375

After-tax IRR and ROI % 28.7% GHG emission reduction cost $/tCO2 Not calculated 45 - - 4,290,375

Simple Payback yr 7.2 Project equity $ 350,738 46 - - 4,290,375

Year-to-positive cash flow yr 3.9 Project debt $ 1,052,214 47 - - 4,290,375

Net Present Value - NPV $ 1,021,996 Debt payments $/yr 115,527 48 - - 4,290,375

Annual Life Cycle Savings $ 104,046 Debt service coverage - 1.73 49 - - 4,290,375

Profitability Index - PI - 2.91 RE production cost ¢/kWh in construction 50 - - 4,290,375

Version 2000 © Minister of Natural Resources Canada 1997 - 2000. NRCan/CEDRL

03/09/2003; BIOH06-B.xls

7. RETScreen® Financial Summary - Biomass Heating Project

Cumulative Cash Flows Graph

Biomass Heating Project Cumulative Cash Flows

Local / District Heating, Ontario, Canada

Year-to-positive cash flow 3.9 yr IRR and ROI 28.7% Net Present Value $ 1,021,996

5,000,000

4,000,000

Cumulative Cash Flows ($)

3,000,000

2,000,000

1,000,000

0

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

(1,000,000)

Years

Version 2000 © Minister of Natural Resources Canada 1997 - 2000. NRCan/CEDRL

03/09/2003; BIOH06-B.xls

8. TEACHER’S NOTES BIOMASS HEATING PROJECT

06 LOCAL / DISTRICT HEATING / ONTARIO, CANADA

• The total heating energy demand was calculated by adding the space heating and domestic hot water (DHW)

heating energy for all buildings. The domestic hot water heating base load is then expressed as a fraction of this

total.

• The heating energy demand for each building cluster was calculated by adding the space heating and DHW heating

energy, as provided in the data table. The heating load for each cluster (in W/m2) was then set to yield the correct

heating energy demand. The Microsoft Excel “Goal Seek” function may also be used to find the right input (e.g.

heating load) when the output (e.g. heating energy demand) is known.

• The formula method was used to calculate the heating network costs and a cost factor of 0.5 was applied to both

the main and secondary distribution lines to reflect the favourable conditions for burying pipe.

• Parasitic electricity was calculated using the method described in the Online User Manual: the biomass boiler is

estimated to have a power draw of 14.2 kW while the power for the circulation pumps is calculated as:

1,337 m x 1,747 kW x (58.7 x 10-6)ºC/m ÷ 40ºC = 3.5 kW.

This calculation is based on the total of the main (707 m) and secondary (630 m) distribution piping. Adding the

boiler and circulation pump loads and multiplying by 2,993 h, the equivalent full load duration hours, gives the

parasitic load of 53,000 kWh/yr.

• Note that in the Financial Analysis worksheet, the RETScreen model calculates the avoided cost of heating energy

($47/MWh) by dividing the total cost of fuel for the base case system ($245,701/yr) by the total heating energy

demand (5,230 MWh). This value is also the cost of the energy that the district heating system’s owner charges to

its client.

• This analysis is done from the perspective of the municipality, which is proposing to install and operate the district

heating system. The five buildings that are to be heated will continue to pay the equivalent rates for energy as they

were paying for the old natural gas heating, but these payments will now be an income stream to the municipality.

For the building owners, financial benefits of the new system will include protection from price volatility of natural

gas and elimination of the capital and maintenance costs associated with operating their old heating systems.