Recovering Energy from Exhaust Pipes

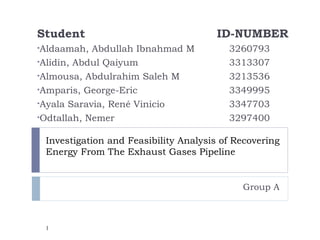

- 1. Student ID-NUMBER •Aldaamah, Abdullah Ibnahmad M 3260793 •Alidin, Abdul Qaiyum 3313307 •Almousa, Abdulrahim Saleh M 3213536 •Amparis, George-Eric 3349995 •Ayala Saravia, René Vinicio 3347703 •Odtallah, Nemer 3297400 Investigation and Feasibility Analysis of Recovering Energy From The Exhaust Gases Pipeline Group A 1

- 2. Scope Recovering the waste heat from the exhaust system and turn it into useful energy 2 George Amparis. 10/10/2011 S3349995

- 3. Summary Using thermogenerator devices, waste heat in the exhaust system is converted to electrical power to be used as an accessory The thermogenerator works on temperature difference to generate a voltage Additional fuel would not have to be consumed to power some of the accessories 3 George Amparis. 10/10/2011 S3349995

- 4. Introduction A series of thermo-generators device was wrapped around the exhaust pipe, so that the side which is in contact with the exhaust is hotter than the side in contact with a fluid to get the temperature difference The voltage from each of the TG’s would be utilised However, in the experiment, only one TG was used to light an LED, using an iron. 4 George Amparis. 10/10/2011 S3349995

- 5. Other ideas considered Using a turbo to turn a generator to produce electrical power. A turbo is normally used to increase the charge of air into the intake in order to increase engine power. Either ways, some waste exhaust heat is utilized. Also a heat exchanger was considered, where the hot exhaust gasses could run a compressor motor, to generate electrical power 5 George Amparis. 10/10/2011 S3349995

- 6. Table of Content Objectives GO Project Planning and Progress Summary GO Thermoelectric Principles GO Energy Storage GO Design GO Simulations GO Feasibility Analysis GO Experiment GO Conclusions GO Future Improvement GO Recommendations GO References GO 6 George Amparis. 10/10/2011 S3349995

- 7. Objectives To increase the effective efficiency of the engine by using the waste heat Analyse if its feasible to install the proposed system into a vehicle Prove that the engine energy waste could be reduced 7 George Amparis. 10/10/2011 HOME S3349995

- 8. Project Planning & Progress Summary Week 1 – Week 12 No Description W1 W2 W3 W4 W5 W6 W7 W8 W9 W10 W11 W12 1 Project selection Literature review and 2 research 3 Information synthesis 4 Midterm presentation 5 Simulation 6 Experiment Recompilation and 7 synthesis Presentation and 8 submission Done In progress Delay 8 George Amparis. 10/10/2011 HOME S3349995

- 9. Thermoelectric Principles Investigation and Feasibility Analysis of Recovering Energy From The Exhaust Gases Pipeline Nemer Odtallah. Student No.: 3297400 9 10/10/2011

- 10. Thermoelectric materials Thermoelectric phenomenon occur when this material exerted to heat source, that can provide voltage potential in the substance itself. This phenomenon can be used both ways, as a generator and as a cooling system. Both applications are used now. The application type can be varied to comply with its usage as a generator or as a cooling system. 10 Nemer Odtallah. 10/10/2011 S3297400

- 11. Inside of the Thermo-electrics Thermoelectric types : • Semiconductor (TE). •Strong conductors (TE). Both types have a cold and hot junction and attached to a load or a battery and the other side is attached to a hot surface to provide the heat as a source or a warm surface to be chilled. Semiconductor thermoelectric material is also known as Peltier device, the state which convert heat into an electrical current. 11 Nemer Odtallah. 10/10/2011 S3297400

- 12. Peltier device The structure of this material is shown in the following slide 12 Nemer Odtallah. 10/10/2011 S3297400

- 13. Thermo electric composition 13 Nemer Odtallah. 10/10/2011 S3297400

- 14. How does the thermoelectric works? It is a silicone semiconductor consists of a P type and N type doped silicone to interact with each other as a positive and negative terminals . Heat is a type of energy that motivates the current flow in silicone material, thus , it sets the electrons free in the last orbit because the material in the n type silicone has a negative charge already because of the extra electron that has doped with. An extra electron will go to the p type silicone which is already needed to make the silicone stable or zero charged . 14 Nemer Odtallah. 10/10/2011 S3297400

- 15. P- type and N-type silicone (voltage generation) 15 Nemer Odtallah. 10/10/2011 S3297400

- 16. Proposed system 16 Nemer Odtallah. 10/10/2011 S3297400

- 17. Adaptability of the system into the vehicle 17 Nemer Odtallah. 10/10/2011 HOME S3297400

- 18. Energy storage Investigation and Feasibility Analysis of Recovering Energy From The Exhaust Gases Pipeline Abdulrahim Almousa. Student No.: 3213536 18 10/10/2011

- 19. Energy Storage & Applications DC/DC voltage converter Ultra-capacitor package 12V lead/acid battery with a battery monitoring sensor(BMS) An example of typical Micro hybrid system architecture 19 Abdulrahim Almousa. S3213536 10/10/2011

- 20. Energy Storage & Applications DC/DC Voltage Converter : To link the high and low voltage power networks on the vehicle. It has 2 operation modes. In forward mode it charge the 12V battery. In reverse mode it uses the 12V battery to charge the ultracapacitor pack. The output capacity is 1.5kW in both directions. 20 Abdulrahim Almousa. S3213536 10/10/2011

- 21. Energy Storage & Applications Ultracapacitor Package : Used to provide energy when there exists a delta of temperature in thermoelectric assembly. The maximum voltage is 28V limited by the ultracapacitor design. The overall package weighs approximately 10kg, compared with approximately 40kg for a lead acid battery package of the same voltage. The dimension of the package is smaller than that of two lead acid batteries with the same voltage level. 21 Abdulrahim Almousa. S3213536 10/10/2011

- 22. Energy Storage & Applications How the charging system works High electric performance 22 Abdulrahim Almousa. S3213536 10/10/2011

- 23. Energy Storage & Applications How the charging system works Low electric performance 23 Abdulrahim Almousa. S3213536 10/10/2011

- 24. Energy Storage & Applications How the charging system works Thermoelectric recovery 24 Abdulrahim Almousa. S3213536 10/10/2011 HOME

- 25. Design Investigation and Feasibility Analysis of Recovering Energy From The Exhaust Gases Pipeline Abdulrahim Almousa. Student No.: 3213536 Vinicio Ayala. Student No.: 3347703 25 10/10/2011

- 26. Evaluation Matrix for Thermoelectric Generator vs. Thermo Dynamic cycle Weighting Property Explanation Factor (0-10) How much energy is recovered from exhaust waste Efficiency 7 heat Manufacturing 10 The viability to manufacture the product viability How expensive will be to mount the system into the Cost 10 vehicle Size 6 Because of the restriction of space in the vehicle Because it's added more load to the engine and more Weight 8 weight exhaust pipeline supports How noxious could be the installation of the system Health risk 9 for the passengers Design viability 8 How easier is the system designed The prove that shows that waste heat is actually Experiment 7 recovered from the exhaust pipeline The biggest constraint in the project due the short Time 10 time to develop the idea 26 Abdulrahim Almousa. S3213536 10/10/2011

- 27. Evaluation Matrix for Thermo-electric generator vs. Thermodynamic cycle Weighting Option A Option B Property Factor (0-10) (Thermoelectric) (Thermodynamic) Weighted Weighted Score (0-10) Score (0-10) Score Score Efficiency 7 4 28 7 49 Manufacturing 10 10 100 5 50 viability Cost 10 5 50 5 50 Size 6 8 48 6 36 Weight 8 7 56 5 40 Health risk 9 8 72 5 45 Design viability 8 10 80 5 40 Experiment 7 10 70 1 7 Time 10 9 90 5 50 Total 594 367 27 Abdulrahim Almousa. 10/10/2011 S3213536

- 28. Thermo-electric generator design 28 Vinicio Ayala. 10/10/2011 S3347703

- 29. Thermo-electric generator design 29 Vinicio Ayala. 10/10/2011 S3347703

- 30. Thermo-electric generator design Dimensions • Pipe Diameter: 2.5 in Thickness: 1/8 in • Water jacket Diameter: 4.5 in Thickness: 1/8 in • Thermo-electric piece: Width: 4 cm Height: 0.4 cm 30 Vinicio Ayala. 10/10/2011 S3347703

- 31. Thermo-electric generator design 31 Vinicio Ayala. 10/10/2011 S3347703

- 32. Thermo-electric generator assembly 32 Vinicio Ayala. 10/10/2011 S3347703

- 33. Water circuit for the Thermo electric generator 33 Vinicio Ayala. 10/10/2011 HOME S3347703

- 34. Simulations Investigation and Feasibility Analysis of Recovering Energy From The Exhaust Gases Pipeline Abdul Qaiyum Student No.: 3313307 Vinicio Ayala Student No.: 3347703 34 10/10/2011

- 35. Electric circuit simulation Switching on LED Charging mode Active controller circuit Source(Heat Capacitor LED ) Source(Heat Capacitor LED ) RC circuit and switching experimentation and simulation 35 Abdul Qaiyum. 10/10/2011 S3313307

- 36. Electric circuit simulation Improved circuit for experimentation Discharging mode Proportional controller Source(Heat Capacitor LED ) RC circuit and switching experimentation and simulation 36 Abdul Qaiyum. 10/10/2011 S3313307

- 37. Exhaust pipe surface temperature range It will be observed in the following slides, that the possible range of temperature outside of the exhaust pipe, oscillates between 400-700 [K]. This range of temperature is given by a city driving condition. 37 Vinicio Ayala. 10/10/2011 S3347703

- 38. Exhaust pipe surface temperature simulation 38 Vinicio Ayala. 10/10/2011 S3347703

- 39. Exhaust pipe surface temperature simulation 39 Vinicio Ayala. 10/10/2011 S3347703

- 40. Exhaust pipe surface temperature simulation 40 Vinicio Ayala. 10/10/2011 S3347703

- 41. Energy recovery simulation Temperature Vs Power Per Thermoelectric Material(PbTe) 2.4564Watt 0.9595 Watt 60oC - 300oC Legend 50oC - 200oC * 323K - 473K + 333K - 573K 41 Abdul Qaiyum. 10/10/2011 S3313307

- 42. Energy recovery simulation Temperature Vs Power Per Thermoelectric Material(PbTe) 7.7226 Watt 4.6441 Watt 80oC - 500oC 70oC - 400oC Legend * 343K - 673K + 353K - 773K 42 Abdul Qaiyum. 10/10/2011 HOME S3313307

- 43. Feasibility Analysis Investigation and Feasibility Analysis of Recovering Energy From The Exhaust Gases Pipeline Abdul Qaiyum Student No.: 3313307 43 10/10/2011

- 44. Feasibility Analysis 1. Motivation in the project • Average distance travelled by the road car annually is approximately 9000 kms • 40% of the total waste energy(2/3) from gasoline exits to exhaust system as hot gases at 300oC to 700oC • Pump price for petrol will increase annually at 6% • Underlying rate of inflation set at 2.4% per annum(mean of previous 10 years) • The car has a useful period of 15 years after which it is scrapped 3. With the engineering technology and advanced tools that we have these days, waste heat could be recovered as much as 5 – 10% of energy and here are few ways to implement the recovery method • Rankine cycle in coil exhaust • Turbo generator • Thermoelectric material generators 44 Abdul Qaiyum. 10/10/2011 S3313307

- 45. Feasibility Analysis Cooling and exhaust Pistons and rings Rolling resistance Bearings Pumping Air resistance Valve train Auxiliaries Mechanical Acceleration Transmission To wheels Mechanical losses Total power from fuel Power to wheels 6.9kW 32kW 3.8kW Typical power distribution in a car during city driving 45 Abdul Qaiyum. 10/10/2011 S3313307

- 46. Feasibility Analysis Assuming typical Power and losses known, • Theoretically we can recover: 7.7226 W /pc (Max) 0.9595 W / pc (Min) • Assuming that the car is driven two hours per day, the total amount of energy recovered for one piece per year will be: 5300 W/year (Max) 700 W /year • Total Energy saved considering a 50 pcs. thermoelectric assembly: 264.9 kW/ year (Max) 35.02 kW/ year (Min) • Wasted Energy per year in 3.8 L V6 Holden Commodore (Considering that the vehicle is working at it maximum load): 111 kW 46 Abdul Qaiyum. 10/10/2011 S3313307

- 47. Feasibility Analysis Holden commodore 3.8 L V6 Distance Petrol Consumption Petrol cost Petrol cost Thermo- per year consumption per year per Liter per year electric system (L/Km) (L/year) ($/L) ($/year) cost ($) (Kms /year) 0.11 9000 990 1.5 1485 1000 47 Abdul Qaiyum. 10/10/2011 S3313307

- 48. Feasibility Analysis This project proves that recovering energy from the exhaust gases pipeline is feasible and its implementation will p Complement the current automotive technology u Reduce consumed petrol p Reduce Greenhouse gas(NOx & CO2) emission e Consumer ROI in 2 years or less 48 Abdul Qaiyum. 10/10/2011 HOME S3313307

- 49. Experiment Investigation and Feasibility Analysis of Recovering Energy From The Exhaust Gases Pipeline Vinicio Ayala. Student No.: 3347703 Abdul Qaiyum Student No.: 3313307 49 10/10/2011

- 50. Energy recovery experiment Cold side temperature Hot side temperature ΔT=Thot-side-Tcold-side ΔT=150.5-19 = 131.5[C] 50 Vinicio Ayala. 10/10/2011 S3347703

- 51. Energy recovery experiment 51 Vinicio Ayala. 10/10/2011 S3347703

- 52. Experiment results Power Efficiency Parameter Re=(phi*Le)/Ae; Wmax=((alpha^2)*(deltaT^2))/(4*Re) Variable Thermoelectric Re - Z merit Material & Heat Phi - Material electrical resistivity sink(water) Le - Thermoelectric material length Ae - Thermoelectric area Alpha - Material Seeback coefficient detaT - Temperature difference Heating iron(exhaust pipe) temperature >100oc Cooling heat sink temperature <10oc Experiment measurement reading(Th > 100oc & Tc < 10oc) Heating and cooling TEG 52 Abdul Qaiyum. 10/10/2011 HOME S3313307

- 53. Conclusions Investigation and Feasibility Analysis of Recovering Energy From The Exhaust Gases Pipeline Nemer Odtallah. Student No.: 3297400 53 10/10/2011

- 54. Conclusions It was confirmed the hypothesis that energy can be recycled from the engine heat waste The ease of design, manufacture and implementation, can make this system really attractive for all the vehicle companies The system is completely feasible, not only because the investment could be recovered in less than 2 year, but also because it could be recovered energy as much as the one that is actually lost during the engine combustion, which means that almost 30% of the total fuel energy could be recovered. 54 Nemer Odtallah. 10/10/2011 HOME S3297400

- 55. Future Improvement Investigation and Feasibility Analysis of Recovering Energy From The Exhaust Gases Pipeline Abdullah Aldaamah. Student No.: 3260793 55 10/10/2011

- 56. Future Improvement Improvement: system analysis optimization designing Performance limits of materials (Higher energy conversion efficiency) Coming government-sponsored outcomes. 56 Abdullah Aldaamah. 10/10/2011 S3260793

- 57. Future Improvement Power produced can be used in: drive power steering brakes water pump turbo charges Analyze the real benefits for the efficiency of the engine 57 Abdullah Aldaamah. 10/10/2011 HOME S3260793

- 58. Recommendations Investigation and Feasibility Analysis of Recovering Energy From The Exhaust Gases Pipeline Abdullah Aldaamah. Student No.: 3260793 58 10/10/2011

- 59. Recommendations Tokeep working and analysing this project in order to improve it and have real results Construct a real model of the proposed system and install it into a vehicle for having a more accurate information about the amount of energy recovered 59 Abdullah Aldaamah. 10/10/2011 HOME S3260793

- 60. References Investigation and Feasibility Analysis of Recovering Energy From The Exhaust Gases Pipeline Abdullah Aldaamah. Student No.: 3260793 60 10/10/2011

- 61. References: HoSung Lee, 2010, Thermal Design, Heat Sinks, Thermoelectrics, Heat Piepes, Compact Heat Exchangers, and Solar Cells, pp. 100-180 B. Gao, K. Svancaara and A. Walker /2009-01-1330 Development of a BISG Micro-Hybrid System (ABL Powertrain UK Ltd, UK), D. Kok, M. Conen and D. Kees (Ford Motor Company, UK) Pasquier, AD, Plitz, I, Menocal, S, Amatucci, G 2002, ‘A comparative study of Li-ion battery, supercapacitor and nonaqueous asymmetric hybrid devices for automotive applications’, Journal of Power Sources, vol. 115, no.2, pp. 171-178, NJ, USA Ehsani M, GaoY, Gay SE and Emadi, A 2005, Modern Electric, Hybrid Electric, and Fuel Cell Vehicles, fundamentals, theory, and design, CRC Press, Florida 61 Abdullah Aldaamah. 10/10/2011 S3260793

Editor's Notes

- Picture reference: http://www.google.com.au/imgres?q=thermoelectric&hl=en&biw=1920&bih=959&gbv=2&tbm=isch&tbnid=lpIoT566-sDbpM:&imgrefurl=http://quanzhou-melcor-huayu-thermoelectric.tradenote.net/catalog.html&docid=d639gEmSvgl8tM&w=600&h=615&ei=xH2RTrGOPMKMmQWdjcX7Dw&zoom=1&iact=hc&vpx=421&vpy=138&dur=951&hovh=227&hovw=222&tx=136&ty=130&page=1&tbnh=145&tbnw=141&start=0&ndsp=45&ved=1t:429,r:1,s:0

- Picture reference: http://www.google.com.au/imgres?q=peltier+device&um=1&hl=en&sa=X&biw=1366&bih=624&tbm=isch&tbnid=-ylshg2Edcvu4M:&imgrefurl=http://autospeed.com/cms/title_Peltier-Intercooler-Water-Spray-/A_110205/article.html&docid=XIXOEsSPNyNgOM&w=302&h=202&ei=-hOSTtPVBIKeiAfhy5mDDg&zoom=1&iact=hc&vpx=392&vpy=165&dur=589&hovh=161&hovw=241&tx=118&ty=78&page=1&tbnh=132&tbnw=190&start=0&ndsp=18&ved=1t:429,r:1,s:0\\

- Picture reference: http://www.google.com.au/imgres?q=thermoelectric&hl=en&biw=1138&bih=499&gbv=2&tbm=isch&tbnid=w7xIWe0YL_xIAM:&imgrefurl=http://www.laserfocusworld.com/articles/print/volume-43/issue-8/features/cmos-detectors-thin-film-tecs-give-new-life-to-cmos-cooling.html&docid=rq3NxmlyySHCOM&w=325&h=226&ei=eyKSTrWREa-HmQWU-LkU&zoom=1&iact=hc&vpx=209&vpy=204&dur=220&hovh=134&hovw=193&tx=114&ty=56&page=6&tbnh=118&tbnw=170&start=54&ndsp=11&ved=1t:429,r:5,s:54

- http://www.google.com.au/imgres?q=n+type+semiconductor&um=1&hl=en&biw=1366&bih=624&tbm=isch&tbnid=cmg-dSB-EaN8wM:&imgrefurl=http://m.eb.com/assembly/71003&docid=3NydjwDwUkoS6M&w=430&h=260&ei=RRiSTqeTDa6aiAe-6smQDg&zoom=1&iact=hc&vpx=364&vpy=304&dur=219&hovh=125&hovw=207&tx=122&ty=38&page=2&tbnh=95&tbnw=157&start=21&ndsp=21&ved=1t:429,r:15,s:21

- Picture reference: http://nextbigfuture.com/2009/11/arpa-e-waste-heat-projects.html

- Picture reference: http://www.google.com.au/imgres?q=thermoelectric+semiconductor+material&um=1&hl=en&sa=N&biw=1366&bih=667&tbm=isch&tbnid=oOmHzW0mPkR1RM:&imgrefurl=http://nextbigfuture.com/2011/05/new-thermoelectric-materials-will-be.html&docid=f4Gfnl9zb-PRjM&w=582&h=418&ei=phGSToL7F6SfiAeVtvygDg&zoom=1&iact=hc&vpx=188&vpy=373&dur=395&hovh=158&hovw=215&tx=144&ty=176&page=5&tbnh=138&tbnw=184&start=90&ndsp=21&ved=1t:429,r:0,s:90

- Picture B. Gao, K. Svancaara and A. Walker /2009-01-1330 Development of a BISG Micro-Hybrid System (ABL Powertrain UK Ltd, UK), D. Kok, M. Conen and D. Kees (Ford Motor Company, UK)

- Picture reference: B. Gao, K. Svancaara and A. Walker /2009-01-1330 Development of a BISG Micro-Hybrid System (ABL Powertrain UK Ltd, UK), D. Kok, M. Conen and D. Kees (Ford Motor Company, UK)

- Picture B. Gao, K. Svancaara and A. Walker /2009-01-1330 Development of a BISG Micro-Hybrid System (ABL Powertrain UK Ltd, UK), D. Kok, M. Conen and D. Kees (Ford Motor Company, UK)

- Picture reference: Ehsani M, GaoY, Gay SE and Emadi, A 2005, Modern Electric, Hybrid Electric, and Fuel Cell Vehicles, fundamentals, theory, and design, CRC Press, Florida

- Picture reference: Ehsani M, GaoY, Gay SE and Emadi, A 2005, Modern Electric, Hybrid Electric, and Fuel Cell Vehicles, fundamentals, theory, and design, CRC Press, Florida

- Picture reference: Ehsani M, GaoY, Gay SE and Emadi, A 2005, Modern Electric, Hybrid Electric, and Fuel Cell Vehicles, fundamentals, theory, and design, CRC Press, Florida

- Fuel Consumption reference: http://en.wikipedia.org/wiki/Holden_VY_Commodore

- Fuel Consumption reference: http://en.wikipedia.org/wiki/Holden_VY_Commodore Cost of the pump=~ $300 Cost of the radiatior=~ $300 Cost of the piping system=~100 Manufacture and incomes to the production company=~ $300