Pqr0

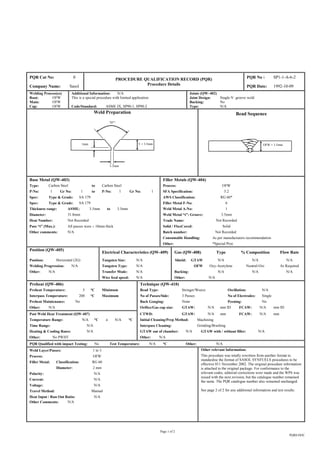

- 1. Page 1 of 2 PQR0.DOC PQR Cat No: 0 PROCEDURE QUALIFICATION RECORD (PQR) Procedure Details PQR No : SP1-1-A-6-2 Company Name: Sasol PQR Date: 1992-10-09 Welding Process(es) Additional Information: N/A Joints (QW–402) Root: OFW This is a special procedure with limited application Joint Design: Single-V groove weld Main: OFW Backing: No Cap: OFW Code/Standard: ASME IX, SP90-1, SP90-2 Type: N/A Weld Preparation Bead Sequence Base Metal (QW-403) Filler Metals (QW-404) Type: Carbon Steel to Carbon Steel Process: OFW P-No: 1 Gr No: 1 to P-No: 1 Gr No: 1 SFA Specification: 5.2 Spec: Type & Grade: SA 179 AWS Classification: RG 60* Spec: Type & Grade: SA 179 Filler Metal F-No: 6 Thickness range: ASME: 3.5mm to 3.5mm Weld Metal A-No: 1 Diameter: 31.8mm Weld Metal “t”: Groove: 3.5mm Heat Number: Not Recorded Trade Name: Not Recorded Pass “t” (Max.): All passes were 10mm thick Solid / FluxCored: Solid Other comments: N/A Batch number: Not Recorded Consumable Handling: As per manufacturers recommendation Other: *Special Proc Position (QW-405) Electrical Characteristics (QW-409) Gas (QW-408) Type % Composition Flow Rate Position: Horizontal (2G) Tungsten Size: N/A Shield: GTAW N/A N/A N/A Welding Progression: N/A Tungsten Type: N/A OFW Oxy-Acetylene Neutral-Oxi As Required Other: N/A Transfer Mode: N/A Backing: N/A N/A N/A Wire feed speed: N/A Other: N/A Preheat (QW-406) Technique (QW-410) Preheat Temperature: 5 °C Minimum Bead Type: Stringer/Weave Oscillation: N/A Interpass Temperature: 200 °C Maximum No of Passes/Side: 3 Passes No of Electrodes: Single Preheat Maintenance: No Back Gouging: None Peening: No Other: N/A Orifice/Gas cup size: GTAW: N/A mm ID FCAW: N/A mm ID Post Weld Heat Treatment (QW-407) CTWD: GTAW: N/A mm FCAW: N/A mm Temperature Range: N/A °C ± N/A °C Initial Cleaning/Prep Method: Machining Time Range: N/A Interpass Cleaning: Grinding/Brushing Heating & Cooling Rates: N/A GTAW out of chamber: N/A GTAW with / without filler: N/A Other: No PWHT Other: N/A PQR Qualified with impact Testing: No Test Temperature: N/A °C Other: N/A Weld Layer/Passes: 1 to 3 Other relevant Information: Process: OFW This procedure was totally rewritten from another format to standardise the format of SASOL SYNFUELS procedures to be effective 011 November 2002. The original procedure information is attached to the original package. For conformance to the relevant codes, editorial corrections were made and the WPS was issued with the next revision, but the catalogue number remained the same. The PQR catalogue number also remained unchanged. See page 2 of 2 for any additional information and test results. Filler Metal: Classification: RG 60 Diameter: 2 mm Polarity: N/A Current: N/A Voltage: N/A Travel Method: Manual Heat Input / Run Out Ratio: N/A Other Comments: N/A 1mm 70°° T = 3.5mm 1-3mm OFW = 3.5mm

- 2. Page 2 of 2 PQR0.DOC Cat No: 0 PROCEDURE QUALIFICATION RECORD (PQR) 2. Test Results PQR No. SP1-1-A-6-2 Date: 1992-10-09 Tensile Tests (QW-150); (QW462) Specimen No: Width (mm) Thickness (mm) Area (mm2 ) Ultimate Load (kN) Ultimate Tensile Strength (MPa) Type of Failure Location of failure Other 1 10 3.3 33 12.9 390 Ductile Base Material None 2 10 3.3 33 12.6 382 Ductile Base Material None 3 10 3.3 33 13.7 415 Ductile Base Material None N/A N/A N/A N/A N/A N/A N/A N/A N/A ASME II part A requirements 325 Min All Weld Tensile Test (QW-150) Specimen No: Diameter (mm) Area (mm2 ) Ultimate Load (kN) Ultimate Tensile Strength (MPa) Type of Failure Location of failure Other N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A Guided Bend Tests (QW-160); (QW-462) Fillet Weld Test (QW-180); (QW-462) Non Destructive Examination: Macro done at 10 x magnification Type: Status: Report No: Bend Angle: 180° Bend Former Size: 10mm Number of Fillet Weld Tests: 0 RT: N/A N/A Bend number: Type: Type of bend: Results: Result Satisfactory (Yes/No): N/A UT: N/A N/A 1 Transverse Face bend Acceptable Penetration in Base Metal (Yes/No): N/A MPI: N/A N/A 2 Transverse Face bend Acceptable Macro Results Acceptable (Yes/No): N/A PT: N/A N/A 3 Transverse Root bend Acceptable Comments: N/A Visual: N/A N/A 4 Transverse Root bend Acceptable Other: N/A N/A Impact Tests (QW-170): Notch Type: N/A Size: N/A Test Temperature: N/A °C Specimen No: Notch Location: Impact Energy (J): Ave (J): Lateral Expansion (mm): % Shear fracture: Other: N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A Hardness tests: Type: Vickers (HV) Load: 5 kg Lab. No: 87/485 Remarks: N/A 1st 2nd 3rd Ave. Location of Hardness Measurements Base Material 1 126 160 - 143.0 HAZ Material 1 154 157 - 155.5 Weld Metal 177 194 - 186.5 HAZ Material 2 154 157 - 155.5 Base Material 2 126 160 - 143.0 Additional Information: N/A We certify that the statements in this record are correct and that the test welds were prepared, welded and tested in accordance with the requirements of Section IX of the ASME Code and the Sasol SP Specifications. By: Peter Smith Signature: Designation: Senior Welding Engineer Date: 01 November 2002 Peter Smith Name Print Stamp Sasol Synfuels Welding Technology Date: Approved Inspection Authority Date: Weld HAZ 2 Base Mat. 2Base Mat. 1 HAZ 1 + + ++ + + + +++ + ++ ++