Introduction to refrigeration systems

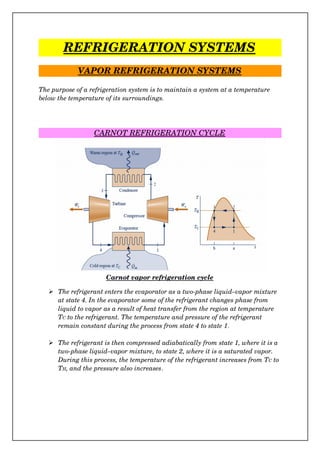

- 2. The refrigerant passes from the compressor into the condenser, where it changes phase from saturated vapor to saturated liquid as a result of heat transfer to the region at temperature TH. The temperature and pressure remain constant in the process from state 2 to state 3 The refrigerant returns to the state at the inlet of the evaporator by expanding adiabatically through a turbine. In this process, from state 3 to state 4, the temperature decreases from TH to TC, and there is a decrease in pressure. Area 1–a–b–4–1 is the heat added to the refrigerant from the cold region per unit mass of refrigerant flowing. Area 2–a–b–3–2 is the heat rejected from the refrigerant to the warm region per unit mass of refrigerant flowing. The enclosed area 1–2–3–4–1 is the net heat transfer from the refrigerant. The net heat transfer from the refrigerant equals the net work done on the refrigerant. The net work is the difference between the compressor work input and the turbine work output COP The coefficient of performance β of any refrigeration cycle is the ratio of the refrigeration effect to the net work input required to achieve that effect. DEPARTURES FROM THE CARNOT CYCLE Actual vapor refrigeration systems depart significantly from the Carnot cycle and have coefficients of performance lower than Carnot. The ways actual systems depart from the Carnot cycle are In actual systems, these heat transfers are not accomplished reversibly as presumed above. To achieve a rate of heat transfer sufficient to maintain the temperature of the cold region at TC requires the temperature of the refrigerant in the evaporator T ’C, to be several degrees below TC. Similarly, to obtain a sufficient heat transfer rate from the refrigerant to the warm region requires that the refrigerant temperature in the condenser, T ‘H, be several degrees above TH.

- 5. WORK AND HEAT TRANSFERS As the refrigerant passes through the evaporator, heat transfer from the refrigerated space results in the vaporization of the refrigerant. For a control volume, rate of heat transfer per unit mass of refrigerant flowing is the mass flow rate of the refrigerant is referred to as the refrigeration capacity. The refrigerant leaving the evaporator is compressed to a relatively high pressure and temperature by the compressor. Rate of power input per unit mass of refrigerant flowing The refrigerant passes through the condenser, where the refrigerant condenses and there is heat transfer from the refrigerant to the cooler surroundings The rate of heat transfer from the refrigerant per unit mass of refrigerant flowing is Refrigerant at state 3 enters the expansion valve and expands to the evaporator pressure. This process is usually modeled as a throttling process for which

- 9. In this case, ammonia is the refrigerant and water is the absorbent. Ammonia circulates through the condenser, expansion valve, and evaporator as in a vaporcompression system. However, the compressor is replaced by the absorber, pump, generator, and valve shown on the right side of the diagram. In the absorber, ammonia vapor coming from the evaporator at state 1 is absorbed by liquid water. The formation of this liquid solution is exothermic. Since the amount of ammonia that can be dissolved in water increases as the solution temperature decreases, cooling water is circulated around the absorber to remove the energy released as ammonia goes into solution and maintain the temperature in the absorber as low as possible. The strong ammonia–water solution leaves the absorber at point “a” and enters the pump, where its pressure is increased to that of the generator. In the generator, heat transfer from a hightemperature source drives ammonia vapor out of the solution (an endothermic process), leaving a weak ammonia–water solution in the generator. The vapor liberated passes to the condenser at state 2, and the remaining weak solution at c flows back to the absorber through a valve. The only work input is the power required to operate the pump, and this is small in comparison to the work that would be required to compress refrigerant vapor between the same pressure levels. MODIFIED AMMONIA–WATER ABSORPTION SYSTEM In this cycle, a heat exchanger is included between the generator and the absorber that allows the strong water–ammonia solution entering the generator to be preheated by the weak solution returning from the generator to the absorber, thereby reducing the heat transfer to the generator . The other modification shown in the figure is the rectifier placed between the generator and the condenser. The function of the rectifier is to remove any traces of water from the refrigerant before it enters the condenser. This eliminates the possibility of ice formation in the expansion valve and the evaporator.

- 11. GAS REFRIGERATION SYSTEMS In gas refrigeration systems working fluid remains a gas throughout. They are used to achieve very low temperatures for the liquefaction of air and other gases and for other specialized applications such as aircraft cabin cooling. BRAYTON REFRIGERATION CYCLE The refrigerant gas, which may be air, enters the compressor at state 1, where the temperature is somewhat below the temperature of the cold region, TC, and is compressed to state 2. The gas is then cooled to state 3, where the gas temperature approaches the temperature of the warm region, TH. Next, the gas is expanded to state 4, where the temperature, T4, is well below that of the cold region. Refrigeration is achieved through heat transfer from the cold region to the gas as it passes from state 4 to state 1, completing the cycle.

- 13. The heat exchanger allows the air exiting the compressor at state 2 to cool below the warm region temperature TH giving a low turbine inlet temperature, T3. Without the heat exchanger, air could be cooled only close to TH, as represented on the figure by state a. In the subsequent expansion through the turbine, the air achieves a much lower temperature at state 4 than would have been possible without the heat exchanger Accordingly, the refrigeration effect, achieved from state 4 to state b, occurs at a correspondingly lower average temperature. SELECTING REFRIGERANTS Refrigerant selection for a wide range of refrigeration and airconditioning applications is generally based on three factors 1) PerformanceIt refers to providing the required cooling or heating capacity reliably and cost effectively 2) Safety It refers to avoiding hazards such as toxicity and flammability 3) Environmental impact It primarily refers to using refrigerants that do not harm the stratospheric ozone layer or contribute significantly to global climate change. The selection of a refrigerant is based partly on the suitability of its pressure– temperature relationship in the range of the particular application. It is generally desirable to avoid excessively low pressures in the evaporator and excessively high pressures in the condenser. Other considerations in refrigerant selection include chemical stability, corrosiveness, and cost. The type of compressor also affects the choice of refrigerant. Centrifugal compressors are best suited for low evaporator pressures and refrigerants with large specific volumes at low pressure. Reciprocating compressors perform better over large pressure ranges and are better able to handle low specific volume refrigerants.