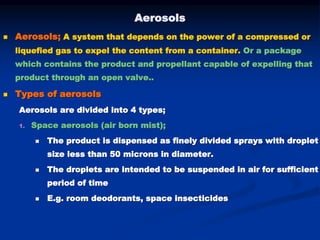

Aerosols1

- 1. Aerosols Aerosols; A system that depends on the power of a compressed or liquefied gas to expel the content from a container. Or a package which contains the product and propellant capable of expelling that product through an open valve.. Types of aerosols Aerosols are divided into 4 types; 1. Space aerosols (air born mist); The product is dispensed as finely divided sprays with droplet size less than 50 microns in diameter. The droplets are intended to be suspended in air for sufficient period of time E.g. room deodorants, space insecticides

- 2. 2. Surface coating aerosols The droplet size is larger than space aerosols. It is intended to be deposited on the surface rather than suspended on air. E.g.; Local anesthetics, hair spray, paints and paint removers. 3. In foam aerosols the product is dispensed in the form of foam E.g.; shaving creams 4. In stream aerosols; The product is expelled from the pressurized package in the form of a simple stream. E.g., hand lotion

- 3. Advantages of Aerosol therapy 1. Convenience, speed and ease of application 2. efficient dispersion 3. Avoidance of manual contact with the medication 4. High concentration of the medication over a limited area. 5. Application without manual contact with the patient thus producing minimum irritation of painful areas. 6. Rapid response to the medication 7. Controlled and uniform dosage produced by metered valve. 8. By changing the pressure in the pack or using special valves the spray characteristics may be varied from a coarse wet spray to a fine dry mist.

- 4. 9. No contamination of the product from the environment since the system is pressurized. 10. The pressure with which the product is applied, increase the penetration of the product into the affected area. 11. Absence of air from aerosol container increases the stability of easily oxidized substances. 12. Hydrolysis of ingredients can be prevented since the propellants contain no water.

- 5. Disadvantages of aerosols; 1. cost, the container, valves, propellants, and filling methods are more expensive than traditional packs. 2. Aerosol packs must not be subjected to heat since high pressure can develop. 3. formulation difficulties 4. Toxicity of propellant over prolonged use in inhalation therapy. 5. The refrigerant effect of highly volatile propellants may cause discomfort on injured skin.

- 6. Components of aerosols It consists of 4 components 1. Container 2. Valve 3. Propellant 4. Product concentrate

- 7. 1. propellants; The material which responsible for expelling the content of aerosol container. Propellant may act as solvent, suspending agent and diluent and may affect the properties of the product. Requirements for the Ideal propellants 1. Posses pressure sufficient for expelling the materials (7 kg/cm). 2. Non-inflammable, Non-toxic, non-irritant and inert 3. Non-expensive

- 8. Types of propellant There are 2 types of propellants are used in pharmaceutical aerosols; 1. Liquefied gas propellant; For many years, the liquefied gas propellants most used in aerosols products were the chlorofluorocarbons (CFCs), however, these propellants are being phased out and will be prohibited due to the following recognition that they reduce the amount of ozone in the stratosphere, which results in an increase in the amount of UV radiation reaching the earth which may increase the incidence of skin cancer. Some exemption from this prohibition, in case of unavailability of other alternative propellant and the product provides a substantial health benefit unobtainable without the use of CFCs.

- 9. Among the CFCs used as propellants in pharmaceuticals were; dichlorteterafluoroethane (Freon 114 or propellant 114) trichloromonofluoromethane (Freon 011) dichlorofluoromethane (Freon 012). N.B the numerical designation system (XYZ); X = number of carbon atoms +1 Y = number of hydrogen atoms - 1 Z = number of fluorine atoms E.g., propellant 113 has 2 C + no H + 3 F Fluorinated hydrocarbons are gases at room temperature. They may be liquefied by cooling below their boiling point or by compression at room temperature.

- 10. They are used as single gas or as a mixture of gases if a single propellant does not give the desired pressure. They form 2 phase system i.e., they are completely miscible with the rest of the formulation. When a liquefied gas propellant is sealed in an aerosol container a portion of the propellant vaporized and the remainder exist as a liquid, until equilibrium, where the vapour phase exerts a pressure in all direction above the liquid and this pressure forces the liquid up the dip tube. When the valve is opened, the liquid passes the valve into atmosphere. The boiling point of the propellant is usually considerably lower than the room temperature, so that the liquefied gas instantly vaporize.

- 11. As the vapour phase leaves the container, the space above the surface of the liquid increases causing a slight depression in the pressure and at this moment some liquid propellant passes from the solution to the vapour phase to compensate this drop in the pressure and restoring the equilibrium between the vapour and liquid phases. Therefore the system has a constant vapour pressure as long as it still contains a liquid phase. Advantages; The product will have a constant pressure as long as there is some liquid propellant in pressurized package.

- 12. Calculations of the vapor pressure: Raoult`s law: Total vapour pressure in a container = Σ (sum of) [Mole fraction X vapor pressure] for each component. Ex: Mix of Propellant 12/11 in 70/30 ratio where: MW 11 = 137.38 Vp 11= 13.4 psig MW 12 = 120.93 Vp 12 = 84.9 psig Calculate total vapor pressure? 1- no of moles of p11= 30/137.38 = 0.218 2- no of moles of p12 = 70/120.93= 0.579 Ptotal= (0.218/0.218+0.579) X13.4 + (0.579/0.218+0.579)X84.9 = 3.67+ 61.68= 65.35 psig.

- 13. 2. Compressed gas propellants Compressed gases are used in preparation of aerosols, where the pressure of the compressed gas in the head space of aerosol container forces the product up the dip tube and out of the valve. The gases used may be; Insoluble gases in liquid phase of aerosol; e.g., Nitrogen It is odourless, tasteless and inert towards the other components of aerosol and protects the product from oxidation. Slightly soluble gases in liquid phase of aerosol; E.g., Carbon dioxide and nitrous oxide used in dispensing foam product.

- 14. Unlike aerosols prepared with liquefied gas propellant, compressed gas filled aerosols have no reservoir of propellant. Thus higher gas pressures are required in these systems, where the pressure in these aerosols diminishes as the product is used.

- 15. 2. Containers of aerosols Various materials have been used in the manufacture of aerosol container, including; 1. Glass, uncoated or plastic coated Advantages; Chemically inert. Not subjected to corrosion, Easily shaped Disadvantages; Accidental breakage. For this reason, plastic coating are commonly applied to the outer surface of glass container to render them more resistant to accidental breakage, and in case of breaking the plastic coat prevents the scattering of glass fragments. Glass containers are safely used for dispensing aerosol products which are working at a pressure not exceed 25 psig and the aerosol product contains not more than 50 % propellant.

- 16. 2. Metal containers a) tin plated steel containers; the most widely used metal containers for aerosols, because they are manufactured from sheets of the metal, these sheets are welded at the junctions which may result in incomplete sealing of the container, this may leads to leak of the container or may make a corrosion of the container. N.B; special protective coating are employed to the inner surface of the container to prevent corrosion and interaction between the container and formulation.

- 17. b) Stainless steel Used for small amount of aerosol product in which a great deal of chemical resistance is required. The main limitation of stainless containers is their high cost. c) Aluminum containers Manufactured by extrusion or by other methods that make them seamless. They have the advantage over the seam type container of greater safety against leakage, incompatibility and corrosion. 3- Plastic containers Advantages Low cost, light, unbreakable and no leakage. Disadvantages Adsorption of aerosol components Drug-plastic interaction Psychologically undesired.

- 18. 3. Valves The function of the valve assembly is to permit expulsion of the contents of aerosol in the desired form, at desired rate, and in case of metered valves, in the proper amount or dose. The materials used in the manufacture of valves should be inert to the formulation and approved by FDA. Among the materials used in manufacture of valve are plastic, rubber, aluminum and stainless steel.

- 19. The usual aerosol valve assembly is composed of the following parts; 1.Actuator 2.Stem 3.Gasket 4.Spring 5.Mounting cup 6.Housing 7.Dip tube

- 20. 1. Actuator; The button the user presses to activate the valve assembly for emission of the product. It permits easy opening and closing of the valve. The size of the actuator orifices affect the physical form of the product discharged (mist, coarse spray, solid stream or foam) The type and quantity of propellant used and the actuator design control the particle size of the emitted product. Where ; Larger orifice and less propellant are used for products to be emitted as foam

- 21. 2. Stem; Support the actuator and deliver the formulation in the proper form to the chamber of the actuator. 3. Gasket; Prevent the leakage of the formulation when the valve is closed. 4. Spring; Hold the gasket in place and when the actuator is depressed and released, the spring will return the valve to its closed position. 5. Mounting cup; Used to attach the valve to the aerosol container. Since it is exposed to the formulation, it should be manufactured from an inert material to prevent an undesired interaction. 6. Housing; Located directly below the mounting cup, it links the dip tube and the stem and actuator. 7. Dip tube; Extends from the housing down into the product; brings the formulation from the container to the valve.

- 22. Metered valve; Are fitted to pharmaceutical preparations when a definite volume of the product is released in one operation of the valve button. Such valves contain a reservoir of definite volume. There are two types 1. Depression of the button may release the content of the of reservoir which refills on release of the button 2. Depression of the button may fill the reservoir and the content of which are ejected on release of the button.

- 23. 4. The concentrate (the active ingredients); The concentrate may present in 4 states; one liquid phase two liquid phase (o /w emulsion spray or w /o emulsion spray powder spray One liquid phase; The propellant is completely miscible with the product to form a single liquid phase in addition to the vapour phase (2 phase aerosol system). This system gives homogenous spray with constant pressure.

- 24. Two liquid phases When the solution of active ingredient in a suitable solvent is not miscible with the propellant gives rise to three phase aerosol systems consisting of the propellant liquid phase, the solution liquid phase and the vapour phase. If the propellant is lighter than the solution, the dip-tube must reach to the bottom of the container. If the propellant is heavier than the solution, the dip-tube must be shortened so that the tube dips in the aqueous phase not in the propellant to avoid spraying the propellant and not the product. The 2 liquid phases may also be emulsified to produce an emulsion system;

- 25. Oil in water emulsion The propellant representing the oil phase which is immiscible with the aqueous phase solution of the product or the products containing water as carrier. So it is necessary to emulsify the propellant in the product solution by using an emulsifying agent. The ratio between the propellant and the emulsifying agent used is 1: 4 or 1: 5 to ensure transparent product. Since the propellant is the internal phase, so when expanded on release from the valve it tends to produce foam and foam actuator must be fitted. Water in oil emulsion By using an emulsifying agent such as polyglyceride ester of fatty acid (Emecol 14) or sorbitan monolourate (span 20) Sine the propellant is the external phase the product can be sprayed to produce coarse wet spray or stream.

- 26. powder spray They consists of a solid phase (the powder) suspended in a liquid phase (the propellant). The vapour phase consisting of the propellant vapour, the inclusion of lubricant and control of the particle size is necessary. Why? Because the too large particles may clog the valve and the agglomeration of the small particle may also cause clogging (the recommended sizes of particles are 5 to 10 um and none greater than 50 um). Due to the density difference between the solid particles and the propellant the dispersed particles may be collected above or below the propellant which may re-disperse by gentile shacking, but in some cases the collected particles form a hard cake on long standing, which can not re-disperse by shacking, in this cases, small balls of stainless steel or ceramic balls are included to break down the hard cake while shacking of the container and re-dispersion can occur.