INTERNSHIP REPORT ps

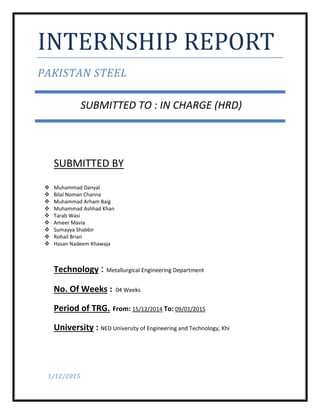

- 1. INTERNSHIP REPORT PAKISTAN STEEL SUBMITTED TO : IN CHARGE (HRD) SUBMITTED BY Muhammad Danyal Bilal Noman Channa Muhammad Arham Baig Muhammad Ashhad Khan Tarab Wasi Ameer Mavia Sumayya Shabbir Rohail Brian Hasan Nadeem Khawaja Technology : Metallurgical Engineering Department No. Of Weeks : 04 Weeks Period of TRG. From: 15/12/2014 To: 09/01/2015 University : NED University of Engineering and Technology, Khi 1/12/2015

- 2. INTERNSHIP REPORT 2015 1 PREFACE This report includes the brief introduction of Pakistan Steel Main Plant and some of its integral departments including IMD, SMD, F&F and Sintering Plant. The report covers the detailed information about the processes being employed in the mentioned departments as well as about the machinery used.

- 3. INTERNSHIP REPORT 2015 2 ACKNOWLEDGEMENT The success and final outcome of this internship program required a lot of guidance and assistance and we are very fortunate to have got this along the completion of our internship at Pakistan Steel. We respectfully thank the honorable Chief Executive Officer, Pakistan Steel, for providing us the opportunity for training and who’s intelligent, wise and sound leadership is remarkable in converting Pakistan Steel into a Gold mine. We wish to express our deepest gratefulness to Mr. Absar Nabi, APEO (HRD) for his consideration and supervision. We are also thankful to Engr. Akhter Hussain, SE/Incharge (HRD) and Mr. Akhlaq Alam, Assistant Manager (HRD) for his precious advice and for the great encouragement and cooperation. We owe our profound gratitude to Mr. Naeem and Mr. Atiq Khan from Sintering Plant, Mr. Sikander Baloch from F&F, Mr. Qamar-uz-Zaman Bhatti and Mr. Arif Afroze from IMD, Mr. Mushtaq Awan and Mr. Naimat Ullah Bhutto from SMD, for their unlisted encouragement and moreover for their timely support and guidance. We are also thankful to and fortunate enough to get constant encouragement, counseling and support from the staff of Pakistan Steel who provided us with all the necessary information required for this program.

- 4. INTERNSHIP REPORT 2015 3 Table of Contents 1. INTRODUCTION ............................................................................................................................... 5 1.1.Background...................................................................................................................................... 5 1.2.Main Units........................................................................................................................................ 5 1.3.Products ………………………………………………………………………………………………………………………………… 5 1.4.Equipment …………………………………………………………………………………………………………………………….. 6 1.5.Services …………………………………………………………………………………………………………………………………. 6 2. SINTERING PLANT............................................................................................................................ 7 2.1. General History …………………………………………………………………………………………………………………….. 7 2.2.Stock Bin and Fuel Grinding Sections ………………………………………………………………………………. 7 2.3.Design Capacity ………………………………………………………………………………………………………………………. 7 2.4.Sintering Section ……………………………………………………………………………………………………………….. 8 2.5.Sorting Section…………………………………………………………………………………………………………………….. 8 2.6.Air Cleaning and Exhauster …………………………………………………………………………………………….. 8 3. IRON MAKING DEPARTMENT (IMD) ................................................................................................ 9 3.1.Equipment ………………………………………………………………………………………………………………………… 9 3.2.Raw Materials …………………………………………………………………………………………………………………….. 10 3.3.Process Engineering and Chemistry …………………………………………………………………………………10 - 12 3.4.Normalities in Blast Furnace ……………………………………………………………………………………………. 13 3.5.Sections …………………………………………………………………………………………………………………………… 13

- 5. INTERNSHIP REPORT 2015 4 4. STEEL MAKING DEPARTMENT (SMD) ………………………………………………………………………………… 14 4.1.Introduction ……………………………………………………………………………………………………………. 15 4.2.Converter in Pakistan Steel …………………………………………………………………………………….. 15 4.3.Casting Method ……………………………………………………………………………………………………………… 16 4.4.Products ………………………………………………………………………………………………………………………… 16 - 20 5. F&F ………………………………………………………………………………………………………………………………….. 21 - 22 6. Concluding Words…………………………………………………………………………………………………………. 23

- 6. INTERNSHIP REPORT 2015 5 1. INTRODUCTION Pakistan Steel is located 40 km south east of Karachi in close vicinity to port Muhammad Bin Qasim. This mill is a coastal site and is spread over an area of 18600 acres with 10,390 acres for the main plant, 8070 acres for the township and 200 acres for the water reservoir. 1.1. BACKGROUND The foundation of Pakistan Steel dates back to 1970’s when Russia helped the government of Pakistan to build the largest industrial complex for the steel in Pakistan. The Prime Minister of Pakistan, Zulfiqar Ali Bhutto (Shaheed) laid the foundation stone on 30th December, 1973 with the production capacity of 1.1 Million ton of steel expandable up to 3.0 Million ton per annum. 1.2. MAIN UNITS Pakistan Steel includes the following main units in its plant, Coke Oven and By Product Plant Sintering Plant Iron Making Department Steel Making Plant Billet Mill Hot Strip Mill Cold Rolling Mill Refractories Thermal Power Plant and Turbo Blower Station Oxygen Plant Iron ore and Coal Jetty 1.3. PRODUCTS Pakistan Steel offers following main products, Coke Pig Iron Billets Cold Rolled Sheets Hot Rolled Sheets Galvanized Sheets

- 7. INTERNSHIP REPORT 2015 6 1.4. EQUIPMENT Following equipment are used in Pakistan Steel for different processes and production units, In coke oven and by product plant there are 02 batteries available each containing 49 ovens. 02 Sinter Machines 02 Blast Furnaces 02 L.D. Converters 01 Bloom Caster 01 Billet Caster 02 Slab Casters 800 mm Reversible Stand in Billet Mill 02 Reheating Furnaces 1700 mm Universal Stand in Hot Strip Mill Four High Reversible machines, 01 Bell Type Annealing Furnace in Cold Rolling Mill Lime Rotary Kiln, Hydraulic Press, Power Press in Refractories 03 Generators of 55 MW each Conveyer Belts 1.5. SERVICES The services offered by Pakistan Steel includes, Engineering Design Electronics Electrical Mechanical Metallurgical Engineering Testing Electrical Testing and Calibration

- 8. INTERNSHIP REPORT 2015 7 2. SINTERING PLANT 2.1. GENERAL HISTORY: Sinter plant was revamped and modernized in 1995-96. During revamping the capacity of the plant has been enhanced from 1.5 M Tons/year to 1.85 M tons/year. The whole sinter plant was modernized and computerized automation/control systems were installed. The whole plant is now electronically controlled through PLC and DCS systems. 2.2. STOCK BINS AND FUEL GRINDING SECTION: a. The stock bins consist of 02 parallel lines of raw material proportioning bins. There are 12 bins on each lines and the raw material proportioning is done through a precisely accurate weighing system installed at every material storage bins. b. The fuel grinding section mainly consists of a Hammer Crushing mill and Coke Crushing unit. There are two Hammer Crushers installed with a crushing capacity of 300 Tons/hour each. At the Coke Crushing unit, 03 Four Roll Crushers are installed. The Lime Stone and Dolomite is crushed to a desired size of less than 03mm at the Hammer Crushers. Whereas Coke is crushed at Four Roll Crushers. The section consists of a Network of Belt Conveyor systems equipped with De-dusting units. The properly weighed raw materials are then conveyed through conveyor to Primary Mixer where these materials are properly homogenized and mixed and water is added to the raw mixer, and then the raw mix is shifted to Sintering Section through a conveyor. 2.3. DESIGN CAPACITY: Sintering plant was initially designed to produce 1.5 million tons of sinter per year with the help of two sintering machines with an effective area of 75 square meter each. After modification and revamping of sintering plant in 1996, the production capacity has been increased from 1.5 million tons per year to 1.85 million tons of sinter per year by increasing the effective area of sintering machines from 75 square meter to 90 square meter. Sinter is supplied to Iron Making Department for the production of Pig Iron/Hot metal.

- 9. INTERNSHIP REPORT 2015 8 2.4. SINTERING SECTION: The raw material mixer is then distributed to storage bins for sintering machines. The mixer is once again homogenized, mixed and balling process is carried out at balling mixer drums and then through control feeding, are charged on to the sintering machines. The mixer is ignited to 12000 C at the start of the sintering process by means of ignition furnaces provided at the charging ends of sintering machines. TECHNICAL PARAMETERS OF TWO SINTERING MACHINES Number of strands 02 Ignition furnace (SMI Japan) 01 at each machine Suction area 90M2 No. of pallet cars at each machine 92 nos. Width of pallet car 2.5 M Bed height 450mm max. No. of suction chambers 18 nos. Winch scrapper arrangement & system One complete system at each machine Sinter crushers one roll type 01 crusher at each machine The top surface of the sinter mix is ignited while travelling of pallet cars through ignition furnace and then the process of sintering continues on the travelling pallet cars which are mounted on rails. The sintering process is completed by the time the pallet car reaches at the end and then after emptying the prepared sinter to the One Roll Crusher chambers, the pallet cars turn back. The travelling speed of pallet cars is 1.5M per minute to 2.5M per minute. The prepared hot sinter then passes through crusher and shoot of sinter coolers. The sinter coolers are again slow moving pallets and hot sinter charged on these coolers and cooled by a blast of air through blowers installed underneath the coolers. The sinter after cooling is screened in two stages at the sorting section. 2.5. SORTING SECTION: Sorting section consists of cold screens, fine screens and a network of sinter fine conveying system. Sinter is screened in two stages. In the first stage, it is passed through cold screen, where sinter less than 16mm in size is separated and sinter greater than 16mm in size is directly send to the blast furnace. The sinter fraction less than 16mm size is further screened and passed through fine screens with sieve openings of 6mm. The sinter fraction of 6-16mm is partially utilized as bed layer at sintering machines. The fraction less than 6mm size is returned back to sinter mix return bins for recycling. 2.6. AIR CLEANING AND EXHAUSTER:There are two exhausters installed for two sintering machines with a suction capacity of 7500M3 /min. And each equipped with 2.5MW slipring motors. The Air Cleaning Plant is equipped with 03 Electrofilter units having exhaust fans of 800 (kW) capacity each. The dust is separated from the sinter suction system and then this dust is again recycled.

- 10. INTERNSHIP REPORT 2015 9 3. IRON MAKING DEPARTMENT – IMD 3.1. EQUIPMENT Iron Making Department produces Pig Iron by using Blast Furnace. There are in total 02 blast furnaces. The characteristics of the Blast Furnaces used in IMD are as follows, SKIP CARS The Blast Furnace feed of 12 ton is fed with the help of skip cars. They carry the feed up to the charging system and dump the feed at the tilting angle of 55 degrees. CHARGING SYSTEM Double bell charging system is used in the furnace to minimize the losses and overcome the effect of pressure. The skip cars dump the feed on the small stationary bell, a distributor is attaches to it, it opens up and the hopper rotates to distribute to even. The feed then enters the large bell which opens up when the outside pressure is equal to the furnace pressure, and finally enters the furnace for further process. HOT BLAST STOVES Cold blast from turbo blow station enters from V-18, which is then heated by using high alumina bricks, the hot blast leaves from V-19 to bustle pipes and then enters the blast furnace at the temperature of 1650 degrees. BLAST FURNACE PROFILE SR NO DESCRIPTION Measuring Unit Blast Furnace No. 1 Blast Furnace No. 2 1 Effective Volume M3 1033 1033 2 Hearth Diameter mm 7200 7200 3 Belly Diameter mm 8200 8200 4 Top Diameter mm 5800 5800 5 Hearth Height mm 3700 3400 6 Bosh Height mm 3000 3000 7 Belly Height mm 2000 2000 8 Stack Height mm 15000 15000 9 Top Height mm 2310 2310

- 11. INTERNSHIP REPORT 2015 10 3.2. RAW MATERIALS The raw materials used in the blast furnace are as follows, Lumpy Iron ore – 6mm to 30mm Sinter – 15mm to 25mm Metallurgical Coke – 25mm to 80mm Additives - Dolomite - Limestone - Quartz - Manganese The feed comprises of about 3.95 tons coke and 25:75 iron ore and sinter. 3.3. PROCESS ENGINEERING AND CHEMISTRY Blast furnace, a vertical shaft furnace that produces liquid metals by the reaction of a flow of air introduced under pressure into the bottom of the furnace with a mixture of metallic ore, coke, and flux fed into the top. Blast furnaces are used to produce pig iron from iron ore for subsequent processing into steel, and they are also employed in processing lead, copper, and other metals. Rapid combustion is maintained by the current of air under pressure. Blast furnaces produce pig iron from iron ore by the reducing action of carbon (supplied as coke) at a high temperature in the presence of a fluxing agent such aslimestone. Ironmaking blast furnaces consist of several zones: a crucible-shaped hearth at the bottom of the furnace; an intermediate zone called a bosh between the hearth and the stack; a vertical shaft (the stack) that extends

- 12. INTERNSHIP REPORT 2015 11 from the bosh to the top of the furnace; and the furnace top, which contains a mechanism for charging the furnace. The furnace charge, or burden, of iron-bearing materials (e.g., iron-ore pellets and sinter), coke, and flux (e.g., limestone) descends through the shaft, where it is preheated and reacts with ascending reducing gases to produce liquid iron and slag that accumulate in the hearth. Air that has been preheated to temperatures from 900° to 1,250° C (1,650° and 2,300° F), together with injected fuel such as oil or natural gas, is blown into the furnace through multiple tuyeres (nozzles) located around the circumference of the furnace near the top of the hearth; these nozzles may number from 12 to as many as 40 on large furnaces. The preheated air is, in turn, supplied from a bustle pipe, a large-diameter pipe encircling the furnace. The preheated air reacts vigorously with the preheated coke, resulting in both the formation of the reducing gas (carbon monoxide) that rises through the furnace, and a very high temperature of about 1,650° C (3,000° F) that produces the liquid iron and slag. The bosh is the hottest part of the furnace because of its close proximity to the reaction between air and coke. Molten iron accumulates in the hearth, which has a taphole to draw off the molten iron and, higher up, a slag hole to remove the mixture of impurities and flux. The hearth and bosh are thick-walled structures lined with carbon- type refractory blocks, while the stack is lined with high-quality fireclay brick to protect the furnace shell. To keep these refractory materials from burning out, plates, staves, or sprays for circulating cool water are built into them. The stack is kept full with alternating layers of coke, ore, and limestone admitted at the top during continuous operation. Coke is ignited at the bottom and burned rapidly with the forced air from the tuyeres. The iron oxides in the ore are chemically reduced to molten iron by carbon and carbon monoxide from the coke.

- 13. INTERNSHIP REPORT 2015 12 The slag formed consists of the limestone flux, ash from the coke, and substances formed by the reaction of impurities in the ore with the flux; it floats in a molten state on the top of the molten iron. Hot gases rise from the combustion zone, heating fresh material in the stack and then passing out through ducts near the top of the furnace. Blast furnaces may have the following ancillary facilities: a stock house where the furnace burden is prepared prior to being elevated to the furnace top by skip cars or a belt conveyor system; a top-charging system consisting of a vertical set of double bells (cones) or rotating chutes to prevent the release of furnace gas during charging; stoves that utilize the furnace off-gases to preheat the air delivered to the tuyeres; and a cast house, consisting of troughs that distribute liquid iron and slag to appropriate ladles for transfer to steelmaking furnaces and slag-reclamation areas. BLAST FURNACE CHARGING Burden materials are delivered from the bins to skip cars by conveyers. Every blast furnace has 14 bins in which 06 are of sinter, 02 ore, 02 coke and 04 for additives. To ensure accurate composition and weighing of burden, the minimum weight which should be poured at a time must not be less than 200 kg including ore and sinter ± 50 Kg and Additives ± 5 Kg. After discharging one skip car the hopper of the charge distributor will be turned by the angle pre-set by the establishment program. The burden descends and stock line position is controlled by two test probes. The level of large bell’s lower edge, when the bell is in open position, is taken as a zero level of the test probe. Movement of large and small bell is 600mm and 800mm respectively. Before the large bell opens the difference between under bell and inter bell space values shall not exceed 0.1 kg/cm2 SLAGS Following three slags are formed, - 1st slag is formed in lower stack area – MnO slag - 2nd slag is formed in bosch – Alumino slag - 3rd slag is formed in hearth – Desulphurization REDUCING AGENTS - Carbon Mono oxide - Hydrogen gas - Coke

- 14. INTERNSHIP REPORT 2015 13 3.4. NORMALITIES IN BLAST FURNACE Upper Hanging Channeling Lower Hanging Tight Run Center Run Periphery Run Chilled Hearth One sided Run Scaffolding Slipping Hot hanging 3.5. SECTIONS Gas cleaning section Hot metal ladle repair shop Pig casting machine Slag granulated plant Pudding wings

- 15. INTERNSHIP REPORT 2015 14 4. STEEL MAKING DEPARTMENT (SMD)

- 16. INTERNSHIP REPORT 2015 15 4.1. INTRODUCTION Steelmaking is the second step in producing steel from iron ore. In this stage, impurities such as sulfur, phosphorus, and excess carbon are removed from the raw iron, and alloying elements such as manganese, nickel, chromium and vanadium are added to produce the exact steel required. Basic oxygen steelmaking is a method of primary steelmaking in which carbon-rich molten pig iron is made into steel. Blowing oxygen through molten pig iron lowers the carbon content of the alloy and changes it into low-carbon steel. The process is known as basic due to the pH of the refractory—calcium oxide and magnesium oxide—that line the vessel to withstand the high temperature of molten metal. The process was developed in 1948 by Robert Durer and commercialized in 1952–1953 by Austrian VOEST and ÖAMG. The LD converter, named after the Austrian towns Linz and Donawitz (a district of Leoben) is a refined version of the Bessemer converter where blowing of air is replaced with blowing oxygen. It reduced capital cost of the plants, time of smelting, and increased labor productivity. Between 1920 and 2000, labor requirements in the industry decreased by a factor of 1,000, from more than 3 worker-hours per ton to just 0.003. The vast majority of steel manufactured in the world is produced using the basic oxygen furnace; in 2000, it accounted for 60% of global steel output. Modern furnaces will take a charge of iron of up to 350 tons and convert it into steel in less than 40 minutes, compared to 10–12 hours in an open hearth furnace. Steel making department is one of the most important departments in whole steel mill. Because of this department it is called steel mill. Here iron is converted into steel. Steel making department converts pig iron into steel that is transferred from iron making department to SMD through locomotive railway in ladle. The pig iron in molten form is first transferred into mixer. Then from mixer it is transferred to converter where other raw materials are also transferred to converter. Then it is heated and after oxidation steel and slag becomes separate. Then they are taken out separately. After than steel is given several shapes as needed. 4.2. CONVERTER IN PAKISTAN STEEL MILL: The Steel Making Plant Complex has two Linz. Donawitz converters. Each converter has a capacity of 130 tons of steel for which there is one bloom caster and two slab casters. Molten metal from the blast furnace is taken to the steel making plant where further reduction of impurities is done in an oxygen furnace (Linz Donawitz converters). The crude steel in liquid form is taken in a ladle for further refining, where ferroalloys are added to the liquid steel.

- 17. INTERNSHIP REPORT 2015 16 4.3. CASTING METHOD: PSMC employs continuous casting technology to cast the liquid steel into semi-finished products (i.e. cast billets, blooms and slabs). Cast billets are sold without any further processing whereas blooms and the slabs are further processed at the Billet Mill and the Hot Strip Mill respectively. Bloom 260 x 260 mm sizes are used for making billets which are utilized for manufacturing various steel products. The slabs of 150-200 mm thickness and 700-1500 mm width sizes produced at the Steel Making Plant are fed to the hot strip mill where they are rolled into stripes, sheets and coils. 4.4. PRODUCTS: Billets: Pakistan Steel billets, are produced to tight tolerances, high surface finish and superior quality. Pakistan Steel's high quality billets are used for Manufacturing plain, deformed, twisted and ribbed bars. Manufacturing steel sections viz, rails, angles, joints, channels, squares, flat bars, rods, wire rods, bailing hoops, tees and chains etc. Manufacturing seamless pipes.

- 18. INTERNSHIP REPORT 2015 17 Sizes & Tolerances Hot Rolled Steel Billets Size Of Square Length Radius Of Round Ends Tolerance Limit From Side Of The Square 50mm up to 6 meters 7mm ±1.2mm 65mm up to 6 meters 9mm ±1.6mm 75mm up to 6 meters 12mm ±2.0mm 100mm up to 6 meters 15mm ±2.4mm 60, 80 and 90mm Square Billets and 50, 56, 60 and 75mm Round Bars can also be produced if ordered in substantial quantity. Cast Steel Billets Size Of Square Tolerance 80mm ±2.0% 100mm ±2.0% 125mm ±1.75% 150mm ±1.50%

- 19. INTERNSHIP REPORT 2015 18 . Hot Rolled steels: Hot rolled carbon steel coils, sheets, strips and plates are produced at our 1700mm Hot Rolling Strip Mill. Fabricated Sections/Structures. General Purpose Sheets/Plates. Wheel Rims. Formed Sections, Steel Flooring and Cold Rolled Products. Standard Sizes Of Hot Rolled Sheets As Rolled Edges In (mm) Thickness (mm) Min. & Max. Sheet Lengths per Width (W) 1000 (W) 1220 (W) 1500 (W) 1.6, 2.0 2440 2440 - 2.35 - 2440 - 2.65, 2.90 2440 2440 - 3.25, 3.65 2440 2440, 6000 2440, 3000, 6000 3.90, 5.0, 6.0 2440, 6000 2440, 6000 2440, 3000, 6000 7.0, 8.0, 9.0, 10.0, 12.0 2440, 6000 2440, 6000 2440, 3000, 6000 Cold Rolled Sheets/Coils: Sizes Thickness: 0.3 to 2.5mm Width: 700 to 1500mm Lengths: 1 to 4 meters Coil inner dia: 600mm

- 20. INTERNSHIP REPORT 2015 19 Coil outer dia: 1800mm (max) Max. coil weight 14.5 tons Min. pack weight 5.0 tons Specification Of Cold Rolled Steel Flat Products Grades Steel Quality Steel Grade Chemical Composition (Cast Analysis) % Mechanical Properties Ref. Standard C Max Mn Max Si Max P Max S Max Al Min Yield Stress Min. (N/mm2) Tensile Strength Max. (N/mm2) Elong'n % Min. Lo=50 mm 180 Bend Mandrel Dia. Hard- ness Max. HRB HR 30T Commercial CR-1 0.15 0.60 - 0.05 0.05 - - - - 0a 65 - ISO 3574-70 Drawing CR-2 0.12 0.5 - 0.04 0.04 - - 370 31 - 57 55 -do- CR-3 0.10 0.45 - 0.03 0.03 - - 350 35 - 53 52 -do- CR-4 0.08 0.45 - 0.03 0.03 - - 340 37 - 50 50 -do- SPCC - - - - - - - 270 min 32 - - - JIS G 3141-91 SPCD - - - - - - - 270 min 34 - - - -do- Structural CR- 220 0.15 - - 0.05 0.05 - 220 300 min 22 1a - - ISO 4997-83 CR- 250 0.20 - - 0.05 0.05 - 250 330 min 20 2a - - -do- CR- 320 0.20 1.50 - 0.05 0.05 - 320 400 min 16 2a - - -do-

- 21. INTERNSHIP REPORT 2015 20 Galvanized Steel: Sizes Thickness: 0.5 to 1.5mm Width: 700 to 1500mm Lengths: 1.5 to 4 meters Zn deposition 120 to 850gm/m2 Pack weight Upto -- 5 - 10MT Coil inner dia: 500mm Coil outer dia: 100mm to 1300mm Weight 5 tons

- 22. INTERNSHIP REPORT 2015 21 5. F&F Metal fabrication techniques are normally preceded by refining, alloying and often heat treating processes that produces alloys with desired characteristics. The classifications of fabrication techniques include metal forming methods, casting, powder metallurgy, welding and machining, often two or more of them are used, before a piece is finished. METAL FABRICATION TECNIQUES FORMING OPERATIONS FORGING EXTRUSION EXTRUSION DRAWING CASTING SAND DIE INVESTMENT LOST FOAM CONTINOUS MWELDING

- 23. INTERNSHIP REPORT 2015 22 Forming operations are those in which the shape of a metal piece is changed by plastic deformation for example: rolling, forging, extrusion and drawing are common forming techniques. In F&F plant, the forging has been done by heating a piece of mild steel in the box furnace first, and then by using the forge hammers the metallic piece has been given the round shape. The fabrication of different parts has been done in order to complete the assembly. The engineering drawing has been given for the guidance which has been used for making the parts into the required shapes. The presence of carbon dioxide welding set up was almost unbelievable. The use of such high technology was beyond the imagination. The straightening of sheets and plates has been observed. The radial thinning of the plates and sheets in accordance with the assembly have also been done. The hot and cold working, both have been applied on the metallic sheets and plates. The most common work been done was rolling and forging along with the welding techniques to join the different parts in to one assembly as per requirement.

- 24. INTERNSHIP REPORT 2015 23 CONCLUDING WORDS “We’ve always been very passionate about Steel Industry and this internship program turns out to be a big encouragement in this regard. We’re overwhelmed with gratitude to each and every person in Pakistan Steel for their appreciable support and guidance throughout the program, their efforts enhanced our engineering and metallurgical knowledge No doubt Pakistan Steel has the best resources and it could be one of the leading industries of the world if used properly. Internship at Pakistan Steel is indeed a valuable experience.”