Resume (Johnson Qi)2016

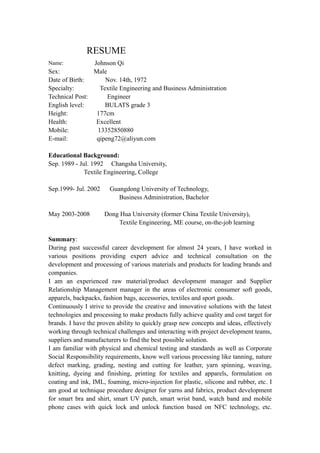

- 1. RESUME Name: Johnson Qi Sex: Male Date of Birth: Nov. 14th, 1972 Specialty: Textile Engineering and Business Administration Technical Post: Engineer English level: BULATS grade 3 Height: 177cm Health: Excellent Mobile: 13352850880 E-mail: qipeng72@aliyun.com Educational Background: Sep. 1989 - Jul. 1992 Changsha University, Textile Engineering, College Sep.1999- Jul. 2002 Guangdong University of Technology, Business Administration, Bachelor May 2003-2008 Dong Hua University (former China Textile University), Textile Engineering, ME course, on-the-job learning Summary: During past successful career development for almost 24 years, I have worked in various positions providing expert advice and technical consultation on the development and processing of various materials and products for leading brands and companies. I am an experienced raw material/product development manager and Supplier Relationship Management manager in the areas of electronic consumer soft goods, apparels, backpacks, fashion bags, accessories, textiles and sport goods. Continuously I strive to provide the creative and innovative solutions with the latest technologies and processing to make products fully achieve quality and cost target for brands. I have the proven ability to quickly grasp new concepts and ideas, effectively working through technical challenges and interacting with project development teams, suppliers and manufacturers to find the best possible solution. I am familiar with physical and chemical testing and standards as well as Corporate Social Responsibility requirements, know well various processing like tanning, nature defect marking, grading, nesting and cutting for leather, yarn spinning, weaving, knitting, dyeing and finishing, printing for textiles and apparels, formulation on coating and ink, IML, foaming, micro-injection for plastic, silicone and rubber, etc. I am good at technique procedure designer for yarns and fabrics, product development for smart bra and shirt, smart UV patch, smart wrist band, watch band and mobile phone cases with quick lock and unlock function based on NFC technology, etc.

- 2. Besides, I am doing well on optimization of material/product supply chain and running consolidation project. Work Experience and Job Description: 2013/11/18-2016/7/1 Working in PCH Innovation Hub(Shenzhen) Director of Material Group Responsible for establishing and managing the Materials Group in PCH. The Materials Group is a shared technology team with strong ties to each project development team. Take lead of team to ensure that material development is implemented in time and initiated in advance including R&D activity and provision of knowledge in all aspects of PCH businesses and in the area of raw and processed materials. Brought auto-nesting program and optimized the cutting process into apple leather case and watch band project to optimize greatly the leather cutting yield rate maximum up to 24% so as to save huge cost for the company. Set up nature leather defect library and minimarker rule for Fitbit leather band project. I applied for the IP about flexible textile sensor which was designed for monitoring heart rate and respiratory rate for PCH in 2015. Besides, as a main product design lead, we formulated functional irreversible UV indicator and designed different sensitive color change charts to help famous global brand L’Oreal group develop the first generation of smart skin patch which was launched to market and exposed to media during 2016 CES. I have applied for new IP for company in May 2016. It's a kind of smart wristband or watch band with quick and safe lock and unlock function based on NFC technology. I initiated the research on silver-conductive ink formulation, reel to reel high speed precision printing way for NFC antenna and FPC which are suitable for biomedical project between 2015 and 2016. May 2013-Nov 2013 Working in Avon APAC Fashion and Home Supply Chain Manager, Supplier Relationship Management, East Asia Hub ♦ Manage Avon Fashion and Home SRM team, FG and RM vendors in the East Asia Sourcing Hub. ♦ Manage sourcing needs and support the order placement, order progressing and production tracking functions to support and complete the sourcing strategies. ♦ Ensure there is adequate and timely capacity available to meet agreed delivery and FOB price targets. ♦ Understand market requirements, identify and get appropriate FG such as intimates, leather band, umbrella and jewelry besides RM vendors on board to

- 3. meet the ongoing sourcing needs of the new product development team. ♦ Undertake accurate FOB cost validation to reduce the impact of price fluctuations on cost structures. ♦ Maintain the Landed Cost Models and provide input for the sourcing strategy to ensure Avon is sourcing from the most cost effective countries in the hub based on duties, tariffs, etc, of the importing markets whilst taking into account finished goods and raw materials supplier capability. ♦ Build an effective working relationship with suppliers and also develop their competences especially on cost, DIFOT, manufacturing excellence and production capacity. ♦ Work in conjunction and managing the needs with QA manager and CSR manager. ♦ Direct the daily work of the Production Engineer and Margin and Costing Analyst and ensure all agreed KPIs are met and respective development plans are enacted. Jul.2003 –April 2013 Working in adidas Sourcing GZ Office Dec. 2010-April 2013 Senior Manager, Material Development ♦ Lead end to end operations in material supplier system including material creation, delivery, standard execution and costing targets. ♦ In alignment with global materials strategy, responsible for T2 supplier strategic direction to support brand business objectives and product expectations, including support of material selection and commercialization. ♦ Work with management and material suppliers to implement supply chain initiatives as introduced by Continuous Improvement, Logistics, Sourcing and others. ♦ Develop new material sources offering - Improved quality, - Optimized material cost - Reduced lead times and minimum order quantities. ♦ Ensure that material libraries, tool boxes are maintained up to date in regard of availability, quality and prices.

- 4. ♦ Playing a key role on sustainable material management according to the Group Environmental Strategy. ♦ Handling the global material profitability project and color consolidation project as a regional role. ♦ Supporting Fast and Lean Creation project for DD (Direct Development) fashion business Units like Originals and NEO. Dec.2007- Nov 2010 Technical Services Manager (title changed to Material Manager one year later due to A&G department reconstruction) in adidas Sourcing Group GZ office. ♦ Main job is to develop new materials and promote the application of new technology for adidas sport goods like World Cup soccer, protective equipment, backpack and fashion hand bag, sport bottle, swimming accessories, belt, etc. ♦ Standard support on CPSIA and A-01 execution. ♦ Ensure that all chosen materials can fulfill adidas quality standard and group policy for the control and monitoring of hazardous substances. ♦ Maintain consolidated material library and share the competitive sources with other sourcing offices like Vietnam Local Office, Pakistan LO and Indonesia LO so as to get cost down for Group. ♦ Design qualified material structure and finishing method so as to meet the target cost according to marketing request. Jul.2003 – Nov.2007 I joined adidas Sourcing Group China Guangzhou office starting from Lab Supervisor up to Lab Manager in A&G department. ♦ Main responsibility is to run MLE (Minimum Lab Equipment) project to standardize tier 1 factory labs and get lab supervisors and technicians trained and qualified for adidas material testing and finished goods testing. ♦ Assist Global Quality Manager to set up SOP for adidas test methods and set up physical requirements for materials and finished goods. ♦ Manage adidas A-01 policy to make sure that all materials used for adidas products are in compliance with adidas requirements for control and monitoring of hazardous substances.

- 5. ♦ Oversee QA process and prevent the potential quality risk of material from starting. Jul.1992 - Jul. 2003 working in Guangzhou Textile Union Group Company Limited Jul.2001 - Jul.2003 Assistant manager in Pre-spinning Workshop Responsible for production and technology management, continuous improvement on production efficiency and quality, HSE management (Health Safety Environment) in Guangzhou Textile Union Group Co., Ltd. Jan. 2000 - June 2001 R&D Supervisor Be in charge of new textile development for yarns, knitting, denim, T-shirt and jeans. Jan.1997 - Dec.1999 Technique Supervisor, Technical Department Be in charge of lab management, processing parameter design of core-spun yarn, optimizing configuration of spinning processes from the quantity and draft force relocation point of view. Jul.1992 - Dec.1996 Be in charge of maintence of imported machines, spinning technology execution and process optimization at the pre-spinning workshop after college graduation. Training Courses: Oct. 1997 Training and certificate on how to operate Uster Evenness Analysis Tester in Uster Company (Shanghai) Nov.2003 Training on “adidas material testing, FIFA ball testing and TUV shin guard testing” at adidas Global Test Center in Germany Dec. 2004 Training on “Lean and 6S Management” Nov. 2005 Training in BV Institute (Hong Kong) regarding “Detection Methods/Result Evaluation of Hazardous Substances based on adidas A-01 policy” Sep. 2006 Training regarding “On Time and Stress Management” Sep. 2007 Training on “How to lead project effectively” April 2008 Training on “How to turn conflict to collaboration” Oct 2009 Training on “Leather Best Practice” June 2010 Training on “Managing change and building team” July 2011 Training on "Hoshin Kanri-deploy or administer by guideline” Dec 2012 Training on “FW outsole material” Computer Skills:

- 6. Familiar with most popular office software, such as Word, Excel, PowerPoint and Outlook Publications: “The Application of Variance-Length Curve in Optimizing Spinning Process” on “Journal of Textile Research”, 1999 Honors: Second Prize in Science and Technology Contest in Guangzhou, 1997 The Best Team Player Year 2007, adidas A&G China, October 2007 Achievement Highlights: ♦ Project management: ♦ Took the lead of auto-nesting program to optimize the leather cutting yield for Apple soft goods project and Fitbit smart leather band project. Cutting yield increased for smart watch leather band ranging from 10.4% up to 24%, 2013- 2016. ♦ Took the lead of the first generation of smart UV patch development for L'Oreal brand. Optimized the skin patch film with high MVTR and super thin thickness around 15um. Designed 15 cycles of precise automatic overprinting process. Provided R&D team with the silver-printed antenna option against expensive copper-etched NFC antenna which is easily leading to skin rash issue, 2015-2016. ♦ Supporting the global profitability project as regional material expert role providing proposals to consolidate and optimize materials. The first stage of outcome in SS14 season for padding and reinforcement materials was around $276,603 from alternative China option, 2012-2013. ♦ Initiated and rolled out global lining color consolidation project and achieved a good number of cost saving for group in SS14 season (China $124,327 out of total $442,453), 2012. ♦ Took the lead of developing the isotropic fabric to enhance the performance of World Cup soccer ball especially on lamination efficiency enhancement and material cost saving, 2008-2010. ♦ Took the lead of optimizing spine formulation for goalkeeper glove by cross- functional cooperation with DuPont, RTP, BASF and Zhongsu Plastic Company, 2008.

- 7. ♦ Took lead of improving the formulation of antibacterial and antifungal finishing for adidas PEVA dry towel so as to fulfill Japanese and US market requirement by passing ASTM G21 and JIS Z2801 in the early 2007. ♦ As a leader to rolled out Minimum Lab Equipment Project for all adidas A&G GZ LO tier 1 suppliers, 2003- 2006. ♦ Took lead of design and optimization of spinning processing according to physical property of yak fibers and succeeded in developing yak yarn and high-end suit fabric successfully, 1998. ♦ Lab and Standard Management: ♦ Organized human sensitivity testing, bio-compatible testing, chemical testing to monitor and control hazardous substances contained in smart patch products, 2015-2016. ♦ Supported adidas miCoach project team on overseeing certification of A-01, FCC and CE. Setting up physical quality standards for webbing of heart rate monitor and armband, 2009-2010. ♦ Assisted Global Quality Manager to set up material specs for A&G products including all inflating balls, shin guard, ski glove, goalkeeper glove, backpack, hand bag, swimming goggle, umbrella and yoga mat. I standardized the quality assurance process in each tier 1 factory. Edited A-01 random testing process and restricted release application process, 2003- 2007. ♦ Rolled out MLE project to certify and manage all key tier 1 factory labs, 2003- 2007. ♦ Finished Goods Development: ♦ Took the lead of smart wrist bands and mobile phone cases with quick unlock and lock function based on NFC technology and applied for IP for company, 2015-2016. ♦ Continuous improvement on non-woven shopper bag and developed the competitive shopper bag via ultrasonic welding technology, 2012. ♦ Developed waterproof backpack with hot melt glued TPU and high frequency technology, 2012.

- 8. ♦ Developed sustainable yoga mat with recycled TPE and EVA foam, 2010. ♦ Developed BPA-free sport bottle with clear PP resin, 2008-2009. ♦ Developed A&G Green Ball/Green Bag/Green Shin Guards according to Group Environmental Strategy, 2009-2010. ♦ Developed the cotton polyurethane core-spun yarn, denim for Niu Tou jean, 2001. ♦ Developed the quick-dry knit fabric and T-shirt with Tactel nylon and Coolmax fiber, 2000. ♦ Material Development: ♦ Developed high performance but cost competitive thermal-bonded composite options for bio-medical garment project, 2015-2016. ♦ Took lead of the research on human skin coating material achieving less than 10um but with high MVTR for L’Oreal smart patch project, 2015-2016. ♦ Developed silver-printed antenna to replace cooper-etched antenna so as to avoid skin rush issue and got cost saving by 33%, 2015-2016. ♦ Proactively started study on innovative outsole with directly injected carbon- reinforced nylon resin which will result in high production efficiency and big cost cut comparing over-molded carbon fabric with TPU layer, 2013. ♦ Actively initiated cost saving suggestions on optimizing material sources like leather, PU, canvas and TPE film to contribute the cost saving around $260,566 to fashion bag and backpack, 2012. ♦ Competitive inside-out TPE formulation used on backpack was successfully developed to replace expensive option. (SS13 $3.23/y VS FW13 $1.88/y) Cost decreased by 41.79%, 2012. ♦ Cost cut for shopper bag made in China by 15.69% and that made in Pakistan by 23.21%. There will be a total of cost saving around $247,840 based on forecast per season through CI actions like special designed fabric width

- 9. leading to almost zero consumption, semi-automatic rolling printing and automatic cutting which leads to high manufacture efficiency, 2012. ♦ Ensure China material competitiveness can be aligned with other countries. For 55 kinds of consolidated fabrics/trims, our local sources are competitive than other regions, 2008-2012. ♦ Finished a research on the PU coating influence on bag fabric performance so as to guide coating/fabric supplier to improve the fabric quality, 2007-2008. Personality: Character: Authentic, self-motivated, innovation and team work spirit. Ability: Is able to perform a variety of tasks with different levels of complexity by developing effective plans and organizing work efficiently. Negotiates skillfully in tough situations with both internal and external groups. Co-operates well and effectively with people from a wide variety of backgrounds within and outside of the company. Identifies key issues and draws conclusions by analyzing and comparing data from different sources of information. Looks for new challenges/tasks and learns quickly when facing them. Is capable of developing the materials and sport products and taking care of continuous performance improvement. Proactively drive the cost saving to align with company annual goals.

- 10. leading to almost zero consumption, semi-automatic rolling printing and automatic cutting which leads to high manufacture efficiency, 2012. ♦ Ensure China material competitiveness can be aligned with other countries. For 55 kinds of consolidated fabrics/trims, our local sources are competitive than other regions, 2008-2012. ♦ Finished a research on the PU coating influence on bag fabric performance so as to guide coating/fabric supplier to improve the fabric quality, 2007-2008. Personality: Character: Authentic, self-motivated, innovation and team work spirit. Ability: Is able to perform a variety of tasks with different levels of complexity by developing effective plans and organizing work efficiently. Negotiates skillfully in tough situations with both internal and external groups. Co-operates well and effectively with people from a wide variety of backgrounds within and outside of the company. Identifies key issues and draws conclusions by analyzing and comparing data from different sources of information. Looks for new challenges/tasks and learns quickly when facing them. Is capable of developing the materials and sport products and taking care of continuous performance improvement. Proactively drive the cost saving to align with company annual goals.