Maintainability engineering

•

1 like•3,318 views

Report

Share

Report

Share

Download to read offline

Recommended

Recommended

More Related Content

What's hot

What's hot (20)

Maintenance and Reliability Case Studies and Bench-marking Data

Maintenance and Reliability Case Studies and Bench-marking Data

Unit 1 - PRINCIPLES AND PRACTICES OF MAINTENANCE PLANNING

Unit 1 - PRINCIPLES AND PRACTICES OF MAINTENANCE PLANNING

Viewers also liked

Viewers also liked (13)

Reducing Product Development Risk with Reliability Engineering Methods

Reducing Product Development Risk with Reliability Engineering Methods

Reliability Maintenance Engineering 2 - 3 Measuring Maintainability

Reliability Maintenance Engineering 2 - 3 Measuring Maintainability

Similar to Maintainability engineering

Innovation day 2013 2.5 joris vanderschrick (verhaert) - embedded system de...

Innovation day 2013 2.5 joris vanderschrick (verhaert) - embedded system de...Verhaert Masters in Innovation

Similar to Maintainability engineering (20)

Resume_Instrumentation Engineer_7.5 year experience

Resume_Instrumentation Engineer_7.5 year experience

Phase gate review development model august 8 2017 - dave litwiller

Phase gate review development model august 8 2017 - dave litwiller

Analytical Instrument Qualification - USP chapter 1058 revision

Analytical Instrument Qualification - USP chapter 1058 revision

Innovation day 2013 2.5 joris vanderschrick (verhaert) - embedded system de...

Innovation day 2013 2.5 joris vanderschrick (verhaert) - embedded system de...

Facility Qualification & Consideration of Validation Aspects

Facility Qualification & Consideration of Validation Aspects

1 - Introduction to Computerized Systems Validation - for review.pptx

1 - Introduction to Computerized Systems Validation - for review.pptx

More from Hilaire (Ananda) Perera P.Eng.

This standard defines methods for calculating the early life failure rate of a product, using accelerated

testing, whose failure rate is constant or decreasing over time. For technologies where there is adequate

field failure data, alternative methods may be used to establish the early life failure rate.

The purpose of this standard is to define a procedure for performing measurement and calculation of early

life failure rates. Projections can be used to compare reliability performance with objectives, provide line

feedback, support service cost estimates, and set product test and screen strategies to ensure that the

Early life Failure Rate meets customers' requirements.

Early Life Failure Rate Calculation Procedure for Semiconductor Components

Early Life Failure Rate Calculation Procedure for Semiconductor ComponentsHilaire (Ananda) Perera P.Eng.

More from Hilaire (Ananda) Perera P.Eng. (20)

ESS and HASS: Concerns with the Practices and Standards

ESS and HASS: Concerns with the Practices and Standards

CALCE Test Services and Failure Analysis (TSFA) Laboratory

CALCE Test Services and Failure Analysis (TSFA) Laboratory

IEEE 1633 Recommended Practice on Software Reliability

IEEE 1633 Recommended Practice on Software Reliability

Reliability Prediction Procedure for Mechanical Components

Reliability Prediction Procedure for Mechanical Components

Early Life Failure Rate Calculation Procedure for Semiconductor Components

Early Life Failure Rate Calculation Procedure for Semiconductor Components

Basic Design Considerations for Surface Mount Technology

Basic Design Considerations for Surface Mount Technology

Recently uploaded

God is a creative God Gen 1:1. All that He created was “good”, could also be translated “beautiful”. God created man in His own image Gen 1:27. Maths helps us discover the beauty that God has created in His world and, in turn, create beautiful designs to serve and enrich the lives of others.

Explore beautiful and ugly buildings. Mathematics helps us create beautiful d...

Explore beautiful and ugly buildings. Mathematics helps us create beautiful d...christianmathematics

Mehran University Newsletter is a Quarterly Publication from Public Relations OfficeMehran University Newsletter Vol-X, Issue-I, 2024

Mehran University Newsletter Vol-X, Issue-I, 2024Mehran University of Engineering & Technology, Jamshoro

Recently uploaded (20)

Ecological Succession. ( ECOSYSTEM, B. Pharmacy, 1st Year, Sem-II, Environmen...

Ecological Succession. ( ECOSYSTEM, B. Pharmacy, 1st Year, Sem-II, Environmen...

Asian American Pacific Islander Month DDSD 2024.pptx

Asian American Pacific Islander Month DDSD 2024.pptx

This PowerPoint helps students to consider the concept of infinity.

This PowerPoint helps students to consider the concept of infinity.

Python Notes for mca i year students osmania university.docx

Python Notes for mca i year students osmania university.docx

Beyond the EU: DORA and NIS 2 Directive's Global Impact

Beyond the EU: DORA and NIS 2 Directive's Global Impact

Explore beautiful and ugly buildings. Mathematics helps us create beautiful d...

Explore beautiful and ugly buildings. Mathematics helps us create beautiful d...

Seal of Good Local Governance (SGLG) 2024Final.pptx

Seal of Good Local Governance (SGLG) 2024Final.pptx

Russian Escort Service in Delhi 11k Hotel Foreigner Russian Call Girls in Delhi

Russian Escort Service in Delhi 11k Hotel Foreigner Russian Call Girls in Delhi

Presentation by Andreas Schleicher Tackling the School Absenteeism Crisis 30 ...

Presentation by Andreas Schleicher Tackling the School Absenteeism Crisis 30 ...

Basic Civil Engineering first year Notes- Chapter 4 Building.pptx

Basic Civil Engineering first year Notes- Chapter 4 Building.pptx

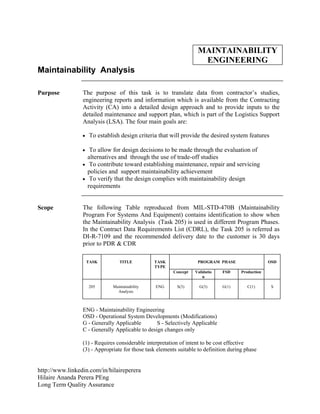

Maintainability engineering

- 1. MAINTAINABILITY ENGINEERING Maintainability Analysis Purpose The purpose of this task is to translate data from contractor’s studies, engineering reports and information which is available from the Contracting Activity (CA) into a detailed design approach and to provide inputs to the detailed maintenance and support plan, which is part of the Logistics Support Analysis (LSA). The four main goals are: • To establish design criteria that will provide the desired system features • To allow for design decisions to be made through the evaluation of alternatives and through the use of trade-off studies • To contribute toward establishing maintenance, repair and servicing policies and support maintainability achievement • To verify that the design complies with maintainability design requirements Scope The following Table reproduced from MIL-STD-470B (Maintainability Program For Systems And Equipment) contains identification to show when the Maintainability Analysis (Task 205) is used in different Program Phases. In the Contract Data Requirements List (CDRL), the Task 205 is referred as DI-R-7109 and the recommended delivery date to the customer is 30 days prior to PDR & CDR TASK TITLE TASK TYPE PROGRAM PHASE OSD Concept 205 Maintainability Analysis ENG Validatio n FSD Production S(3) G(3) G(1) C(1) ENG - Maintainability Engineering OSD - Operational System Developments (Modifications) G - Generally Applicable S - Selectively Applicable C - Generally Applicable to design changes only (1) - Requires considerable interpretation of intent to be cost effective (3) - Appropriate for those task elements suitable to definition during phase http://www.linkedin.com/in/hilaireperera Hilaire Ananda Perera PEng Long Term Quality Assurance S

- 2. MAINTAINABILITY ENGINEERING Maintainability Analysis, Continued Definitions CDRL = Contract Data Requirements List PDR = Preliminary Design Review CDR = Critical Design Review FSD = Full Scale Development MTTR = Mean Time To Repair Mmax(φ) = Maximum Time To Repair for the φ percentile BIT = Built - In - Test Responsibilitie s It is the responsibility of the maintainability engineer assigned to the particular project to do the Analysis. The Analysis should be reviewed and approved by the Maintainability Group Leader and the Project Manager. Procedure The maintainability analysis integrates data from contractor’s studies with engineering reports and information which is available from the CA into a detailed design approach. Outputs from Tasks 201 and 202 of MIL-STD2165, if called out should form the basis for testability and diagnostic analysis. The elements specified in the Statement Of Work and to be considered in the maintainability analysis should include: • Mean Time To Repair (MTTR) and Maximum Time To Repair for the φ percentile (Mmax(φ)) for all levels (organizational, intermediate, depot) of maintenance. MIL-HDBK-472 Notice 1, Procedure V is an easy method for this task. If repair times cannot be synthesized from data books, time and motion studies should be performed and data statistically corrected to obtain times for analysis. • Maintenance man-hours and maintenance time expended/maintenance task/flight hour/operating hour for all appropriate levels of maintenance • False Alarm Rates (FAR), Cannot Duplicate (CND) Rates, Retest OK (RTOK) Rates associated with all levels of maintenance http://www.linkedin.com/in/hilaireperera Hilaire Ananda Perera PEng Long Term Quality Assurance

- 3. MAINTAINABILITY ENGINEERING Maintainability Analysis, Continued Procedure (Continued) • Proportion of faults detectable (all levels of maintenance, including system/equipment/unit built-in detection, and external fault detection subsystems) • Level(s) of isolation or ambiguity (for example, does the built-in-test or external test system or tester identify N possible units or assemblies etc., only one of which is failed) for the system, equipment, unit, assembly, subassembly, etc., for each level of maintenance. • Identification of the required mix of automatic, semiautomatic, built-in and manual test capability, plus the maintenance aids and manual diagnostic procedures required at all levels of repair and their associated software and technical costs, skill levels required and manpower requirements, as well as acquisition costs if available. • Levels of repair associated with each equipment design and each test system alternative as derived from the LSA. • Development of unique external test systems and testers versus use of existing units (stock listed or commercial) • Producibility considerations relating to the realization of each test system alternative. • Determination of system/subsystem/equipment parameters that are monitored and not monitored by BIT or other diagnostic/test systems. • Impact of scheduled and preventive maintenance workload: • Mean time between scheduled and preventive maintenance at each required level of maintenance • Mean preventive maintenance time http://www.linkedin.com/in/hilaireperera Hilaire Ananda Perera PEng Long Term Quality Assurance

- 4. MAINTAINABILITY ENGINEERING Maintainability Analysis, Continued Procedure (Continued) • Maintainability mathematical models, life cycle cost models, and acquisition cost estimates if specified in the Statement Of Work should be developed from the inputs and considerations described above to: • Show the impacts on cost, maintainability and on system readiness parameters of the germane maintainability elements • Allocate quantitative maintainability requirements to all significant item levels of the system/subsystem/equipment. (details are in Task 202 of MIL-STD-470B) • Develop the most cost effective maintainability design and test system configuration which meets support and personnel constraints as well as system readiness and mission performance objectives • Performance Design Trade-offs. NOTE: This task has significant possibilities for overlap with LSA efforts, and should therefore be coordinated closely with the LSA community and LSA Statement Of Work, to ensure consistency and prevent duplication. • Trade-offs between maintainability design alternatives and equipment design parameters should be made to provide an economical design which best satisfies systems or equipment requirements • Trade-offs involving impacts on maintainability attributed to changes in areas such as packaging, fault detection and isolation portions of the design or to external test equipment or testers should be incorporated in status reports submitted . http://www.linkedin.com/in/hilaireperera Hilaire Ananda Perera PEng Long Term Quality Assurance

- 5. MAINTAINABILITY ENGINEERING Maintainability Analysis, Continued Associated Documents Customer provided Statement Of Work and the Equipment Specifications ISO 9001 Level II Document: Design Control - The Product Assurance Process MIL-STD-470: Maintainability Program For Systems And Equipment MIL-HDBK-472: Maintainability Prediction MIL-STD-2165: Testability Program For Electronic Systems And Equipment MIL-STD-721: Definitions Of Terms For Reliability And Maintainability http://www.linkedin.com/in/hilaireperera Hilaire Ananda Perera PEng Long Term Quality Assurance