Andritz

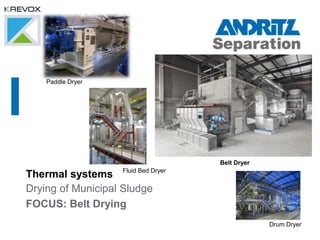

- 1. Drying of Municipal Sludge FOCUS: Belt Drying Thermal systems Paddle Dryer Fluid Bed Dryer Belt Dryer Drum Dryer

- 2. Andritz Sludge Drying Systems 2 Content Introduction / Presentation Andritz Separation Andritz Drying Technologies for Municipal Sludge Focus on Andritz Belt Drying Systems Worldwide References LVIV, Sludge Conference; 11 2015; ANDRITZ Separation

- 3. 3 Torrefaction of Biomass; CIBC; Price George; June 2012 The ANDRITZ Group Overview Company ANDRITZ AG, Graz, Austria (Group Headquarters) More than 180 production and service sites worldwide Employees: approximately 24,800 worldwide (2014) Key figures 2014 Order intake: 6,100 MEUR Sales: 5,860 MEUR Products and services Plants and services for hydropower stations, the pulp and paper industry, solid- liquid separation in the municipal and industrial sectors, the steel industry, and the production of animal feed and biomass pellets

- 4. 4 ANDRITZ SEPARATION ANDRITZ SEPARATION is a leading global supplier for state-of-the-art separation technologies, offering a wide range of high quality equipment, systems and services for specific industries. With more than 150 years of experience in the separation business, we serve our customers every year with: Products Thickeners Flocculant Plants Drum and Belt Dryers, Paddle Dryers Fluid Bed Dryers Filter Presses Disc Filter Drum Filter Filter Centrifuges Decanters Separators ThickenersCentrifuges and Separators Filters and Filter Presses Thermal Systems Screens, Drains, Screw and Belt Presses Belt Filters, Belt Presses Screens Screw Presses Conveying Systems Belt Conveyors Chain Conveyors Screw Conveyors

- 5. ANDRITZ SEPARATION We have offices in 24 countries serving your local requirements. 5 ANDRITZ SEPARATION | August 2014 Global presence

- 6. 6 Sludge Drying Dewatered Sludge Dried Granules • 18 - 35% DS • Sticky • Caloric heating value < 1 MJ/kg • biologically active ( digestion processes ) • > 90% DS • free flowing • Caloric heating value - 8 - 11 MJ/kg (digested) - > 12 MJ/kg ( non-digested ) • pathogen free • biologically stable by from Waste to Product Transfer of the dewatered sludge Andritz Sludge Drying Systems Why Drying??

- 7. Andritz Sludge Drying Systems 7 4 Different Technologies Fluid Bed Dryer ( FDS ) Drum Dryer ( DDS ) Belt Dryer ( BDS ) Gouda Paddle Dryer ( GPD ) Contact dryer Convective dryer LVIV, Sludge Conference; 11 2015; ANDRITZ Separation

- 8. 8 1. Drying in a triple pass drum containing three concentric cylinders revolving around a joint axis. 2. The pre-granulated (backmixed) sludge is fed into the inner cylinder of the drum and is conveyed pneumatically by the stream of hot gases ensuring evenly dried pasteurised granules. 3. The drum itself has internal flights that lift the sludge and allow it to fall through the gas stream resulting in homogeneous dried granules. DDS – The principle Andritz Sludge Drying Systems LVIV, Sludge Conference; 11 2015; ANDRITZ Separation

- 9. 9 Capacity up to 14.000 kg/h Water Evaporation (~ 20 t Sludge / h) per Line Round shaped granulate with defined particle size due to backmixing process! Convective drying; closed air loop for high thermal efficiency Directly heated with primary heatsources (biogas, natural gas, diesel, LPG,..) Andritz References: > 150 dryer worldwide DDS – The Features Andritz Sludge Drying Systems LVIV, Sludge Conference; 11 2015; ANDRITZ Separation

- 10. 10 • characterised by movement of the granules achieved by passing of the gas stream through the product layer • The granules become “floating” ( free floating ) and mixed thoroughly. FDS - The Principle Particle in floating motion Andritz Sludge Drying Systems LVIV, Sludge Conference; 11 2015; ANDRITZ Separation

- 11. 11 Direct sludge feeding into highly turbulent fluidized bed Small footprint of Dryer, Minimum Offgas Quantity Indirectly heated with heating medium such as thermal oil or steam used in heat-exchanger Heat recovery from condenser possible Capacity up to 10.000 kg/h Water Evaporation FDS – The Features Andritz Sludge Drying Systems LVIV, Sludge Conference; 11 2015; ANDRITZ Separation PICTURES

- 12. Contact Dryer (indirect) with heated trough, shafts and paddles Closed process chamber (no air) Two counter rotating shafts Wedges shaped paddles ensure perfect local mixing and mechanical fluidization No sweep gas / air intake Low mechanical speeds – low wear Overflow weir to keep filling degree inside machine 12 GPD - The Principle Andritz Sludge Drying Systems LVIV, Sludge Conference; 11 2015; ANDRITZ Separation

- 13. 13 GPD – The Features Andritz Sludge Drying Systems LVIV, Sludge Conference; 11 2015; ANDRITZ Separation Simple drying concept; Minimum Offgas Quantity Partial Drying possible (65-90% DS) Indirectly heated with heating medium such as thermal oil or steam used in paddles and shaft Heat recovery from condenser possible Capacity up to 6000 kg/h Water Evaporation per line PICTURES

- 14. BDS - The Principle 1. Designed as belt conveyor in a casing. The drying gases are flowing through the product layer distributed evenly on top of the belt. 2. By means of a slow moving belt the drying gases are enabled to heat up the wet granulate and evaporate the water. 3. The granulate bed acts as a filter media to prevent dust generation inside the dryer. Andritz Sludge Drying Systems LVIV, Sludge Conference; 11 2015; ANDRITZ Separation14

- 15. 15 BDS – The Features Andritz Sludge Drying Systems LVIV, Sludge Conference; 11 2015; ANDRITZ Separation Low temperature heat-source possible (if cheap waste energy is available) Stable and easy operation: low speed, low temperatures Direct or indirect heated (primary energy sources or heating medium thermal oil, hot water,..) Good product quality due to back-mixing process Capacity up to 6000 kg/h Water Evaporation per line with standard sizes

- 16. 16 Natural gas/ Biogas Sludge Cake Waste heat Thermal oil Steam, etc. Belt dryer CondenserCirculation Air fan Mixing screw / Mixer To exhaust air treatment Exhaust air fan Wet sludge silo Belt cooler (Option) Fresh air fan Potable water Final effluent Waste water Principle flowsheet of an Andritz BDS Heat- exchan ger Duct- Burner Heat- exchan ger OPTION: Hot Water = low Temp. heat recovery Heat- exchan ger Andritz Belt Drying System BDS LVIV, Sludge Conference; 11 2015; ANDRITZ Separation

- 17. 17 Backmixing technology • Formation of granules which result in a high quality and easy to handle product • Homogenously dry product: drying process starts with a particle which already has a dry core so DS is homogenouse and e.g. hygenisation can easily be guaranteed • Excellent circumstances for drying: the mixture fed to the belt consists of numerous granules therefore huge specific surface which enables an optimum saturation of drying air, which results in an efficient drying process. Wet sludge is applied in a thin layer on each particle which makes water vapor “transport” easy and not limiting. • Flexibility in feed DS-content: fluctuations in cake DS are levelled out by the mixing process. • Even distribution of feed on belt: free flowing mixture ensures a even distribution and best possible use of belt area • No problem with sticky phase: dewatered sludge cake has problematic properties in the range of approx. 40-60% DS. This can be overcome with backmixing. Advantages: 90% DS Partially dry (backmixed) Andritz Belt Drying System BDS LVIV, Sludge Conference; 11 2015; ANDRITZ Separation

- 18. 18 Reference: Psyttalia, Greece • Water evaporation: 4 x 8.625 kg/h • Heat source: thermal oil • Operation per week : 24 h / day, 7 days • Final product: granulates > 90% DS • Commissioning: 2007 Andritz Drum Drying System (DDS)

- 19. 19 Reference: Changi ( Singapore ) Andritz Drum Drying System (DDS ) Technical Data: • Water evaporation capacity: 5x 11.000 kg/h • Sludge input: 25 – 28%DS • Heat source: diesel / bio gas • Operation: 24 h / day, 7 days per week • Final product: dried granulate > 90% DS • Commissioning: 2008

- 20. 20 Andritz Fluid Bed Drying Plant • Water evaporation: 3 x 2.830 kg/hr • Heat source: bio gas • Operation per week: 24 h / day, 7 days • Final product: granules 70 - 90% DS • Commissioning: 2010 Dryer workshop Dryer building Reference - Shanghai Bailonggang / China

- 21. 21 Andritz Fluid Bed Drying Plant Reference: Bern2 / Switzerland • Water evaporation: 3,430 kg/h • Heat source: heating steam • Operation per week: 24 h/day, 7 days/week • Final product: granules >90% DS • Commissioning: 2015 During erection ( sludge silos ) Dryer building

- 22. References: Ambarli, Istanbul / Turkey 22 ANDRITZ Paddle Drying System – GPD Technical Data: • Water evaporation capacity: 6x 3000 kg/h • Sludge input: digested 25 %DS • Heat source: flue gas • Operation: 24 h / day, 7 days per week • Final product: dried product > 90% DS • Commissioning: 2012

- 23. Reference SMAT, Torino / Italy 23 Technical Data: • Water evaporation capacity: 2x 3500 kg/h • Heat source: flue gas • Operation: 24 h / day, 7 days per week • Final product: dried product > 90% DS • Commissioning: 2007/2012 ANDRITZ Paddle Drying System – GPD

- 24. Reference - Hereke, Turkey Technical Data: • Water evaporation capacity: 8.150 kg/h • Sludge input: 250 t/d ( 20%DS ) • Heat source: Waste heat from the cement kiln • Operation: 24 h / day, 7 days per week • Final product: dried granulate > 90% DS • Commissioning: 2009 Andritz Belt Drying Systems

- 25. Reference – Koszalin, Poland Andritz Belt Drying Systems Technical Data: • Water evaporation capacity: 1500 kg/h • Input dewatered sludge • Heat source: natural gas • Operation: 24 h / day, 5 days per week • Final product: dried granulate > 90% DS • Commissioning: 2011

- 26. Thank you 26 for your attention! Klaus Trattner, MSc SEPARATION ANDRITZ AG Stattegger Strasse 18 8045 Graz, Austria Phone: +43 (316) 6902 2990, Fax: +43 (316) 6902 453 www.andritz.com LEGAL DISCLAIMER All data, information, statements, photographs, and graphic illustrations contained in this presentation are without any obligation to the publisher and raise no liabilities to ANDRITZ AG or any affiliated companies, nor shall the contents in this presentation form part of any sales contracts, which may be concluded between ANDRITZ GROUP companies and purchasers of equipment and/or systems referred to herein. © ANDRITZ AG 2014. All rights reserved. No part of this copyrighted work may be reproduced, modified or distributed in any form or by any means, or stored in any database or retrieval system, without the prior written permission of ANDRITZ AG or its affiliates. Any such unauthorized use for any purpose is a violation of the relevant copyright laws. LVIV, Sludge Conference; 11 2015; ANDRITZ Separation