Report

Share

Recommended

Recommended

More Related Content

Similar to Liquid Fuels 5

Similar to Liquid Fuels 5 (20)

Fireball Formation and Combustion of Coal in a Boiler

Fireball Formation and Combustion of Coal in a Boiler

3. gas turbines direct injection engines fixed bed combustors

3. gas turbines direct injection engines fixed bed combustors

Combustion chamber of Gas turbine power plant cycle

Combustion chamber of Gas turbine power plant cycle

Combustion Chamber for Compression Ignition Engines

Combustion Chamber for Compression Ignition Engines

More from AhsanN2

More from AhsanN2 (17)

To find out percentage of sodium chloride(updated1).pptx

To find out percentage of sodium chloride(updated1).pptx

Recently uploaded

Call Girl Aurangabad Indira Call Now: 8617697112 Aurangabad Escorts Booking Contact Details WhatsApp Chat: +91-8617697112 Aurangabad Escort Service includes providing maximum physical satisfaction to their clients as well as engaging conversation that keeps your time enjoyable and entertaining. Plus they look fabulously elegant; making an impressionable. Independent Escorts Aurangabad understands the value of confidentiality and discretion - they will go the extra mile to meet your needs. Simply contact them via text messaging or through their online profiles; they'd be more than delighted to accommodate any request or arrange a romantic date or fun-filled night together. We provide –(INDIRA) Call Girl Aurangabad Call Now 8617697112 Aurangabad Escorts 24x7

(INDIRA) Call Girl Aurangabad Call Now 8617697112 Aurangabad Escorts 24x7Call Girls in Nagpur High Profile Call Girls

Call Girl Meerut Indira Call Now: 8617697112 Meerut Escorts Booking Contact Details WhatsApp Chat: +91-8617697112 Meerut Escort Service includes providing maximum physical satisfaction to their clients as well as engaging conversation that keeps your time enjoyable and entertaining. Plus they look fabulously elegant; making an impressionable. Independent Escorts Meerut understands the value of confidentiality and discretion - they will go the extra mile to meet your needs. Simply contact them via text messaging or through their online profiles; they'd be more than delighted to accommodate any request or arrange a romantic date or fun-filled night together. We provide –(INDIRA) Call Girl Meerut Call Now 8617697112 Meerut Escorts 24x7

(INDIRA) Call Girl Meerut Call Now 8617697112 Meerut Escorts 24x7Call Girls in Nagpur High Profile Call Girls

Call girls in delhi ✔️✔️🔝 9953056974 🔝✔️✔️Welcome To Vip Escort Services In Delhi [ ]Noida Gurgaon 24/7 Open Sex Escort Services With Happy Ending ServiCe Done By Most Attractive Charming Soft Spoken Bold Beautiful Full Cooperative Independent Escort Girls ServiCe In All-Star Hotel And Home Service In All Over Delhi, Noida, Gurgaon, Faridabad, Ghaziabad, Greater Noida,

• IN CALL AND OUT CALL SERVICE IN DELHI NCR

• 3* 5* 7* HOTELS SERVICE IN DELHI NCR

• 24 HOURS AVAILABLE IN DELHI NCR

• INDIAN, RUSSIAN, PUNJABI, KASHMIRI ESCORTS

• REAL MODELS, COLLEGE GIRLS, HOUSE WIFE, ALSO AVAILABLE

• SHORT TIME AND FULL TIME SERVICE AVAILABLE

• HYGIENIC FULL AC NEAT AND CLEAN ROOMS AVAIL. IN HOTEL 24 HOURS

• DAILY NEW ESCORTS STAFF AVAILABLE

• MINIMUM TO MAXIMUM RANGE AVAILABLE.

Call Girls in Delhi & Independent Escort Service –

CALL GIRLS SERVICE DELHI NCR

Vip call girls in Delhi

Call Girls in Delhi, Call Girl Service 24×7 open

Call Girls in Delhi Best Delhi Escorts in Delhi

Low Rate Call Girls In Saket Delhi

X~CALL GIRLS IN Ramesh Nagar Metro

best Delhi call girls and Delhi escort service.

CALL GIRLS SERVICE IN ALL DELHI …

(Delhi) Call Girls in (Chanakyapuri)

Hot And Sexy Independent Model Escort Service In Delhi Unlimited Enjoy Genuine 100% Profiles And Trusted Door Step Call Girls Feel Free To Call Us Female Service Hot Busty & Sexy Party Girls Available For Complete Enjoyment. We Guarantee Full Satisfaction & In Case Of Any Unhappy Experience, We Would Refund Your Fees, Without Any Questions Asked. Feel Free To Call Us Female Service Provider Hours Opens Thanks.

Delhi Escorts Services 100% secure Services.Incall_OutCall Available and outcall Services provide.

We are available 24*7 for Full Night and short Time Escort Services all over Delhi NCR.

Delhi All Hotel Services available 3* 4* 5* Call Call

Delhi Escorts Services And Delhi Call Girl Agency 100% secure Services in my agency. Incall and outcall Services provide.

We are available 24*7 for Full Night and short Time Escort Services my agency in all over New Delhi

Delhi All Hotel Services available my agency

SERVICES [✓✓✓]

Housewife

College Girl

VIP Escort

Independent Girl

Aunty

Without a Condom sucking )?

Sexy Aunty.DSL (Dick Sucking Lips)?

DT (Dining at the Toes English Spanking)

Doggie (Sex style from no behind)??

OutCall- All Over Delhi Noida Gurgaon 24/7

FOR APPOINTMENT Call/Whatsop / 9953056974Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service9953056974 Low Rate Call Girls In Saket, Delhi NCR

Recently uploaded (20)

Call for Papers - African Journal of Biological Sciences, E-ISSN: 2663-2187, ...

Call for Papers - African Journal of Biological Sciences, E-ISSN: 2663-2187, ...

BSides Seattle 2024 - Stopping Ethan Hunt From Taking Your Data.pptx

BSides Seattle 2024 - Stopping Ethan Hunt From Taking Your Data.pptx

Call for Papers - International Journal of Intelligent Systems and Applicatio...

Call for Papers - International Journal of Intelligent Systems and Applicatio...

(INDIRA) Call Girl Aurangabad Call Now 8617697112 Aurangabad Escorts 24x7

(INDIRA) Call Girl Aurangabad Call Now 8617697112 Aurangabad Escorts 24x7

(INDIRA) Call Girl Meerut Call Now 8617697112 Meerut Escorts 24x7

(INDIRA) Call Girl Meerut Call Now 8617697112 Meerut Escorts 24x7

Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Call for Papers - Educational Administration: Theory and Practice, E-ISSN: 21...

Call for Papers - Educational Administration: Theory and Practice, E-ISSN: 21...

Coefficient of Thermal Expansion and their Importance.pptx

Coefficient of Thermal Expansion and their Importance.pptx

FULL ENJOY Call Girls In Mahipalpur Delhi Contact Us 8377877756

FULL ENJOY Call Girls In Mahipalpur Delhi Contact Us 8377877756

CCS335 _ Neural Networks and Deep Learning Laboratory_Lab Complete Record

CCS335 _ Neural Networks and Deep Learning Laboratory_Lab Complete Record

Liquid Fuels 5

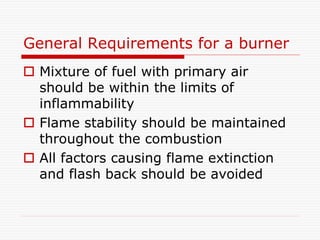

- 1. General Requirements for a burner Mixture of fuel with primary air should be within the limits of inflammability Flame stability should be maintained throughout the combustion All factors causing flame extinction and flash back should be avoided

- 2. General Requirements for a burner Adequate combustion space should be provided for its completion Complete mixing of oxygen and fuel is desirable( may be obtained by creating turbulence in the combustion space) Flame shape should correspond to the geometry of furnace

- 3. Burner Selection Flame Shape Combustion Volume Stability Drive Turndown Ratio: Ratio of maximum to minimum heat input rates within which burner operates satisfactorily Maximum limit depends upon flame blow off. Minimum limit depends upon flame flash back

- 4. Simple Burner Fuel Air Burning Velocity Flow velocity • Burning Velocity > Flow Velocity : Flash Back Limit • Burning Velocity < flow Velocity : Blow Off Limit • Burning Velocity = Flow Velocity : Stable Flame. • The ability of the combustion process to sustain itself in a continuous manner is called Combustion Stability. • Stable and efficient combustion can be upset by too lean or too rich mixture.

- 5. Burners for Liquid Fuels The purpose of a fuel burning system are to To position flame at areas of useful heat release Initiate and maintain ignition Mix the fuel and air Volatilize the fuel Proportion the fuel to air

- 6. Schematic of an Industrial Combustion Process

- 7. Liquid Fuel Burners Oils may be burnt in two ways it is vaporized before ignition so that it burns like a gas (vaporising burners) it is converted into droplets which are injected into hot air so that they evaporate while burning (atomising burners)

- 8. Liquid Fuel Burners Atomising burners: On industrial scale, most commonly used burners are atomising burners Oil is heated to low viscosity and atomised (i) Mechanically by means of a rotating disc or cup with a uniform droplet size (50 microns) (ii) By a high pressure ejection from a fine orifice which gives a conical spray

- 9. Liquid Fuel Burners by an entrainment in a blast of air or steam air atomisation gives a better theoretical flame temperature as compared to steam steam atomisation is preferred for high viscosity fuels to reduce the viscosity e.g. for residual fuel oils

- 10. Liquid Fuel Burners For most of the applications compressed air is the atomising fluid The minimum temperature at which an oil is pumpable in practice depends upon the viscosity of the oil