Melden

Teilen

Downloaden Sie, um offline zu lesen

Empfohlen

Empfohlen

Weitere ähnliche Inhalte

Was ist angesagt?

Was ist angesagt? (19)

How manufacturers can save electricity with electric motors javid iqbal sodagar

How manufacturers can save electricity with electric motors javid iqbal sodagar

NEW TECHNOLOGIES IN ELECTRIC ARC FURNACE (EAF) AND LADLE FURNACES (LF) BY CVS...

NEW TECHNOLOGIES IN ELECTRIC ARC FURNACE (EAF) AND LADLE FURNACES (LF) BY CVS...

Comparative Efficiency Measurements on Permanent Magnet Synchronous Motors an...

Comparative Efficiency Measurements on Permanent Magnet Synchronous Motors an...

Dr J Rhett Mayor - Georgia Institute of Technology

Dr J Rhett Mayor - Georgia Institute of Technology

Synthesis, characterization and mechanical behavior of nickel coated graphite...

Synthesis, characterization and mechanical behavior of nickel coated graphite...

Synthesis, characterization and mechanical behavior

Synthesis, characterization and mechanical behavior

International Journal of Computational Engineering Research(IJCER)

International Journal of Computational Engineering Research(IJCER)

Andere mochten auch

Andere mochten auch (8)

New generation of copper alloy conductors for overhead electricity lines

New generation of copper alloy conductors for overhead electricity lines

Micro-alloyed copper overhead line conductors - Wire & Cable Technology Inter...

Micro-alloyed copper overhead line conductors - Wire & Cable Technology Inter...

Copper alloy conductors for overhead lines - CIGRÉ Regional South-East Europe...

Copper alloy conductors for overhead lines - CIGRÉ Regional South-East Europe...

Micro-alloyed copper overhead line conductors - PowerGrid International Augus...

Micro-alloyed copper overhead line conductors - PowerGrid International Augus...

New generation of copper conductors for overhead lines

New generation of copper conductors for overhead lines

Ähnlich wie Copper rotor leaflet

Ähnlich wie Copper rotor leaflet (20)

RAUTOMEAD TECHNOLOGY FOR CONTINUOUS CASTING OF OXYGEN-FREE COPPER, COPPER-MA...

RAUTOMEAD TECHNOLOGY FOR CONTINUOUS CASTING OF OXYGEN-FREE COPPER, COPPER-MA...

RAUTOMEAD TECHNOLOGY FOR UPWARDS CONTINUOUS CASTING OF COPPER ALLOYS

RAUTOMEAD TECHNOLOGY FOR UPWARDS CONTINUOUS CASTING OF COPPER ALLOYS

RAUTOMEAD TECHNOLOGY FOR CONTINUOUS CASTING OF OXYGEN-FREE COPPER AND DILUTE...

RAUTOMEAD TECHNOLOGY FOR CONTINUOUS CASTING OF OXYGEN-FREE COPPER AND DILUTE...

Industrial Training Report on Steel Melting Shop(SMS)

Industrial Training Report on Steel Melting Shop(SMS)

Innovative engineering design in circulating fluid bed technology

Innovative engineering design in circulating fluid bed technology

Motors with Copper Rotors Can Cost Less to Produce

Motors with Copper Rotors Can Cost Less to Produce

Mehr von Leonardo ENERGY

Mehr von Leonardo ENERGY (20)

A new generation of instruments and tools to monitor buildings performance

A new generation of instruments and tools to monitor buildings performance

Addressing the Energy Efficiency First Principle in a National Energy and Cli...

Addressing the Energy Efficiency First Principle in a National Energy and Cli...

Auctions for energy efficiency and the experience of renewables

Auctions for energy efficiency and the experience of renewables

Energy efficiency first – retrofitting the building stock final

Energy efficiency first – retrofitting the building stock final

How auction design affects the financing of renewable energy projects

How auction design affects the financing of renewable energy projects

Five actions fit for 55: streamlining energy savings calculations

Five actions fit for 55: streamlining energy savings calculations

Energy and mobility poverty: Will the Social Climate Fund be enough to delive...

Energy and mobility poverty: Will the Social Climate Fund be enough to delive...

Does the EU Emission Trading Scheme ETS Promote Energy Efficiency?

Does the EU Emission Trading Scheme ETS Promote Energy Efficiency?

Energy efficiency, structural change and energy savings in the manufacturing ...

Energy efficiency, structural change and energy savings in the manufacturing ...

Energy Sufficiency Indicators and Policies (Lea Gynther, Motiva)

Energy Sufficiency Indicators and Policies (Lea Gynther, Motiva)

The Super-efficient Equipment and Appliance Deployment (SEAD) Initiative Prod...

The Super-efficient Equipment and Appliance Deployment (SEAD) Initiative Prod...

Modelling and optimisation of electric motors with hairpin windings

Modelling and optimisation of electric motors with hairpin windings

Motor renovation - Potential savings and views from various EU Member States

Motor renovation - Potential savings and views from various EU Member States

The need for an updated European Motor Study - key findings from the 2021 US...

The need for an updated European Motor Study - key findings from the 2021 US...

Efficient motor systems for a Net Zero world, by Conrad U. Brunner - Impact E...

Efficient motor systems for a Net Zero world, by Conrad U. Brunner - Impact E...

Kürzlich hochgeladen

💉💊+971581248768>> SAFE AND ORIGINAL ABORTION PILLS FOR SALE IN DUBAI AND ABUDHABI}}+971581248768

+971581248768 Mtp-Kit (500MG) Prices » Dubai [(+971581248768**)] Abortion Pills For Sale In Dubai, UAE, Mifepristone and Misoprostol Tablets Available In Dubai, UAE CONTACT DR.Maya Whatsapp +971581248768 We Have Abortion Pills / Cytotec Tablets /Mifegest Kit Available in Dubai, Sharjah, Abudhabi, Ajman, Alain, Fujairah, Ras Al Khaimah, Umm Al Quwain, UAE, Buy cytotec in Dubai +971581248768''''Abortion Pills near me DUBAI | ABU DHABI|UAE. Price of Misoprostol, Cytotec” +971581248768' Dr.DEEM ''BUY ABORTION PILLS MIFEGEST KIT, MISOPROTONE, CYTOTEC PILLS IN DUBAI, ABU DHABI,UAE'' Contact me now via What's App…… abortion Pills Cytotec also available Oman Qatar Doha Saudi Arabia Bahrain Above all, Cytotec Abortion Pills are Available In Dubai / UAE, you will be very happy to do abortion in Dubai we are providing cytotec 200mg abortion pill in Dubai, UAE. Medication abortion offers an alternative to Surgical Abortion for women in the early weeks of pregnancy. We only offer abortion pills from 1 week-6 Months. We then advise you to use surgery if its beyond 6 months. Our Abu Dhabi, Ajman, Al Ain, Dubai, Fujairah, Ras Al Khaimah (RAK), Sharjah, Umm Al Quwain (UAQ) United Arab Emirates Abortion Clinic provides the safest and most advanced techniques for providing non-surgical, medical and surgical abortion methods for early through late second trimester, including the Abortion By Pill Procedure (RU 486, Mifeprex, Mifepristone, early options French Abortion Pill), Tamoxifen, Methotrexate and Cytotec (Misoprostol). The Abu Dhabi, United Arab Emirates Abortion Clinic performs Same Day Abortion Procedure using medications that are taken on the first day of the office visit and will cause the abortion to occur generally within 4 to 6 hours (as early as 30 minutes) for patients who are 3 to 12 weeks pregnant. When Mifepristone and Misoprostol are used, 50% of patients complete in 4 to 6 hours; 75% to 80% in 12 hours; and 90% in 24 hours. We use a regimen that allows for completion without the need for surgery 99% of the time. All advanced second trimester and late term pregnancies at our Tampa clinic (17 to 24 weeks or greater) can be completed within 24 hours or less 99% of the time without the need surgery. The procedure is completed with minimal to no complications. Our Women's Health Center located in Abu Dhabi, United Arab Emirates, uses the latest medications for medical abortions (RU-486, Mifeprex, Mifegyne, Mifepristone, early options French abortion pill), Methotrexate and Cytotec (Misoprostol). The safety standards of our Abu Dhabi, United Arab Emirates Abortion Doctors remain unparalleled. They consistently maintain the lowest complication rates throughout the nation. Our Physicians and staff are always available to answer questions and care for women in one of the most difficult times in their lives. The decision to have an abortion at the Abortion Cl+971581248768>> SAFE AND ORIGINAL ABORTION PILLS FOR SALE IN DUBAI AND ABUDHA...

+971581248768>> SAFE AND ORIGINAL ABORTION PILLS FOR SALE IN DUBAI AND ABUDHA...?#DUbAI#??##{{(☎️+971_581248768%)**%*]'#abortion pills for sale in dubai@

A Principled Technologies deployment guide

Conclusion

Deploying VMware Cloud Foundation 5.1 on next gen Dell PowerEdge servers brings together critical virtualization capabilities and high-performing hardware infrastructure. Relying on our hands-on experience, this deployment guide offers a comprehensive roadmap that can guide your organization through the seamless integration of advanced VMware cloud solutions with the performance and reliability of Dell PowerEdge servers. In addition to the deployment efficiency, the Cloud Foundation 5.1 and PowerEdge solution delivered strong performance while running a MySQL database workload. By leveraging VMware Cloud Foundation 5.1 and PowerEdge servers, you could help your organization embrace cloud computing with confidence, potentially unlocking a new level of agility, scalability, and efficiency in your data center operations.Deploy with confidence: VMware Cloud Foundation 5.1 on next gen Dell PowerEdg...

Deploy with confidence: VMware Cloud Foundation 5.1 on next gen Dell PowerEdg...Principled Technologies

Kürzlich hochgeladen (20)

ProductAnonymous-April2024-WinProductDiscovery-MelissaKlemke

ProductAnonymous-April2024-WinProductDiscovery-MelissaKlemke

From Event to Action: Accelerate Your Decision Making with Real-Time Automation

From Event to Action: Accelerate Your Decision Making with Real-Time Automation

+971581248768>> SAFE AND ORIGINAL ABORTION PILLS FOR SALE IN DUBAI AND ABUDHA...

+971581248768>> SAFE AND ORIGINAL ABORTION PILLS FOR SALE IN DUBAI AND ABUDHA...

Deploy with confidence: VMware Cloud Foundation 5.1 on next gen Dell PowerEdg...

Deploy with confidence: VMware Cloud Foundation 5.1 on next gen Dell PowerEdg...

Apidays New York 2024 - Scaling API-first by Ian Reasor and Radu Cotescu, Adobe

Apidays New York 2024 - Scaling API-first by Ian Reasor and Radu Cotescu, Adobe

Understanding Discord NSFW Servers A Guide for Responsible Users.pdf

Understanding Discord NSFW Servers A Guide for Responsible Users.pdf

HTML Injection Attacks: Impact and Mitigation Strategies

HTML Injection Attacks: Impact and Mitigation Strategies

Bajaj Allianz Life Insurance Company - Insurer Innovation Award 2024

Bajaj Allianz Life Insurance Company - Insurer Innovation Award 2024

The 7 Things I Know About Cyber Security After 25 Years | April 2024

The 7 Things I Know About Cyber Security After 25 Years | April 2024

Tata AIG General Insurance Company - Insurer Innovation Award 2024

Tata AIG General Insurance Company - Insurer Innovation Award 2024

Bajaj Allianz Life Insurance Company - Insurer Innovation Award 2024

Bajaj Allianz Life Insurance Company - Insurer Innovation Award 2024

Exploring the Future Potential of AI-Enabled Smartphone Processors

Exploring the Future Potential of AI-Enabled Smartphone Processors

Powerful Google developer tools for immediate impact! (2023-24 C)

Powerful Google developer tools for immediate impact! (2023-24 C)

Mastering MySQL Database Architecture: Deep Dive into MySQL Shell and MySQL R...

Mastering MySQL Database Architecture: Deep Dive into MySQL Shell and MySQL R...

Repurposing LNG terminals for Hydrogen Ammonia: Feasibility and Cost Saving

Repurposing LNG terminals for Hydrogen Ammonia: Feasibility and Cost Saving

AWS Community Day CPH - Three problems of Terraform

AWS Community Day CPH - Three problems of Terraform

Polkadot JAM Slides - Token2049 - By Dr. Gavin Wood

Polkadot JAM Slides - Token2049 - By Dr. Gavin Wood

Copper rotor leaflet

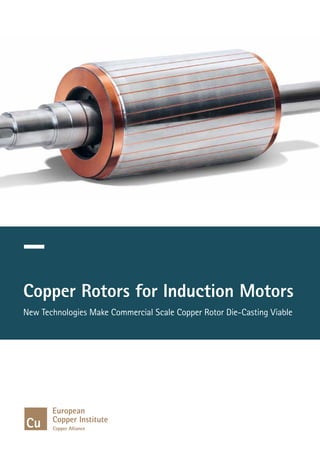

- 1. Copper Rotors for Induction Motors New Technologies Make Commercial Scale Copper Rotor Die-Casting Viable

- 2. New technological breakthroughs Several breakthroughs in copper die-casting have removed the previous problems. The technology has been fine-tuned to make it economically viable. A number of companies in Europe, US and Asia are now up and running with copper die-casting production facilities. Mass production is now possible and commercially viable. Around 2 million copper die-cast units are already in use worldwide. As a result, the market for copper die-cast rotors is expected to grow significantly. Current applications proven; new ones under development Initial interesting applications include industrial high efficiency low voltage induction motors (100 W – 100 kW) and traction applications. More applications in niche sectors are following closely behind. These include corrosive atmospheres, special cooling needs and cranes. Recycling: Technologically and economically feasible Beyond manual processes for separation of copper from iron, a number of automated sorting techniques are tested and proved, such as X-ray fluorescence. As well, new tools are under development, such as laser induced breakdown spectroscopy (LIBS). Copper rotors contain typically around 25% copper in weight (the rest is steel). 9/10 of the scrap value corresponds to copper. There is then a strong economic rationale to recycle copper rotors. Recycling of copper is also environmentally responsible. It leads to the emission of few, if any, harmful gases and avoids its expensive disposal in landfills. It also leads to significant energy savings. To extract copper from copper ore, the energy required is approximately 100 GJ/tonne. Recycling copper uses much less energy, about 10 GJ/tonne. This energy saving leads to the conservation of valuable reserves of fossil fuels and consequent reduction of CO2 emissions. Finally, recycling helps as well to preserve raw material reserves. What is a copper rotor? Innovations stimulate market growth A copper rotor is a rotor made of electrical steel (laminations) in which the rotor bars and end rings are made of cast copper instead of cast aluminium. Why copper? Why not copper? The use of copper in place of aluminium can lead to significant benefits: • Higher efficiency – A first possibility of design is to get higher efficiency, while using approximately the same motor size as the aluminium rotor version. Copper’s higher electrical conductivity allows the rotor to conduct electricity more efficiently, resulting in lower resistive losses and lower operating temperature. • Extended life expectancy – As motor life is doubled for every 10°C reduction in operating temperature, this lower operational temperature results in extended motor life expectancy. The lower operating temperature combined with the high thermal conductivity of copper allows for fewer forced cooling units. This further improves efficiency. • Smaller size and cost – A second design avenue consists in the reduction of the overall size and weight of the motor by using a copper rotor, while maintaining the motor efficiency. This is because the higher efficiency of the copper rotor allows the overall length of the rotor (and motor) to be decreased, while still matching the performance of a motor utilizing an aluminium rotor. Shortening the motor eliminates some of the rotor and stator laminations; decreases the number of stator windings; and reduces the length of the shaft. A more compact and lighter machine is possible, and the rotor more easily fits into a monoblock motor system. Copper melts at 1083°C, compared to 660°C for aluminium. The higher melting point of copper has historically led to die-casting problems. In fact, the die-casting of (pure) copper was technically difficult or virtually impossible for a long time. This meant that copper had not been greatly utilized for industrial rotor production. However, all these problems now belong to the past, thanks to the availability of new processes. Copper is an excellent material to use for rotors because of its high conductivity. Copper’s conductivity is rated at 57 MS/m, which is significantly higher than that of aluminium (37 MS/m). This makes copper the material of choice for a number of induction motor applications worldwide. VEM motor with copper rotor casted by Breuckmann

- 3. This leaflet is an initiative of the European Copper Institute: Founded in 1996 in the UK, the European Copper Institute (ECI) is a joint venture between the International Copper Association Ltd. (ICA), headquartered in New York, representing the majority of the world’s leading mining companies, custom smelters and semi-fabricators, and the European copper industry. ECI is also part of the Copper Alliance, an international network of industry associations. Its shared mission is to work, with its members, to defend and grow markets for copper based on its superior technical performance and contributions to a higher quality of life. More information on www.copperalliance.eu European Copper Institute Avenue de Tervueren 168, b 10 1150 Brussels, Belgium Phone: +32 (0) 2 777-7070 Fax: +32 (0) 2 777-7079 www.copperalliance.eu 2013 © European Copper Institute Contact the European Copper Institute at eci@copperalliance.eu to discuss how you can play a role in the further growth of the copper rotor phenomenon. Leading European copper rotor manufacturers: www.copper-rotor.eu presents copper rotor technology for induction motors, focusing on industrial applications, and includes: • An introduction to the technology. • An economic analysis to support decision-making. • A comprehensive view over the supply chain of this technology in Europe and other regions. • An environmental approach: recycling avenues. www.coppermotor.com focuses on copper rotor induction motors for automotive applications and is packed full of manufacturing and design resources. Want to know more? Here are two websites where you can discover more about innovative copper rotor technologies and applications: