Pharma Uptoday - Volume 3 issue jun 2014

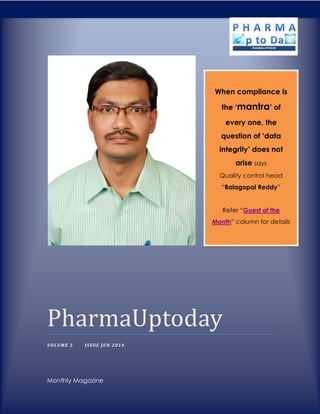

- 1. PharmaUptoday VOLUME 3 ISSUE JUN 2014 Monthly Magazine When compliance is the ‘mantra’ of every one, the question of ‘data integrity’ does not arise says Quality control head “Balagopal Reddy” Refer “Guest of the Month” column for details

- 2. PAGE 1PHARMA UPTODAY About PharmaUptoday: The "PharmaUptoday" Newsletter initiated on 18-Jul-2013 to refresh the subject, update the guidelines, regulations & current happenings. This website is restricted to people in Drugs & Pharmaceutical industry who are enthusiastic to know about current happenings and learn and implement the same. It doesn't include the topics related to Pre- clinical, Clinical, Biotech / Biosimilar, Medical device (with some exceptions). This Group and the Website is initiated to share the knowledge, to minimise / avoid 483's, Warning letters, deviations etc as “Together we can make Global Pharma excel”. Updates in this Newsletter include: • Updates & News on Warning letters, 483s, US FDA, GMP etc. • Literature & Topic Related to Pharma / General requirement • Presentations, Webinars, Guidelines, Books, Articles etc. Message from the Editor Highlights of PharmaUptoday: • Current members in the group : 238 • Number of Posts till date : 554 • Regular topics include: GMP, Article of the week, 483s, Regulations, Drug Category and News. • Few previously posted topics can accessed from "PharmaUptoday" website :https://sites.google.com/site/pharmauptoday/. • To subscribe the Newsletter send an email to "pharmauptoday@gmail.com" with a subject "Add email". Inside This Issue 1 Message from the Editor 2 News Uptoday 6 New Guidelines 13 Audit Findings 20 Guest of the Month 22 Regulations of the Month Together we can make Global Pharma excel. PHARMA UPTODAY VOLUME 3 ISSUE JUN 2014 08-Jun-2014

- 3. PAGE 2 PHARMA UPTODAY FDA Inspected Wockhardt US Unit in March FDA has made some observations about the production process of the US unit of Indian generic drugmaker WockhardtLtd, the company said on Tuesday. The FDA last year banned Wockhardt’s two Indian units from exporting to the United States, its biggest market, citing quality lapses in the manufacturing process. Managing Director Murtaza Khorakiwala told an analysts briefing the FDA had inspected the company’s Chicago-based Morton Grove Pharmaceuticals unit, which accounts for more than 50% of its sales in the United States, in the March quarter. He did not give further details. “It’s difficult to say what kind of position the FDA will take but according to us the inspection was not a very negative inspection,” Khorakiwala said. Wockhardt on Monday reported a 78% drop in net profit for the March quarter, as it continues to reel under the US and U.K. import bans due to manufacturing quality lapses. In November, the US Food and Drug Administration (FDA) issued an import alert, effectively a ban, against Wockhardt’s Chikalthana plant in western India. The FDA had imposed a ban on the company’s Waluj plant in May. FDA to inspect more Sun plants in the next few weeks When the FDA issued an import alert against Sun Pharma's plant in Gujarat in March, the drugmaker reassured investors the facility accounted for just 1% of U.S. sales. But with the allegations of failings at the plant becoming more and more damning, the FDA is reportedly following its now-familiar strategy of going after other facilities in the network. The FDA is reportedly focusing on two export-oriented ingredient plants, plus two formulation units. And Sun only has to look to the company it is trying to buy, Ranbaxy, to see how the FDA can throttle exports. The import ban placed on Ranbaxy covered plants that generated almost half of its U.S. sales. In the worst-case scenario, Sun could have to fix several of its sites to meet FDA standards at the same time as remediating the facilities it is set to buy from Ranbaxy. Last week's warning letter hinted at the impending actions, with the FDA calling on Sun to take a close look at all of its production plants. FDA has already begun broadening its investigation, with an unnamed source telling the newspaper regulatory inspectors have visited a couple of Sun sites recently. Detailed inspections are expected in the next few weeks. The outcomes of the inspections have big implications for overseas sales. EDQM signs confidentiality agreement with TFDA The European Directorate for the Quality of Medicines & Healthcare (EDQM, Council of Europe), which celebrates its 50th anniversary in 2014, has signed a confidentiality agreement with the Taiwan Food and Drug Administration (TFDA). The parties share the common goal ofprotecting public health by ensuring the quality of medicinal products and the signature of the agreement is an additional step to strengthen the collaboration with the TFDA which had been granted observer status to the European Pharmacopoeia Commission in November 2013. The scope of the confidentiality agreement concerns the procedure for ‘certification of suitability to the monographs of the European Pharmacopoeia’ and includes exchange of information relating to the quality assessment of active pharmaceutical ingredients and excipients used in the manufacture of medicinal products as well as to GMPinspections of related manufacturing sites. News Uptoday

- 4. PAGE 3PHARMA UPTODAY News Uptoday CDSCO in the process of constituting 38 more new drug advisory committees With a view to further beef up the process of approvals to clinical trials, the health ministry has begun the process of increasing the number of new drug advisory committees (NDACs) from the current 12 to 50. The Central Drugs Standard Control Organisation (CDSCO) has already in principle finalized the composition of the new NDACs. The members for the new panels have already been contacted and many of them had given consents verbally and through mails. As and when the consents come from other members, the panels would be formally constituted, sources said. Following the recommendations by the Parliamentary committee on the functioning of the regulatory mechanism and under pressure from the judiciary, the Health Ministry had formed 12 NDACs to advise on matters related to review and regulatory approval of clinical trials and new drugs (except for Investigational New Drugs). The technical committee and the apex committee on clinical trials, the two high-level panels set up by the ministry, had recommended the increase in the number of NDACs with a view to involve more experts in the process of clearing the clinical trials in a fool-proof manner. However, there were criticism that the NDACs were not functioning properly. Another concern was the lack of sufficient number of pharmacologists in the panels. It has been decided that the permission for clinical trials should not be given without consultation with the pharmacologists. In case of permissions cleared by NDACs without pharmacologists, the proposals would again be referred to the pharmacologists of other NDACs. In some of the NDACs, the expert members have retired, some of the members are no more associated with the organisation and some had refused to attend the meetings, citing busy schedules and engagements, thus defeating the very purpose of the NDACs. The practice is that the pharmacologist specified for particular NDACs are only called to offer expert opinion, not full-time attendance at the meetings. Maha FDA upgrades system to provide WHO GMP certificates in 10 days The Maharashtra Food and Drug Administration (FDA)'s online WHO GMP certificate generation system, introduced by the FDA around two years ago, has now been upgraded through a robust IT backed system to such a level that the FDA is now able to provide the WHO GMP certificate to the exporters in 10 days. Besides creating an electronic storage of data for easy retrieval at any time, the new online system developed by the FDA ensures avoiding duplication or counterfeiting of the certificates by assigning a software generated unique authorisation code to each certificate. Among the other unique attributes of the system, the SMS delivery system keeps the manufacturers updated when they are offline and authentication of the certificates can be verified by the authorities very easily. The new system will go a long way in boosting the exports from the state as this new system will help manufacturing units to get WHO GMP certification for exports in 10 days time as compared to three months in the past. The manual process was time consuming and entailed scrutiny of the application at three levels by the concerned authorities which once approved was sent by post as a Compliance Letter. This system was followed from 2000 to August 14, 2012. Earlier, joint commissioner (HQ) was designated for signing the various certificates issued under the WHO GMP certificates. Manufacturers from across the state had to come to Mumbai to apply for the certificates and had to submit a sizeable amount of data in the form of papers. The application thus received was cumbersome as it was first received by the drug inspectors at WHO-GMP section and then by the assistant commissioner, WHO- GMP section followed by the final signatures on the certificates by the joint commissioner (HQ). There are 1703 manufacturing units in the state out of which 247 units are WHO GMP certified. Exports of medicines worth Rs.15,500 crore have been accounted from Maharashtra in the year 2013-14. There are 883 allopathic units, 452 ayurvedic units, 31 homoeopathic units and 337 cosmetic product units across the state.

- 5. PAGE 4 PHARMA UPTODAY News Uptoday EMA publishes 2013 annual report The European Medicines Agency (EMA) has published today its 2013 annual report. In 2013, the EMA’s Committee for Medicinal Products for Human Use(CHMP) recommended 81 medicines for human use for marketing authorisation, compared with 57 in 2012. The number of medicines containing a new active substance has continuously increased for the past three years, while the number of generics is stable compared with 2012 but generally decreasing over the last few years. Two new advanced-therapy medicinal products (ATMPs) were recommended for approval in 2013, bringing to four the total number of ATMPs recommended for approval by the CHMP since the legislation on advanced therapies became operational. The number of recommendations for approval of medicines intended for the treatment of rare diseases is steadily increasing with eleven orphan medicines recommended in 2013 compared with eight in 2012 and four in 2011. 2013 also saw the first two positive opinions for marketing authorisations of biosimilar monoclonal antibodies, successfully applying the biosimilar concept to such structurally complex substances. The annual report also highlights some of the main projects, initiatives and achievements in 2013 that had and still have a profound impact on the Agency and the way it operates. These include the EMA’s commitment to publish and give access to clinical trial data submitted to the Agency as part of a marketing authorisationapplication, the stronger interaction with health-technology assessment bodies to facilitate patients’ access to medicines, the reorganisation of the EMA and the implementation of new legislation. The document reports in particular on the range of pharmacovigilance activities that have been embedded into the core business of the Agency as part of the implementation of the EU pharmacovigilance legislation. Please Refer http://www.ema.europa.eu/ema/index.jsp?curl=pages/news_and_events/news/2014/04/news_detail_002 090.jsp&mid=WC0b01ac058004d5c1# and http://www.ema.europa.eu/ema/index.jsp?curl=pages/news_and_events/news/2014/04/news_detail_002 090.jsp&mid=WC0b01ac058004d5c1# for more information. US FDA asks Indian pharma leaders to make quality, their top priority Top management of drug making companies must make quality control their top priority, said a senior US Food and Drug Administration (FDA) official at Hyderabad kicking off a series of FDA- Drug Controller General of India workshops to be held this year for Indian pharma companies to help them comply better to the US prescribed standards. "Companies must ensure that they are saying what they do and they do what they say and demonstrate that they did it" said Leslie Ball, deputy director , office of international program, FDA. Since the beginning of last year, there's been a spike in "violations" at India based drug plants, according to data from FDA's Centre for Drug Evaluation and Research, the US drug safety office. The sites of leading drugmakers such as Ranbaxy Laboratories, Wockhardt, Strides Arcolab and Sun Pharma are on the list. Many of these allegations relate to 'data-fudging'.

- 6. PAGE 5PHARMA UPTODAY News Uptoday This regulatory workshop in tie-up with Indian Pharma Alliance, a grouping of leading domestic drugmakers would be followed by 16 more of such meetings across India, which would be attended by 350 delegates from Indian pharma companies and 40 representative from central and state drug regulators' offices. Howard Sklamberg, deputy commissioner, global regulatory operations and policy, (FDA) said in video message that leadership is all about choices and senior management in the companies must commit to pro-active rather than reactive approach to quality control and allocate adequate resources for managing quality. Every time the top executives see a slippage happen, they should follow it through with a sound internal investigation, he said. At a time when leading Indian pharmaceutical companies have been cited for infringements by the US drug regulator, its chief Margaret Hamburg made her first visit to India in February this year. During her visit to India Hamburg ha burg had told "While some Indian companies operate state-of-the-art facilities and meet CGMPs (current good manufacturing practices), others do encounter problems and operational challenges. Staff from the FDA's India office will work with these companies to identify the problems and will take the necessary steps to self-correct". Two criminal cases await Ranbaxy pharmaceuticals in Kerala Ranbaxy faces two criminal cases in Kerala — one over amoxycilliin tablets that contained less of the ingredient than stated and another for selling an osteoporosis drug as a 'dietary supplement' in the state. The Supreme Court recently paved the way for this when it dismissed twin petitions filed by the company for quashing both cases. The Kerala High Court had refused to stay the complaints in both instances. In the first case, the state drug controller seized cartons of Roscillin AMX with two different strengths of the key ingredient amoxycillin, 250 mg and 500 mg, from Ranbaxy distributor Mohan Pharma Agencies Pvt Ltd. The 500 mg tablets were found to contain only 302.49 mg of amoxycilliin, i.e. about 51.75% of the label claim. The distributor claimed that the company could not be held liable in this case as it had only stored the drugs at the place where they were seized and the stocks at the godown premises were not for sale. Ranbaxy also claimed that it hadn't made the drugs in question and had merely purchased them from a licensed manufacturer and stored them. Ranbaxy on its part claimed that the sample batches, manufactured for it by the Rajasthan-based Medicamen Biotech Ltd, were recalled from the market and destroyed. The state of Kerala filed a criminal complaint against the three companies alleging offences under Sections 18 (A) (1), 18B, 22(3) of the Drugs Act. The magistrate then issued summons against the two companies. Ranbaxy moved the High Court at Ernakulam for quashing of the summons but this was refused on July 22, 2011. The company then moved the top court, where Kerala, through counsel MR Ramesh Babu, again opposed quashing of the case. Thought the top court initially stayed the High Court ruling, it ruled in favour of the state last Wednesday. In the second case, Ranbaxy will face a criminal trial for selling Rosatin Gel Tab as a dietary supplement instead of a drug. Dietary supplements carry lower taxes than drugs. The state claimed that rosatin was a drug as one of its ingredients, glucosamine, was defined as such and had to be manufactured and sold only under a drug manufacturing licence. Ranbaxy claimed that glucosamine was permitted as a substance to be used for infant food under the Food Safety and Standards Act, 2006. It also said that it was not registered as a drug under the Drugs Act and was marketed in India and many other countries as a dietary supplement. All these issues will now be decided in the lower court, state counsel Ramesh Babu said.

- 7. PAGE 6 PHARMA UPTODAY New Guidelines Clinical Pharmacology Data to Support a Demonstration of Biosimilarity to a Reference Product FDA published Draft Guidance on Clinical Pharmacology Data to Support a Demonstration of Biosimilarity to a Reference Product This draft guidance is intended to assist sponsors with the design and use of clinical pharmacology studies to support a decision that a proposed therapeutic biological product is biosimilar to its reference product. This guidance pertains to those products—such as therapeutic biological products—for which pharmacokinetic (PK) and pharmacodynamic (PD) data are required as part of a stepwise approach to developing the data and information necessary to support a demonstration of biosimilarity. Specifically, the guidance discusses some of the overarching concepts related to clinical pharmacology testing for biosimilar products, approaches for developing the appropriate clinical pharmacology database, and the utility of modeling and simulation for designing clinical trials. Source: http://www.fda.gov/downloads/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/UCM397017.pdf ANDAs: Stability Testing of Drug Substances and Products Questions and Answers This guidance provides answers to questions from the public comments we received on the draft guidance for industry on ANDAs: Stability Testing of Drug Substances and Products (FDA stability guidance) that published in the Federal Register of September 25, 2012. The final guidance for industry of the same title published in the Federal Register of June 20, 2013. Comments received on the draft of this guidance published in the Federal Register of August 27, 2013 have also been incorporated. General issues; drug master files (DMFs); drug product manufacturing and packaging; and stability studies are discussed in this guidance and are intended to clarify the stability testing data recommendations for abbreviated new drug applications (ANDAs). In this document, the terms drug substance and active pharmaceutical ingredient (API) are used interchangeably. Source: http://www.fda.gov/downloads/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/UC M366082.pdf USP Proposed new general chapter on <1029> Good Documentation Guidelines: This proposed new general chapter provides guidelines on how to develop and maintain good documentation practices within Good Manufacturing Practice (GMP) operations. This chapter was created to address a need for descriptions of what constitutes good documentation, for example, records of all types that are clear, accurate, and complete. These records may include protocols, procedures, reports, and raw data. The overarching goal of this chapter is to provide useful information to the GMP-regulated industries, thereby assisting the user in designing procedures that will promote record integrity and control. In turn, record integrity and control are essential for the evaluation and reconstruction of GMP activities, and ultimately for ensuring the quality and safety of regulated ingredients and products. Comment deadline: July 31, 2014

- 8. PAGE 7PHARMA UPTODAY New Guidelines Guidance for Industry: Expedited Programs for Serious Conditions – Drugs and Biologics These expedited programs include: Fast track designation: Providing for more frequent meetings and communications with FDA to discuss the drug’s development plan and ensure collection of appropriate data needed to support drug approval, including such things as the design of the proposed clinical trials and use of biomarkers. Accelerated Approval: Basing approval not on a clinical endpoint but on an agreed upon surrogate marker, that is a measure such as blood test or urine marker, that is believed to be indicative of a disease state and treatment effect, but not demonstrative of a direct health gain to the patient. Priority review: Acting on drug applications within 6 months instead of 10 months for standard review, and; Breakthrough Therapy Designation: Providing all of the benefits of Fast Track designation plus intensive guidance on an efficient drug development program, beginning as early as Phase 1, and the commitment from FDA’s review staff, including senior managers, to work closely together throughout the drug development and review process. Source: http://www.fda.gov/downloads/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/UCM358301.pdf Guidance for Industry: Product Development Under the Animal Rule This guidance provides information and recommendations on drug and biological product development when human efficacy studies are not ethical or feasible. The regulations that set forth the pathway for approval of these products under 21 CFR 314.600 (drugs) or 21 CFR 601.90 (biological products) are commonly referred to as the Animal Rule. Source: http://www.fda.gov/downloads/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/UCM39921 7.pdf What's in a Drug Name? FDA Explains in New Draft Guidance How should you name a new drug product? That question is the subject of a new draft guidance by the US Food and Drug Administration (FDA), which hopes to help industry in selecting a proprietary name that can clear the agency's various regulatory hurdles. Background The proprietary name for a drug is its "brand" name. For example, the erectile dysfunction drug sildenafil is marketed by Pfizer under the brand name "Viagra." In many cases, the brand name is easier to understand and recall for both consumers and healthcare providers alike.

- 9. PAGE 8 PHARMA UPTODAY New Guidelines However, because brand names are generally shorter than the established non-proprietary name for a drug, the potential for confusion can exist. A May 2013 article in the New England Journal of Medicine noted that many drugs approved in the last few years have started with the letters ”X” and “Z,” potentially confusing patients. To name a few from the last few years: Xofigo, Xtandi, Xarelto, Xalkori, Xgeva, Zaltrap, Zytiga, Zelboraf, Zioptan, and Zometa. FDA regulators try to reduce the potential for confusion by approving final trade names submitted by companies, assessing them for similarity to other names. For example, if a company requested a proprietary name of "Simplus," but a similar drug was named "Simplos," regulators would almost certainly reject it based on the potential for mix-ups and errors. New Guidance Now FDA is out with a new draft guidance intended to establish how companies can navigate the drug naming process more easily. As FDA explains at the outset of the draft guidance, its prime concern is that an individual drug is clearly identifiable by a single drug name without the possibility of confusion. Regulators cite a 1999 report by the Institute of Medicine (IOM) which estimates that 7,000 deaths each year are attributable to medication errors. A subsequent 2006 report by IOM identified eight problems are contributing to medication errors, including that the names of drug products can sound or look the same, causing consumers to take the incorrect product. EU regulators have estimated that the medication-error rate in primary care is as high as 9.1% in some cases, though some of that is due to a medicine's physical attributes, and not its name. In 2007, as part of the FDA Amendments Act (FDAAA), FDA unveiled an initiative aimed at reducing instances of so-called "look-alike sound-alike" (LASA) drugs, taken to mean drug products with names that either look similar to one another (Simplos/Simples) or sound similar to one another (Sohydroxy/Zohydroxee). This new guidance is a continuation of that initiative, FDA explains in the document. Guidance Details The draft guidance is extensive at nearly 37 pages and covering a wide range of possible cases and evaluation methods, including computer-driven methods like the Phonetic Orthographic Computer Analysis (POCA). Some key points to consider from the guidance: • Avoid proprietary names which have "obvious similarities in spelling and pronunciation" to other, already-marketed drugs. Sponsors should screen for these similarities in early-stage assessments. • Proprietary names should not incorporate medical abbreviations, as this could "inadvertently be a source for error." Consult the Joint Commission's "Do Not Use List" or the ISMP's "List of Error- Prone Abbreviations, Symbols and Dose Designations" for more information. • The name should not reference the drug's inactive ingredient in such a way as to infer that it has a value greater than it provides. • The name should "not include or suggest the name of one or more, but not all, of its active ingredients," as this can mislead the user into thinking the drug only has one of the drug ingredients in it. • Names should not incorporate US Adopted Name (USAN) stems, as those designate a pharmacological or chemical trait of a drug, and are not unique (and can therefore lead to confusion). • Proprietary names or the same root proprietary name should not be shared among products, even if owned by the same company, if they don't contain at least one common active ingredient contained in the original marketed product. • Discontinued names should not be reused. Source: Guidance for Industry: Best Practices in Developing Proprietary Names for Drugs

- 10. PAGE 9PHARMA UPTODAY New Guidelines TGA - ARGOM Appendix 2: Guidelines on quality aspects of OTC applications 6. Control of excipients: The information concerning the specifications applying to the excipients should include: • a critical summary and justification for the acceptance testing specifications applied by the finished product manufacturer. • test methods and validation data, where required (see 'Section 6.1 Pharmacopoeial excipients' and 'Section 6.2 Non-pharmacopoeial excipients'). In all cases, the specifications must characterise the excipients and ensure that all batches are of suitable and consistent quality for use in the manufacture of the medicine. Where all of the tests, limits and test methods are of a default standard monograph (and none of the compendial tests has been deleted) it is generally sufficient to state this. Where non-pharmacopoeial specifications are applied, a description of the tests, test methods and limits should be provided [e.g. assay (non aqueous titrimetry: 99.0 101.0%]. The specifications applied should be justified in respect of their ability to assure the quality and consistency of the ingredients used. Similarly, where a pharmacopoeial monograph is used as the specification any deviation from the pharmacopoeial tests, test methods or limits should be justified. • 6.1 Pharmacopoeial excipients • 6.2 Non-pharmacopoeial excipients • 6.3 Solvent/Sterilant residues • 6.4 Proprietary ingredients • 6.5 Perfumes (fragrances) and flavours • 6.6 Colourings in medicines for topical and oral use Colourings used in medicines for topical and oral use The guideline Colourings used in medicines for oral use has been updated to include colourings permitted in medicines for topical use, and include the following colourings for use in oral medicines: calcium carbonate, Lutein, Chlorophyllins, Riboflavin-5-phosphate and tartrazine. <http://www.tga.gov.au/industry/medicines-colourings.htm> Previously ARGPM Appendix 22 and Colourings used in medicines for oral use, July 2013 This guidance relates to: • colourings in medicines for topical and oral use that do not require evaluation of data by the TGA • the information required to evaluate a colouring that is not in: o Table 1 Colourings for use as excipients in medicines for topical use only o Table 2 Colourings a for use in medicines for oral and topical use Contents • Why colourings are used in medicines for topical and oral use • Colourings that do not require evaluation • Compliance with monographs and other standards for colourings • Data requirements for new colourings • Version history

- 11. PAGE 10 PHARMA UPTODAY New Guidelines Why colourings are used in medicines for topical and oral use Colourings are inactive substances that may be used in topical or oral formulations of medicines, for various reasons such as: • to distinguish between strengths, indications or markings • to assist with identifying the medicine • to distinguish between other medicines. The TGA guidance on literature based submissions has been updated The purpose of this guidance is to assist applicants compile a literature based submission (including mixed applications), and replaces the previous TGA guidance: Literature-Based Submissions - Points to consider (2003). This guidance is now in three parts: • Pre submission guidance for literature based submissions • Dossier requirements for literature based submissions • Systematic literature searches for literature based submissions For Over-the-Counter (OTC) medicines, you should also refer to the: · Australian Regulatory Guidelines for OTC Medicines Appendix 1: Guidelines on efficacy and safety aspects of OTC applications, Section 2 - literature based submissions. Note: (This includes LBS pre-submission requirements for OTC medicines.) What is a literature based submission? These rely solely, or predominantly, on bibliographic data (i.e. based on published literature) to support the safety and efficacy claims. For the purpose of evaluating prescription and OTC medicines (either an application to register, or an application to vary an existing registration) the TGA accepts three types of applications: • Conventional applications - containing full study reports of company sponsored studies conducted by them (or on their behalf) that demonstrate safety and efficacy claims • Literature based submissions - relying solely on bibliographic data to support safety and efficacy claims • Mixed applications - Mixed applications refer to dossiers where Module 4 and/or 5 consists of a combination of complete study reports of limited nonclinical and/or clinical studies carried out by the applicant and supported with bibliographical references. The nonclinical aspects of mixed applications are further discussed in Guideline on the non-clinical documentation for mixed marketing authorisation applications CPMP/SWP/799/95. · Mixed applications are treated in the same way as literature-based submissions. Source: http://www.tga.gov.au/industry/pm-literature-based-submissions.htm

- 12. PAGE 11PHARMA UPTODAY New Guidelines Interim Revision Announcement <41> Balances : Official July 1, 2014 Comment Summary #1: Two commenters indicated concerns that the use of a weight near minimum weight, combined with 2s vs. the previous 3s in the calculation and 0.10% vs. 0.1% for acceptance criteria may cause unforeseen and/or unreported failures even with new balances. Response: Comment not incorporated. The weight used for the calculation of the standard deviation during the repeatability test does not need to be small. Although the change from 0.1% to 0.10% makes the requirement tighter, the change in the coverage factor from 3 to 2, makes the overall requirement essentially unchanged compared with the previous requirement. Comment Summary # 2: Two commenters indicated that the term “desired smallest net weight” is not clearly defined. Response: Comment incorporated. Comment Summary #3: The commenter recommended retaining the reference to the nominal value and defining a range that would reduce the challenges presented by large and small test weights. Response: Comment not incorporated. The new text will eliminate the possibility of passing the test by the use of a heavy weight. Comment Summary #4: A commenter indicated that the fact that a smallest net weigh must be used seems to contradict with the statement about the independence of the repeatability with the weight used. Response: Comment incorporated. It was clarified that the Standard deviation of the repeatability is independent of the weight used for the test.

- 13. PAGE 12 PHARMA UPTODAY Canada Releases Biowaiver Guidance Release of Guidance Document: Biopharmaceutics Classification System Based Biowaiver Health Canada is pleased to announce the release of a guidance document, entitledBiopharmaceutics Classification System Based Biowaiver. The purpose of this document is to provide guidance to sponsors of new drugs with the information necessary to apply for a waiver from submitting comparative bioavailability studies as part of the safety and effectiveness requirements under Division 8 of the Food and Drug Regulations. The information required applies to only Biopharmaceutics Classification System (BCS) Class I and III drugs. The scope of this document is limited to immediate-release, solid oral pharmaceutical drug products regulated under the Food and Drugs Act that are intended to deliver medication to the systemic circulation. It is not applicable to disinfectants or drugs for veterinary use. A draft version of this guidance document was released for consultation in August 2012. Comments from stakeholders have been considered in the development of this final version. Comments received during the most recent consultation process, together with responses from the Therapeutic Products Directorate (TPD) have been collated in a separate document, which is available upon request. Requests for this document should be directed to the e-mail address below. This guidance comes into effect as of the date of publication. Please find the Guidance document enclosed. Source : http://www.hc-sc.gc.ca/dhp-mps/prodpharma/applic-demande/guide-ld/bcs_guide_ld_scb- eng.php New Guidelines

- 14. PAGE 13PHARMA UPTODAY Audit Findings 483 Observations: AMCOL Health and Beauty Solutions • Laboratory controls do not include the establishment of scientifically sound and appropriate specifications, standards, and test procedures designed to assure that drug products conform to appropriate standards of identity, strength, quality and purity. Deb USA, Inc. • Written procedures are not followed for evaluations done at least annually and including provisions for a review of complaints and investigations conducted for each drug product. American National Red Cross Heart of America Region • Failure of distribution and receipt procedures to include a system by which the distribution or receipt of each unit can be readily determined to facilitate its recall. United Guardian, Inc. • Procedures describing the warehousing of drug products are not established and followed. Cardinal Health. • Your batch production and control records did not include the initials or signatures of persons performing or checking each significant step in the operation. Fresenius Kabi USA LLC • The responsibilities and procedures applicable to the quality control unit are not fully followed. Medimmune • Re-usable spray bottles labeled as sterile are used for cleaning biosafety cabinets used for inoculating eggs as part of release testing of the bulk material used in manufacture of the product. Ranbaxy Laboratories Ltd. • Raw materials, intermediates and finished API analytical results found to be failing specifications or otherwise suspect are retested until acceptable results are obtained. These failing or otherwise suspect results are not reported. American Red Cross Blood Services • Records are not concurrently maintained with the performance of each significant step in the storage of each unit of blood and blood components so that all steps can be clearly traced. Lantheus MI Radipharmaceuticals, Inc. • When errors occurred or a production batch failed to meet specifications, you did not determine the need for an investigation, conduct an investigation and take appropriate corrective actions when necessary.

- 15. PAGE 14 PHARMA UPTODAY Audit Findings 483 Observations: PureTek Corp. • There is a failure to thoroughly review any unexplained discrepancy and the failure of a batch or any of its components to meet any of its specifications whether or not the batch has been already distributed. Emcure Pharmaceuticals USA, Inc. • Written procedures have not been developed for the evaluation of post marketing adverse drug experiences. Formula Corp. • Control procedures are not established which monitor the output and validate the performance of those manufacturing processes that may be responsible for causing variability in the characteristics of in-process material and the drug product. LNK International, Inc. • Control procedures are not established which monitor the output and validate the performance of those manufacturing processes that may be responsible for causing variability in the characteristics of in-process material and the drug product. CMIC CMO USA Corp. • There is a failure to thoroughly review the failure of a batch or any of its components to meet any of its specifications whether or not the batch has been already distributed. B. Braun Medical, Inc. • There is a failure to thoroughly review any unexplained discrepancy and the failure of a batch or any of its components to meet any of its specifications whether or not the batch has been already distributed. Brisas del Caribe Corp. • Laboratory controls do not include a determination of conformance to appropriate specifications for drug products. Jerome Stevens Pharmaceuticals, Inc. • Investigations of an unexplained discrepancy did not extend to other batches of the same drug product and other drug products that may have been associated with the specific failure or discrepancy.

- 16. PAGE 15PHARMA UPTODAY Audit Findings 483 Observations: Morton Grove (Wockhardt) Pharmaceuticals, Inc. FDA 483 • The responsibilities and procedures applicable to the quality control unit are not in writing and fully followed. • Laboratory controls do not include the establishment of scientifically sound and appropriate test procedures designed to assure that components, drug product containers, in-process materials, and drug products conform to appropriate standards of identity, strength, quality and purity. • Laboratory records do not include a complete record of all data secured in the course of each test, including all graphs, charts, and spectra from laboratory instrumentation, properly identified to show the specific component, in-process material, lot tested, and drug product tested. Trial injections do not include documentation of sample weights and preparation of sample solutions. In addition trial injection chromatogram data cannot be traced to a documented sample solution prep. Chromatograms from trial injections are not always kept with the testing record. Analytical data on the hard drive of the instrument is with no assignable project folder. • Appropriate controls are not exercised over computers or related systems to assure that changes in master production and control records or other records are instituted only by authorized personnel. Some laboratory instruments are accessed through a general windows login accessible to all personnel and are not configured with administrative restrictions. • The written stability testing program is not followed. • There is a failure to thoroughly review any unexplained discrepancy and the failure of a batch or any of its components to meet any of its specifications whether or not the batch has been already distributed. • The quality control unit lacks authority to review production records to assure that no errors have occurred and fully investigate errors that have occurred. • Changes to written procedures are not drafted, reviewed and approved by the appropriate organizational unit and reviewed and approved by the quality control unit. • Time limits are not established when appropriate for the completion of each production phase to assure the quality of the drug product. • Buildings used in the manufacture, processing, packing or holding of drug products are not maintained in a clean and sanitary condition. • GMP training is not conducted to assure that employees remain familiar with CGMP requirements applicable to them. • Production personnel were not practicing good sanitation and health habits.

- 17. PAGE 16 PHARMA UPTODAY Audit Findings Warning Letters: Greer Laboratories Inc 1. You failed to manufacture drug products in the manner described in your approved BLA. You combine various types and amounts of your licensed allergenic extracts to produce allergenic “custom mixtures;” however, you have not obtained a license to manufacture and distribute these combined product mixtures, as required by 21 CFR 610.17. 2. You failed to establish and follow written procedures that describe the in-process controls, and tests, or examinations to be conducted on appropriate samples of in-process materials of each batch, in order to monitor the output and to validate the performance of those manufacturing processes that may be responsible for causing variability in the characteristics of the in-process material and the drug product [21 CFR 211.110(a)]. 3. You failed to assure an adequate system for monitoring environmental conditions [21 CFR 211.42(c)(10)(iv)]. 4. You failed to perform the general safety test for the detection of extraneous toxic contaminants on biological products intended for administration to humans as required by 21 CFR 610.11(c). Specifically, there is no documentation of the observation of each test animal every working day following injection with the allergenic test material, including any animal response which is not specific for or expected from your product. 5. You failed to thoroughly investigate any unexplained discrepancy or the failure of a batch or any of its components to meet any of its specifications [21 CFR 211.192]. 6. You failed to demonstrate that the drug product containers and closures used in the manufacture of your allergenic products are not reactive, additive, or absorptive so as to alter the safety, identity, strength, quality, or purity of the drug beyond the official or established requirements [21 CFR 211.94(a)]. Specifically, extractable and leachable studies have not been conducted on the (b)(4) stoppers used in the manufacture of your allergenic products. 7. You failed to establish the reliability of the supplier’s certificate of testing through appropriate validation of the supplier’s test results at appropriate intervals [21 CFR 211.84(d)(3)]. 8. You failed to maintain buildings used in the manufacture, processing, packing, or holding of your allergenic products in a clean and sanitary condition and free of infestation by insects [21 CFR 211.56]. Investigations QAINV 12-015 and QAINV 13-010 were conducted in response to a continuing trend of live insects being observed in the aseptic filling suite, (b)(4). Live insects were observed during and after filling operations. Further, your corrective actions implemented as a result of the investigations were inadequate in that live insects continued to be observed in these areas. Source: http://www.fda.gov/ICECI/EnforcementActions/WarningLetters/2014/ucm395263.htm

- 18. PAGE 17PHARMA UPTODAY Audit Findings Warning Letters: Sun Pharmaceutical Industries Limited - Karkhadi 1. Failure to ensure that laboratory records included complete data derived from all tests necessary to ensure compliance with established specifications and standards. a. Your firm is missing the fundamental raw data and information necessary to document your analyses. For example, these analyses lack the following critical data: b. Your firm frequently performs “unofficial testing” of samples, disregards the results, and reports results from additional tests. For example, during stability testing, your firm tested a batch sample six times and subsequently deleted this data. 2. Failure to assign and identify raw materials with a distinctive code, batch, or receipt number, and to identify the disposition of materials. a. Your firm failed to exercise appropriate controls over computer or related systems to assure that only authorized personnel institute changes in master production and control records, or other records (21 CFR 211.68(b)). E.g. The software (“GC Solutions”) on the computers used to control the GC instruments allowed your analysts to delete files from the computer’s hard drive with no audit trail or other adequate form of traceability in the operating system to document the deletion activity. When a raw data file was deleted or moved out of the designated folder, the next file recorded into the folder would be saved with an identical name as the deleted file. As a result, data can be manipulated so that saved files appear to be in sequence even if they were not generated sequentially. b. Your firm failed to maintain written production, control, or distribution records specifically associated with a batch of a drug product for at least one year after the expiration date of the batch (21 CFR 211.180(a)). E.g. calibration check record for balance #FI-002 was torn and partially destroyed. Corrective action and preventive action (CAPA) records (form F03-QA-076/01) were torn. Five completed preventive maintenance forms were torn. 3. Your firm failed to ensure that each person engaged in the manufacture, processing, packing, or holding of a drug product has the education, training, and experience, or any combination thereof, to enable that person to perform his or her assigned functions (21 CFR 211.25(a)). Source : http://www.fda.gov/ICECI/EnforcementActions/WarningLetters/2014/ucm397054.htm

- 19. PAGE 18 PHARMA UPTODAY Audit Findings Warning Letter: SANUM-Kehlbeck GmbH & Co. KG API CGMP VIOLATION 1. Drug substance production of highly sensitizing materials, such as penicillin, were not performed in dedicated production areas, which include facilities, air handling equipment and/or process equipment. CGMP DRUG PRODUCT VIOLATIONS 1. Your firm failed to perform operations related to the manufacture, processing, and packing of penicillin in facilities separate from those used for other drug products for human use (21 CFR 211.42(d)). 2. Your firm failed to establish and follow appropriate written procedures that are designed to prevent microbiological contamination of drug products purporting to be sterile, and that include validation of all aseptic and sterilization processes (21 CFR 211.113(b)). 3. Your firm failed to ensure that manufacturing personnel wear clothing appropriate to protect drug product from contamination (21 CFR 211.28(a)). 4. Your firm failed to ensure that each person engaged in the manufacture, processing, packing, or holding of a drug product has the education, training, and experience, or any combination thereof, to enable that person to perform his or her assigned functions (21 CFR 211.25(a)). 5. Your firm failed to establish and follow adequate written procedures that describe the in-process controls, and tests, or examinations to be conducted on appropriate samples of in-process materials of each batch, to assure batch uniformity and integrity of drug products (21 CFR 211.110(a)). Source : http://www.fda.gov/ICECI/EnforcementActions/WarningLetters/2014/ucm397240.htm Grandpa's Compounding Pharmacy 1. Your firm failed to establish an adequate air supply filtered through high-efficiency particulate air filters under positive pressure in the aseptic processing areas (21 CFR 211.42(c)(10)(iii)). 2. Your firm failed to establish and follow appropriate written procedures that are designed to prevent microbiological contamination of drug products purporting to be sterile, and that include validation of all aseptic and sterilization processes (21 CFR 211.113(b)). 3. Your firm failed to ensure that manufacturing personnel wear clothing appropriate to protect drug product from contamination (21 CFR 211.28(a)). 4. Your firm failed to establish an adequate system for monitoring environmental conditions in aseptic processing areas (21 CFR 211.42(c)(10)(iv)). 5. Your firm does not have, for each batch of drug product purporting to be sterile and/or pyrogen- free, appropriate laboratory determination of satisfactory conformance to final specifications for the drug product (21 CFR 211.167(a)). Source : http://www.fda.gov/ICECI/EnforcementActions/WarningLetters/2014/ucm396239.htm

- 20. PAGE 19PHARMA UPTODAY EHS Consultancy & Training Services Would like to offer services pertaining to EHS (Environment, health and safety) to enable business enhancement and continuity through high level of EHS and Fire protection systems and thereby minimize national wealth drain and pain. • By understanding EHS gaps and bridging them. • By regular EHS training, education, awareness & competence building. • By suggesting economically viable and practicable actions and measures. • By outsourcing certain routine but important EHS related activities You may like to patronize, support and avail the benefits. Services offered: • EHS training: for improvement & meet legal requirements (with training material) • Safety Audits: for improvement & meet legal requirements (with documented reports) • Providing assistance and undertaking EHS related jobs (with documented reports) For additional information and charges please contact bhupeshu158@gmail.com Bhupesh H. Upadhyay Experience: 34 years Formerly Vice President EHS - Alembic pharma, Vadodara; General Manager EHS - Ranbaxy Labs Limited, Mohali &Toansa. (B. Tech Industrial Engg., B.Sc., PGDIS, PGDIM, Lead auditor ISO-14001 & BS:OHSAS-18001, Six- sigma green belt.) Phone: +919915082436 Email: bhupeshu158@gmail.com Advertisement Plot No. 51and 52, Prashanthi Nagar, Kukatpally, Hyderabad- 500 072 E mail: sreechemanalyticalservices@gmail.com M/s. Sreechem Analytical Services Pvt. Ltd. is a testing laboratory which is approved by DCGI and ISO certified company established in 2003. It does all pharmaceutical testing in the areas of chemical and microbiology. It does test all raw materials well as finished products and well equipped with instrumentation like HPLC, GC, FTIR, dissolution apparatus etc. Sreechem provide services to bulk drug industries as well as formulation units. Contact : Dr. Y. Jyothi, Managing Director Mobile no. : (+91)7702540516 Advertisement SREECHEM ANALYTICAL SERVICES PVT.LTD.

- 21. PAGE 20 PHARMA UPTODAY PharmaUptoday: What are the challenges in the quality testing of parenterals? Balagopal: Unlike solid orals, parenterals are always manufactured in low concentrations (as low as 2mcg/ml) and they are administered when patient’s life is in danger or during surgical procedures. Parenterals give quick therapeutic effect when compared with any other type of dosage forms. Any inadvertent error in quality control testing would result in ‘life threatening situation of the patient’. In that prospective, most challenging part in the quality testing of parenterals is ‘accuracy in pippetting and dilutions’.. PharmaUptoday: How can we ensure data integrity in quality control units? Balagopal: Ensuring data integrity is not the responsibility of one person or group of persons. It is the responsibility of every one in quality control unit. The term ‘data integrity’ is always interlinked with ‘personal character’ of honesty and integrity. In present scenario, it would be difficult to find people who uphold the personal character as it was not taught in the education of 16-20 years that we undergo and the competitive world in which we live in. So, it may not be fair to expect the new comer in to Pharma industry to have an attitude of ‘personnel character’. It would be even worse to expect from the personnel who are already in the industry from reasonably good length of time. The only way that works is; quality control unit managements shall create an environment, so that people can escalate the failures / deviations that would occur in day to day work as they occur or found. When someone escalates a failure / deviation, managements shall give an utmost priority for investigation to find out the root cause and not assume / decide ‘what would have gone wrong’. Sharing of the errors / deviations with the team is the best way that would help in eradicating the ‘data integrity’ issues in quality control laboratories. Balagopal Reddy Gudibandi Currently Site Quality Control Head – AurobindoPharma Limited, Unit – IV (Parenterals). Guest of the Month

- 22. PAGE 21PHARMA UPTODAY Guest of the Month PharmaUptoday: Can you suggest few check points to ensure compliance in QC laboratories especially for parenterals? Balagopal: Round the clock compliance shall be the objective. To ensure, that we have to have a mechanism of review of every activity that is being planned to execute. Traditional thinking of ‘review for compliance’ shall be changed to ‘execute with compliance and review online’ irrespective wither the activity is priority or not. PharmaUptoday: How can Indian pharma industries get back the confidence from US FDA for Data integrity? Balagopal: As long as we think of satisfying someone, it may be difficult to gain the confidence of US FDA. Establish the system in such a way that compliance is part of every action that is planned. Everyone who is working in the Pharma industry should feel that he / she is responsible for ensuring the compliance. When compliance is the ‘mantra’ of every one, the question of ‘data integrity’ does not arise. ‘Transparency’ is only the way that can bring the confidence of US FDA or any other regulatory agency on ‘data integrity’. Indians tend to follow ‘Yes boss’ concept. This shall be replaced with ‘Why should we do this way boss’ PharmaUptoday: Please give a message to Pharma Uptoday readers to ensure compliance? Balagopal: Know completely what you are going to do. Don’t attempt to conduct trail. Document what is done. Escalate the deviations if any as they occur / found. Ensure the investigation / review happened online. Working in Pharma industry is not rocket science. Balagopal Reddy Gudibandi Currently Site Quality Control Head – AurobindoPharma Limited, Unit – IV (Parenterals).

- 23. PAGE 22 PHARMA UPTODAY Subpart I--Laboratory Controls § 211.160 General requirements. (b) Laboratory controls shall include the establishment of scientifically sound and appropriate specifications, standards, sampling plans, and test procedures designed to assure that components, drug product containers, closures, in-process materials, labeling, and drug products conform to appropriate standards of identity, strength, quality, and purity (4) The calibration of instruments, apparatus, gauges, and recording devices at suitable intervals in accordance with an established written program containing specific directions, schedules, limits for accuracy and precision, and provisions for remedial action in the event accuracy and/or precision limits are not met. Instruments, apparatus, gauges, and recording devices not meeting established specifications shall not be used. § 211.165 Testing and release for distribution. (a) For each batch of drug product, there shall be appropriate laboratory determination of satisfactory conformance to final specifications for the drug product, including the identity and strength of each active ingredient, prior to release. Where sterility and/or pyrogen testing are conducted on specific batches of shortlived radiopharmaceuticals, such batches may be released prior to completion of sterility and/or pyrogen testing, provided such testing is completed as soon as possible. (b) There shall be appropriate laboratory testing, as necessary, of each batch of drug product required to be free of objectionable microorganisms. (c) Any sampling and testing plans shall be described in written procedures that shall include the method of sampling and the number of units per batch to be tested; such written procedure shall be followed. (d) Acceptance criteria for the sampling and testing conducted by the quality control unit shall be adequate to assure that batches of drug products meet each appropriate specification and appropriate statistical quality control criteria as a condition for their approval and release. The statistical quality control criteria shall include appropriate acceptance levels and/or appropriate rejection levels Regulations of the Month To get the previous issue of March& April 2014, browse the below link http://www.slideshare.net/skvemula/pharma-uptoday-mm-volume-1-issue-april-2014 http://www.slideshare.net/skvemula/pharma-uptoday-volume-2-issue-may-2014