Erp software for textile

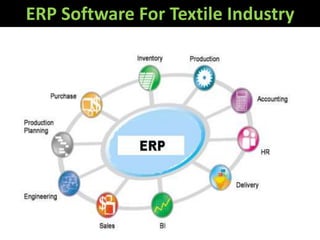

- 1. ERP Software For Textile Industry

- 2. Prepared By : Mazadul Hasan sheshir ID: 2010000400008 13th Batch (session 2009-2013) Department : Wet Processing Technology Email: mazadulhasan@yahoo.com Blog : www. Textilelab.blogspot.com (visit) Southeast University Department Of Textile Engineering I/A 251,252 Tejgaon Dhaka Bangladesh Prepared By : ©right

- 3. An exploratory Assignment of ERP systems in textile manufacturing was in conducted 2013. The Assignment investigated the following issues: Introduction 1. What functions are included in textile ERP systems? 2. Who are the vendors of ERP systems used in Textiles? 3. What are the main factors in selecting an ERP system? 4. What are the barriers to implementing ERP systems? 5. What functions are linked with textile ERP systems? 6. Are companies using electronic commerce?

- 4. Enterprise Resource Planning is Software for running a business. ERP was coined as an extension of the concept of manufacturing resource-planning (MRP) software, which automated the process of keeping a manufacturing line supplied with materials to meet incoming orders. ERP is a suite of applications including financials, manufacturing, human resources and other modules, that together automate the back-office business administration functions of an enterprise. Leading ERP vendors include SAP, Oracle, People soft and JD Edwards. Enterprise Resource Planning refers to the integration and extension of a business's operational IT systems, with the end goals of making information flow within (and beyond) a company more immediate and dynamic; increasing the usefulness and shelf life of information; eliminating redundancy and automating routine processes; and making information system components more flexible. Departmental boundaries generally become softer, accessibility of data is increased for partner companies and customers, and the company's ability to respond to the marketplace is generally enhanced. Enterprise Resource Planning is the latest high-end solution information technology has lent to business application. The ERP solutions seek to streamline and integrate operation processes and information flows in the company to synergies the resources of an organization namely men, material, money and machine through information. Initially implementation of an ERP package was possible only for very large Multi-National Companies and Infrastructure Companies due to high cost involved. Today many companies in India have gone in for implementation of ERP and it is expected in the near future that 60% of the companies will be implementing one or the other ERP packages since this will become a must for gaining competitive advantage Description :

- 5. ERP (Enterprise resource planning) can be defined as a software solution that addresses the enterprise needs taking the process view of the organization, to meet the organizational goals tightly integrating all functions of an enterprise It is an industry term for the broad set of activities supported by multi-module application software that help a manufacturer or other business manage the all the parts of its business. ERP facilitates integration of company-wide information systems with the potential to go across companies. Definition

- 6. ERP - Definition “Software solution that addresses the Enterprise needs, taking a process view of the overall organization to meet the goals, by tightly integrating all functions and under a common software platform”

- 9. 1. Do we know that our bottom lines profits are down but we do not know why? 2. Do we have clear visibility of all our orders through all stages of production and fulfillment process? 3. Can we keep optimum inventory level in warehouse? 4. Are we able to plan appropriate of all the orders through all the resource available in the production floor(like sewing lines/dyeing machines/weaving looms)so that every production step completes on time & delivery dates can be met? Industries often face difficulties to find out answers of following queries-

- 10. Why ERP? For Management – to know what is happening in the company One solution for better Management For cycle time reduction To achieve cost control & low working capital To marry latest technologies To shun the geographical gaps To satisfy the customers with high expectations To be Competitive & for survival

- 11. Traditionally the textile industry is highly concerned with the design or manufacture of clothing as well as the distribution and use of textiles. However, the industry has been changed extremely in the last few yearsFlexibility and rapid response has become essential qualities for any successful textile business. Achieving them requires dynamic management of the entire organization. Eresource ERP system maintains the benefits of a standard package with a high level of adaptability, ensuring that the solution can be tailored to almost any requirement. Its modules could be configured to the needs of any textile business, whatever its size. Eresource ERP provides a framework within which textile industries can organize their business and manufacturing know-how to create a vital management resource. Of course industry decision makers have to have rapid access to company data, but the most pressing need is to have answers to critical questions such as "What happens if...?", "How can we...?". 1. How important is ERP in textile industries? 2. Is resource ERP a suitable?

- 12. Technology Support Costs 5 Strategic Requirement Levels Functionality Goal: To select the Most Suitable Software Package Solution Vendor ERP Product selection Criteria

- 13. 1. Framing ERP Implementation Strategies 2. Formation of Apex & Steering committees 3. Functional & IT team formation 4. Training on ERP functions & features 5. Scope finalization 6. GAP analysis 7. Action plan to resolve the gaps Preparation Phase

- 14. Benefits 1. Increase operational efficiencies, maximize cash flow & ROI. 2. Reduce order-cycle times. 3. Always maintain inventories at proper levels. Reduce wastage of Materials 4. Make quick business decisions using real-time 5. Manage in-house and job work production React to changing business needs swiftly Built by experts in Fashion business 6. Low cost of ownership

- 15. Garment industry specific functionalities. Fe at ur es 1. Multi Company Multi Language Multi Currencies Manage processes from Spinning / Knitting / Weaving / Dyeing to Production in a single system 2. Project and monitor production/sourcing 3. Track raw materials availability automatically 4. Monitor production orders real time 5. Visual Dashboards for easy access 6. Reliable technology platform that supports a high volume of transactions 7. Modular functions for need based implementation 8. Smooth flow of information across the company and outside Features of ERP

- 16. 1. Easily monitoring of an industry: 2. Compiling report within a very short time 3. No chance for data manipulation 4. Saving time 5. Easy access anywhere from the world Benefits of ERP in Textile?

- 17. Benefits of ERP in Textile? Easily Monitoring of an Industry: A large number of textile & garments are coming into operations every year in Bangladesh, and entrepreneurs are moving towards expansion of their business. Therefore,it is too tough for management to monitor closely since there are so many divisions-like for o knit composite knitting,dyeing,sewing,all are maintained in separate plant but in synchronized manner;again there are so many departments marketing,merchandising, production,commercial, administrative-it is quite difficult to maintain MIS(management information system through manual operations and it is yet time consuming to prepare all reports manually for the management.

- 18. Benefits of ERP in Textile? Compiling Report Within a Very Short Time: ERP enterprise resource planning can handle exclusive report both on daily basis and summary type to give operational visibility, and take a good second to find out any of reports from the system. When the reports are compiled manually(even through excel sheet), it often so tough to get the actual scenario of order wise production process, planned dates item availability in warehouse etc. since a concurrent date has been entered in the system on-time huge time will be saved and management will get a perfect picture online of what is happening actually in the production flood and again optimum inventory level can be maintained, therefore that allocation of money can be invested in order areas of concern.

- 19. Benefits of ERP in Textile? No Chance for Data Manipulation: With the use of ERP data manipulation can’t take place as authorized users will use the system and there will be a log file maintaining which person is dealing with what, so in that way it would be easy to track. And as all the departments are integrated under one crown, it should be an orchestrate process flow Saving Time: Any information once entered in the system, need not to re-enter again. Among many ERP solution vendors,datatex is one of the leading ERP solution providers keeping in mind the necessities of textile & apparel industry.datatex ERP solution now network oriented world has been dedicated only towards textile & apparel sector and has been able to build large customer base(400+customers in 42 countries worldwide).

- 20. Easy Access Anywhere from the World: It is completely web based solution so can be accessed anywhere from the world .crucial area that need more attention by management. Problems in Production Planning: With many rushed production orders, it is difficult for a planner to plan the tasks to carry out in the production floor considering both the resources (machineries and equipment, raw material) and limitations at hand. Benefits of ERP in Textile?

- 21. Sales order entry: considering color size combinations, creation of preformed invoice, shipping document, salesinvoice, picking of finished goods, packing list generation, handling letter of credit facilities. Inventory: availability of raw materials/work-in progress/ finished goods per lot,container,batch wise,order wise. Procurement: requisition, approvals,purchase order creation, receiving goods through receiving document. Functions of ERP Software’s:

- 22. Functions of ERP Software’s: Production: production steps with consumption breakdown, starting and end dares, waste calculation, and production progress tracking. Costing: pre-costing by merchandisers and actual costing from raw materials in reality utilized in production floor. Managing dye house: a lot of wastage comes from dyeing industry that certainly increases the fabric price. ERP software facilitates dye house management. Providing chemical inventory, batch management system,daily production report with waste calculation, recipe creation, lab-management, actual cost calculation reprocess dyeing etc. in their recognized ERP system.

- 23. System Implementation Respondents were asked what they thought were the main barriers to implementing an ERP system. The most frequently cite barriers were: •Resistance to change •Lack of top management support •User training & education Some of the other issues that were mentioned included cost, having the right project team, lack of a clear view of the function of ERP, and that textiles does not follow and ERP business flow. Umble and Umble describe 10 categories of ERP implementation failures which area as follows: 1. Poor leadership from top management 2. Automating existing redundant or non-value-added processes 3. Unrealistic expectations, 4. Poor project management 5. In adequate education and training 6. Trying to maintain the status quo 7. Mismatch between the system capabilities and and the organizations processes and procedures 8. Inaccurate data 9. Implementation viewed as an IT project 10. Significant technical difficulties.

- 24. Textile ERP projects appear to have the same difficulties as all other ERP implementations. As stated in Bobbin magazine both Pillowtex and Crown Crafts inc. had problems implementing their ERP systems. As summarized in Figure the median time to implement an ERP system was 12-18 months. Several of the respondents were still implementing their ERP system. Fifty-six percent of the systems were identified as being fully integrated and another thirty-two percent were labeled as being integrated within a business unit. System Implementation

- 28. ERP Software Solution for Textiles Industries Finance ERP, Spinning ERP, Yarn Dyeing ERP, Technical Textiles ERP, Weaving ERP, Asset Management ERP, HRMS, Swing Thread ERP

- 29. Quality Management in eresource ERP is 100% configurable module. This module allows a wide variety of characteristics and parameters to be specified in the stand inspection operation and maintain an extensive history to improve product quality and identify recurring problems. Eresource ERP Quality Management allows the quality department to define its own quality test cases required at different juncture of production, beginning from quality check required during the inward of raw materials. Further Quality Characteristics, parameters and expected results, under each quality process check can be configured without any programming assistance. The material inspection sub system offers a wide range of capabilities for process supervision and control. These capabilities are fully integrated with the other modules such as purchasing, inventory management and shop floor control function to ensure that the right quality control procedures are followed. Capabilities include on-line maintenance of product specifications by production method and customer, event driven sample requests, sample log-in, test results entry; quality performance analysis and equipment calibration support is available in eresource ERP. Quality Management by ERP in Apparel Industry

- 30. Use Of ERP in Apparel Industry : • Production Planning & Control • Manufacturing Resource Planning (MRP II) • Material Requirement Planning(MRP) • Master Production Schedule • Customer Relationship Management (CRM) • Bill of Material (BOM) • Warehouse Management • Inventory Management • Purchasing Management • Shop Floor Control (SFC) • Capacity Requirements Planning (CRP) • Cost Reporting/Management • Lot Traceability • Engineering Change Control • Repetitive Manufacturing • HR Management • Plant Maintenance • Service Management • Finance Management • Purchase Order Management • Quote Management • Quality Management

- 31. Benefits of ERP in apparel industry Reduction in cycle time: As of now, allocation of material to specific customer order is not possible with the current system. Such allocations are useful for making deliveries as planned, as there is no possibility of the material, which is required by one order, getting consumed for different order. In such cases earlier order would get delayed if material were not available in the stock while production time is spent on other order, which could have waited without causing any problem. Cost savings: Company losses 2% of its sales value in discounts, which are the result of surplus production, implementing quality management system can help to bring down excess production, as management will be assured of the quality right from the raw material itself. Supplier developer module would be useful in proper selection of suppliers, which can focus on quality, cost and delivery aspects of supplier. Reduction in machinery downtime: 5 % machinery downtime is attributed to non-availability of raw material in the stores. This is due to absence of proper planning system and due to communication delays at every place because of information recompiling. Prompt communication coupled with effective supplier selection module and planning system would be useful in bringing down the machinery downtime.

- 32. Improvement in sales: 75 % customers place repeat orders. Three factors-price, order and delivery affect orders. Integrated system will definitely be useful on this account. Price is one of the causes of losing customers; there is ample scope for cost reduction and therefore company can offer lower prices and incentives to attract customers through integrated information management solution. Customer satisfaction: Current system is ineffective in tracking problems related to customers. The response regarding effectiveness falls in unsatisfactory category. Capacity planning for received order also falls in average category. Efficient capacity management system can bring down the delivery time for execution of the order and improve customer satisfaction. This management scheme can be very useful in maintaining better customer relations with prompt response and by knowing their past history. Well –formulated procedures for customer dialog will be useful in having better customer relations. It takes approximately 3 days to answer any of customer’s queries. This period can be brought down to a day, which will have very good impact on customer’s perception of the oganisation. Benefits of ERP in apparel industry

- 34. Apparel ERP Software Features 1. Sales inquiry from Customers 2. Standard Costing and Quotation to customers For Single garments For “PACK” – Set Articles For Assortments Allows multiple versions of costing Allows calculation of selling price based on expected profit margin Approval of costing 3. Product Development Flexible Bill of Material (BOM) rules Detailed BOM based on BOM rules Standard Process Flow (SAM) Styling Details for Apparel Lab Dip for Fabric Submission of Samples and approvals from Customers 4. Pre-production Critical Path 5. Sales Order booking 6. Purchase Budgets for each sales order 7. Customer Compliance management for factories 8. Managing Nominated Suppliers per customer 9. Managing contractors (job-work units) MARKETING & MERCHANDISING

- 36. Benefits of ERP in Knitting industry KnitManager is an MIS software for small to large Knitting Dyeing organizations. Its a production management software which can monitor and analyze all of the production parameters of a typical knitting dyeing factory from LC to order processing to dyeing to delivery. KnitManager for Knitting consists of mainly 5 (four) modules – 1. Order Management 2. L/C Management 3. Planning & Scheduling 4. Production Management 5. Inventory Management

- 37. Requirements of Successful ERP Software For A Textile Dye-House Management • Test for the harmful azo colorants in textiles • Datacolor Learning Resources • Efficient Water Utilisation in Textile Wet Processing • Comprehensive View on Garment Dyeing and Finishing • PANTONE for Fashion and Home Color Chooser 3.0 • PANTONE® TEXTILE Color Chooser • Denim Product Development – An Analysis • Sourcing Strategies in Clothing Retail Firms: Product Complexity Versus Overseas Supply Chain • Requirements of Successful ERP Software For A Textile Dye-House Management • Problems With Fiber Reactive Dyeings Not Repeating - A Look at Five Typical Cases • Troubleshooting In Dyeing Part I & II

- 38. • Dirty Laundry - a Greenpeace report on China's Textile Industry • Test for the harmful azo colorants in textiles • Datacolor Learning Resources • Efficient Water Utilisation in Textile Wet Processing • Comprehensive View on Garment Dyeing and Finishing • PANTONE for Fashion and Home Color Chooser 3.0 • PANTONE® TEXTILE Color Chooser • Denim Product Development – An Analysis • Sourcing Strategies in Clothing Retail Firms: Product Complexity Versus Overseas Supply Chain • Requirements of Successful ERP Software For A Textile Dye-House Management • Problems With Fiber Reactive Dyeings Not Repeating - A Look at Five Typical Cases • Troubleshooting In Dyeing Part I & II • Dirty Laundry - a Greenpeace report on China's Textile Industry Requirements of Successful ERP Software For A Textile Dye-House Management

- 40. The ERP system needs regular maintenance in order to function properly. The ERP plan needs revision and updating as per the changing situations in the organization. We have already seen that the ERP system should be reviewed regularly. The review comments and suggestions should be incorporated into the system. Also the ERP system needs fine- turning as the employees become familiar with it. Once the ERP system has reached a stable state necessary action should be taken to improve the performance. The ERP tools that are implemented are another area that needs maintenance. The project manager should be in regular contact with the vendors to see whether any upgrades or updates are available. All patches and upgrades should be installed to ensure that the tools are working at their maximum efficiency. Employees should be given refresher courses on the new functionality that gets added with each new upgrade. The training documentation should also be updated so that it is in sync with the procedures and processes. What is the importance of ERP maintenance phase?

- 41. ERP Software Software Name Website ACS Optima www.cgsinc.com/softwaresolutions/index.html Bann www.baan.com BPCS www.ssagt.com Datatex www.datatex-tim.com Intenia MovexFashion www.intentia.com/w2000.nsf/Index J D Edwards www.jdewards.com PointMan www.pivotpoint.co.uk SAP www.sap.com SyteFashion None found

- 42. Systems Linked to ERP Function Software Website Advanced Planning & Scheduling 1. I2 2. Manugistics www.i2.com www.manugustics.com Business Intelligence Board www.board.com Customer Resource Management Omina Financials & Accounting Forecasting 1. Futurion 2. Demand Solutions www.futurcast.com www.demandsolutions.com Manufacturing Execution Systems Camstar www.camstar.com Supply Chain Management i2 www.i2.com

- 43. Materials: ( ERP in Textile ) Production Planning Software - Materials is a comprehensive and user-friendly system covering all areas related To Materials management. The Materials system of the following modules.

- 44. Engineering: Define Units and Conversion Rules Define items and their detailed properties Define Bill of material for each product Material Requirement Planning : Define Production Plan Carry out BOM explosion for the plan and generate Materials requirements Generate MRP on any interval and create Purchase requisitions based on MRP Plan Purchase Define Payment Terms and Standard Purchase Terms Define Sales Tax Rules, Customs & Excise Rules for each item (as applicable) Create Vendor-Item Catalog Send Request for Quotation to vendors Enter quotation received and perform comparative analysis Approve quotation for purchases Create P.O. on-line based requisitions Suspend, cancel or close P.O. (if required) Create Delivery Schedule Releases Create P.O. Amendments (if required) Track Complete amendment history» Assess vendor performance To Materials management. The Materials system of the following modules

- 45. Sales : Production Planning Software - Sales is a comprehensive, flexible and user-friendly system covering all areas related to sales. The sales system consists of the following modules. Distribution Planning : Define each Product and its complete details such as Pack Size, Weight etc. Group products by Product Groups for planning , reporting and analysis Group marketing areas by Zone, Regions and Territories Define Depot wise Sales Forecast Create Depot Distribution Plans based on Sales Forecast and Inventories held Create Depot Dispatch Schedules from Distribution Plan and Production Plan Finished Goods Inventory : Enter all stores transactions on-line Track stocks Batch wise with manufacturing and expiry date details Print Stock Statements and Stock Ledgers instantly with ultra-fast processing engine Print Excise Bond Stock Statement (RG-1) To Materials management. The Materials system of the following modules

- 46. Inventory Control : Enter all stores transaction on-line Track all material by Batch No./Lot No. Generate stock ledgers instantly Value inventory based on several methods Create various analysis reports (ABC, XYZ, FSN, VED) Quality Control : Define comprehensive Quality Control specification for each item Access GRNs awaiting Q.C. on-line Access Test Intimations from Production Generate Q.C. register for items/batches to be analyzed and print Sampling Slips Update test results on-line and match with standards to approve or reject material Print Test Certificates Post accepted/rejected quantities in stock ledger online» Track rejections by vendors as well by items Depot Inventory : Record F.G. receipt by Depots Record Depot Sales Record Inter-Depot Transfers Generate Depot wise Stock Statement and various other reports including Depot wise Sales, Product wise Sales, Region wise Sales To Materials management. The Materials system of the following modules

- 47. Sales: Maintain finished products price lists Comprehensive Pricing Model provides you Define state wise Sales Tax , Trade Discounts, Retailer’s Margins Automatically calculate Net Trade Prices and Assessable Rates (for Excise) Define Free Quantities under Schemes Create state wise price lists for various states for items with uniform M.R.P Maintain extensive Customer’s information Process Request for Quotations Process Sales Orders Create Dispatch Orders from Sales Orders Create Dispatch Order from Depot Dispatch Schedule Create Sales Invoices, Depot Stock Transfer Notes and Excise Gate Pass Registration For Free ERP Software Print Sales Register Print Daily Stock & Sales Statement Print various other reports Fully integrated with A/c Receivables To Materials management. The Materials system of the following modules

- 49. Production Planning and Control

- 50. GARP ERP System: Product: It is necessary to estimate the consumption rate of a material by primary calculation. Then a decision is made for the price setup of the material.

- 51. Product Life Cycle Management (PLM): Now all CAD companies include PLM in their software system because PLM system allows to go back to design library at any time to reprocess and reuse the data. Designer can change the design in different ways as they wish. Design can be converted easily into specification sheet and these design are stored in organized way in a central servers where authorized persons can use the data whenever needed rather than using individual memory. PLM gives the best collaboration facility within internal and external global supply chain partners. Every task is determined by collaborating with different departments through time and action calendars and workflow can co-ordinate with all parties' activity to launch the product within a shorter time- to-market. Operational, planning, and business management report of PLM helps people to manage and work more efficiently.

- 52. Textile companies are looking for ERP solutions to fit their specific needs. Both generic and textile specific packages are been used in the industry. The barriers to implementation in textiles seem similar to those in other industries. Textiles uses electronic commerce in the form of traditional EDI, but not electronic marketplaces, which have see lots of changes in the last year. Textile companies are looking to integrate their ERP systems with supply chain management and business intelligence systems. The Gartner group has now coined the phrase ERP II . ERP II systems address the issues of sharing information across the supply chain with trading partners. It is expected that these systems will not be deployed till 2005; however, companies will move towards this new model. Software vendors will provide solutions for specific industries. What will be the textile specific requirements for these new ERP II systems? Conclusions

- 53. ©right

- 54. 1. Yarn Manufacturing Technology Link : http://www.facebook.com/pages/Yarn-Manufacturing-Technology/485014954866808 2. Fabric Manufacturing Technology Link : http://www.facebook.com/pages/Fabric-Manufacturing-Technology/459520217425605 3. Garments Manufacturing Technology Link : http://www.facebook.com/pages/Garments-Manufacturing- Technology/472364799463126 3. Wet processing Technology Link : http://www.facebook.com/pages/Wet-Processing-Technology-Dyeing-/468645219825404 4. Fashion-Design-and-Technology Link : http://www.facebook.com/pages/Fashion-Design-and- Technology/587655294583875?ref=ts&fref=ts My Facebook Textile related Pages http://www.textilelab.blogspot.com (Visit My Blog for more Info )