Reliability Engineering Blended Learning Training

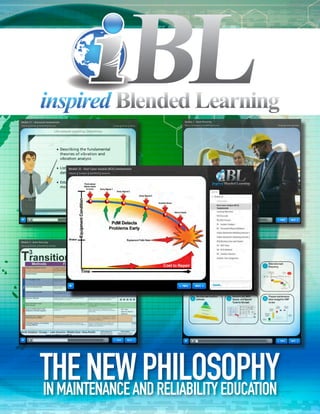

- 1. THE NEWAND RELIABILITY EDUCATION IN MAINTENANCE PHILOSOPHY

- 2. THE SOLUTION GPAllied’s inspired Blended Learning empowers participants to take control of their learning experience through instructor-led classes, online curriculum, and skill applications within your facility or industrial environment. GPAllied’s inspired Blended Learning is aimed at maximizing the value of training for our clients. Advanced adult learning techniques drive documented return on training dollars through the use of: Direct Real world Face-to-face eLearning Video Application examples Instruction iBL IS AIMED AT MAXIMIZING BUSINESS CASE THE VALUE OF TRAINING GAINS Tough to get training dollars? Let iBL help you build your business case. We can help you define FOR OUR CLIENTS. your project and calculate projected return on investments for your iBL training program. As opposed to traditional training, inspired Blended Learning is driven by direct application at your site. Upon completion of each Learning Project, participants will t n me be able to demonstrate the new knowledge, as well as document the return on training investment. GPAllied’s inspired Blended Learning enables organizations ls st to: S kil Inve of on Expand the capabilities of existing Maintenance and Reliability on urn ti Engineers et en Ret Develop new Maintenance and Reliability Engineers to meet growing R needs Expect to see documented operating costs decrease, revenues increase, or both Ensure retention and documentation of the learning and the results through virtual learning project coaching Build a successful reliability improvement project plan by completing activities following each of the learning modules

- 3. 3-STEP PROCESS eLearning Modules 1 Asset Health Management • Introduction to AHM • Preparing the Asset Catalog • Analyzing Asset Criticality • Vibration Analysis Fundamentals • Ultrasound Fundamentals • Thermography Fundamentals • LEARNING PROJECT Motor Circuit Analysis Fundamentals • Oil Analysis Fundamentals • KICKOFF Reliability-based Lubrication Fundamentals • Selecting Quantitative PMs • Evaluating PM Program Effectiveness Participants attend a one-week Learning Project Kickoff • Direct Application and Coaching on Asset Health Management at GPAllied’s headquarters in Charleston, SC. The focus in your Facility of the kickoff is to build a learning process foundation by Work Execution Management Overview providing exposure to the core philosophies • Introduction to WEM of the discipline selected. • Introduction to Planning & Scheduling 2 • Direct Application and Coaching on Work Execution Management in your Facility Developing Effective Work Procedures • Creating a Job Map • Writing Effective PM Procedures • Establishing Standard Work • Direct Application and Coaching on Developing Effective Work Procedures in your Facility eLEARNING Reliability Centered Maintenance • Creating a Job Map Through the iReliabilityTM Learning Management System, • Writing Effective PM Procedures • Establishing Standard Work GPAllied delivers interactive, virtual modules. Each • Direct Application and Coaching on Reliability Centered module begins with a discussion of a singular concept Maintenance in your Facility using animated graphics that break the concept down Root Cause Analysis into manageable bits of information. Some animations are • Introduction to RCA interactive, allowing the student to manipulate the graphic • RCA Fundamentals • Facilitating a Transparency-based RCA in order to simulate various scenarios and further enhance • Facilitating a Tree-based RCA the learning objective. Activities such as quizzes, matching • Facilitating a Time-based RCA exercises, and fill-in-the-blank exercises are then used to • Introduction to Failure Mechanisms • Identifying Common Mechanical Failure Modes reinforce comprehension level learning objectives. • Identifying Common Electrical Failure Modes • Identifying Common Stationary Failure Modes 3 • Creating RCA Corrective Action Reports • Direct Application and Coaching on Root Cause Analysis in your Facility Reliability Engineering • Introduction to Reliability Statistics • Calculating Process Reliability • Calculating Overall Equipment Effectiveness • Calculating Life Cycle Costs PRACTICAL APPLICATION • • Modeling System Reliability Calculating Maintainability Following each eLearning module, the GPAllied Coach • Writing an Asset Validation Procedure • Introduction to Energy Management will engage with the attendee for a total of 160 hours of • Management of Change Fundamentals additional guidance. Coaches will employ the iReliabilityTM • Direct Application and Coaching on Reliability Engineering in your Facility Learning Management System to deliver custom-designed tasks and real world, on-site applications of core skills Materials Management Optimization to blend learning objectives and skills applications while • Creating an Equipment Bill Of Materials • Calculating MRO Inventory Metrics facilitating the improvement of your maintenance reliability • Establishing Just-In-Time Inventory Controls program. GPAllied utilizes the R5 Rapid Improvement • Direct Application and Coaching on Materials Management Optimization in your Facility Process structure to execute the Learning Project.

- 4. apid Improvement and Reliability Maintenance Process apid Improvement Process Engineering Core Skills Development Maintenance and Reliability Engineering Core Skills Development RECOGNIZE RATIONALIZE RATIFY Learning Selection of Map Project Complete Present Project Enroll in Task Candidates Work to Project Project Philosophy Curriculum Assignments and Focus Sessions Charter Charter Fundamentals Lines Reliability Additional Skills Centered Development Maintenance Leadership Session (RCM) Alignment to Charter Failure Life Cycle Cost Reporting and Analysis Corrective Action System Asset Health Management Reliability (Electrical and Statistics Energy) Asset Health Root Cause Management Complete Case Advanced Analysis (RCA) Certification (Mechanical) Study Awarded Consideration Presented RESOLVE REALIZE North America • Latin America • Europe • Middle East • Asia-Pacific World Headquarters GPAllied EMEA 4200 Faber Place Drive Guldensporenpark 21-Blok C Charleston, SC 29405 B-9820 Merelbeke, Belgium o. 888.335.8276 o. +32(0)9.210.17.20 f. 843.414.5779 f. +32(0)9.210.17.28 info@gpallied.com • www.gpallied.com