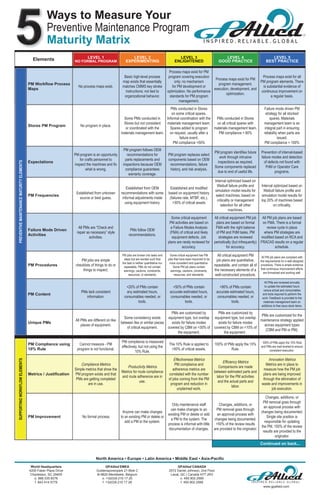

Preventive Maintenance Maturity Matrix 2013 version

- 1. Elements LEVEL 1 NOT ENGAGED LEVEL 2 EXPERIMENTING LEVEL 3 ENLIGHTENED LEVEL 4 GOOD PRACTICE LEVEL 5 BEST PRACTICE PM Workflow Process Maps No process maps exist. Basic high-level process map exists that essentially matches CMMS key stroke instructions; not tied to organizational behavior. Process maps exist for PM program covering execution only; no mechanism for PM development or optimization. No performance standards for PM program management. Process maps exist for PM program management, execution, development, and optimization. Process maps exist for all PM program elements. There is substantial evidence of continuous improvement on a regular basis. Stores PM Program No program in place. Some PMs conducted in Stores but not consistent or coordinated with the materials management team. PMs conducted in Stores on some critical spares. Informal coordination with the materials management team. Spares added to program on request, usually after a failure event. PM compliance <50% PMs conducted in Stores on all critical spares with materials management team. PM compliance > 80% Failure mode driven PM strategy for all stocked spares. Materials management team is an integral part in ensuring reliability when parts are issued. PM compliance = 100% Expectations PM program is an opportunity for crafts personnel to inspect the machines and fix what is wrong. PM program follows OEM recommendations for parts replacements and inspections because OEM compliance guarantees warranty coverage. PM program replaces select components based on OEM recommendations, failure history, and risk analysis. PM program identifies future work through intrusive inspections as required. Some components replaced due to end of useful life. Prevention of interval-based failure modes and detection of defects not found with PdM or Operator Care programs. PM Frequencies Established from unknown source or best guess. Established from OEM recommendations with some informal adjustments made using equipment history. Established and modified based on equipment history (failures rate, MTBF, etc.). >30% of critical assets Interval optimized based on Weibull failure profile and simulation model results for select machines; based on criticality or management selection for all other machines. Interval optimized based on Weibull failure profile and simulation model results for top 20% of machines based on criticality. Failure Mode Driven Activities All PMs are “Check and repair as necessary” style activities. PMs follow OEM recommendations. Some critical equipment PM activities are based on a Failure Modes Analysis (FMA) of critical and likely equipment defects. Job plans are rarely reviewed for accuracy. All critical equipment PM job plans are based on formal FMA with the right balance of PM and PdM tasks. PM strategies are reviewed periodically (but infrequently) for accuracy. All PM job plans are based on FMA. There is a formal review cycle in place where PM strategies are modified based on RCA and FRACAS results on a regular schedule. PM Procedures PM jobs are simple checklists of things to do or things to inspect. PM jobs are broken into tasks and steps but are worded such that the task is neither quantitative nor repeatable. PMs do not contain warnings, cautions, constraints, resources, or standards. Some critical equipment has PM jobs that have been improved to be more consistent and quantitative. Some PM job plans contain warnings, cautions, constraints, resources, and standards. All critical equipment PM job plans are quantitative, repeatable, and contain all of the necessary elements of a well-constructed procedure. All PM job plans are compliant with the requirements for a well-designed procedure. There is ample evidence that continuous improvement efforts are formalized and working well. PM Content PMs lack consistent information. <20% of PMs contain any estimated hours, consumables needed, or tools. <50% of PMs contain accurate estimated hours, consumables needed, or tools. >90% of PMs contain accurate estimated hours, consumables needed, or tools. All PMs are reviewed annually to update the estimated hours versus actual and consumables and tools required to perform the work. Feedback is provided to the materials management team on additions to free issue stock items. Unique PMs All PMs are different on like pieces of equipment. Some consistency exists between like or similar pieces of critical equipment. PMs are customized by equipment type, but overlap exists for failure modes covered by CBM on <30% of the equipment. PMs are customized by equipment type, but overlap exists for failure modes covered by CBM on <10% of the equipment . PMs are customized for the maintenance strategy applied across equipment types (CBM and PM or PM). PM Compliance using 10% Rule Cannot measure - PM program is not functional. PM compliance is measured effectively, but not using the 10% Rule. The 10% Rule is applied to >50% of critical assets. 100% of PMs apply the 10% Rule. 100% of PMs apply the 10% Rule and PMs are load leveled to ensure consistent execution. Metrics / Justification Compliance Metrics Simple metrics that show the PM program exists and that PMs are getting completed are in use. Productivity Metrics Metrics for route compliance and route adherence are in use. Effectiveness Metrics PM compliance and adherence metrics are correlated with the number of jobs coming from the PM program and reduction in unplanned work. Efficiency Metrics Comparisons are made between estimated parts and labor for the PM activities and the actual parts and labor. Innovation Metrics Metrics are in place to measure how the PM job plans are being improved through the elimination of waste and improvements in job execution. PM Improvement No formal process. Anyone can make changes to an existing PM or delete or add a PM to the system. Only maintenance staff can make changes to an existing PM or delete or add a PM to the system. The process is informal with little documentation of changes. Changes, additions, or PM removal goes through an approval process with changes being documented. >50% of the review results are provided to the originator. Changes, additions, or PM removal goes through an approval process with changes being documented. Single site position is responsible for updating the PM. 100% of the review results are provided to the originator. Continued on back... PREVENTIVEMAINTENANCEMATURITYELEMENTSPREVENTIVEMAINTENANCEMATURITYELEMENTSPREVENTIVEMAINTENANCEMATURITYELEMENTS Ways to Measure Your Preventive Maintenance Program Maturity Matrix LEVEL 1 NOT ENGAGED LEVEL 1LEVEL 1LEVEL 1LEVEL 1LEVEL 1LEVEL 1LEVEL 1LEVEL 1LEVEL 1LEVEL 1 NO FORMAL PROGRAMNO FORMAL PROGRAMNO FORMAL PROGRAMNOT ENGAGEDNO FORMAL PROGRAMNOT ENGAGEDNO FORMAL PROGRAMNOT ENGAGEDNO FORMAL PROGRAMNOT ENGAGED LEVEL 2 EXPERIMENTING LEVEL 2LEVEL 2LEVEL 2LEVEL 2LEVEL 2LEVEL 2LEVEL 2LEVEL 2LEVEL 2LEVEL 2 EXPERIMENTINGEXPERIMENTINGEXPERIMENTINGEXPERIMENTINGEXPERIMENTINGEXPERIMENTINGEXPERIMENTINGEXPERIMENTINGEXPERIMENTINGEXPERIMENTING ENLIGHTENED LEVEL 3 ENLIGHTENED LEVEL 3LEVEL 3LEVEL 3LEVEL 3LEVEL 3LEVEL 3 ENLIGHTENEDENLIGHTENEDENLIGHTENEDENLIGHTENEDENLIGHTENEDENLIGHTENEDENLIGHTENEDENLIGHTENEDENLIGHTENEDENLIGHTENEDENLIGHTENED LEVEL 4 GOOD PRACTICE LEVEL 4LEVEL 4LEVEL 4LEVEL 4LEVEL 4LEVEL 4LEVEL 4LEVEL 4LEVEL 4LEVEL 4 GOOD PRACTICEGOOD PRACTICEGOOD PRACTICEGOOD PRACTICEGOOD PRACTICEGOOD PRACTICEGOOD PRACTICEGOOD PRACTICEGOOD PRACTICEGOOD PRACTICE LEVEL 5 BEST PRACTICE LEVEL 5LEVEL 5LEVEL 5LEVEL 5LEVEL 5LEVEL 5LEVEL 5LEVEL 5LEVEL 5LEVEL 5 BEST PRACTICEBEST PRACTICEBEST PRACTICEBEST PRACTICEBEST PRACTICEBEST PRACTICEBEST PRACTICEBEST PRACTICEBEST PRACTICEBEST PRACTICE North America • Europe • Latin America • Middle East • Asia-Pacific GPAllied EMEA Guldensporenpark 21-Blok C B-9820 Merelbeke, Belgium o. +32(0)9.210.17.20 f. +32(0)9.210.17.28 www.gpallied.com World Headquarters 4200 Faber Place Drive Charleston, SC 29405 o. 888.335.8276 f. 843.414.5779 GPAllied CANADA 2572 Daniel Johnson, 2nd Floor Laval, QC | Canada H7T 2R3 o. 450.902.2569 f. 450.902.2568

- 2. Elements LEVEL 1 NOT ENGAGED LEVEL 2 EXPERIMENTING LEVEL 3 ENLIGHTENED LEVEL 4 GOOD PRACTICE LEVEL 5 BEST PRACTICE Quality of PM Inspection PM inspections are simple checklists of things to inspect. Some items on PM checklist detail specific faults to be identified, but no detail as to severity. Most items on PM checklist for critical equipment have defined degrees of severity. Most inspections are still qualitative in nature. Most items on all PM checklists have defined degrees of severity with some examples. Some items are quantitative. All PM inspections are quantitative in nature and have defined degrees of defect progression with examples for clarity. Each degree designates conditions as either “good”, “future work”, or “immediate work.” PM Activity Types PM activities are only inspections and lubrication tasks. Maintenance does all PM tasks. Maintenance does most inspections and lubrication tasks. Operations has only a few tasks on a few machines. PM activities include inspections, lubrication tasks, and adjustments/calibrations. Maintenance still has most tasks, but operations has some for almost all machines. PM activities include inspections, lubrication tasks, adjustments/ calibrations, and some interval-based replacements. Operations has most of the qualitative inspections, while maintenance has the quantitative inspections. PM program includes a mixture of clean, inspect, adjust, replenish, replace, and rebuild as activity types. Maintenance has the highly technical tasks requiring advanced machinery knowledge, techniques, and tools. Operations has all qualitative inspections and cleaning tasks, as well as basic lubrication, and adjustment responsibilities. PM Scheduling PM scheduling has no idea which PMs require downtime or how much. Some PMs include downtime requirements and are scheduled as the PM comes due. Some PMs are grouped by system and PM downtime is coordinated. PMs for critical machines are grouped and executed by system. System downtime is coordinated for all PM activities. All PMs are grouped by system for convenient scheduling. Each PM designates the required clock hours, labor-hours, and downtime hours for completion. Load Leveling System shows no concept of distributing PM loads across the balance of the required time period or with production demands. PM load is known and is sometimes distributed evenly across time window, though production demands usually override. PM load is known and at least the monthly PMs are distributed evenly across the month or coordinated with planned downtime. PM load is known and monthly and quarterly PMs are distributed evenly across the time window. PMs are leveled across the month, quarter, semi- annual, or annual time frame. There is no spike in the PM load unless coordinated with significant planned operational downtime. PM Procedure Creation Planner or engineer built PM procedure from OEM checklist or from past experience. A few PM procedures were built with technician input, but just for critical machines. Most critical machines have had PMs reviewed and modified by technicians. All critical machines and many other machines have had PMs reviewed and modified by teams of technicians for accuracy and required instructional detail. PM procedures were built in collaboration with technicians who regularly perform the work. Technicians provided required instructions and guidance on needed level of detail. PM Prioritization PMs worked into the schedule where possible. Weekly schedule contains most of the PM load but labor is redistributed as needed for emergency and high-priority work on a regular basis. Weekly schedule is base loaded with PM work. Critical PM activities are protected; lower criticality PM work may be substituted with emergency work as needed. PM work is rarely substituted with emergency work, but does happen on occasion. PM work is protected on schedule; no labor substitution happens, even during emergencies. Feedback Mechanism No feedback from crafts. >20% of PM procedures have crafts’ feedback when returned. >40% of PM procedures have crafts’ feedback when returned; critical feedback is processed by Planner. 90% of PM procedures have crafts’ feedback when returned; most feedback is processed by Planner. All PM procedures have crafts’ feedback when returned; all feedback is processed by Planner; feedback process is formalized. PM/PdM Balance Inspection plus Findings by Labor Hours by PM / PdM 100% PM and Results of PM / No PdM being performed. >50% Overall <5% PdM + Results >60% PM + Results >60% Overall <15% PdM + Results >50% PM + Results >70% Overall <30% PdM + Results >40% PM + Results >80% Overall 50% PdM + Results 30% PM + Results Route Adherence & Route Compliance Not measured . >30% of the PMs are completed with no measurement of call window adherence or route compliance. >50% of the PMs are completed within +/- 50% of the call window, with >50% route compliance. >75% of the PMs are completed within +/- 20% of the call window, with >75% route compliance. >90% of the PMs are completed within +/- 10% of the call window, with >95% route compliance. RESULTS/SCORECARDSRESULTS/SCORECARDSRESULTS/SCORECARDS Ways to Measure Your Preventive Maintenance Program Maturity Matrix LEVEL 1 NOT ENGAGED LEVEL 1LEVEL 1LEVEL 1LEVEL 1LEVEL 1LEVEL 1LEVEL 1LEVEL 1LEVEL 1LEVEL 1 NO FORMAL PROGRAMNO FORMAL PROGRAMNO FORMAL PROGRAMNOT ENGAGEDNO FORMAL PROGRAMNOT ENGAGEDNO FORMAL PROGRAMNOT ENGAGEDNO FORMAL PROGRAMNOT ENGAGED LEVEL 2 EXPERIMENTING LEVEL 2LEVEL 2LEVEL 2LEVEL 2LEVEL 2LEVEL 2LEVEL 2LEVEL 2LEVEL 2LEVEL 2 EXPERIMENTINGEXPERIMENTINGEXPERIMENTINGEXPERIMENTINGEXPERIMENTINGEXPERIMENTINGEXPERIMENTING ENLIGHTENED LEVEL 3 ENLIGHTENED LEVEL 3LEVEL 3LEVEL 3LEVEL 3LEVEL 3LEVEL 3 ENLIGHTENEDENLIGHTENEDENLIGHTENEDENLIGHTENEDENLIGHTENEDENLIGHTENEDENLIGHTENEDENLIGHTENEDENLIGHTENEDENLIGHTENEDENLIGHTENED LEVEL 4 GOOD PRACTICE LEVEL 4LEVEL 4LEVEL 4LEVEL 4LEVEL 4LEVEL 4LEVEL 4LEVEL 4LEVEL 4LEVEL 4 GOOD PRACTICEGOOD PRACTICEGOOD PRACTICEGOOD PRACTICEGOOD PRACTICEGOOD PRACTICEGOOD PRACTICE LEVEL 5 BEST PRACTICE LEVEL 5LEVEL 5LEVEL 5LEVEL 5LEVEL 5LEVEL 5LEVEL 5LEVEL 5LEVEL 5LEVEL 5 BEST PRACTICEBEST PRACTICEBEST PRACTICEBEST PRACTICEBEST PRACTICEBEST PRACTICEBEST PRACTICE North America • Europe • Latin America • Middle East • Asia-Pacific GPAllied EMEA Guldensporenpark 21-Blok C B-9820 Merelbeke, Belgium o. +32(0)9.210.17.20 f. +32(0)9.210.17.28 www.gpallied.com World Headquarters 4200 Faber Place Drive Charleston, SC 29405 o. 888.335.8276 f. 843.414.5779 GPAllied CANADA 2572 Daniel Johnson, 2nd Floor Laval, QC | Canada H7T 2R3 o. 450.902.2569 f. 450.902.2568