Bioprocessing

- 1. BY REHANA KHALIQ LucIAN BLAgA uNIvERsItY sIBIu

- 2. What is bio processing? 1. A technique that produces a biological material, such as a genetically engineered microbial strain, for commercial use. 2. Production of a commercially useful chemical or fuel by a biological process, such as microbial fermentation or degradation. To prepare, produce, or treat (a substance) by means of a bioprocess. In other words, a bioprocess consists of a cell culture in a bioreactor, which is a process able to create an optimal growth environment. The central object of a bioprocess is the cell. A living cell is a highly complex system which is often defined as the smallest autonomous biological unit.

- 3. BIopRocEss modELINg In order to improve process understanding or performance, different automatic tools can be developed: simulators able to reproduce system behaviors, software sensors which allow obtaining an estimation of an unmeasured signal or controllers to maintain optimal conditions. All these tools rely on a representation of the considered system, a mathematical model. Such a model may come in various shapes and be phrased with varying degrees of mathematical formalism. Once the model is established it can then be used, with reasonable confidence, to predict performance under differing process conditions, and used for process design, optimization and control. Input of plant or experimental data is, of course, required to establish or validate the model, but the quantity of data required as compared to the empirical approach is considerably reduced.

- 4. Fig. 1: Steps in model building

- 5. compARIsoN of tHE modELINg ANd EmpIRIcAL AppRoAcHEs Empirical Approach: Measure productivity for all combinations of plant operating conditions, and make correlations. Advantage: Little thought is necessary. Disadvantage: Many experiments are required. Modeling Approach: Establish a model and design experiments to determine the model parameters. Compare the model behavior with the experimental measurements. Use the model for rational design, control and optimization. Advantage: Fewer experiments are required and greater understanding is obtained. Disadvantage: Time is required for developing models.

- 6. General Aspects of the Modeling Approach A basic use of a process model is to analyze experimental data and to use this to characterize the process, by assigning numerical values to the important process variables. The application of a combined modeling and simulation approach leads to the following advantages: Modeling improves understanding. Models help in experimental design. Models may be used predicatively for design and control. Models can be used in training and education. Models may be used for process optimization.

- 7. StageS in the modeling procedure proper definition of the problem formulated in mathematical terms. Numerical methods of solution with digital simulation The validity of the solution depends on the correct choice of theory (physical and mathematical model), the ability to identify model parameters correctly and accuracy in the numerical solution method. Care and judgement must be taken such that the model does not become over complex

- 9. •dynamic modeling In a dynamic model the simple assumptions of a steady-state model – for example, that material always flows from an upstream unit where the pressure is higher to a lower pressure downstream pressure unit – may no longer be valid. Transients in the system may cause the “downstream” pressure to become higher than the “upstream” pressure, causing flow reversal; the model has to allow for this possibility. Flow reversal Equipment geometry Process control and control devices Modeling Examples: 1. Actuator System Models. 2. Sensor Models. 3. CST Thermal Mixing Tank.

- 10. Uses of Dynamic Models: Process Design Analysis of Process Control Approaches Operator Training Start-up/Shutdown Strategy Development Dynamic Balance Equations: Mass Balance Equation Mole Balance Equation Thermal Energy Balance Equation Fig. 4: Schematic of a System made up of an actuator, a process and a sensor.

- 11. Formulation oF Dynamic moDels Mass Balance Equations: Steady-State Balances: Basic principle is that of conservation of mass (Rate of mass flow into the system) = (Rate of mass flow out of the system) Dynamic Total Mass Balances: If a steady-state mass balance is inappropriate and must be replaced by a dynamic or unsteady-state mass balance, expressed as (Rate of accumulation of mass in the system) = (Rate of mass flow in) – (Rate of mass flow out) Here the rate of accumulation terms represents the rate of change in the total mass of the system, with respect to time, and at steady-state is equal to zero. (Rate of accumulation) = 0 = (Mass flow in) – (Mass flow out) Hence, when steady-state is reached (Mass flow in) = (Mass flow out)

- 12. chemical kinetics Rate of Chemical Reaction: d (V Ci) = ri V dt Expressed in terms of volume V and concentration C i. This is equivalent to with the units of moles/time. Here r i is the rate of chemical reaction, expressed as the change in the number of moles of a given reactant and product per unit time and per unit volume of the reaction system. EQUATION: rA = -k CA α CBβ Here, k is the reaction rate constant, C A, CB are the concentrations of the reactants A, B (moles/volume); (α+β) is the overall order of the reaction.

- 13. moDeling oF reaction kinetics Unstructured Kinetic Models: In unstructured models, all cellular components are pooled into a single biomass component represented by the total biomass concentration x. For specific growth rate µ = ƒ (s, p, x). Unstructured Model Based on the Monod (1942) Verbal Model: Even when there are many substrates, one of these substrates is usually limiting. This is the verbal formulation of the Monod (1942) Model: µ = µmax For example when the glucose is the limiting substrate the value of K s is normally in the micro molar range and it is experimentally difficult to determine and represent overall saturation constant for the whole growth process. Some of the most characteristic features of the microbial growth by the Monod Model: The constant specific growth rate at high substrate concentration The first order dependence of the specific growth rate on substrate concentration at low substrate concentrations

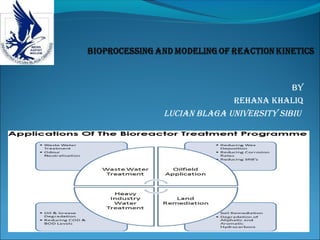

- 14. concept oF Bioreactor A bioreactor may refer to any manufactured or engineered device or system that supports a biologically active environment. This process can either be aerobic or anaerobic. These bioreactors are commonly cylindrical, ranging in size from litres to cubic metres, and are often made of stainless steel. A bioreactor may also refer to a device or system meant to grow cells or tissues in the context of cell culture. These devices are being developed for use in tissue engineering or biochemical engineering. On the basis of mode of operation, a bioreactor may be classified as batch, fed batch or continuous (e.g. a continuous stirred-tank reactor model). An example of a continuous bioreactor is the chemostat

- 15. continuous stirreD-tank reactor (cstr) The continuous stirred-tank reactor (CSTR), also known as vat- or backmix reactor, is a common ideal reactor type in chemical engineering. A CSTR often refers to a model used to estimate the key unit operation variables when using a continuous, agitated-tank reactor to reach a specified output. The mathematical model works for all fluids: liquids, gases, and slurries. Integral mass balance on number of moles Ni of species i in a reactor of volume constant density (valid for most liquids; valid for gases only if there is no net change in the number of moles or drastic temperature change) isothermal conditions, or constant temperature (k is constant) steady state single, irreversible reaction (νA = -1) first-order reaction (r = kCA) A → products NA = CA V (where CA is the concentration of species A, V is the volume of the

- 16. Fig. 3: Cross-sectional diagram of Continuous stirred-tank reactor

- 17. SenSor SyStemS An industrial feedback control loop is made up of a controller, an actuator system, a process, and a sensor system. Sensor systems are composed of the sensor, the transmitter, and the associated signal processing. The sensor measures certain quantities (e.g., voltage, currents or resistance) associated with devices in contact with the process such that the measured quantities correlate strongly with the actual controlled variable value. There are two general classifications for sensors: Continuous Measurements Discrete Measurements Continuous measurements are, as the term implies, generally continuously available while the discrete measurements update at discrete times. Pressure, temperature, level, and flow sensors typically yield continuous measurements while certain composition analyzers (e.g., gas chromatographs) provide discrete measurements.

- 18. Several terms are used to characterize the performance of a sensor : Span Zero Accuracy Repeatability Process measurement dynamics Calibration Temperature measurements: The two primary temperature sensing devices used in the CPI are thermocouples (TC’s) and resistance thermometer detectors (RTD’s). Pressure measurements: The most commonly used pressure sensing devices are strain gauges. Flow measurements: The most commonly used flow meter is an orifice meter. Level measurements: The most commonly type of level measurement is based upon measuring the hydrostatic head in a vessel using a differential pressure measurement. This approach works well as long as there is a large difference between the density of the light and heavy phases.