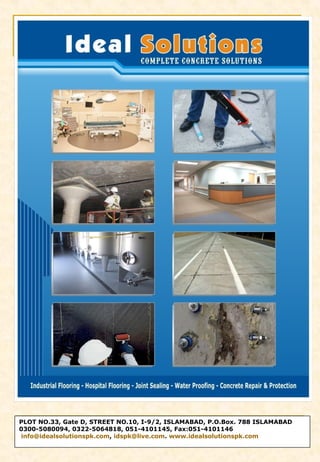

Our Services

- 1. PLOT NO.33, Gate D, STREET NO.10, I-9/2, ISLAMABAD, P.O.Box. 788 ISLAMABAD 0300-5080094, 0322-5064818, 051-4101145, Fax:051-4101146 info@idealsolutionspk.com, idspk@live.com. www.idealsolutionspk.com

- 2. ABOUT THE COMPANY IDEAL SOLUTIONS, was established in 2007 by a group of Construction & Chemicals professionals. The objective of the company is to provide its customers best possible services based on the latest construction techniques for saving time, money and misery. The well qualified teams behind the company posses rich experience of carrying out numerous application projects. The marketing & sales division is involved in sales of construction chemicals with technical back up to end users. We believe that a small business serves its customer better than larger competitors because we all meet directly with our customers and aren’t hidden away in a multi- layered corporate structure. We hear about your problems, what’s working and what’s not, and we get to know our customers better. OUR PHILOSOPHY At IDEAL SOLUTIONS, we strive to deliver results, perform to highest standards, develop our people, provide quality customer service and actively pursue consistent durability improvements. The corporate philosophy of the company is based on quality services for quality jobs with a clear understanding of the variations in the clients’ requirements; IDEAL SOLUTIONS tends to approach every project with an utmost flexibility. The client is assisted at every stage with tailor made solutions using wherever possible, readily available products. The underlying principle has always been to develop a lasting business relationship that is mutually beneficial. This approach is the core stone of the company’s success in the region, resulting in a reputation of impeccable quality backed by unmatched services. OUR VISION IDEAL SOLUTIONS, is organized for excellence, with a clear mission and vision, the determination and motivation to succeed. The company has always striven for greater heights and greater achievements, offering services that continuously exceed customers’ expectations, through excellent services and competitive prices in a timely manner. The company has seen dynamic growth and developed an outstanding reputation in Pakistan for all the products and services we provide. Our approach has earned us an image for quality service, integrity dependability and value for money approach. Our determination to continue this dynamic growth, banking on solid infrastructure, available financial and human resources and stable position holding in the market makes us confident of our strengths to enhance organic growth. www.idealsolutionspk.com

- 3. MANAGING DIRECTOR Rana Imran Ahmad Khan Rana Imran has a vast experience in the field of construction chemicals. He has represented different international companies in Pakistan WORDS OF CONFIDENCE “The success story of IDEAL SOLUTIONS has been the blend of skilled and efficient work force that has always worked extra miles to meet the clients’ requirements in the most efficient and cost effective manner. I am confident that my professionals are the best in the industry.” ORGANIZATIONAL CHART www.idealsolutionspk.com

- 4. OUR SERVICES We have upgraded our company as a “Total Solutions Company” for our customers busy in building construction and its maintenance. We have created some new divisions in our company to fulfill the requirements of our customers. WATERPROOFING BY CHEMICAL COATINGS WATERPROOFING BY BITUMEN EMULSION COATINGS WATERPROOFING BY BITUMEN MEMBRANES PU FOAM INJECTIONS FOR WATER LEAKAGE EPOXY INDUSTRIAL FLOORING SYSTEMS PU INDUSTRIAL FLOORING SYSTEMS PU / CR / ACRYLIC INDUSTRIAL PROTECTIVE COATINGS PU / PS EXPANSION JOINT SEALING SPALLED CONCRETE REPAIRS / HONEY COMBING REPAIRS CHEMICAL ANCHORING / DOWEL FIXING CORE / HAMMER CUTTING CONCRETE RE-STRENGTHENING BY CARBON FIBERS REINFORCED CONCRETE JACKETING CONCRETE PROTECTION COATINGS EPOXY INJECTIONS FOR CONCRETE CRACKS BUILDING PAINTS / COLOR SCHEMES BUILDING EXTERIOR COATINGS CONCRETE WORKS / BUILDING RENOVATIONS ANTI TERMITE TREATMENTS BOARDS/ SHEETS/ PU FOAM HEAT INSULATIONS CR / THERMOPLASTIC ROAD LANE MARKING PARKING LANE MARKING RUNWAY MARKING SIGN BOARDS & ROAD SAFETY MATERIALS www.idealsolutionspk.com

- 5. “WATERPROOFING” All structures require waterproofing – weather to keep water out (Basements), or to keep water in (reservoirs). Waterproofing a structure is a critical element of its design and construction. Water infiltration and leakage damage a building’s structure and its contents. Because of the damaging effect of water, one must pay particular attention in selecting a quality waterproofing system and applicators to provide proper in place performance. The best way to avoid the problem is through the proper design and careful selection of the waterproofing system. “JOINT SEALING” Joints are essential features of modern buildings and structures. They allow for shrinkage, contraction, expansion and other movements which cause tensile or compressive stress. Shear movements, design tolerances and breaks between phases of construction are also accommodated by joints. Joints can not be left open. Any kind of joint that might be penetrated by wind, dirt, water or other undesirable material needs to be sealed. After a building has been completed, joints are a small, usually unnoticed part of the whole. But if joints are not properly designed and sealed against wind and weather, the result can lead to total failure of the structure- larger the project, the greater the disaster. If the sealing of exterior joints is concerned with keeping the elements out, interior joint sealing fulfils rather different functions. In addition to ensuring a joint impenetrable to moisture, there are many other important considerations: hygiene, acoustics, interior décor and finishes-there are even aspects of safety. www.idealsolutionspk.com

- 6. “REPAIR AND PROTECTION OF REINFORCED CONCRETE” CONCRETE DECAY Visible Symptoms….. The decay of reinforced concrete is now a common sight around the world , Symptoms can include: Cracking, Sapling, Rusting of exposed steel reinforcement, Staining of concrete surfaces etc. Affecting Concrete Itself….. Attacks on concrete can be physical or chemical: •Physical Attack includes -Water erosion, Wind-borne sand erosion, abrasion by wheels, or machinery, impact damage, Overload, Fire, Freezing and thawing cycles in colder climates etc. •Chemical Attack includes: -industrial spillage of aggressive chemicals, action of sulphates in ground water, internal crystal growth (in hot climates), alkali-silica reaction (ASR), Typical Causes The many and varied causes of concrete ‘distress’ may be divided into two distinct categories: -attack on the concrete it self And…….. -those causing corrosion of embedded reinforcing steel Both can exacerbated by the shortcomings in the original construction process. Causing Corrosion Of Reinforcing Steel Corrosion of reinforcing steel is the most common reason for concrete distress. While many factors accelerate the process, there are two fundamental mechanisms which cause the problem: •Carbonation – the effect of carbon dioxide (and/ or other acidic gases) present in the atmosphere •Chloride attack – the contaminating effect of chloride ions which may be present from one or more of the following sources: -marine or costal locations, -use of road de-icing salts, -within the concrete matrix as a result of the use of contaminated raw materials during construction Due To Poor Workmanship….. The original construction process can be the source of many problems. The most common reasons include •Poor Concrete Mix Design •Poor Placement of steel reinforcement and shuttering •Inadequate Site Supervision during concrete placement Decay Aggravated By Ambient Conditions •Inadequate Concrete Vibration – failure to ensure Each of the following will accelerate the mechanisms proper compaction of deterioration described above: •Elevated temperatures, High humidity/rain, •Poor Curing Techniques – failure to ensure full strength Wet/dry cycling gain www.idealsolutionspk.com

- 7. “REPAIR AND PROTECTION OF REINFORCED CONCRETE” REPAIR METHODS Step 1: Remove the spalled concrete – Remove the concrete at the spalled areas to expose the corroded steel bars. Step 2: Clean and paint the corroded steel bars – Scrape and clean the exposed steel bars to remove the rust by using a wire brush, and apply two coats of anti-rust paint to the steel bars. Step 3: Patch – Apply a bonding agent to the affected surface before patching to ensure proper adhesion and Patch up the hacked area using polymer modified cement mortar. Step 4: Paint – Paint the area to match the rest of the ceiling. EPOXY CRACK INJECTION KITS The epoxy crack injection formula is another repair option for internal/ external small concrete wall and floor cracks. With the epoxy crack injection formula, it not only stops water from penetrating through the cracks once repaired it also has structural advantages. Epoxy injection provides structural strength due to the bonding of the concrete and epoxy material combination rather then just concrete, therefore the two materials create a superior bonding agent makes them stronger. Just be aware if the main structural damage is not initially resolved, this repair option is basically a waste of time and money. That’s why it’s so important; to always seek advice before attempting to repair concrete yourself. Surface Sealer For Crack Injection Most standard types of epoxy crack injection repair kits contain two parts, one jar is the epoxy content and the other is a surface sealer product. Surface sealers as part of an epoxy crack injection repair kit is an important formula which is applied after the cracks have been filled which provide short and long term protection. CEMENTOUS BASED CRACK INJECTION A cementous crack injection is one of the more versatile repair methods for medium to large concrete cracks and structural damages. The mixing content is mainly made up of high ratio of portland cement along with other small ratios of certain mixing materials and bonding agents that are poured into injection equipments. This method of crack injection is more often used by professionals for concrete walls and floors that are severely cracked or have structural damage. CARBON FIBER REINFORCEMENT Carbon fiber sheets may be used to reinforce some wall and concrete failures. Carbon fiber sheets are a form of pure polymerized carbon used as reinforcement in composite materials employed in vehicles and aircraft combining very high tensile strength with light weight and ease of deployment. Typically a carbon fiber sheet will be pressed against the repair area (such as a basement wall bulging in from lateral soil pressure) and bonded to the wall with epoxy. Some systems require attachments to floor or ceiling, while others do not. The carbon fiber sheets are very thin and thus non-obtrusive and may readily be painted over for an attractive finish. REINFORCED CONCRETE JACKETING Jacketing is one of the most frequently used techniques to strengthen reinforced concrete (RC) columns. With this method, axial strength, bending strength, and stiffness of the original column are increased. It is well known that the success of this procedure is dependent on the monolithic behavior of the composite element. To achieve this purpose, the treatment of the interface must be carefully chosen. The common practice consists of increasing the roughness of the interface surface and applying a bonding agent, normally an epoxy resin. Steel connectors are also occasionally applied. These steps involve specialized workmanship, time, and cost. Concerning the added concrete mixture and due to the reduced thickness of the jacket, the option is usually a grout with characteristics of self-compacting concrete (SCC) and highstrength concrete (HSC). www.idealsolutionspk.com

- 8. “INDUSTRIAL FLOORING” Floors in industry and commerce are not just parts of a structure. Industrial floors are heavily exposed to stress. Many production processes and procedures take place on these floors. They are also exposed to industrial chemicals. On top of this, industrial floors also have to meet a variety of operational requirements. Slip Resistance, Crack Bridging, Non-flammability, Conductivity, Aesthetics, Ease Of Maintenance, and, last but not least, Long Life – these are just a few examples of the expectations for functional industrial floors. CONCEPT Every industrial floor consist of two elements; Element 1, the base course, which always consists of the structural reinforced concrete slab. The purpose of this “load-bearing” course is to absorb or distribute static and dynamic loads. Element 2, the wearing course is the dominant part. The wearing course protects the floor from physical and/or chemical attack. The wearing course also has to meet the individual operational demands. Each element has its function, which is precisely defined. An industrial Floor can not be high – quality unless both the base course and the wearing course meet all of the requirements. www.idealsolutionspk.com

- 9. “INDUSTRIAL FLOORING” Two factors are particularly important in the Selection, Analysis And Preparation Of A construction or design of a high quality yet Suitable Substrate economic industrial floor: The second and equally important factor in selection of a suitable wearing course is the type of substrate and its - The Operational Requirements condition. Any wearing course can only be as good as its - The Selection, Analysis And Preparation Of A base. If the load- bearing course or substrate is Suitable Substrate. defective even the best and most expensive wearing course cannot improve it. To select the right coating system, both must be examined in detail and coordinated. This is 1. Base Courses/ Substrates the only way to ensure that the industrial - Concrete flooring meets the requirements of the - Cement/granolithic screed/overlay project – cost effective and just right for the - anhydrite screed application. - Magnesite screed - poured asphalt OPERATIONAL REQUIREMENTS - old coatings The application and the severity of the operational - Ceramic tiles requirements can vary widely. Below are a - Timber boards few examples of typical exposures; - Steel 1. Mechanical Exposure From: - Pedestrian 2. Location Of The Substrate and/or vehicular traffic, Low and light lift - Internal areas trucks, Transport containers, such as pallets, - External exposed steel mesh boxes, containers, drums, reel - On garde /no d.p.m holders etc., Weight of - Risk of rising damp tools/products/machines, Abrasion, shock - without insulation and impact (broken glass etc) 3. Substrate Condition - Age (new or old), Moisture content, 2. Chemical Attack From: - Oil, greases, - surface profile Soluble salts, Alkalis, acids, Fuels, solvent, - Density Cleaning agents etc - Porosity 3. Thermal Stress From: -Heat: Short term - Brittle by steam cleaning etc, Long term in specific - Dehydrated production areas. - Cold: Short term by - Physical strength shock, open doors, etc, Long term in specific - Compressive production areas, cold storage etc. - Pull-off - surface harness 4. Weathering, Mainly On External Surfaces, From: - Sunlight, UV, Frost, 4. Contamination thermal shock, Rain. - Dust, laitance - Oils, greases 5. Aesthetics - Colour, design/coding, - Acids, alkalis Coloured chips, Gloss/ Matt - Paints, plastics 6. Surface Texture - Smooth, Textured - Fuels, solvents 5. Damages 7. Safety - Slip resistant, Electrically insulating, - Shrinkage, isolation or settlement cracks conductive, Crack-bridging, Waterproof, - Sapling, voids Non-flammable, Decontaminable, Colour - Roughness, erosion stable, Low – odour, environmentally - Joint damage, broken arises friendly, solvent free 8. Care And Maintenance: - Easy to clean, Easy to repair, Overcoat able 9. Comfort - Insulating effect (warm), Dampening effect, Sound deadening www.idealsolutionspk.com

- 10. “BUILDING PAINTS / COLOR SCHEMES” Just as an outfit can enhance or mar the image of a person, the quality and visual appeal of painting can do the same for your home interiors. Picking house paint colors isn't just difficult. It's terrifying! Pick colors that are blah, and your house will seem flat and featureless. But if the colors you pick are too bold, they might overwhelm the architecture... and upset the neighbors. The best colors will highlight the most beautiful features of your home. Skillful use of color can even disguise design flaws, boosting the curb appeal and market value of your home. Additionally, the cost of painting being so high, it is all the more important to take wise and efficient decisions with regard to painting. PREPARING FOR THE JOB Ensure that the plaster on the walls is fully dried before the commencement of the paint job. In case, there is any seepage on the walls, ensure that the fault is fully rectified. Remove electric plates and cover all sockets & switches with tape. Cover the floor with plastic sheeting to avoid paint spilling on the floor. Ensure to use only high-quality POP material to provide a better base for paint colours. CHOOSING THE RIGHT PAINT For most paint jobs, water-based paints are a good choice as they dry faster. Flat finishes are ideal in hiding minor imperfections on the wall surfaces, but they don't have a shine. Velvet finishes are ideal to enhance the visual appeal of your home interiors and are easy to clean. Glossy and semi-glossy finishes are also good options as they have a durable finish and can easily withstand scrubbing. Satin paints are excellent to give a warm and inviting look to your rooms. CHOOSING THE RIGHT COLOUR This may be the toughest choice as regards painting is concerned. While choosing colours, it may be helpful to consult an interior designer, as the choice of paint colour would set the theme for the complete interiors. You would have to choose the colours of the upholstery and furniture accordingly. For ceilings, it is best to go in for light and sober shades as they give a spacious look to the rooms. In fact, white and off-white are ideal shades for ceilings. In case of wall colours, choice should be made on the basis of age-group and personality of the inhabitants. For example, light pink can be a great shade for a young girl's room. In case of boys, you can be more experimental. All shades have specific effects on the moods of a person: •Blue and off-white are soothing shades. •Shades of red can be stimulating for the mind. •Orange is excellent for kitchen and dining room as it stimulates the appetite. •Using purple is a great way of creating a royal ambience. www.idealsolutionspk.com

- 11. “EXTERIOR COATINGS” Stucco or render is a material made of an aggregate, a binder, and water. Stucco is applied wet and hardens to a very dense solid. It is used as a coating for walls and ceilings and for decoration. Stucco may be used to cover less visually appealing construction materials such as concrete, cinder block, or clay brick and adobe. www.idealsolutionspk.com

- 12. “TERMITE PROOFING” Termites are a group of eusocial insects that, until recently, were classified at the taxonomic rank of order Isoptera but are now accepted as the epifamily Termitoidae, of the cockroach order Blattaria. While termites are commonly known, especially in Australia, as "white ants," they are not closely related to true ants. Like ants, some bees, and wasps—which are all placed in the separate order Hymenoptera—termites divide labour among castes, produce overlapping generations and take care of young collectively. Termites mostly feed on dead plant material, generally in the form of wood, leaf litter, soil, or animal dung, and about 10 percent of the estimated 4,000 species (about 2,600 taxonomically known) are economically significant as pests that can cause serious structural damage to buildings, crops or plantation forests. Termites are major detritivores, particularly in the subtropical and tropical regions, and their recycling of wood and other plant matter is of considerable ecological importance. As eusocial insects, termites live in colonies that, at maturity, number from several hundred to several million individuals. Colonies use decentralised, self-organised systems of activity guided by swarm intelligence to exploit food sources and environments that could not be available to any single insect acting alone. A typical colony contains nymphs (semi-mature young), workers, soldiers, and reproductive individuals of both genders, sometimes containing several egg-laying queens. Termite pre-treatment to new structures is one of the things that everybody should do. It is so cheap, and so effective, when you compare it to post construction treatments, but you'd be surprised as to how few buildings are actually pre-treated. Wise and savvy architects always specify pre- treatment, knowledgeable builders include it in every structure they erect, and prospective buyers should demand it for any new house they buy or build. Pre-treatment is far better than post treatment. Post treatment (after you get termites) is actually a "spot" treatment. You can drill a thousand holes, but there will still be places you can't reach, no matter how hard the exterminator tries. With a proper pre-treatment, the soil next to the foundations is treated with a termiticide and is sealed in after the foundations are in place. As shown in the following pictures, treatment is applied during construction, at certain times, depending on the type of structure. Properly treated structures are sometimes able to resist termites for a much longer period of time, and termiticides applied during construction are generally applied to areas that are unavailable after construction is complete. This one fact would tend to make pre-treatments preferable to post treatments. www.idealsolutionspk.com

- 13. “HEAT INSULATIONS” Thermal insulation is the reduction of the effects of the various processes of heat transfer between objects in thermal contact or in range of radiative influence. Heat is the transfer of thermal energy between objects of differing temperature. The means to stem heat flow may be especially engineered methods or processes, as well as suitable static objects and materials. Heat flow is an inevitable consequence of contact of objects of differing temperature. Thermal insulation provides a means to maintain a gradient of temperature, by providing a region of insulation in which heat flow is reduced or thermal radiation is reflected rather than absorbed. In building construction, insulating materials are assigned a quantitative measure of the insulating capability, called the R- value. The R-value is a measure of thermal resistance used in the building and construction industry. Under uniform conditions it is the ratio of the temperature difference across an insulator and the heat flux (heat transfer per unit area, ) through it or .The R- value being discussed is the unit thermal resistance. This is used for a unit value of any particular material. It is expressed as the thickness of the material divided by the thermal conductivity. Maintaining acceptable temperatures in buildings (by heating and cooling) uses a large proportion of global energy consumption. When well insulated, a building: •is energy-efficient, thus saving the owner money. •provides more uniform temperatures throughout the space. There is less temperature gradient both vertically (between ankle height and head height) and horizontally from exterior walls, ceilings and windows to the interior walls, thus producing a more comfortable occupant environment when outside temperatures are extremely cold or hot. •has minimal recurring expense. Unlike heating and cooling equipment, insulation is permanent and does not require maintenance, upkeep, or adjustment. Many forms of thermal insulation also reduce noise and vibration, both coming from the outside and from other rooms inside a building, thus producing a more comfortable environment. www.idealsolutionspk.com

- 14. “HEAT INSULATIONS” R VALUE COMPARISON OF MATERIALS Some common roofing materials and their corresponding values for Thermal Conductance (C) and Thermal Resistance (R) are shown in the following table. Material Thickness In C-Value R-Value Inches Metal N/A 0.000 0.00 Concrete 1.0 3.333 0.30 Gypsum 1.0 1.667 0.60 Wood 1.0 1.099 0.91 Tectum 1.0 0.500 2.00 Inside Air Film N/A 1.087 0.92 Outside Air Film - Summer N/A 4.000 0.25 Outside Air Film - Winter N/A 5.882 0.17 Vapor Retarders N/A 0.000 0.00 BUR Gravel N/A 2.941 0.34 BUR Smooth N/A 4.167 0.24 Fiberboard 1.0 0.360 2.78 Perlite 1.0 0.360 2.78 Phenolic Foam* 1.0 0.120 8.30 Fiber Glass 1.0 0.256 3.90 Polyisocyanurate 1.0 0.180 5.56 Polyisocyanurate Composite 1.5 0.240 4.17 Polystyrene Bead Board 1.0 0.280 3.57 Polystyrene Composite Board 1.5 0.301 3.32 Polystyrene - Expanded (EPS)** 1.0 0.260 3.85 Polystyrene - Extruded (XEPS)*** 1.0 0.200 5.00 Sprayed Polyurethane Foam**** 1.0 0.150 6.88 Cork 1.0 0.280 3.57 www.idealsolutionspk.com

- 15. “HEAT INSULATIONS” MERITS & DEMERITS OF MATERIALS Spray Polyurethane Foam (SPF) - Spray foam insulation is an expanding foam which is sprayed on concrete slabs or on wall cavities of unfinished walls or through holes drilled into finished walls. The foam expands to fill bypasses and resists air infiltration. Spray foam insulation can be used in small quantities to fill tight spaces while increasing structural stability and providing sound insulation. Due to expansion, installation of SPF is not recommended in closed cavities like stud walls with drywall, lath-and-plaster or sheetrock. Many spray foam products need to be protected from sunlight and solvents and most can release toxic fumes when burning. R Value of many spray foam insulation products will ultimately diminish and foam can shrink while curing if not applied at the correct temperature. Rigid Panels - All rigid panels are strong and lightweight and provide thermal and sound insulation. The panels are water resistant and will not rot. It will protect the foundation and add to the structural strength of walls. Rigid panels have a high R Value and works well in cramped or tight spaces. However, all panels are flammable and release toxic fumes when burning. They are also vulnerable to damage from UV light and solvents, and can be used as termite nests. Structural Insulated Panels (SIP) - Also referred to as stressed-skin walls. They consist of plywood, strandboard or drywall that is glued around a core of expanded polyurethane, polyisocyanurate , polystyrene, compressed wheat straw or epoxy, and can be used for ceilings, floors, walls and roofs. These panels vary in thickness and are glued together and secured with lumber. SIPs provide sound insulation and strength in a home and resist moisture, but are more expensive than other insulation types. Fiberglass Batts & Blankets - Typically made with 20 to 30 percent recycled industrial waste and similar post consumer content. This material is not flammable, with the possible exception of its facing. Fiberglass blankets are provided in continuous rolls while batts are precut. Blankets can cover joists and studs, as well as the space between them but can be difficult to hang under floors between joists. Gaps between batts can defeat the purpose of the insulation because they invite air infiltration or condensation. Cotton Batts - Sometimes known as Blue Jean Batts. Cotton batts have a higher R Value than the average fiberglass batts and are made with recycled content, no toxic substances. There is no risk of airborne fibers causing cancer. Cotton batts are often difficult to cut to fit the cavity. Unlike cellulose or expanding foam, batts will not totally seal the cavity against air transfer. Loose Fill / Blown In Insulation (Including Cellulose) - Materials can be blown in to attics, finished walls and tough to reach areas. The loose fill material can also be sprayed in with a water-based adhesive. It is environmentally friendly, consisting of 80 percent recycled newspapers, and is less of a health hazard to the installer than fiberglass. Loose fill insulation does not seal bypasses as effectively as foam. If materials are heavy, there is a risk of sagging ceilings. Some of its effectiveness can diminish over time due to material settling. Aerogels - High performing, low density material used for skylights, solariums. Aerogels provide the best form of insulation using a combination of silica and carbon, allowing light to enter while absorbing heat from the sun. Straw Bales - Compressed straw bales are being used more often in recent years due to a high R Value and low cost. The effectiveness can be greatly reduced by moisture or air pockets. Radiant Barriers - Effectively prevents the transfer of radiant heat, equally, in both directions. Types of radiant barriers include foil or foil laminates. Foil backed bubble packs are thin and flexible and are often used as vapor barriers for cold pipes, ducts and roof sheathing. Foil faced polystyrene panels are more flexible than rigid panels and operate as a thermal break as well as a vapor barrier. These are used on roofs and should not be used to fill cavities. Other radiant barrier methods can be as simple as light colored roofs and reflective paint, or metal roofs made of aluminum or copper. R Value cannot be determined for radiant barriers. www.idealsolutionspk.com

- 16. “LANE MARKING” ROAD SURFACE MARKING is any kind of device or material that is used on a road surface in order to convey official information. They can also be applied in other facilities used by vehicles to mark parking spaces or designate areas for other uses. Road surface markings are used on paved roadways to provide guidance and information to drivers and pedestrians. Uniformity of the markings is an important factor in minimizing confusion and uncertainty about their meaning, and efforts exist to standardise such markings across borders. However, countries and areas categorize and specify road surface markings in different ways. Road surface markings are either mechanical, non-mechanical, or temporary. They can be used to delineate traffic lanes, inform motorists and pedestrians or serve as noise generators when run across a road, or attempt to wake a sleeping driver when installed in the shoulders of a road. Road surface marking can also indicate regulation for parking and stopping. There is continuous effort to improve the road marking system, and technological breakthroughs include adding reflectivity, increasing longevity, and lowering installation cost. A LANE is a part of the roadway (British: carriageway) within a road marked out for use by single line of vehicles to the control and guide drivers so reduce conflicts. Most public roads (highways) have at least two lanes, one for traffic in each direction separated by Lane markings. Major highways often have two roadways separated by a median, each with multiple lanes. A single-track road carries traffic in both directions within a single lane with passing places to allow vehicles to pass. CR PAINT Paint, sometimes with additives such as reflective glass beads, is generally used to mark travel lanes. It is also used to mark spaces in parking lots or special purpose spaces for handicap parking, loading zones, or time restricted parking areas. Colors for these applications vary by locality. Paint is a low-cost marking and has been in widespread use since approximately the early 1950s. Paint is usually applied right after the road has been paved. THERMOPLASTIC One of the most common types of road marking based on its balance between cost and performance longevity, thermoplastic binder systems are generally based on one of three core chemistries: hydrocarbons, rosin esters or maleic modified rosin esters (MMRE). Thermoplastic coatings are generally homogeneous dry mixes of binder resins, plasticizers, glass beads (or other optics), pigments, and fillers. Their use has increased over paints mainly due to the performance benefits of increased durability, retro-reflectivity, and a lack of VOC solvents. Thermoplastic markings are applied using specially designed vehicles. The thermoplastic mix is heated in trucks to about 200 °C (400 °F)before being fed to the application apparatus. This is often a screed box or ribbon gun. Immediately after the thermoplastic has been applied, glass beads are laid onto the hot material so that they embed before the plastic hardens. These beads provide initial retro-reflection. As the marking wears during use and the initial beads are lost, the beads mixed with the binder are uncovered, providing long term reflectivity. Most thermoplastic is produced in white and yellow colors. www.idealsolutionspk.com

- 17. “RUNWAY MARKING” According to ICAO a runway is "A defined rectangular area on a land aerodrome prepared for the landing and take-off of aircraft." Runways may be a man-made surface (often asphalt, concrete, or a mixture of both) or a natural surface (grass, dirt, gravel, ice, or salt). There are runway markings and signs on most large runways. Larger runways have a distance remaining sign (black box with white numbers). This sign uses a single number to indicate the thousands of feet remaining, so 7 will indicate 7,000 ft (2,134 m) remaining. The runway threshold is marked by a line of green lights. Airport runways and taxiways are consistently under attack from the tires of landing airplanes, weather and the myriad of operational vehicles. Proper pavement markings in and around airports are essential for pilots and vehicles. IDEAL SOLUTIONS has highly durable paints and plural component markings that provide clear guidance to both aircraft and ground personnel. High friction surface treatments assure pedestrian safety and vehicular guidance on crosswalks and approaches to the terminal areas. It is crucial that markings need to be clearly visible to the naked eye and all Instrument Landing Systems. The purpose of airport runway and taxiway markings is to increase visibility and decrease any potential runway incursions. www.idealsolutionspk.com

- 18. “OUR MAJOR PROJECTS” • HAIDRI BEVERAGES (ISLAMABAD) • NORTHERN BOTTLING (PVT) LTD (KPK) • UCH POWER PLANT (BALUCHISTAN) • PAKISTAN TOBACCO COMPANY AKORA KHATTAK (KPK) • WAPDA STAFF COLONY (MUZZAFFARABAD AJK) • DISTT HQS HOSPITAL (ATHMUQAM AJK) • OLD MESS BUILDING PAF RISALPUR (KPK) • RESIDENTIAL BLOCK 115 PAF RISALPUR (KPK) • FDL HATTAR (KPK) • DG OFFICE WAPDA (MUZZAFFARABAD AJK) • SECRETARY DEFENSE’S HOUSE CHAKLALA CANTONMENT RAWALPINDI • TEHSIL HEADQUARTERS HOSPITAL (HATTIAN BALA AJK) • TEHSIL HEADQUARTERS HOSPITAL (HAJIRA AJK) • OFFICE OF THE XEN BARQIAYAT (GARI DOPATA AJK) • KSB (HASSANABADAL, KPK) • MALAKAND HYDRO POWER PROJECT III (DARGAI, KPK) • CLASSIFIED PROJECTS (PUNJAB) • MUREED AIR BASE (PUNJAB) • MIANWALI AIR BASE (PUNJAB) • NISHAT POWER LTD (PUNJAB) PLOT NO.33, GATE D, STREET NO.10, I-9/2, ISLAMABAD, P.O.BOX. 788 ISLAMABAD Mobile:0300-5080094, 0322-5064818, Tele:051-4101145, Fax:051-4101146 info@idealsolutionspk.com, idspk@live.com. www.idealsolutionspk.com