Twelve steps of qc

•Download as PPT, PDF•

24 likes•50,364 views

how to possible achieve qc standered, ,

Report

Share

Report

Share

Recommended

Recommended

More Related Content

What's hot

What's hot (20)

Qcc Quality Control Circle (Collaborative Problem Solving)

Qcc Quality Control Circle (Collaborative Problem Solving)

Viewers also liked

Viewers also liked (8)

Similar to Twelve steps of qc

تتحدث هذه المحاضرة عن تحليل أسباب جذور المشكلة أو

Root Cause Analysis (RCA)

وهي أداة يتم استخدامها بغرض معرفة جذر أو جذور أسباب مشكلة ما ومن ثم وضع الحل المناسب لعدم تكرار حدوث المشكلة

قمت في هذه المحاضرة بتعريف تحليل أسباب جذور المشكلة او ال

Root Cause Analysis (RCA)

والمبادئ التي يقوم عليها وأنه يركز على تقديم حلول جذرية تمنع عودة المشكلة مرة أخرى بدلا عن التركيز على وضع حلول وقتية لأعراض المشاكل

قمت بعد ذلك بتوضيح خطوات تحليل أسباب جذور المشكلة او ال

Root Cause Analysis (RCA)

متطرقا لعدة أدوات تستخدم في تحليل أسباب جذور المشكلة او ال

Root Cause Analysis (RCA).

Root Cause Analysis تحليل أسباب جذور المشكلة

Root Cause Analysis تحليل أسباب جذور المشكلةAbdelrahman Elsheikh PMOC,PMP,CBAP,RMP,ACP,SP,MCITP,ITIL

Similar to Twelve steps of qc (20)

8D Training Material From VDiversify.com | 8D Training Material PDF Free Down...

8D Training Material From VDiversify.com | 8D Training Material PDF Free Down...

Pick 2 topics and discusstalk about the topics. No plagiarism wi.docx

Pick 2 topics and discusstalk about the topics. No plagiarism wi.docx

More from Prabhat Pandey

More from Prabhat Pandey (7)

Recently uploaded

Recently uploaded (20)

Presentation by Andreas Schleicher Tackling the School Absenteeism Crisis 30 ...

Presentation by Andreas Schleicher Tackling the School Absenteeism Crisis 30 ...

ICT Role in 21st Century Education & its Challenges.pptx

ICT Role in 21st Century Education & its Challenges.pptx

Mixin Classes in Odoo 17 How to Extend Models Using Mixin Classes

Mixin Classes in Odoo 17 How to Extend Models Using Mixin Classes

Role Of Transgenic Animal In Target Validation-1.pptx

Role Of Transgenic Animal In Target Validation-1.pptx

Food Chain and Food Web (Ecosystem) EVS, B. Pharmacy 1st Year, Sem-II

Food Chain and Food Web (Ecosystem) EVS, B. Pharmacy 1st Year, Sem-II

Micro-Scholarship, What it is, How can it help me.pdf

Micro-Scholarship, What it is, How can it help me.pdf

Python Notes for mca i year students osmania university.docx

Python Notes for mca i year students osmania university.docx

Asian American Pacific Islander Month DDSD 2024.pptx

Asian American Pacific Islander Month DDSD 2024.pptx

Web & Social Media Analytics Previous Year Question Paper.pdf

Web & Social Media Analytics Previous Year Question Paper.pdf

Seal of Good Local Governance (SGLG) 2024Final.pptx

Seal of Good Local Governance (SGLG) 2024Final.pptx

Measures of Central Tendency: Mean, Median and Mode

Measures of Central Tendency: Mean, Median and Mode

Beyond the EU: DORA and NIS 2 Directive's Global Impact

Beyond the EU: DORA and NIS 2 Directive's Global Impact

ICT role in 21st century education and it's challenges.

ICT role in 21st century education and it's challenges.

Twelve steps of qc

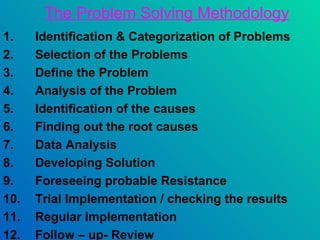

- 1. The Problem Solving Methodology 1. Identification & Categorization of Problems 2. Selection of the Problems 3. Define the Problem 4. Analysis of the Problem 5. Identification of the causes 6. Finding out the root causes 7. Data Analysis 8. Developing Solution 9. Foreseeing probable Resistance 10. Trial Implementation / checking the results 11. Regular Implementation 12. Follow – up- Review

- 2. 1. Identification problems If brainstorming is done in the proper way, minimum 50 problems can be easily identified. So the marks to be given are as follows: 50 and more problems : 5 marks 40 to 49 problems : 4 marks 30 to 39 problems : 3 marks 20 to 29 problems : 2 marks Below 20 : 1 mark

- 3. Categorization of Problems Quality Circle members are advised to categories the problems generated as: ‘A’ : Minimum involvement of other departments needed in solving them. ‘B’ : Involvement of other department is a necessity. ‘C’ : Management sanction may be needed in implementing the solution.

- 4. Basis of Categorization They can also use a different method to categories them such as pollution related, safety related, waste related, productivity related etc. Therefore, As long as there is a systematic approach for categorization, it is taken it is acceptable for evaluation.

- 5. 2. Selection of Problems Selection of problem can be done., • Based on data • Using weightage basis • Using group consensus method or any other acceptable system. Best way of selecting a problem is based on data. Brain Storming, Data Collection, Pareto Analysis and Flow Diagram and Graphs are used. Where data is not available weightage basis or group consensus method may be

- 6. 3. Define the Problem • Quality Circle activity is a group activity and one should get synergistic effect through that. They call for effective contribution from all participants. Participants can contribute only when there is clarity about the problem. • Such clarity can be achieved with the help of Flow Diagram and also carrying out Brainstorming. • This is the stage in which Quality Circle will have to work out the action plan, setting up a target of achievement and also time needed to carry out the entire task. • A Gantt Chart or Milestone Chart need to be made in this stage. Flow diagrams may be also used for this.

- 7. 4. Analysis of the Problem For this step Quality Circle should • collect further data, • study the flow diagram, • stratify the data available, • check up the graphs or make graphs with the data available. Brainstorming also need to be done.

- 8. 5. Identification of Causes • Quality Circles should at the initial stage make C & E diagram using dispersion Analysis Method. Here logical approach and questioning ‘why’ is done for finding the sub cause, sub-sub cause, sub-sub-sub cause by the circles. • Once they become knowledgeable after a year or two Quality Circles should use C & E Diagram or Enumeration Method. This will help to have creative thinking. Ultimately, C & E Diagram Process Oriented type is to be used.

- 9. 6. Identification of the Root Causes • This is the stage of selecting the root causes and establishing them beyond doubts. • Brainstorming is need to be done in this stage. A Flow Diagram will be very useful. • All analysis are based on data collected. Stratification, Graphs will be of great use. • ‘AA’ category circles of five years and above are expected to use Scatter Diagram to establish correlation and Histogram to find out the frequency distribution.

- 10. 7. Data Analysis • This is the step for confirming of one’s finding before proceeding for finding out the solution. • Pareto Diagram, Stratification, Graphs, Scatter Diagram, Histogram and Control Charts are very useful here. Use of them depends upon the type of Quality Circle.

- 11. 8. Developing the Solution • Brain Storming can be used but data collection is a must. Flow Diagram, Graphs, Scatter Diagram and Control also will be helpful in this activities.

- 12. 9. Foreseeing Probable Resistance • Changes are not easily acceptable to the people. Brain Storming to find out ways to over come the resistance is needed here. Flow diagram will be very useful here.

- 13. 10. Trial Implementation • It is not advisable to go for regular complementation straight away. Trial implementation is to be done. • Then collect data on the trial implementation to find out the effectiveness. They can be made as Graphs, Stratification may be needed of the data collected. • Scatter Diagram, Histogram and Control Charts are of additional use.

- 14. 11. Regular Implementation • Once this is done QC should ensure that changes are made in the standard practice or working system. • Data Collection is a must to know the real benefit, Graphs are needed. Control Charts are useful for regular follow up.

- 15. 12. Follow up / Review • This is the report based on follow up over a period. Review need to be done to see whether any further improvement is possible and also to ensure necessary measures are taken to hold the gain achieved. • Flow Diagram, Data Collection, Graphs are needed here. Control Chart is recommended.

- 16. NOTE • Is it necessary that all the steps have to be compulsorily used by the QC? Not necessarily. This is a systematic way of problem solving. For some problems there may not be any need to use a particular step. • QC should mention in those places reason for not using those steps. If the evaluator is satisfied, the Circle can be given the appropriate marks for that step.