Kaizen System Diagnosis(1)

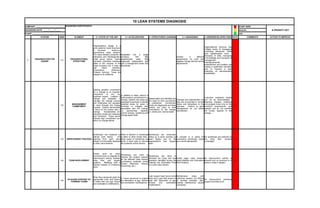

- 1. 10 LEAN SYSTEMS DIAGNOSIS DIAGNOSIS PARTICIPANTS: COMPANY: _______________________________ START NOW DIAGNOSIS DATE: _____/_____/_____ MEDIUM ◄ PRIORITY KEY PLANT: __________________________________ LOW SYSTEM WBS ELEMENT 5 = STATE OF THE ART 4 = ACCELERATING 3 = STRUCTURED LEARNING 2 = AWAKENING 1 = UNDERDEVELOPED VISIONRATE COMMENTS ACTION TO IMPROVE Organizational design is a Organizational structure has work systems model structured multiple levels of managerial in top-down bottom-up controlling influences. Wide autonomous value streams. area departmental 'silos' . The value streams comprise of Integrated into a single Monopoly of skills, monopoly interactive and interdependent company with little Divided in different of knowledge and monopoly of ORGANIZATION FOR ORGANIZATIONAL small group teams. Teams departmental walls. Well departments, bu work well 1 KAIZEN 1.1 STRUCTURE members contribute individual organized collaborative with = together though skill old school management. 1 Interdepartmental ideas to the success of the just 3 management levels fully departments. protectionism and isolation are larger business unit. 4 rules in disciplined. making a systematic transition use (Work Activities, plan to become a lean Connections Pathways, enterprise an administrative Problem Solving). These are impossibility. integral to its existence. Gaining people's commitment for a change is an important component of any key In addition to basic actions to business project. Leaders of build people's commitment to a Long-term sustained results change are equipped to Stakeholders are identified and change, specific risk areas are Changes are implemented, but can not be demonstrated. manage the change process the need for their commitment assessed proactively to identify they are surrounded in turmoil Business changes, initiatives and employees are equipped is understood. Commitment MANAGEMENT potential areas for action to stress and disruptions to the and projects focus only on the 1.2 to work through the change levels are diagnosed and basic 1 COMMITMENT minimize or mitigate risks business. Actions by plant technical requirements and process. Actions demonstrate actions are done to build associated with the change, management do not reflect aspects and do not consider a focus on the human side of commitment for the change, i.e. sponsorship, capacity, commitment. the human aspects of the change. Sustainability and i.e. clarify and communicate. culture synergy, resistance and change. disruption levels are measured change agent skills. and monitored. These results indicate high commitment and return on change efforts. Workshops are replaced by What is learned in workshops Workshops are conducted, natural work teams. The is taken to other similar lines. follow up is done routinely by A process is in place for No workshops are planned so 1.3 IMPROVEMENT PROCESS learning from each value Many types of workshops are team leader and by the conducting workshops, follow the shop floor remains 1 stream is horizontally deployed done in each area to remove organization's lean support up is done haphazardly. unchanged. to other value streams. the problems at the Gemba. team. Teams work as cross- Workshops are done to functional body to integrate the Workshops are done to improve the support systems improvement activity between eliminate the muda and flow Audits begin value streams No improvement activity is for the affected value streams 1.4 TEAM INVOLVEMENT shop floor and support (purchasing, materials control problems identified during the using Material and Information planned and no structure is in 1 systems. Meetings held at material and Information Flow Flow Analysis. place to make it happen. human resources, finance, Gemba instead of conference on a pilot value stream. accounting, etc.) room. Lean support team given some Maintenance helps with Shop floor personnel given the In house personnel to support tools and a part time person to workshop support, but difficult IN-HOUSE SUPPORT OF appropriate tools and training No improvement workshop 1.5 FORMING TEAMS to make their own jigs, fixtures the fabrication of jigs, fixtures, help with fabrication of jigs, to develop priorities, often support provided at all. 1 and workstation modifications. fixtures and workstation outside maintenance people and workstation modifications. modifications. contracted.

- 2. All plant personnel receive 40+ hours of Lean training per About 50% of the plant year. Employees regularly Most of the plant leadership personnel participate in some participate in events that alter quot;walks the talkquot; and exhibits a type of Lean training (F-K Way the current status-quo. Change good understanding of Lean 'Lego' Lean Basics voluntary or is part of the culture and is concepts. Change not). Lean principles and Knowledge of Lean principles expected by all personnel. management methodology is concepts are understood and by plant personnel is limited. plant does not have a Lean Senior and middle understood and how to apply it are incorporated into business Sponsors, advocates and awareness or education plan management are capable of EDUCATION AND and appropriate tools for projects. There is an change agents do not have designed or in place. Change 1.6 UNDERSTANDING teaching Lean and regularly handing resistance and other acceptance of change but not clearly defined or understood is perceived to be a weakness 2 teach multiple modules of the risks. Change sponsors, widespread support. Some roles and responsibilities for of management inability to Lean /Concepts. In addition to agents and participants are managers are seen as Change managing the change to a control the plant. a formal methodology for educated in these areas. 75% Agents and attempt to make Lean environment. change, all project leaders and of the leadership have improvements. All employees team members understand attended train the trainer are educated on the change how to recognize and address training. process and their roles within resistance, ineffective it. sponsorship, and other key risk factors. Leaders of change make Change plans are integrated efforts to enable the Resistance is anticipated and into the Project Plan and organization to prepare, build drawn out early on in a The culture is open to change address the needs of people to acceptance and implement the change. Effective strategies and is aware that it will be met prepare, build acceptance and change, but these efforts are for addressing resistance are with some understandable Compliance with business implement the change. These inconsistent and informal. in place. Lessons learned are resistance. Leaders are changes is expected. plans are formal and utilize They rely on the personalities captured, shared and equipped to recognize and Resistance and other key risks project or staff forums for of the change leaders and are leveraged. Change plans effectively address resistance. to the change are review, but the plant may often done as a response to extend beyond the project Diagnoses are conducted to underestimated or ignored. 1.7 PLANNING FOR CHANGE implementation date and identify any human risks to the underestimate the impact of resistance rather than in Fear of change is prevalent 1 people's resistance to change. anticipation of resistance. include actions to continue to project. Project plans are among plant personnel. The Change management activities There is covert resistance to build commitment and sustain updated to include the risk culture is deep rooted and are centered on impacted change that is not recognized the change. These activities management activities. These entrenched and resists employee groups. These or addressed. Often this work are primarily owned by plant are monitored and updated change. activities are cascaded is done in the isolation of the management and supported by throughout the project and throughout the organization by project team and sustaining key members of the project beyond implementation. change agents and managers sponsors are not engaged until team of impacted employees. the project is near implementation. Human objectives and either project success measures are Human objectives for a project Human objectives for a project established at the onset of a are identified, but are often not are identified, but are often not Business leaders are project. These are achieved or measured. In achieved or measured. In Change Leaders do not measured on the sustainability communicated to all impacted these cases plant leaders do these cases plant leaders do consider the human side of the of the change projects in their and are monitored and 1.8 ACCOUNTABILITY areas. These results indicate not take ownership for poor measured throughout the not take ownership for poor change project. Project 1 implementation of sustained implementation of sustained objectives do not include a positive return on change project. Role maps are results. The project teams results. The project teams quot;human objectivesquot;, efforts. created that identify ownership appear to have sole ownership appear to have sole ownership and accountability for the for success or failure. for success or failure. change across the organization. Change projects are implemented on time with minimal disruption to the business. The organization is Changes project are able to manage more change Organizational capacity for prioritized. People have a Plant does not see the need The organization is initiatives than the prior year change is assessed. This clear understanding of these for change. No plan exists to overwhelmed by the volume, and is increasing its capacity to assessment is a factor in priorities, but it is still incorporate change rate and complexity of changes handle an increasing volume, setting organizational priorities. somewhat of a struggle to management plans into the required. Priorities are not 1.8 RESILIENCE complexity and rate of change. A formal change management make progress on changes in strategic plans. Change clear and work items are often 5 The organization expects process is followed. People in the face of day to day projects are started but see late or incomplete. People in ongoing change and views it the organization adapt to the responsibilities and many disruptions and the organization demonstrate as the quot;normquot;. plant leaders changes and are ready for quot;emergenciesquot;. Sustainability reprioritizations in the face of signs of stress and are measured on the more. of the changes is a common quot;emergenciesquot; dysfunction. sustainability of the change issue. projects in their areas. These results indicate a positive return on change efforts.

- 3. Some of the support organizations willingly get Some alignment of non- involved in applying Lean manufacturing functions concepts. There is awareness Complete alignment of non- (administrative and of the potential benefits but the A few of the support manufacturing functions Lean is viewed as a engineering) to support the regular application of Lean organizations show interest in (administrative and manufacturing focus and manufacturing function. There tools is not in evidence. Some applying Lean concepts. There engineering) to support the applicable to anything else. is continuous elimination of high-level department goals is awareness of the potential manufacturing function. There There is little to no awareness waste in many of the functional and some plant level goals benefits but not a concerted is continuous elimination of of Lean principles in non- NON-MANUFACTURING units of the organization. Many include waste elimination effort to get started. Some 1.9 SUPPORT waste in all functional units of high-level department goals actions such as need to reduce dialogue between manufacturing areas. 5 the organization. Continuous Department goals and include waste elimination manufacturing cycle time, manufacturing and the support improvement is incorporated objectives do not include the actions such as need to reduce improve responsiveness and areas to work together. Lean into the mission/vision for the identification and elimination of transactional cycle time, lead time. There is increased terminology starts to appear in plant. Proactive dialogue to waste. quot;Usquot; vs quot;Themquot; is the improve responsiveness, and dialogue between communications and eliminate problems before they prevailing culture. improve lead time. Continuous manufacturing core process discussions. occur is the norm. improvement is a major focus work group leaders, value for many managers. stream managers and the support areas to resolve daily production problems. Vision is developed as a prerequiplant to improvement Vision is not developed. The planning by top management. purpose of a vision in planning Vision is clearly communicated is not understood by to all. Gaps between current Organization is energized by Vision aligned to strategy and Management beginning to leadership. Management and reality and vision are identified vision and how then see model 2 LEADERSHIP 2.1 INTERNAL VISION and serve as a basis for ideal lines becoming the reality beginning to link to model ideal develop a vision, but not associates are often confused 5 line projects. aligned to strategy or goals. by the initiatives brought in by improvement planning. across the whole company. leadership and unable to link Leaders continue to evaluate them to a particular vision or and adjust vision and strategy. subsequent strategies as required. Cross-functional cooperation and total systems improvement participated in by all key leaders lead by the top Performance reviews done Systems improvement work is Departmental functions are STYLE AND CROSS executives of the company. using cross functional beginning, Cross functional Task force and event focused working separately - quot;as long 2.2 FUNCTIONAL Focus on product, safety, measures and manager's measures and policy being improvement. as we do our work right, 5 COOPERATION quality, delivery, cost & collaboration between developed. everything will be okayquot; employee morale (PQCDSM departments. ODCOTODD) & what delights the customer - short medium and long range. Policy is deployed top down/bottom up, linked to a clear vision. kaizen planning is There is no clear management integrated to business system. There are no clear challenges and reflected in the plans to improve either the company's president (Mike internal business or the Roeder) business A3 plan. internal processes in the Managers at different levels Action plans are effectively Functional charts are made company. Alignment of work together, playing quot;catch Goals and objectives of communicated at all levels and with details, enabling the resources is not clear. People ball' and also evaluating the management are broken down 2.3 POLICY MANAGEMENT incorporate ongoing feedback organization for its level of to detail for each level of the elimination of the duplication are not viewed as assets 5 regarding process and results and assuring important capable of self-managed work ability for each of the 10 organization. of activities at all levels. projects to not get dropped. or providing essential systems of kaizen. Middle and top management knowledge. Management provide visible support and skills required for policy involvement at workstations. management and deployment Management aligns people, not in place. Communication systems & resources to between levels is not effective. achieve the vision and in support of the core process.

- 4. Most leadership promotes and implements world-class Organization uses leadership practices in all business cycles. Plant leadership periodically to promote and implement Plant management makes a Actions by plant management There is a high level of demonstrates a commitment to world-class practices. There is token effort towards do not reflect commitment. personal commitment and making the plant a Lean sustained personal commitment to Lean. Knowledge of Lean principles involvement to drive Lean environment. The plant commitment and involvement Knowledge of Lean principles by plant personnel is limited. 2.4 TECHNICAL LEADERSHIP to drive Lean practices by all of practices by most of the leadership will separate the is limited a few key change Plant does not see the need 5 organization's managers. A daily needs of the business the organization's managers. A agents. Plant management for change. No plan exists to plan for establishing and from Lean principles in times of plan for establishing and provides little vision of how incorporate Lean plans into the deploying the Lean principle is business pressures (e.g. end deploying the Lean principles lean will benefit the business. Strategic plans. in place, reviewed and of month, increased demand). is in place and executed. supported by most plant leadership. Value Stream Managers and Work Group Leadership teams Value Stream Manager and Value Stream Managers and hold monthly detailed reviews World class manufacturing work group leaders teams are work group leaders teams hold World class manufacturing is of projects, team members do status is consistently not reviewing projects, World LEADERSHIP monthly detailed reviews of mentioned in some employee 2.5 COMMUNICATIONS the presentations, status projects and consistent communicated to employees communications but it is not class manufacturing is rarely 5 covered in every all-employee and some management review mentioned in all-employee communication of status to all consistent or frequent. meeting, articles included in of WCM projects occurs. meetings or written employees. every periodical or written communications. communication. Decisions are top down/bottom up to achieve vision. Safety, Quality, Delivery and Cost targets are clear and based upon effective benchmarking Decisions are strictly top/down processes and data collection. with little input from associates Customers, suppliers and and middle management. associates are seen by leaders Safety Quality, Delivery and Decision making and target as key sources for SQDC Cost targets are arbitrarily set setting is spread throughout Decision making and target target selling and routinely Leaders begin to analyze the and not verified with customers the company by use of projects setting begins in model project involved. Leaders follow key needs of the customer and the (external or internal). Quality is whose goals are to satisfy the areas, aligning process output 2.6 DECISION MAKING principles of Process and needs of the organization not put first in the production customer. Visual controls are with customer requirements. Results and Total Systems internally, focusing on making process and production data used to manage the workplace Decisions are made to thinking in decision making. quot;Quality Firstquot; decisions. are not effectively collected or through empowered small increase customer value. Quality in the process is used for improvement. group teams. always, before Cost and Inconsistency of decisions is Delivery, and supported by pervasive and reduces Value Stream Managers and associate's confidence in supervisors in production and leadership decisions. support services. Internal measurements and targets are directly linked to financial measurements. Company newsletter (The Company newsletter (The Communication strategy used Pellet) and details of Pellet) and company briefings Improvement activity is No one in the company knows COMPANY-WIDE in annual reports to show workshops used to horizontally 2.7 show kaizen plan and tell discussed in plant or company- about any improvement COMMUNICATION integration of business deploy improvement activity stories of what has been done wide meetings. activities. strategy. from one area or plant to in various workshops. another. Departmental communication Departmental communication Line communication dashboards/storyboards show dashboards/storyboards show dashboards/storyboard show Improvements tracked on line VALUE STREAMS attainment, current No communication of 2.8 attainment and improvement attainment and improvement communication COMMUNICATIONS improvement activity and improvements. for value stream's safety for each line's safety, quality, dashboard/storyboard. future planned improvement quality, delivery and cost delivery and cost. activity to S.Q.C.D. Single point lessons are used Line associates develop single Improvement done and Improvement done and Improvement is not done and 2.9 SINGLE POINT LESSONS to train all who work in that as point lessons to help learn the standards written by team standards written by standards are not followed. standard work. details of a process. members. engineers. Improvement data is collected Improvement data is Improvement data is collected Improvement data is not PERFORMANCE DATA INFORMATION Improvement data is only 3 3.1 visible and integrated to the consistently collected by the by area, but each area has its collected. Trends or Pareto MEASUREMENT COLLECTION collected during workshops. company improvement plan. Value Stream Managers own scorecard. analysis of data is not done.

- 5. Selected measures vertically integrated. All measures are displayed for all employees to The measures are related to Measurements are primarily see and reviewed for Partial attempt at a Balanced the type of business and efficiency based and used as a understanding at frequent Scorecard is made with some product produced. Customer Still a large number of negative motivator. intervals. Customer vertical link to business Sat. has sizeable influence measures tracked but a few Employees do not see a Satisfaction is the driving measures. Employees are PERFORMANCE over performance decisions. get the most attention. Some connection between their job 3.2 MEASUREABLES measure. The measures exposed to various Some visibility of the measures awareness of Customer and the organization making 3 package is constantly reviewed measurements and see the is gained through Satisfaction and the profitability money. Customer satisfaction and updated to ensure a link between their job and weekly/monthly measures but of the business. is not important. Large number Balanced Scorecard is in profits. Priorities become a little adherence to a “hot” few is of measures in place causing effect. Priorities are clear to all. clearer. common. conflict. Trends are positive. Leadership regularly reviews data with Line Technicians. Employees are clearly aware of the need to meet changing Most employees understand customer demands and Employees are interested in and participate in ongoing Passive suggestion system is Only real concern is the improve to succeed. improving and are given limited improvement and have in place, but no real training or paycheck. No interest in Improvement activity is regular feedback and training. knowledge of customer motivation supplied to general business operation, 3.3 PERFORMANCE FOCUS and vigorous. Needs and demands. Focus on However, involvement is low employees. Little feedback or improvements, or belief in 3 feedback are communicated key and not well organized. performance still needs to be communication to employees change. Very little/no contact well. Line Technicians Some customer awareness is built into on their involvement in or interest with the customer. understand and present present. training/compensation. performance to the leadership team. Training deployed from training strategy to support core Training is a low priority. Tools process. Managers aligned brought in without with training support implementation strategy or All areas have multiple skill responsibility. Natural & cross- Training across job Multiple skill cross training alignment to business plan and matrix dashboards & all functional teams form to meet classifications and kaizen tools begins within process areas organizational needs. Leaders 4 PEOPLE 4.1 SKILLS AND TRAINING organizational needs. All are learned & used by all associates have doubled their using standards and matrix do not participate in training or 3 skill base within the last employees trained in core associates. skill boards. adequately support quarter. competency and job task skills implementation. No one is and this information is posted interested in multiple skills in matrix form in the forming development. teams departments. Improvement & problem Associates understand how solving are the responsibility of their equipment works and managers and technical improve constantly. experts (engineers, process Each area has teams in place Every major work area has Model improvement areas Performance evaluation tracks technicians). Improvement is INVOLVEMENT and complete two projects per improvement area. 24 developed for associates to participation in kaizen at all viewed negatively and a 4.2 IMPROVEMENT IDEAS AND levels, including management. year per team. 24 improvement ideas per person, make improvement items. 6 source of tension between 3 TEAMS improvement idea per person, per year. Improvements done improvement ideas per person, People recognized and worker & management. per year. through teams and individuals. per year. rewarded to encourage Associates see kaizen as a participation. 60 improvement burden, adding work rather ideas per person, per year. than eliminating it, reducing it, simplifying it or incorporating it. Work group leaders and Steady, easy predictable supervisors and associates quot;Tool Boxquot; meetings are held Punctuality with respect to rhythm in all jobs. Standards Associated work entire shift work on time control issues. at the beginning of each start start, end, breaks, lunch 4.3 TIME MANAGEMENT clearly communicated and with no punctuality problems. Breaks, lunches, and of cycle for each team and meetings is not tracked or 2 supervision for time meetings, last as long as each shift. important. management is not required. scheduled.

- 6. Leadership direction is People are competent, self ambiguous and unclear. managed, and empowered, Blaming is pervasive with little driven by data and collaborate attempt to problem solve or in solving problems rather than Management leads teams to Every work area has projects Begin training in principles and prevent future issues. assigning blame. kaizen do improvement projects. Each in place which are aligned with concepts of kaizen Favoritism and politics frame EMPOWERMENT AND principles used as a barometer 4.4 CULTURE of self assessment. All levels area has teams in place and management goals and driven (foundation). Model areas leadership and management 4 complete two projects per year by management. Complete working on specific decisions. Management and disciplines respect the per team one project per year per team. improvement projects. believes associates need to be need for diversity of their roles highly supervised. Poor and skills and work together. information flow at all levels. People have confidence in the kaizen principles and concepts direction of leadership. are not known or understood. II Improvement Idea) system is fully operational and is management closely. Ideas on how associates can improve Safety, Quality, Delivery, Cost, Productivity, Manufacturing Archaic 'suggestion box' in Cycle Time, Overtime, Scrap, which employees suggest Defects, Outbound Freight, No employee improvement 4.5 IMPROVEMENT IDEAS Inventory Accuracy, Customer ideas that do touch on ideas program exists. 4 companies performance Service, First Time Quality, metrics. Internal Quality, External Quality, On-time Delivery, Redundancies, New products, Current Products Breakdowns or increase morale average 30 a month. Product quality is competitive (as shown by benchmarking data in the market) with few returns or complaints from users. Quality problems are Customer returns and detected, solved and complaints are common and prevented on the line, not at measured in percentage and the end of the line. Line not PPM's. Inspection sorting technicians are responsible for are routinely performed, both quality characteristics in the Most production processes are Waste of rework, scrap and in house and at the customer process and manage defect left running and unmonitored regrind equipment monitoring plant. Focus is on product and error resolution (visual during lunch and breaks. All recognized. Shift to quality at rather than process quality at controls and mistake proofing) Process capability across the office operations have a one the source associates inspect all levels. Quality is seen as a as part of their daily jobs. board is 1.3 CpK or higher. 5 QUALITY 5.1 PRODUCT QUALITY Customer input regarding page standard. Customer 10% of office operations have their own quality. Model areas QA department and 5 returns low measured in parts have specific quality engineering responsibility. quality cost and delivery a one page standard. per million. Intense work with standards. Process capability high variations in process requirements is continual and suppliers to improve product studies done on major resulting in high rework scrap supported by effective systems and process quality. equipment. and regrind. Outdated or non- of communication. Quality in documented standards exist. 7 the process is a shared visual controls are not in place. understanding at all levels. Processes are monitored one Supplier to customer value machine one person quot;because chair is emphasized as they could make a defect.quot; essential to Quality First. Teams use appropriate problem solving tools (5 Whys/ 8D) to prevent quality problems. QA systems better than Quality system is based upon ISO-9000 requirements. Quality system ISO-9000 level Improvement of quality system Quality systems change is military standards and is Quality data (internal 7 in all areas of the plant and seen in all areas of the plant being modeled in pilot areas. inspection oriented. ISO-9000 external) effectively collected, company. Alignment of 5.2 ASSURANCE SYSTEM per ISO-9000 requirements. ISO-9000 implementation has is seen as a required quality reported, documented & used management system to Associates along with begun. Standards are system rather that a standards for improvement leads to associate activity on shop supervisors write standards. associated assuring quality. checklist common to all ongoing kaizen of all floor. systems. standards.