Mayor's Message 152

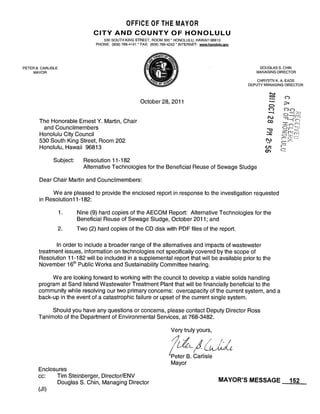

- 1. OFFICE OF THE MAYOR CITY AND COUNTY OF HONOLULU 530 SOUTH KING STREET, ROOM 300 * HONOLULU, HAWAII 96813 PHONE: (808) 768-4141 * FAX: (808) 768-4242 * INTERNET: wwwbo~~~uaov PETER B. CARLISLE DOUGLAS S. CHIN MAYOR MANAGING DIRECTOR CHRYSTN K. A. EADS DEPUTY MANAGING DIRECTOR c-) October 28, 2011 The Honorable Ernest Y. Martin, Chair and Councilmembers Honolulu City Council 530 South King Street, Room 202 Honolulu, Hawaii 96813 Subject: Resolution 11-1 82 Alternative Technologies for the Beneficial Reuse of Sewage Sludge Dear Chair Martin and Councilmembers: We are pleased to provide the enclosed report in response to the investigation requested in Resolution 1 1-182: 1. Nine (9) hard copies of the AECOM Report: Alternative Technologies for the Beneficial Reuse of Sewage Sludge, October 2011; and 2. Two (2) hard copies of the CD disk with PDF files of the report. In order to include a broader range of the alternatives and impacts of wastewater treatment issues, information on technologies not specifically covered by the scope of Resolution 11-182 will be included in a supplemental report that will be available prior to the November 1 6th Public Works and Sustainability Committee hearing. We are looking forward to working with the council to develop a viable solids handling program at Sand Island Wastewater Treatment Plant that will be financially beneficial to the community while resolving our two primary concerns: overcapacity of the current system, and a back-up in the event of a catastrophic failure or upset of the current single system. Should you have any questions or concerns, please contact Deputy Director Ross Tanimoto of the Department of Environmental Services, at 768-3482. Very truly yours, 7~~A (~ Peter B. Carlisle Mayor Enclosures cc: Tim Steinberger, Director/ENV Douglas S. Chin, Managing Director MAYOR’S MESSAGE 152 (JI)

- 2. Alternative Technologies for the Beneficial Reuse of Sewage Sludge Response to Resolution 11-182 Oahu, Hawaii Final October 2011 Prepared for: City & County of Honolulu Department of Environmental Services 1000 Uluohia Street Suite 308 Kapolei, Hawaii 96707 Prepared by: 1001 Bishop Street, Suite 1600 Honolulu, Hawaii 96813

- 3. Alternative Technologies for the Beneficial Reuse of Sewage Sludge Response to Resolution 11-182 October 2011 CONTENTS EXECUTIVE SUMMARY .......................................................................................................... vii 1.0 INTRODUCTION AND OVERVIEW ................................................................................1 1.1 Background .....................................................................................................................1 1.2 Purpose ...........................................................................................................................2 1.3 Objectives .......................................................................................................................2 1.4 Methodology ....................................................................................................................3 2.0 OVERVIEW OF SOLIDS TREATMENT AND PROCESSING ..........................................4 2.1 Terminology.....................................................................................................................4 2.2 Regulatory Background ...................................................................................................5 2.2.1 Land Application................................................................................................5 2.2.2 Emissions for Sewage Sludge Incineration (SSI)...............................................6 2.3 Current CCH Treatment and Processing Operations .......................................................6 2.4 Treatment and Processing Technology Classification....................................................10 2.4.1 Digestion .........................................................................................................10 2.4.2 Composting .....................................................................................................11 2.4.3 Heat Drying Only .............................................................................................12 2.4.4 Incineration .....................................................................................................13 2.4.5 Gasification and Pyrolysis ...............................................................................14 2.4.6 Alternative Combustion ...................................................................................15 2.4.7 Alternative “Smokeless” Sludge Oxidation.......................................................15 2.4.8 Fuel Production ...............................................................................................16 2.4.9 Other Solids Technologies ..............................................................................16 2.4.10 Non-Solids Technologies ................................................................................16 2.4.11 Unknown Technologies ...................................................................................16 2.5 Technology Development Status ...................................................................................16 2.6 Consideration of Sludge Characteristics ........................................................................16 3.0 POTENTIAL TECHNOLOGIES AND VENDORS...........................................................18 3.1 Digestion Technologies .................................................................................................18 3.1.1 Omnivore ........................................................................................................18 3.1.2 Thermal Hydrolysis (TH) .................................................................................18 3.1.3 VERTAD .........................................................................................................18 3.2 Composting ...................................................................................................................18 3.2.1 Biozyme ..........................................................................................................18 3.2.2 Solorganics .....................................................................................................18 3.3 Heat Drying ...................................................................................................................18 3.3.1 Conventional Heat Drying ...............................................................................18 3.3.2 VitAg ...............................................................................................................19 3.4 Incineration ....................................................................................................................19 3.4.1 Fluid Bed Incineration (FBI).............................................................................19 3.5 Gasification and Pyrolysis (Closed-Coupled) .................................................................19 3.5.1 Kruger BioCon + Energy Recovery System (ERS) ..........................................20 3.5.2 MaxWest .........................................................................................................20 3.5.3 Nexterra ..........................................................................................................20 Page i of xvii

- 4. Alternative Technologies for the Beneficial Reuse of Sewage Sludge Response to Resolution 11-182 October 2011 3.5.4 Prime Energy Gasification ...............................................................................21 3.5.5 Pyrobuster.......................................................................................................21 3.6 Gasification and Pyrolysis (Two Stage) .........................................................................21 3.6.1 Ascent BioEnergy............................................................................................22 3.6.2 Carbon BioEngineers Inc. ...............................................................................22 3.6.3 D4 ...................................................................................................................22 3.6.4 HGE – Korea (a KBI Group) High Temperature Conversion of Waste (HTCW) ........................................................................................................................22 3.6.5 Integrated Environmental Technologies LLC – S4 Energy Solution.................23 3.6.6 Intellergy .........................................................................................................23 3.6.7 Kopf ................................................................................................................23 3.6.8 Kore Process (G2E! Green Earth Energy).......................................................23 3.6.9 Nexterra ..........................................................................................................23 3.7 Alternative Combustion .................................................................................................23 3.7.1 Fabgroups Technologies – Plasma Assisted Sludge Oxidation (PASO) ..........23 3.7.2 Kunmin ............................................................................................................23 3.8 Alternative “Smokeless” Sludge Oxidation .....................................................................24 3.8.1 ATHOS Wet Air Oxidation (WAO) ...................................................................24 3.8.2 Sci-Fi SuperCritical Water Oxidation (SCWO) – AquaCritox™ ........................24 3.9 Fuel Production .............................................................................................................24 3.9.1 Enertech SlurryCarb™ ....................................................................................24 3.9.2 N-Viro International .........................................................................................24 3.9.3 Panatech .........................................................................................................24 3.10 Other Solids Technologies.............................................................................................24 3.10.1 Astec Thermal Remediation ............................................................................24 3.10.2 BioRenewables – Applied Filter Technologies.................................................24 3.10.3 HydroCell Dewatering .....................................................................................25 3.10.4 Ledcor .............................................................................................................25 3.10.5 PyroBioMethane™ ..........................................................................................25 3.11 Non-Solids Technologies ...............................................................................................25 3.11.1 Beneficial Active Microorganisms (BAM) .........................................................25 3.11.2 BioCleaner ......................................................................................................25 3.11.3 ECO-H2O ........................................................................................................25 3.11.4 Global Environmental Technology Services (GETS) .......................................26 3.11.5 SunPower .......................................................................................................26 3.12 Unknown Technologies .................................................................................................26 3.12.1 Ebara ..............................................................................................................26 3.12.2 Waste to Energy..............................................................................................26 4.0 EVALUATION CRITERIA ..............................................................................................27 4.1 Intent of the Resolution ..................................................................................................27 4.2 Onsite vs. Offsite Technologies .....................................................................................27 4.3 List of Criteria ................................................................................................................27 4.4 “Fatal Flaw” ...................................................................................................................28 4.5 Technology Development Status and Piloting................................................................29 4.6 Risks of Unknown Technologies ....................................................................................30 5.0 TECHNOLOGIES FOR FUTURE CONSIDERATION ....................................................33 6.0 SELECTION AND IMPLEMENTATION .........................................................................34 Page ii of xvii

- 5. Alternative Technologies for the Beneficial Reuse of Sewage Sludge Response to Resolution 11-182 October 2011 6.1 Supplemental Report for Resolution 11-182: Alternative Technologies for the Treatment and Minimization of Sewage Sludge .........................................................................................34 6.2 Island-wide Solids Master Plan......................................................................................34 6.2.1 Island-wide Solids Quantity and Quality ..........................................................34 6.2.2 Solids Reduction at Smaller WWTPs (< 5 mgd) ..............................................34 6.2.3 Island-wide Transportation, Treatment, and Disposal ......................................34 6.2.4 Redundancy and Reliability for Processing and Disposal ................................35 6.2.5 Island-wide Solids Processing and Disposal Plan ...........................................35 6.3 Life-Cycle Cost Analysis ................................................................................................35 6.4 Schedule and Implementation .......................................................................................36 6.4.1 Pilot Testing ....................................................................................................36 6.4.2 Master Plan Timeline.......................................................................................36 6.4.3 Design and Construction .................................................................................36 6.4.4 Honouliuli and Sand Island Secondary Treatment ...........................................36 6.4.5 Facilities Planning for Kailua, Honouliuli, Sand Island, and Waianae WWTPs.36 TABLES Table 2-1. Island-wide Solids Production ....................................................................................9 Table 2-2. Characteristics of Different Thermal Processing Technologies .................................14 Table 4-1. Technology Comparison ..........................................................................................31 FIGURES Figure 2-1. Location of WWTPs and Waimanalo Gulch Landfill ..................................................7 Figure 2-2. Honouliuli, Kailua, and Sand Island Process Flow Diagrams.....................................8 Figure 2-3. Anaerobic Digester Schematic ................................................................................11 Figure 3-1. Close-Coupled Gasification System for Energy Recovery .......................................20 Figure 3-2. Two Stage Gasification System for Energy Recovery .............................................22 APPENDICES Appendix A – Resolution 11-182 Appendix B – RFI Appendix C – Technology Fact Sheets Page iii of xvii

- 6. Alternative Technologies for the Beneficial Reuse of Sewage Sludge Response to Resolution 11-182 October 2011 WORKS CITED AECOM. (2011). Technical Memorandum Work Task 11.C: Solids Processing Technology. Metcalf & Eddy. (2003). Wastewater Engineering Treatment and Reuse. 4th Edition. US EPA. (1994). A Plain English Guide to the EPA Part 503 Biosolids Rule, EPA/832/R-93/003. Chapter 4 – Incineration of Biosolids. US EPA. (2006). Emerging Technologies for Biosolids Management, EPA 832-R-06-005. US EPA. (2011). “Standards of Performance for New Stationary Sources and Emission Guidelines for Existing Sources: Sewage Sludge Incineration Units,” Federal Register / Vol. 76, No. 54, pp. 15372-15454, 40 CFR Part 60. Water Environment Federation (WEF) Website. Glossary of Terms (http://www.wef.org/AWK/page.aspx?id=1951). Page iv of xvii

- 7. Alternative Technologies for the Beneficial Reuse of Sewage Sludge Response to Resolution 11-182 October 2011 ACRONYMS/ ABBREVIATIONS ATAD Autothermal Thermophilic Aerobic Digestion BAM Beneficial Active Microorganisms Bioconversion Facility In-vessel Bioconversion Facility BOD Biological Oxygen Demand BTU British Thermal Units CCH City and County of Honolulu CEM Continuous Emission Monitoring CFR Code of Federal Regulations CH4 Methane CHP Combined Heat and Power CO Carbon Monoxide CO2 Carbon Dioxide cu. ft. cubic feet cu. yd. cubic yard DB Design and Build DBB Design, Bid, and Build DBO Design, Build, and Operate DBOM Design, Build, Operate, and Maintain DBOOF Design, Build, Own, Operate, and Finance DS Dry Solids dtpd dry tons per day ENV Department of Environmental Services EPA Environmental Protection Agency ERS Energy Recovery System ESPC Energy Savings Performance Contract FBI Fluid Bed Incineration FOG Fats, Oils and Grease G2E! Green Earth Energy GE General Electric GETS Global Environmental Technology Services H2 Hydrogen H2O Water IATS Innovative Anaerobic Treatment System IC Internal Combustion HER Hawaiian Earth Recycling, LLC HTCW High Temperature Conversion of Waste lb pound MABA Mid-Atlantic Biosolids Association MBR Membrane Bioreactor mgd million gallons per day MHI Multiple Hearth Incineration MSAP Modified Static Aerobic Pile MW e Mega Watt equivalent NBP National Biosolids Partnership NEBRA North East Biosolids and Residuals Association O&M Operation & Maintenance ORC Organic Rankine Cycle PASO Plasma Assisted Sludge Oxidation Page v of xvii

- 8. Alternative Technologies for the Beneficial Reuse of Sewage Sludge Response to Resolution 11-182 October 2011 PEM Plasma Enhanced Melter PFRP Processes to Further Reduce Pathogens psig pounds per square inch gauge PSRP Process to Significantly Reduce Pathogens Resolution Resolution 11-182 RFI Request for Information SCWO Supercritical Water Oxidation SEP Supplemental Environmental Projects SOUR Specific Oxygen Uptake Rate SPV Special Purpose Vehicle SSI Sewage Sludge Incineration Synagro Synagro WWT, Inc TCOM Thermal Conversion of Organic Material TH Thermal Hydrolysis TS Total Solids TSK Tsukishima Kikai VS Volatile Solids WAO Wet Air Oxidation WEF Water Environment Federation WWTP Wastewater Treatment Plant Page vi of xvii

- 9. Alternative Technologies for the Beneficial Reuse of Sewage Sludge Response to Resolution 11-182 October 2011 EXECUTIVE SUMMARY INTRODUCTION Background The City and County of Honolulu (CCH) entered into the 1995 Consent Decree (Civil No. 94- 00765DAE) with the State of Hawaii and the Environmental Protection Agency (EPA). As part of the 1995 Consent Decree, CCH committed to Supplemental Environmental Projects (SEPs) which included spending at least $10 million on beneficial sludge reuse. The result of the 1995 Consent Decree was a contract in 2004 between CCH and Synagro WWT, Inc. (Synagro) in which Synagro would design/build/operate an In-vessel Bioconversion Facility (Bioconversion Facility) at the Sand Island Wastewater Treatment Plant (WWTP) to convert the sludge into a pellet fertilizer. The main components of the Synagro In-vessel Bioconversion Facility are an egg-shaped digester for anaerobic digestion, two centrifuges for dewatering, and a dryer for pelletizing. The 2010 Consent Decree between CCH, State of Hawaii, and EPA included the upgrade of the Sand Island and Honouliuli WWTPs to full secondary treatment. In addition, CCH is evaluating alternatives to the Waimanalo Gulch Landfill by conducting an Island-wide Biosolids Master Plan. Currently the egg shaped digester at Sand Island WWTP is at full capacity resulting in the need to consider either expansion of existing operations or alternative technologies for processing and treatment. On June 28, 2011, the City Council signed Resolution 11-182 (herein referred to as the Resolution), which stated concerns about the current bioconversion facility including: (1) Public health and safety (2) Impact to businesses and residents (3) Visual blight and impacts to tourism (4) Marketability of fertilizer pellets (5) Reputation and credibility (6) The cost to construct the existing bioconversion facility was over $40 million, including cost overruns exceeding $7 million, and the projected cost of the second facility was budgeted at $26 million As part of an ongoing contract with ENV, AECOM began work in August 2010 on a Leeward Region Solids Master Plan. In June 2011 ENV requested AECOM expand the effort to prepare an Island-Wide Solids Master Plan. The Island-wide Solids Master Plan is evaluating the existing solids treatment and disposal at all the CCH operated WWTPs with the goal of recommending improvements or upgrades at these WWTPs. On July 1, 2011 AECOM was further tasked by ENV to investigate and prepare a report in response to Resolution 11-182, which requested the administration to: “...investigate alternative technologies for the beneficial reuse of sewage sludge other than the technology used at the Sand Island WWTP’s bioconversion facility that will be sustainable and less harmful to the environment, including technologies successfully used in Europe, Asia and North America by companies with good reputations for credibility... to the end that the Council [would] work with the City administration Page vii of xvii

- 10. Alternative Technologies for the Beneficial Reuse of Sewage Sludge Response to Resolution 11-182 October 2011 expeditiously to implement a safe and healthful alternative to the Synagro technology so as to ensure that any necessary construction may commence as soon as possible.” Overview of Solids Handling Operations CCH currently operates nine WWTPs on Oahu including Honouliuli, Kahuku, Kailua, Laie, Paalaa Kai, Sand Island, Wahiawa, Waianae, and Waimanalo WWTP. Currently, Honouliuli, Kailua, and Waianae WWTPs’ sludge goes through anaerobic digestion for stabilization and centrifuges for dewatering. The biosolids are then hauled to Waimanalo Gulch Landfill for disposal. Synagro Bioconversion Facility at Sand Island WWTP also has anaerobic digestion for stabilization, followed by dewatering, and drying for pelletization. The pellets produced at Synagro Bioconversion Facility have been used as a fertilizer at agricultural farms, golf courses, and parks. The dried product from the Synagro facility is either beneficially reused as a fertilizer product for land application or hauled to Waimanalo Gulch Landfill for disposal. Synagro indicated that currently most of their generated product is being beneficially used without revenue. The Kahuku, Paalaa Kai, Wahiawa, and Waimanalo WWTPs haul liquid waste to the large facilities for further treatment. The Laie WWTP has an onsite composting facility that is operated by CCH staff. The compost that has been approved for distribution is used by the Mormon Church that owns the WWTP for agricultural purposes and the compost that is not approved for distribution (mostly due to metal content) is disposed of at the Waimanalo Gulch Landfill. Figure 1 shows the location of the existing WWTPs, currently available solids outlets and transfer of solids between the various facilities. Table 1 provides an estimate of solids production at each of the WWTPs as well as some key aspects associated with treatment and disposal at each. Purpose and Objectives The purpose of this report is to respond to the Resolution by identifying potential alternative sludge processing technologies for the beneficial reuse of sewage sludge other than the technology used at Sand Island WWTP. Some of the technologies included in this report are from vendors that responded to a Request for Information, were known by AECOM or had approached the CCH and/or the City Council directly. The outcome of this report is a list of technologies meeting the requirements of the Resolution for consideration as part of the ongoing island-wide solids planning effort. The intent of this technology listing is to have appropriate technologies to evaluate in considering island-wide sludge management needs. This report is not intended to be a decision making document that recommends a best solution. Some additional factors that will need to be determined as part of any evaluation and selection process would likely include: An assessment of a particular alternative technology specific to the WWTP with respect to the facilities already existing there. Capital and O&M costs specific to the WWTP in which it is being evaluated for. Implementation timeline for planning, design, permitting, procurement, construction and startup. Compatibility of technology with overall Island-wide Solids Master Plan New development and increased future capacity needs Planned upgrades at the existing WWTPs (i.e. upgrade to secondary treatment) Page viii of xvii

- 11. Alternative Technologies for the Beneficial Reuse of Sewage Sludge Response to Resolution 11-182 October 2011 It should be noted that technology and process selection for implementation at any of the nine WWTPs will need to be looked at from an island-wide perspective due to the issues of combining/transportation of solids between WWTPs as well as the identified end user needs and beneficial use limitations. Other key elements that were considered include reliability and redundancy planning in the event that a WWTP treatment unit (i.e. centrifuge or digester) or solids outlet (i.e. landfill or composting facility) is temporarily out of service. Table 1 - Island-Wide Solids Production Average Solids State of Dewatering Solids WWTP Flow1 Stabilization Production2 Solids Method Distribution (mgd) (dtpd) Waimanalo Anaerobic Honouliuli 25.92 7.28 Cake Centrifuge Gulch Landfill Digester (~7 mi) Aerobic Kailua Regional Kahuku 0.19 0.26 Liquid None Digester WWTP (~34 mi) Waimanalo Kailua Anaerobic 11.49 2.65 Cake Centrifuge Gulch Landfill Regional Digester (~32 mi) Mormon Church/ Laie 0.46 Clarigester ---3 Compost Composting Waimanalo Gulch Landfill Aerobic Honouliuli Paalaa Kai 0.09 0.05 Liquid None Digester WWTP (~21 mi) Class A Fertilizer Pellets Anaerobic Reuse/ Sand Island 61.29 9.21 Dried Pellets Centrifuge/Dryer Digester Waimanalo Gulch Landfill (~23 mi) Honouliuli Wahiawa4 1.64 Not Stabilized 2.00 Liquid None WWTP (~17 mi) Waimanalo Anaerobic Waianae 3.31 0.44 Cake Centrifuge Gulch Landfill Digester (~8 mi) Anaerobic Kailua Regional Waimanalo 0.55 0.26 Liquid None Digester WWTP (~33 mi) 1 Source: City and County of Honolulu, Dept of Environmental Services, Wastewater Management website (FY 2011). Million gallons per day (mgd) 2 Source: Annual Biosolids Production Reports – January 1 to December 31, 2010, Division of Wastewater Treatment and Disposal, ENV. Dry tons per day (dtpd) 3 Dry weight is not available (no percent solids data). Laie WRF produced a total of 1,056 cu. yd. of compost that was disposed at the landfill. This is approximately 727.6 wet tons (based on a measured unit weight of 51 lbs/cu. ft.) Source: Note 8, Annual Biosolids Production Reports – January 1 to December 31, 2010, Division of Wastewater Treatment and Disposal, ENV 4 Wahiawa is currently being upgraded to an MBR facility, so solids characteristics will change when the new processes are in operation. Page ix of xvii

- 12. Alternative Technologies for the Beneficial Reuse of Sewage Sludge Response to Resolution 11-182 October 2011 Insert Figure 1 - Location of WWTPs and Waimanalo Gulch Landfill Page x of xvii

- 13. Alternative Technologies for the Beneficial Reuse of Sewage Sludge Response to Resolution 11-182 October 2011 Identification and Classification of Technology Potential technologies and technology vendors were identified by several methods. The initial listing of technologies was developed using known technologies and technology vendors that are currently active within the municipal wastewater industry. This includes technologies and vendors identified as part of the ongoing island-wide solids master planning effort that could be implemented at large (>5 mgd) WWTPs. Additional technologies and vendors were obtained through a formal Request for Information (RFI) and solicitation process through various professional organizations. Technology vendors that had previously contacted the CCH were sent the RFI to provide key information required for evaluation. Technology Classification The identified vendors and their technologies covered a wide range of treatment and processing types. In order to facilitate an organized approach to determining applicability many of the vendors were organized by the general classification or technology category which best described the process using standard industry terminology as described in the following paragraphs. It should be noted that some solution providers responding to the RFI were not actually equipment manufacturers or suppliers. These solution providers were often system integrators that provided an alternative means of financing, often involving a rate payback system or power purchase agreement to recuperate initial construction costs. As discussed further in the report the economics and life-cycle cost comparison of the various alternatives will be conducted as part of the Island-wide Solids Master Plan and as such only the specific technologies proposed by any respective vendor are considered, irrespective of financing methodology. The categories used for technology classification are identified below and described in detail in the following report. In some instances an entire technology category was not considered for future consideration since the category itself did not meet the defined requirements. The technology classifications are as follows with the more established technologies listed first, followed by the newer and innovative processes: Digestion Composting Heat Drying Only Incineration Gasification and Pyrolysis (Closed-Coupled) Gasification and Pyrolysis (Two Stage) Alternative Combustion Alternative “Smokeless” Sludge Oxidation Fuel Production Other Technologies Technology Development Status The processes are generally classified in the industry based on the stage of development. In this report, the technologies are classified either as either “concept”, “emerging”, “demonstration”, or “established” technology as defined below: 1. Concept technologies are ones that are not proven at pilot and/or small scales. Page xi of xvii

- 14. Alternative Technologies for the Beneficial Reuse of Sewage Sludge Response to Resolution 11-182 October 2011 2. Emerging technologies are proven at pilot/small scale but are not proven at a full scale installation. 3. Demonstration technologies are proven at one to three full scale installations. 4. Established technologies are proven at more than three sites. “Concept” technologies are not considered further in this evaluation unless the vendor would like to conduct pilot testing at one of the WWTPs at no expense to CCH. Pilot testing will not guarantee that the technology would be chosen; however, a successful demonstration would reclassify the development status from “Concept” to “Emerging”. TECHNOLOGY EVALUATION As stated in the Resolution, this report “…investigate[d] alternative technologies for the beneficial reuse of sewage sludge other than the technology used at the Sand Island WWTP’s bioconversion facility that will be sustainable and less harmful to the environment, including technologies successfully used in Europe, Asia and North America by companies with good reputations for credibility...” As such, technologies other than anaerobic digestion, drying only, and pelletization are considered if the byproducts are beneficially reused or energy is being generated for on-site use. The beneficial reuse technologies considered are focused on the on-site treatment of solids at the larger facilities (Honouliuli, Kailua, and Sand Island WWTPs). Although composting is considered a beneficial reuse, the product may be considered a soil amendment or fertilizer and the Resolution states that “…uses of sewage sludge byproducts for purposes other than fertilizer should be explored...” The offsite incineration at H-power may be considered a beneficial reuse of the sludge; however, the energy produced would not be beneficial to the WWTP. Therefore, offsite technologies including composting by HER and incineration at H- Power are considered in the Supplemental Report for Resolution 11-182: Alternative Technologies for the Treatment and Minimization of Sewage Sludge. Evaluation Criteria The evaluation criteria for the technologies are as follows: Is it a Solids Handling Process? Process Input Requirement Responded to RFI? Status of Technology Development Ease of Operation Regulatory and Permitting Impact Footprint Ability and Willingness of Vendor to Pilot Is Upstream Anaerobic Digestion Required or Desired for Energy Production? End Product Ability to Produce Electricity Beneficial Byproducts Other Materials That Can Be Accepted Is Existing or Different Drying Required? Consumables Capital Cost for 25 dtpd Facility (Vendor Provided) Page xii of xvii

- 15. Alternative Technologies for the Beneficial Reuse of Sewage Sludge Response to Resolution 11-182 October 2011 O&M Cost (Vendor Provided) Does Capital and O&M estimate include upstream processing required such as drying? It should be noted that capital and O&M costs presented are unverified vendor estimates and may not include or take into account site requirements, ancillary items, and cost of installation in Hawai‘i. In addition, some of the vendors do not have full scale installations. In order to further consider appropriate technologies for solids processing, technologies with one or more of the listed “fatal flaws” below were not considered appropriate for future consideration. Technologies that are not considered “solids processing based” Technologies unable to process the 25 dtpd minimum amount of sludge Technologies where the main product is material that requires land application Technologies that are currently at the conceptual level Technologies where the vendor actively declined to respond to the RFI. Technologies where the providing vendor did not acknowledge or respond to the RFI. Table 2 presents all technologies that were evaluated in this report, with the technologies recommended for future consideration highlighted. The listed and evaluated technologies exclude those used at the Synagro Bioconversion Facility. As the table shows, there is a wide range of technologies included. The list and development status of technologies/vendors will be continually updated during the island-wide master planning process. Risks of Unknown Technologies As many of the “appropriate” technologies considered are not “established” and there are limited installations world-wide, the risk of unknown information is high. There may be unknown disadvantages and unknown costs for the newer technologies. For “concept” technologies, the unknowns include unknown results of a pilot test and unknown costs and it may be difficult to prove the claims of the vendor. For “emerging” technologies, there is the unknown of upsizing to a full scale installation for both results and costs. For “demonstration” technologies, the unknown is if the results from the full scale installation can be reproduced. Page xiii of xvii

- 16. Alternative Technologies for the Beneficial Reuse of Sewage Sludge Response to Resolution 11-182 October 2011 Insert Table 2 Screened Technologies Page 1 Page xiv of xvii

- 17. Alternative Technologies for the Beneficial Reuse of Sewage Sludge Response to Resolution 11-182 October 2011 Insert Table 2 Screened Technologies Page 2 Page xv of xvii

- 18. Alternative Technologies for the Beneficial Reuse of Sewage Sludge Response to Resolution 11-182 October 2011 SELECTION AND IMPLEMENTATION Supplemental Report of Additional Technologies In addition to this document, the Supplemental Report for Resolution 11-182: Alternative Technologies for the Treatment and Minimization of Sewage Sludge will be completed by November 11, 2011 to identify other solids technologies that may be appropriate for solids treatment but may not directly meet the Resolution requirements. These technologies may be applicable to both the small and large WWTPs. Similar to this report, the Supplemental Report for Resolution 11-182: Alternative Technologies for the Treatment and Minimization of Sewage Sludge will list technologies to consider for further evaluation during the master planning process. Further Evaluation and Life-Cycle Cost Analysis For each technology classification a single technology/vendor will be used as a representative for comparison purposes during the island-wide planning effort. This evaluation should not be viewed as selecting the vendor for CCH rather selecting the category that best suits CCH current and future needs. The ultimate selection of the vendor/technology would be based on competitive bidding by the appropriate method such as design, bid and build (DBB), design and build (DB), design, build and operate (DBO), design, build, operate and maintain (DBOM), and design, bid, own, operate and finance (DBOOF). Further evaluation of technologies will be qualitatively conducted during the island-wide study evaluation using the criteria listed below in order to arrive at a group of technologies that are most appropriate for solids processing. Expected capital cost Expected O&M cost Ease of operation and maintenance Energy producing potential Sustainable technology (measured as CO2e potential) Public perception of the facility Although some of the information above is presented in the current comparison tables, it should be noted that the values listed are for a “generic” plant that produces 25 DT/day and not a specific WWTP operated by CCH. A more detailed evaluation and check should be performed to ensure that comparable scope items are included in the capital and O&M costs and that the “cost” factors are the same for all options based on the local island costs. For example, Nexterra provided a capital and O&M cost for their gasification systems but did not include the drying component as a part of the cost. In addition, the scope boundary for an O&M estimate should be thoroughly checked in the detailed evaluation to ensure that any comparison made for further screening is based on an “apples to apples” comparison. Moreover, inclusion of any boundaries set for labor and hauling costs should be the same for all screened technologies. This type of thorough check has not been completed at this time and will be included in the Island-Wide Solids Master Planning for the “short-listed” technologies. Island-wide Solids Master Planning CCH is currently underway with an Island-wide Solids Master Plan to evaluate the existing solids treatment and disposal at all the CCH operated WWTPs. The goal of this master plan is to recommend improvements or upgrades at these WWTPs. The solids recommendations from Page xvi of xvii

- 19. Alternative Technologies for the Beneficial Reuse of Sewage Sludge Response to Resolution 11-182 October 2011 the Honouliuli, Kailua, and Sand Island facilities plans will be incorporated into the Island-wide Solids Master Plan. Key elements of the master planning effort are outlined below: Island-wide Solids Quantity and Quality Estimates - Determine existing and project future solids quantity and quality at each WWTP. Solids Reduction at Smaller WWTPs (< 5 mgd) - Determine the cost effectiveness of onsite solids reduction treatment to reduce hauling, offsite treatment, and/or disposal costs for the smaller WWTPs, especially the WWTPs that haul liquid waste to the larger facilities. Island-wide Transportation, Treatment, and Disposal - Evaluate the cost effectiveness of transportation, treatment, and disposal options for all nine CCH operated WWTPs. Redundancy and Reliability for Processing and Disposal - Determine the reliability and back-up options for the planned solids processing and disposal in the event that one option is unavailable due to mechanical failure or other causes. Island-wide Solids Processing and Disposal Plan - Incorporate the findings of the previous reports to recommend upgrades to the existing solids processing and disposal at each WWTP. Schedule and Implementation Pilot Testing – If conducted, pilot testing of technologies is anticipated to take at least 18 to 24 months. This includes 12 months of data collection once the pilot testing facility is in operation. Master Plan Timeline - The master plan timeline is as follows: o Complete Sampling and Testing - January 2012 o Island-wide Solids Quantity and Quality Estimates – April 2012 o Solids Reduction at Smaller WWTPs – May 2012 o Island-wide Transportation, Treatment, and Disposal – May 2012 o Redundancy and Reliability for Processing and Disposal – August 2012 o Island-wide Solids Processing and Disposal Plan – December 2012 Design and Construction - Design and construction scheduling depends on the construction and phasing recommendations in the Island-wide Solids Processing and Disposal Plan. It is anticipated that design for each project would take one year and procurement and construction would take two to three years. It is assumed that some projects may run concurrently. Honouliuli and Sand Island Secondary Treatment - The Honouliuli and Sand Island WWTPs are anticipated to begin full secondary treatment by 2024 and 2035, respectively, in accordance with the 2010 Consent Decree. The solids quantity is expected to increase substantially when these WWTPs become secondary WWTPs. Master planning efforts along with any near term design and construction will take into consideration the timing and future anticipated needs at both facilities. Facilities Planning for Kailua, Honouliuli, Sand Island, and Waianae WWTPs – The net outcome of Facilities Plans and Island-wide Solids Master Plan will be coordinated to be in agreement regarding the proposed solids handling facilities at the referenced WWTPs Page xvii of xvii

- 20. Alternative Technologies for the Beneficial Reuse of Sewage Sludge Response to Resolution 11-182 October 2011 1.0 INTRODUCTION AND OVERVIEW 1.1 Background The City and County of Honolulu (CCH) entered into the 1995 Consent Decree (Civil No. 94- 00765DAE) with the State of Hawaii and the Environmental Protection Agency (EPA). As part of the 1995 Consent Decree, CCH committed to Supplemental Environmental Projects (SEPs) which included spending at least $10 million on beneficial sludge reuse. The result of the 1995 Consent Decree was a contract in 2004 between CCH and Synagro WWT, Inc. (Synagro) in which Synagro would design/build/operate an In-vessel Bioconversion Facility (Bioconversion Facility) at the Sand Island Wastewater Treatment Plant (WWTP) to convert the sludge into a pellet fertilizer. The main components of the Synagro In-vessel Bioconversion Facility are an egg-shaped digester for anaerobic digestion, two centrifuges for dewatering, and a dryer for pelletizing. The 2010 Consent Decree between CCH, State of Hawaii, and EPA included the upgrade of the Sand Island and Honouliuli WWTPs to full secondary treatment. In addition, CCH is evaluating alternatives to the Waimanalo Gulch Landfill by conducting an Island-wide Biosolids Master Plan. Currently, the egg shaped digester at Sand Island WWTP is at full capacity resulting in the need to consider either expansion of existing operations or alternative technologies for processing and treatment. On June 28, 2011, the City Council signed Resolution 11-182 (herein referred to as the Resolution and provided in Appendix A), which stated concerns about the current bioconversion facility including: (1) Public health and safety (2) Impact to businesses and residents (3) Visual blight and impacts to tourism (4) Marketability of fertilizer pellets (5) Reputation and credibility (6) The cost to construct the existing bioconversion facility was over $40 million, including cost overruns exceeding $7 million, and the projected cost of the second facility was budgeted at $26 million As part of an ongoing contract with ENV, AECOM began work in August 2010 on a Leeward Region Solids Master Plan. In June 2011 ENV requested AECOM expand the effort to prepare an Island-Wide Solids Master Plan. The Island-wide Solids Master Plan is evaluating the existing solids treatment and disposal at all the CCH operated WWTPs with the goal of recommending improvements or upgrades at these WWTPs. On July 1, 2011 AECOM was further tasked by ENV to investigate and prepare a report in response to Resolution 11-182, which requested the administration to: “...investigate alternative technologies for the beneficial reuse of sewage sludge other than the technology used at the Sand Island WWTP’s bioconversion facility that will be sustainable and less harmful to the environment, including technologies successfully used in Europe, Asia and North America by companies with good reputations for credibility... to the end that the Council [would] work with the City administration expeditiously to implement a safe and healthful alternative to the Synagro technology so as to ensure that any necessary construction may commence as soon as possible.” Page 1 of 36

- 21. Alternative Technologies for the Beneficial Reuse of Sewage Sludge Response to Resolution 11-182 October 2011 1.2 Purpose The purpose of this report is to respond to the Resolution by identifying potential alternative sludge processing technologies for the beneficial reuse of sewage sludge other than the technology used at Sand Island WWTP. Some of the technologies included in this report are from vendors that responded to a Request for Information (RFI), were known by AECOM or had approached the CCH and/or the City Council directly. It should be noted that this report is not intended to be a decision making document and it is only intended to identify appropriate technologies to consider moving forward and provide a high level comparison. A more detailed and thorough analysis will be conducted with the island-wide study. 1.3 Objectives The objectives of this report include: Assemble a formal RFI, provided in Appendix B, for a generic WWTP that produces 25 dry tons per day (dtpd) of solids but does not use the treatment process currently at Sand Island WWTP. Submit the RFI to the National Biosolids Partnership (NBP), the Mid Atlantic Biosolids Association (MABA), and the North East Biosolids and Residuals Association (NEBRA) to post on their websites and pass on to their respective members to allow experts in the field to comment and provide information about innovative and emerging technologies. Submit the RFI to various technology vendors that directly contacted CCH or City Council. Compile a list of technologies or vendors and information that was received from the RFI process. Compile a list of criteria to evaluate the technologies or vendors. Compile a list of technologies that should be further evaluated in the upcoming Island- wide Solids Master Planning. The outcome of this report is a list of technologies meeting the requirements of the Resolution for consideration as part of the ongoing island-wide solids planning effort. The intent of this technology listing is to have appropriate technologies to evaluate in considering island-wide sludge management needs. This report is not intended to be a decision making document that recommends a best solution. Some additional factors that will need to be determined as part of any evaluation and selection process would likely include: An assessment of a particular alternative technology specific to the WWTP with respect to the facilities already existing there. Capital and O&M costs specific to the WWTP in which it is being evaluated for. Implementation timeline for planning, design, permitting, procurement, construction and startup. Compatibility of technology with overall Island-wide Solids Master Plan New development and increased future capacity needs Planned upgrades at the existing WWTPs (i.e. upgrade to secondary treatment) It should be noted that technology and process selection for implementation at any of the nine WWTPs will need to be looked at from an island-wide perspective due to the issues of combining/transportation of solids between WWTPs as well as the identified end user needs and beneficial use limitations. Other key elements that were considered include reliability and Page 2 of 36

- 22. Alternative Technologies for the Beneficial Reuse of Sewage Sludge Response to Resolution 11-182 October 2011 redundancy planning in the event that a WWTP treatment unit (i.e. centrifuge or digester) or solids outlet (i.e. landfill or composting facility) is temporarily out of service. 1.4 Methodology The vendors contacted during the compilation of technologies for this report included technologies known by AECOM, technologies included in Work Task 11.C – Solids Processing Technology (April 2011), technologies from vendors that contacted CCH and City Council directly, and vendors that responded to the posting on NBP, MABA, and NEBRA websites. The vendors were sent and asked to respond to the RFI. The information collected from the RFI was compiled and screening criteria were developed to determine technologies and vendors that may be applicable for beneficial reuse of sewage sludge at the larger WWTPs. Page 3 of 36

- 23. Alternative Technologies for the Beneficial Reuse of Sewage Sludge Response to Resolution 11-182 October 2011 2.0 OVERVIEW OF SOLIDS TREATMENT AND PROCESSING The following section provides background information that was taken into account when evaluating the different technology vendors. This section discusses common industry terminology, provides some regulatory background and summarizes the islands current biosolids plan. This section also provides background on the technology classification used to categorize the vendors as well as a summary of how the technology development was rated and the impact of site specific sludge characteristics. 2.1 Terminology This section defines terminology used in this report. Aerobic – Describes a condition where bacteria are living or occurring in the presence of oxygen. Many secondary treatment processes occur aerobically and sewage sludge can be digested under aerobic conditions to stabilize sewage sludge and generate biosolids. Anaerobic – Describes a condition where bacteria are living or occurring in the absence of oxygen. Many WWTPs digest their sludge anaerobically for stabilization, generating biosolids. Anaerobic process also produces methane (CH4) as a byproduct that can be beneficially used for energy production. Biosolids – Describes Solid materials resulting from wastewater treatment that meets government criteria for beneficial use, such as for fertilizer. To be classified as biosolids the sewage sludge must have undergone additional stabilization such as digestion, composting, drying or alkaline stabilization to meet federal and state standards for beneficial use. The stabilization requirements to convert sewage sludge to Biosolids are defined by the EPA under 40 CFR (Code of Federal Regulations) Part 503 Cake – Informal term used to describe dewatered sludge or dewatered biosolids coming off of a dewatering device such as a belt filter press or centrifuge. Class A Biosolids – Describes biosolids that are processed to the requirements defined by the EPA under 40 CFR, Part 503 with regards to pathogen and vector attraction reduction requirements. The goal of developing class A standards was to provide a quality of biosolids where pathogens in sewage sludge (including enteric viruses, pathogenic bacteria and viable helminth ova) were below detectable limits as defined in the 1992 regulation. Class B Biosolids – Describes biosolids that are processed to the requirements defined by the EPA under 40 CFR, Part 503 with regards to pathogen and vector attraction reduction requirements. The goal of developing class B standards was to provide a quality of biosolids where pathogens were below levels considered likely to pose a threat to public health and the environment under the specific use conditions. Applying Class B sludge involves site use restrictions to minimize the potential for human or animal exposure to Class B solids for a set period of time. Dewatering – The process of extracting or removing water from sludge or slurry Drying – To remove water through the means of evaporation Dry Tons – A unit of measurement representing only the dry mass of a substance. One dry ton is equal to 2,000 dry pounds (lbs) (Example: 10.0 dry tons at 35% solids 28.6 wet tons) In-vessel Bioconversion Facility – A term used by Synagro to describe the full sludge processing system at Sand Island including digestion, dewatering and drying. The process as installed converts thickened sewage sludge to a dry pelletized biosolids product that meets Class A requirements and can be marketed as a fertilizer product. Page 4 of 36

- 24. Alternative Technologies for the Beneficial Reuse of Sewage Sludge Response to Resolution 11-182 October 2011 In-vessel Composting Facility – A composting system with integral materials handling and in-vessel mixing and aeration. Solids Minimization – Process that reduces the mass and volume of sludge for further processing, beneficial reuse or disposition Pelletizing – A process that generates a uniform round or cylindrical dry biosolids product (a pellet). Some dryers are designed with back mixing, screening or other mechanisms to produce pellets at the dryer’s outlet. A second process can also be added to convert a non-uniform dried material to pellets. Percent Solids – The percentage of a sludge or biosolids total mass that is solid material. The percent water fraction is equal to one minus the percent solids Sludge - Solid matter that settles to the bottom of septic tanks or WWTP sedimentation; must be disposed of by bacterial digestion or other methods of stabilization. Sludge can also be pumped out for land disposal or incineration. Stabilization – A process that is applied to sludge for the purpose of reducing pathogens, eliminating offensive odors, and inhibiting, reducing or eliminating the potential for putrefication (EPA’s 503 documents). Volatile Solids (VS) - Materials, generally organic, that can be driven off from a sample by heating, usually to 550 °C (1022 °F); nonvolatile inorganic solids (ash) remain1. Wet Tons - A unit of measurement representing only the total mass of a substance including the mass of water. One wet ton is equal to 2,000 wet lbs (example: 10.0 wet tons 3.5 dry tons at 35% solids) 2.2 Regulatory Background 2.2.1 Land Application For Land Application under EPA Federal Regulations (Under 40 CFR Part 503), processed residuals to produce biosolids are grouped into two categories depending on pathogen reduction: Class A and Class B. Class A biosolids that meet metal contamination limits are deemed Exceptional Quality. Class A biosolids are treated to reduce the presence of pathogens to very low levels and can be used without any pathogen related restrictions. Class B biosolids are also treated to reduce pathogens but to levels that are not as low as Class A biosolids. To compensate, there are a number of site restrictions for land application of Class B biosolids including buffer zones and restrictions to public access which are intended to safeguard public health. Class B beneficial reuse is effectively restricted to agricultural applications. Sewage sludge that is not processed to either Class A or Class B standards is not considered biosolids. To meet Class A requirements a process must be used to reduce pathogen levels to certain criteria. The process must also include a vector attraction reduction step either before or co- current with the pathogen reduction step which is meant to stabilize the biosolids. Currently the EPA defines six alternatives to meet Class A pathogen requirements. The objective of the six alternatives is to reduce pathogen densities below detectable limits as defined when the regulations were written. Class A pathogen requirements are met by Alternative 1 through high temperature treatments based on set time and temperature curves. Alternative 2 requires high pH and high temperature processes (alkaline treatment) for producing class A. A process that does not meet one of the specific alternatives can achieve Class A through extensive pathogen, enteric virus and helminth ova testing through Alternative 3. Alternative 4 also allows for Class A of biosolids that are treated in an unknown process through extensive pathogen testing similar 1 Water Environment Federation (WEF) Website. Glossary of Terms (http://www.wef.org/AWK/page.aspx?id=1951). Page 5 of 36

- 25. Alternative Technologies for the Beneficial Reuse of Sewage Sludge Response to Resolution 11-182 October 2011 to what is required in Alternative 3. Alternative 4 is mainly targeted for solids that are stockpiled or stored for extended periods in lagoons. Alternative 5 defines several Processes to Further Reduce Pathogens (PFRP) which include processes such as heat drying, composting, and pre- pasteurization among others. Alternative 6 allows for other processes to be classified as being equivalent to an existing PRFP defined in Alternative 5. To meet Class B requirements, a process must be used to reduce pathogen levels but not to quite as low of a level as it required for Class A. The EPA currently defines three alternatives to meet Class B. Alternative 1 is to perform fecal coliform testing to ensure it is below the defined threshold. Alternative 2 is to use a Process to Significantly Reduce Pathogens (PSRP) such as aerobic digestion, air drying, anaerobic digestion, composting, or lime stabilization. Biosolids can also be classified as Class B by proving that a process is equivalent to a PSRP. Vector attraction reduction is also an important component of both Class A and Class B requirements. A vector is defined by the EPA as “any living organism capable of transmitting a pathogen from one organism to another either mechanically (by simply transporting the pathogen) or biologically by playing a specific role in the life cycle of the pathogen.” Vectors for sewage sludge pathogens include insects, rodents, and birds. There are several defined methods for meeting vector attraction reduction. The vector attraction reduction methods are generally related to VS destruction, specific oxygen uptake rate (SOUR) tests, aerobic requirements, pH requirements, percent dryness, or through a method of applying the biosolids to the land where it would prevent the attraction of vectors. 2.2.2 Emissions for Sewage Sludge Incineration (SSI) A major concern for any SSI technology is the impact of the process on air quality and potentially rigorous air permitting requirements. In March 2011, New Sewage Sludge Incinerators Rules regulated under 40 CFR, Part 60 and Section 129 of the Clean Air Act were enacted. From the new rules, all sewage sludge incinerators will now require a Title V air permit. The ruling requires stricter air permitting and monitoring requirements than was previously required under the previous rules which were regulated under Section 112 of the Clean Air Act. The new regulations are specific for Multiple Hearth Incineration (MHI) and Fluid Bed Incineration (FBI); however, they may also impact the gasification technologies discussed herein. It is expected that two stage gasification technologies may be exempt from the ruling since the process includes syngas cleaning. However, there is not a biosolids gasification system installed in the US that has been permitted since the new rules were enacted so there is not currently a precedent set to know exactly how concept and emerging combustion or gasification technologies will be regulated. 2.3 Current CCH Treatment and Processing Operations CCH currently operates nine WWTPs on Oahu including Honouliuli, Kahuku, Kailua, Laie, Paalaa Kai, Sand Island, Wahiawa, Waianae, and Waimanalo WWTP. Figure 2-1 shows the locations of the WWTPs along with the location of the Waimanalo Gulch Landfill. Figure 2-2 shows the process flow for the CCH’s three largest WWTPs; Kailua, Honouliuli, and Sand Island WWTPs. Page 6 of 36

- 26. Alternative Technologies for the Beneficial Reuse of Sewage Sludge Response to Resolution 11-182 October 2011 Figure 2-1. Location of WWTPs and Waimanalo Gulch Landfill Page 7 of 36

- 27. Alternative Technologies for the Beneficial Reuse of Sewage Sludge Response to Resolution 11-182 October 2011 Figure 2-2. Honouliuli, Kailua, and Sand Island Process Flow Diagrams Page 8 of 36

- 28. Alternative Technologies for the Beneficial Reuse of Sewage Sludge Response to Resolution 11-182 October 2011 Under normal operating conditions, all WWTPs except for Wahiawa WWTP stabilize their solids via aerobic or anaerobic digestion. Currently, Honouliuli, Kailua, and Waianae WWTPs sludge goes through anaerobic digestion for stabilization and centrifuges for dewatering. The biosolids are then hauled to Waimanalo Gulch Landfill for disposal. The Synagro Bioconversion Facility at Sand Island WWTP also has anaerobic digestion for stabilization, followed by dewatering, and drying for pelletization. The pellets produced at the Synagro Bioconversion Facility have been used as a fertilizer at agricultural farms, golf courses, and parks. The pellets that do not meet the specifications or cannot be marketed are hauled to Waimanalo Gulch Landfill for disposal. The Kahuku and Waimanalo WWTPs haul liquid waste to Kailua WWTP and Paalaa Kai and Wahiawa WWTPs haul liquid waste to Honouliuli WWTP for further treatment. The Wahiawa WWTP is currently being upgraded with membrane bioreactors (MBRs); the solids quality and quantity will differ once the MBRs are in service. The Laie WWTP has an onsite windrow composting facility that is operated by CCH staff but owned by the Mormon Church. The compost that has been approved for distribution is used by the Mormon Church for agricultural purposes and the compost that is not approved for distribution (mainly due to metal content) is disposed of at the Waimanalo Gulch Landfill. Table 2-1 presents information on the Island-wide Solids Production. Table 2-1. Island-wide Solids Production Average Solids State of Dewatering Solids WWTP Flow1 Stabilization Production2 Solids Method Distribution (mgd) (dtpd) Waimanalo Anaerobic Honouliuli 25.92 7.28 Cake Centrifuge Gulch Landfill Digester (~7 mi) Aerobic Kailua Regional Kahuku 0.19 0.26 Liquid None Digester WWTP (~34 mi) Waimanalo Kailua Anaerobic 11.49 2.65 Cake Centrifuge Gulch Landfill Regional Digester (~32 mi) Mormon Church/ Laie 0.46 Composting ---3 Compost Belt Filter Press Waimanalo Gulch Landfill Aerobic Honouliuli Paalaa Kai 0.09 0.05 Liquid None Digester WWTP (~21 mi) Class A Fertilizer Pellets Anaerobic Reuse/ Sand Island 61.29 Digester/Drye 9.21 Dried Pellets Centrifuge/Dryer Waimanalo r Gulch Landfill (~23 mi) Honouliuli Wahiawa4 1.64 Not Stabilized 2.00 Liquid None WWTP (~17 mi) Waimanalo Anaerobic Waianae 3.31 0.44 Cake Centrifuge Gulch Landfill Digester (~8 mi) Anaerobic Kailua Regional Waimanalo 0.55 0.26 Liquid None Digester WWTP (~33 mi) 1 Source: City and County of Honolulu, Dept of Environmental Services, Wastewater Management website (FY 2011) 2 Source: Annual Biosolids Production Reports – January 1 to December 31, 2010, Division of Wastewater Treatment and Disposal, ENV 3 Dry weight is not available (no percent solids data). Laie WRF produced a total of 1,056 cu. yd. of compost that was disposed at the landfill. This is approximately 727.6 wet tons (based on a measured unit weight of 51 lbs/cu. ft.) Source: Note 8, Annual Biosolids Production Reports – January 1 to December 31, 2010, Division of Wastewater Treatment and Disposal, ENV 4 Wahiawa WWTP is currently being upgraded to an MBR facility, so solids characteristics may change when the new processes are in operation. Page 9 of 36

- 29. Alternative Technologies for the Beneficial Reuse of Sewage Sludge Response to Resolution 11-182 October 2011 2.4 Treatment and Processing Technology Classification The identified vendors and their technologies covered a wide range of treatment and processing types. In order to facilitate an organized approach to determining applicability many of the vendors were organized by the general classification or technology category which best described the process using standard industry terminology as described in the following paragraphs. It should be noted that some solution providers responding to the RFI were not actually equipment manufacturers or suppliers. These solution providers were often system integrators that provided an alternative means of financing, often involving a rate payback system or power purchase agreement to recuperate initial construction costs. As discussed further in the report, the economics and life-cycle cost comparison of the various alternatives will be conducted as part of the Island-wide Solids Master Plan and as such only the specific technologies proposed by any respective vendor are considered, irrespective of financing methodology. The technology classifications are presented with the more established technologies listed first, followed by the newer and innovative processes. This section summarizes the technology classifications. Additional information is provided in Appendix C. 2.4.1 Digestion Digestion is decomposition of organic matter in sewage treatment. There are two main types of digestion; aerobic digestion (with air) or anaerobic digestion (without air). Both aerobic and anaerobic digestion are well established technologies that have been used throughout the world. CCH currently has two facilities that include aerobic digestion and five facilities that use anaerobic digestion. Aerobic digestion is a well proven process and is similar to activated sludge processes used in secondary treatment. Aerobic digestion uses aerobic microbes to decompose organic matter, stabilize sewage sludge and generate biosolids. Aerobic digestion is most commonly practiced at plants less than 5 mgd. Aerobic digestion typically yields high VS destruction, has a low biological oxygen demand (BOD) concentration in the side streams from dewatering, produces a relatively odorless stable end product, maintains a high nutrient value in the biosolids, is simple to operate and involves relatively low capital costs. The aerobic process, however, requires a lot of air input which requires a high electrical consumption. The resulting liquid biosolids are typically difficult to dewater. The process is also very dependent on operating conditions and does not produce a useful energy producing byproduct (CH4). Conventional Aerobic digestion produces Class B biosolids. A system can also be designed as an Autothermal Thermophilic Aerobic Digestion (ATAD) process which uses the exothermic energy in the biological process to heat the reactor to thermophilic conditions generating Class A biosolids. Since Aerobic Digestion is energy intensive and not suitable for large plants, it is not considered an appropriate solution for CCH’s larger plants and will not be discussed further in this report. Anaerobic digestion is another well proven process that involves the decomposition of organic matter and inorganic matter in the absence of oxygen. The decomposition process produces a digester gas that consists of mostly CH4 (~65%) and carbon dioxide (CO2) (~35%). Anaerobic digestion of municipal wastewater solids can, in many cases, produce sufficient digester gas to meet the energy requirements of digestion and other plant operations. Therefore, due to the emphasis on energy conservation and recovery, the process continues to be advantageous for stabilizing sewage sludge. In principle, the conversion of organic matter to CO2 and CH4 reduces biological solids leaving the digestion process. Digestion can reduce the total volume Page 10 of 36

- 30. Alternative Technologies for the Beneficial Reuse of Sewage Sludge Response to Resolution 11-182 October 2011 of solids to be dewatered and the polymer cost for dewatering. There are a number of digestion designs which can produce Class A and Class B biosolids, allowing for flexibility with reuse options, by meeting the requirements of EPA’s Part 503 Rule. Anaerobic digestion does however, require a relatively large footprint when compared to alternative technologies and can have a high capital cost. Also since anaerobic digestion is a biological process, it slowly recovers from an upsets. The process may also accumulate with scum and grit which could be difficult to clean and foaming may be problematic as well. Downstream dewatering centrate may also be high in ammonia and could require separate treatment if there are tight nitrogen limits. The process may also be susceptible to struvite formation which can cause operation and maintenance issues with scaling in pipes, heat exchangers, valves and other equipment. Figure 2-3 shows the anaerobic digester schematic. Figure 2-3. Anaerobic Digester Schematic (Figure from www. meniscus.co.uk) The biogas produced can be captured and treated for various energy recovery uses including heat and electrical power in combined heat and power (CHP) system. CCH currently operates anaerobic digesters at the Kailua, Honouliuli, Sand Island, and Waianae WWTPs and CCH is evaluating CHP options at these WWTPs in upcoming Energy Savings Performance Contracts (ESPCs). 2.4.2 Composting Composting is a well-established process in which biodegradable material is decomposed by aerobic microorganisms in a controlled environment. The heat generated in composting pasteurizes the product and significantly reduces pathogens. The heat generated also drives off water vapor, further dewatering the product and reducing reuse volume. Composting that is performed according to regulatory guidelines produces Class A Biosolids. Composting that is performed properly can produce a nuisance-free humus-like material. The three different methods of composting typically used for wastewater sludge are aerated static pile, windrow and in-vessel composting. Composting is a relatively simple process to operate and all composting processes generally include common basic steps. First, the dewatered sludge is mixed with an amendment and/or Page 11 of 36

- 31. Alternative Technologies for the Beneficial Reuse of Sewage Sludge Response to Resolution 11-182 October 2011 bulking agent to increase porosity of the mixture and provide a carbon source to improve the degradability of the compost. A rule of thumb for composting is to have a 25:1 to 35:1 ratio of carbon to nitrogen (mass basis). The resulting mixture is piled or placed in a vessel where microbial activity causes the temperature to rise starting the “active composting” period. The desired temperature required for optimal operation and end quality vary based on the method of composting and desired use of the end product. The key is to keep the material aerated to allow aerobic bacteria to work. After the “active composting” period is complete, the material is cured and distributed. Static pile and windrow composting are generally manual in operation and can be operator intensive. In-vessel composting is generally a proprietary process provided by a vendor or solution provider and is typically more automated and sophisticated than other composting methods. Composting is an established technology with more than 300 installations nationwide. CCH currently operates the Laie WWTP which has an onsite composting facility. Due to the large footprint requirements required for composting, CCH may not be able to implement an onsite composting facility at any other WWTP, however, off-site composting such as the system proposed by Hawaiian Earth Recycling, LLC (HER) may be a feasible alternative. It would be the responsibility of the composting company to market and distribute the product. 2.4.3 Heat Drying Only Dryers come in several types, all of which operate with the goal of decreasing water content in wastewater sludge. Drying is typically used in the last stage of solids processing and is done in combination with a dewatering process. Dryers are typically fed with dewatered sludge at approximately 15-35% dry solids (DS) and dry the biosolids to 90-95% DS. Sludge fed to dryers can be either undigested or digested dewatered sludge, although some vendors have restrictions with handling undigested primary sludge. As a general rule upstream digestion is typically recommended for primary sludge due to potential for odors in the final product. Dryers are able to produce Class A biosolids which can be beneficially used. Even if beneficial use is not the desired option, the drying process greatly reduces the storage, transportation and disposal cost since it significantly lowers the water content and reduces the weight. Dryers are classified into three categories: 1) direct (convective) dryers, 2) indirect (conductive) dryers, and 3) combination direct/indirect dryers. Direct dryers use a drying medium such as hot air, which comes in direct contact with the sludge to increase the sludge temperature through convective heat transfer and evaporate the water in the sludge. Indirect dryers use a medium such as hot oil or steam that heats the sludge through a conducting surface, so that the heating medium does not come in direct contact with the sludge. Combination dryers use two mediums, one which comes in direct contact with the sludge and one which heats the sludge through a membrane. Most dryers are flexible and able to use most fuel sources such as natural gas, propane, diesel fuel or fuel oil. The dryers can also be equipped with burners that can directly use digester or other biogas sources, although there typically needs to be a supplemental or standby fuel in addition. Some dryers use the fuel to directly heat hot air for drying while others may use a heat transfer fluid such as thermal oil, steam or hot water to provide heat to the dryer. The ability to use waste heat from other processes, such as a CHP system, depends on the specific dryer design and operating temperature. Lower temperature dryers that utilize a heat transfer fluid are generally better suited for low temperature waste heat recovery applications. Unless waste heat or fuel that results as a byproduct from another process (i.e. CH4) is used, the operating cost of drying can be high due to the cost of consuming a large amount of fossil fuels. Page 12 of 36

- 32. Alternative Technologies for the Beneficial Reuse of Sewage Sludge Response to Resolution 11-182 October 2011 There are potential risks and safety concerns with dryers related to fire and explosion potential due to combustible gases and dust. Safety systems such as a sprinkler system or water deluge system are typically incorporated in the event an emergency condition such as high temperature or carbon monoxide (CO) level is detected. Some dryers may also contain fugitive dust monitoring, explosion relief panels and nitrogen purge systems. The safety system incorporated typically depends on the type of dryer used and designed operating conditions. The dry product can also be a risk for fires and explosions if large amounts of product are stored in a storage vessel or silo. Specific safety precautions such as temperature and CO or CO2 monitoring, and inert air (nitrogen) blankets are typically required. Drying is an established technology that requires a relatively small footprint and does not generally require chemical additives. CCH currently has a third party operated direct rotary drum dryer at the Sand Island WWTP that produces class A pellets that are marketed for beneficial reuse. The pellets are currently beneficially reused for agricultural purposes although they can also be beneficially reused for energy production. Dryers can be capital cost intensive and are more complicated to operate than other stabilization technologies. 2.4.4 Incineration Incineration or advanced thermal oxidation is a combustion reaction that occurs in the presence of excess oxygen. Incineration is the most commonly used thermal conversion process practiced for sewage sludge today. FBI and MHI are established technologies and are the most common types of incineration used for sewage sludge. MHI is now considered an outdated technology and very few if any new systems are being constructed. Since MHIs and FBIs are mature technologies, there is extensive experience with both operation and applying air emission control technologies. With a full array of 204 incineration installations (144 MHIs and 60 FBIs) in operation throughout the country, there is a substantial database of background data available with which owners, vendors, and regulators are able to predict the expected performance of any proposed incinerator. With the future implementation of new EPA emission limits and standards for MHIs and FBIs, it would take some time for all parties to recalibrate their design guidelines to the stringent new standards. However, in general, vendors and engineers would be able to provide system guarantees to meet the emission limits. Incineration achieves significant volume reduction and produces a byproduct that is inert, sterile and free of pathogen and toxic organic compounds. Incineration can also be equipped with provisions for energy recovery and electrical generation. Incineration systems do not require prior stabilization and raw dewatered sludge feed is typically preferred since it has a higher heat value than digested biosolids. Incinerators also require a relatively small footprint. The Air permitting of a new incineration system, however, can be tedious and difficult especially with the new SSI rules and may not be feasible for a nonattainment2 area. Incinerators have a high capital cost and may require supplemental fossil fuel consumption if the feed is low in heat value or the moisture content is too high. The process can also be very complicated requiring a sophisticated operating staff and high operation and maintenance costs. The new SSI rules also require a continuous emission monitoring (CEM) for multiple pollutants. Besides tedious air permitting and monitoring requirements, incineration is not popular in many places and may be subject to public opposition. Furthermore the ash product residual from incineration many times 2 Nonattainment area per the EPA’s website is defined as “Any area that does not meet (or that contributes to ambient air quality in a nearby area that does not meet) the national primary or secondary ambient air quality standard for the pollutant.” Page 13 of 36