Scaffolding awareness presentation

- 2. COURSE ITINERARY •Introduction & Course Aims. •The law and your responsibilities •Types of scaffolding. •Component identification & use.. •Scaffolding terminology •Inspection of scaffolding. •Recording of inspections. •Reasons for collapses. •Course questionnaire 1

- 3. INTRODUCTION & COURSE AIMS THE REASON FOR THIS COURSE IS THAT “THE WORK AT HEIGHT REGULATIONS 2005” PLACES AN IMPLICIT DUTY ON THOSE USING SCAFFOLDING TO INSPECT AND RECORD THE RESULTS OF THOSE INSPECTIONS, BEFORE USE AND WITHIN SEVEN DAYS. THE AIM OF THE COURSE IS THAT THOSE TAKING PART WILL HAVE AN AWARENESS OF WHAT A LEGAL SCAFFOLDING SHOULD BE THAT THEY ARE RESPONSIBLE FOR 2

- 4. LEGISLATION • Health & Safety at Work Act 1974 • Provision and Use of Work Equipment Regulations 1998 • Management of Health & Safety at Work Regulations 1999 • Work at Height Regulations 2005 • Manual Handling Regulations 1992 3

- 5. Health & Safety at Work Act 1974 • • 1. 2. 3. 4. • • • Places a duty of care on your employer, who MUST; Protect your health & safety and the health & safety of others who they may not employ this basic duty involves providing you with; A SAFE PLACE OF WORK A SAFE SYSTEM OF WORK SAFE PLANT & EQUIPMENT TRAINING, INFORMATION, INSTRUCTION OR SUPERVISION You have a duty of care to protect yourself & others whilst at work; You may be held liable for any harm you cause to others at work; Suppliers have a duty to supply equipment that is safe to use, and to supply the relevant information/instructions for safe and correct use. 4

- 6. Provision & Use of Work Equipment Regulations 1998 1. 2. 3. These Regulations place duties on employers & suppliers to provide equipment for use at work which meets three basic criteria; IT MUST BE FIT FOR USE (it must work) IT MUST BE FIT FOR IT’S INTENDED PURPOSE ( it must do what you want it to do) IT MUST COMPLY LEGALLY & MEET ALL STANDARDS The provision of instructions, information, and training on the safe use of work equipment or the provision of competent supervision is a mandatory requirement under these regulations! If you find any work equipment unsafe or inoperative you must not use it, you must take out of service and inform your supervisor. 5

- 7. Management of Health & Safety at Work Regulations 1998 These Regulations place duties on Employers to carry out Risk Assessments on all work activities which will identify significant risks to peoples health & safety. Hazards found during work activities which have the potential to cause harm need to be removed if possible or if this is not possible they must be controlled in such a way as to reduce the likelihood of harm to the lowest possible risk. Safe systems of work are formulated from these risk assessments usually in the form of method statements which detail a safe method of work, the hazards identified, the controlling provisions put in place to protect workers and any residual risks for which appropriate PPE will be issued and must be worn. Employers are duty bound to Manage Health & Safety in such a way as to prevent foreseeable accidents and injuries to people in their employment and also people not in their employment. Workers who are to carry out working operations covered by a method statement must follow the safe method of work if this cannot be done then stop work! 6

- 8. Work at Height Regulations 2005 These regulations place an implicit duty on places from where it may be possible to fall. The overriding principal for employers to comply with these regulations is to do all that is reasonably Practicable to prevent anyone from falling. The hierarchy of control for managing and selecting equipment for work at height is: 1. 2. 3. Avoid work at height whenever possible. Use work equipment or other measures to prevent falls where they cannot avoid working at height. Where they cannot eliminate the risk of a fall, use work equipment or other measures to minimise the distance and consequences of a fall should one occur. 8

- 9. Work at Height Regulations 2005 These regulations place an implicit duty on places where it may be possible to fall. Fall prevention measures include the provision of; 1. Top hand-rail no less than 950mm; 2. Toe boards on all open edges from which objects can fall; 3. Toe board minimum height 150mm; 4. Maximum gap between the top of the toe board and any guardrail 470mm this usually means double guardrails are employed, but other suitable protection can replace the middle rail such as a substantial mesh panel, but the requirement for this protection to remain in place for the life of the working platform must be enforced by management. 5. Minimum width of a working platform must be adequate for the work to be carried out but not less than 600mm for persons only, if depositing materials then minimum width must be 800mm. 6. Maximum vertical climb to a working platform must not exceed 9mtrs (rest deck) 7

- 10. Manual Handling Regulations 1994 These regulations place a duty on employers to carry out risk assessments on activities which may involve manually handling loads. The risks of manual handling injuries must be reduced by; • Removing the need to manually handle loads; • Redesigning the work place or equipment or redesigning the working process to reduce manual handling operations; • Reducing size, weight, shape or centre of gravity of loads; • Making available mechanical means so loads can be moved safely; If loads have to be moved by human effort the employer must provide manual handling training so that people know how to lift & move loads correctly so as to reduce the risk of a manual handling injury. 9

- 11. LEGAL REQUIREMENTS The three main pieces of legislation / codes of practice governing the use of scaffolding are: •Work at Height Regulations 2005 •BS EN12811-1 •Regulation 12 (10) - WAHR Inspections are required by competent persons: •Training. •Knowledge. •Experience. •Under supervision. 10

- 12. LEGAL REQUIREMENTS •Regulation 12 - WAHR - Inspections are required on all scaffolding from which a person can fall : •Before use •After substantial alteration •After adverse weather or occurrence •Within every seven days 11

- 13. TYPES OF SCAFFOLDING •INDEPENDENT •BIRDCAGE •PUTLOG •TOWER •SYSTEM •Kwikstage •Cuplok •Alloy towers 12

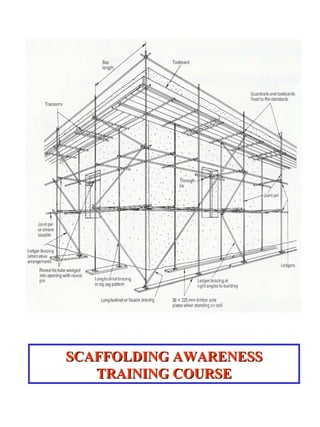

- 14. INDEPENDENT 13

- 15. BIRDCAGE 14

- 16. PUTLOG 15

- 17. TOWER 16

- 18. SYSTEM SCAFFOLDING There are numerous types of system scaffolding on the market and they all have their good points and bad points. The three types of system scaffolding we are concentrating on in this course are probably the most popular: • Alloy Tower • Kwikstage • Cuplok 17

- 19. ALLOY TOWER 18

- 21. IDENTIFICATION EXERCISE ANSWERS 1. 2 metre standard. 2. 3.54 metre diagonal brace. 3. 1.2 metre transom. 4. 2.4 metre Steelstage / battens. 5. 2.4 metre ledger. 6. Collar jack. 7. 1.2 metre Steelstage / toeboard. 8. 2.4 metre Guardrail. 20

- 24. SCAFFOLDING COMPONENTS •Base Plate •Brick Guard •Double Coupler •Girder Clamp •Joint Pin •Putlog Coupler •Reveal Pin •Scaffold Boards •Sleeve Coupler •Swivel Coupler 23

- 25. BASE PLATE Must be 150mm x 150mm with a pin centrally positioned and be placed under every standard at all times. 24

- 26. BRICKGUARD 25

- 27. DOUBLE COUPLERS These are load bearing couplers or fittings which must be used for ties at all times. 26

- 28. GIRDER CLAMP Used to tie scaffolds to steel girders, must always be used in pairs. 27

- 29. JOINT PIN / SPIGOT Used to butt join scaffold tubes end to end, should not be used in ledgers or sway braces. 28

- 30. PUTLOG COUPLERS Mills hook Wrapover Used to fasten intermediate transoms to ledgers, non load bearing fitting. 29

- 31. REVEAL PIN Used to fix tubes between two opposing faces as part of a reveal tie 30

- 33. BOARDED PLATFORMS Faults that should be checked for when inspecting a boarded platform are: • Oversail no less than 50mm. • Oversail no more than 150mm. • No gaps in working platform. • Correctly spaced transoms. •Max.1.2m for visually graded boards. • Boards fixed to prevent movement. • Not Damaged. • No undue cracks. • Not contaminated. • Not banded or Scaffplated. 32

- 34. SLEEVE COUPLER Should always be used to butt join ledgers and sway bracing in preference to joint pins. 33

- 35. SWIVEL COUPLER Used to connect any two tubes at any angle other than 90°, often used with a small butt to splice joints which require staggering. 34

- 36. SCAFFOLDING TERMINOLOGY •Bay. - Distance between standards. • Brace- Tube at an angle to give stability. • Guardrail - To stop persons falling. • Ledger - Tube supporting transoms. • Lift - Distance between ledgers. • Soleboard - placed under baseplate to spread weight on soft ground. • Standard - Upright tube. • Ties - Means of fixing scaffold to structure. • Toeboard - Upstand to prevent tools falling. • Transom - Tubes to support platform. • Working platform - set of boards to work on. 35

- 37. SCAFFOLDING TERMINOLOGY There are three types of bracing used in scaffolding, with three distinct functions and they are: • Ledger brace - to add rigidity to it. • Sway brace - to stop it from swaying. • Plan brace - to stop it twisting. The foundations or base of a scaffold is of vital importance and must be adequate to carry the weight of the scaffold and any load to be placed on it. The three main criteria when inspecting the base of a scaffold is: • Firm and level base. • Base plates at all times. • Soleboards when required. 36

- 39. SCAFFOLD INSPECTION All scaffolding must be inspected at the four times previously mentioned, by a competent person. This inspection must be completed before the end of the working period and after completing the inspection they must provide the report or a copy of it to the person responsible for the scaffolding, within 24 hours. This report must include the following: •Name & address of the person on whose behalf the inspection was carried out. •Location of the scaffold inspected. •Date & time of inspection. •Details of any faults identified. •Any action taken to rectify those faults. •Any further action required. •Name & position of person making the report. 38

- 40. 39

- 41. REASONS WHY SCAFFOLDS COLLAPSE •Constructed with inadequate materials. •Inadequate for the intended purpose. •Erected by incompetent people. •Placed on inadequate foundations. •Overloaded. •Undermined. •Altered by incompetent people. •Hit by machinery or shock loaded. •Subjected to excessive wind loads by being sheeted, whether flexible or solid. •Not regularly inspected by competent people 40

- 42. TYING SCAFFOLDS TO STRUCTURES Adequate stability for most scaffolds is achieved by tying them to the structure, these ties need to be positive two way ties. They are usually constructed from tubes & load bearing fittings in different configurations depending on the type of structure being tied to. Any scaffold which has been sheeted or debris netted will require more ties than one without, so no scaffold should be sheeted or debris netted without consultation with the scaffolding company. Any structure used to tie scaffolding to must be strong enough to take the weight and stress of the scaffolding and any weight to be placed on it. Most structures would be classed as normal facades and would be tied using one of the five most common methods of tying scaffolding which are: 41

- 43. TYING SCAFFOLDS TO STRUCTURES •Through Tie •Box Tie •Anchor Tie •Lip Tie •Raker Tie Other methods used are: •Reveal Tie •Buttress ties. Ties would usually start at the four metre level then as a rule of thumb they would be every other lift and every other standard. 42

- 46. TYING SCAFFOLDS TO STRUCTURES ANCHOR TIES 45

- 47. TYING SCAFFOLDS TO STRUCTURES LIP TIES RAKER TIE The maximum length of raker is 21feet or 6 metres because that is the longest scaffold tube and they should not be jointed for rakers. 46

- 48. TYING SCAFFOLDS TO STRUCTURES REVEAL TIE 47

- 49. LADDERS • TIED AT TOP AROUND STILES. • TIED IN MIDDLE (WHEN NECESSARY. • FIRM & LEVEL FOOTING. • GOOD CONDITION. • TOP RUNG LEVEL OR JUST ABOVE STEPPING OFF POINT. • 4 : 1 RATIO (APPROX. 75°) • NOT PAINTED. • PROJECTING AT LEAST 1.05M OR WITH SUITABLE HANDHOLD. 48

- 50. HAZARDS WITH LADDERS • UNSECURED. • OVER BALANCING. • SLIPS ON RUNGS. • DEFECTIVE. • FALSE STEPS. 49

- 51. INTERFERENCE • TIES REMOVED. • PLATFORM BOARDS REMOVED. • GUARDRAILS REMOVED. • BRICKGUARDS REMOVED • TOEBOARDS REMOVED. • STRUCTURAL PARTS REMOVED. • UNDERMINED. 50

- 52. PROTECTING THE PUBLIC • CAP TUBES BELOW HEAD HEIGHT • PROTECT ALL SHARP EDGES • HIGHLIGHT HAZARDOUS TUBES • AMPLE HEADROOM • PROTECTION FAN OR GANTRY • SIGNS AND BARRIERS. • SHEETING / DEBRIS MESH. 51

- 55. PRE - ERECTION CHECKS Points to check before allowing the erection of any type of scaffolding: •Is the surface to be erected on firm and level and will it take the weight of the scaffolding and everything to be placed on it. •Are there sufficient materials to complete the scaffold or the part to be erected. •Are the materials in good condition. •Is the access and egress suitable. •Are the persons erecting the scaffolding competent & have they seen and understood a risk assessment and if required a method statement. 54

- 56. PRE - ERECTION CHECKS CONT. •On soft ground solepads or soleboards must be used to spread the weight. •Any sole pad must be a minimum length of 450mm (18”). •On concrete or steel, base plates may now be omitted. •At all times ladders must be used to gain access to all levels of scaffolding. •Ladders should be placed at an angle of 4 -1 (75°) and should be tied at the top. •Ideally ladder access towers should be separate from the main scaffolding. 55

- 57. DISMANTLING PROCEDURES Points to check before dismantling any type of scaffolding: •Have any ties been removed? •Have any ledgers been removed? •Have any transoms been removed? •Have any braces been removed. •Have any other structural parts been removed? •Is there any damage to the scaffolding? •Are there any changes to the ground conditions? •Has the area been cordoned off with barriers and signs to warn others? 56

- 61. HANDOVER CERTIFICATE This will show a scaffold is, Fit for use, fit for purpose & will comply with all legal requirements. 60

- 62. PROTECTION FROM FALLS OF SCAFFOLDERS Basic principles of SG4:10 “Preventing Falls From Scaffolding” •Scaffolders will fit an advanced guardrail on all lifts before accessing it, if this is not possible they will follow these rules. •Scaffolders will wear harnesses at all times while erecting, altering & dismantling scaffolding. •Scaffolders will work on a three board wide correctly supported platform. •Scaffolders will work behind a minimum of a single guardrail protection. •If the two bullet points above can not be followed and the scaffolders are at four metres or above , then they will clip on their harnesses to an adequate anchorage point above head height or if not possible at foot height or above. 61

- 63. SCAFFOLD INSPECTION QUESTIONNAIRE Name: ---------------------------------------------- Date: ----------------------Company: -------------------------------------------------------------------------1) a) b) c) d) Name the 4 instances when scaffold requires to be inspected? ----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- 2) a) c) e) On inspecting a ladder on a scaffold, what will you be looking for? ----------------------------------------- b) --------------------------------------------------------------------------------------- d) --------------------------------------------------------------------------------------- f) ----------------------------------------------- 3) a) c) e) Give the 5 legal requirements of a working platform with dimensions ----------------------------------------- b) --------------------------------------------------------------------------------------- d) ------------------------------------------------------------------------------------------------------------------------------------------ 4) a) c) e) What are the 5 most common methods of tying scaffold? ------------------------------------------ b) --------------------------------------------------------------------------------------- d) ----------------------------------------------------------------------------------------------------------------------------------------- 1) What type of fitting should you not use for butt joining ledgers & sway braces? ------------------------------------ what should you use? ---------------------------- 1) What three checks should you be looking for at the base of a scaffold? • ------------------------- b) ---------------------------- c) ------------------------------- a) What type of fitting or coupler must be used for tying scaffolds? -------------------------------------------------------------------------------------------62

- 64. 8) As a rule of thumb what should you be looking for in the spacing of ties? -------------------------------------------------------------------------------------------- 9) Show allowable safe working loads and bay sizes for the following ? BAY SWL a) Very light duty --------- ---------- b) General Purpose Scaffold --------- ---------- a) Heavy duty ---------- ---------- 10) What spacings for transoms for the following thickness of boards? a) 38mm ------------------------------- b) 34mm ---------------------------------------- 11) a) c) e) What faults would you be looking for when inspecting a boarded platform? ------------------------------------------ b) --------------------------------------------------------------------------------------- d) ----------------------------------------------------------------------------------------------------------------------------------------- 12) Explain the following scaffolding terminology? 9) 10) Bay size: Lift height: 13) Explain the purpose of the following braces? a) b) c) Ledger brace: Sway brace: Plan brace: 14) What is the maximum length of a raker tube and why? a) -------------------------------------------------------------------------------------------Give 5 precautions you should look for to protect members of the public? a) 10) e) ------------------------------------------ b) --------------------------------------------------------------------------------------- d) --------------------------------------------------------------------------------------------------------------------------------------- --------------------------------------------------------------------------------------------------------------------------------- --------------------------------------- --------------------------------------------------------------------------- --------------------------------------------- ------------------------------- 63

- 65. 16) What must be done with a scaffold inspection report after the inspection has taken place and by what time scale? -------------------------------------------------------------------------------------------- 17) Although not a legal requirement what are the 3 benefits of asking for a handover certificate? a) b) c) ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- 18) Using the Scafftag system, what is the weight allowable on a light duty scaffold in either kilonewtons / kilograms or men & tools? 19) -------------------------------------------------------------------------------------------Using the Scafftag system, what is the weight allowable on a heavy duty scaffold in either kilonewtons / kilograms or men & equipment? 20) --------------------------------------------------------------------------------------Name 6 things which can contribute to scaffold collapses? a) c) e) --------------------------------------- b) ------------------------------------------------------------------------------------ d) ------------------------------------------------------------------------------------ f) ------------------------------------------------ MAXIMUM POINTS ACHEIVABLE: -------------------- ACTUAL POINTS ACHIEVED: -------------------- 64

- 66. FOR MORE INFORMATION ON ALL OF OUR COMPETENCY TRAINING COURSES PLEASE CONTACT: Bob Robinson AIIRSM AIOSH Proprietor A1 Training & Safety 10 Trenholme Road, Middlesbrough, Cleveland, TS4 2JX. Tel/Fax: Mob: 01642 - 292178 07790 675193 E- Mail: info@a1trainingandsafety.gbr.cc Web site: www.a1trainingandsafety.co.uk

Hinweis der Redaktion

- As you can see today's course is Scaffold Inspection Competency & my name is Bob Robinson, my experience is ……….. The course is two days duration, the majority theory & some practical, with questionnaire/s to see if the information given has been retained.Toilets are situated ……….. There is no smoking but there will be ample breaks for those that do. The fire alarms sound like …………. & if they go off we will leave quickly & quietly by the nearest exit which is situated …………. Any questions before we start?

- Run thro’ itinerary, expanding on points where necessary.

- Go thro’ aims & objectives, expanding on points as required.

- As each bullet point is revealed go thro’ them explaining where they fit into the use, erection, dismantling & inspection of Scaffolding e.g. Constr. Regs. Is an implicit duty, which means you can not change it or bend the rules, they must be followed exactly.

- Explain each point after reading them out.

- Explain each point after reading them out.

- Explain each point after reading them out.

- Explain each point after reading them out.

- Explain each point after reading them out.

- Explain each point after reading them out.

- Explain that although there is numerous legislation and codes of practice covering persons at work that these are the main two. As each bullet point is revealed go thro’ them explaining where they fit into the use, erection, dismantling & inspection of scaffolding e.g. Constr. Regs. Is an implicit duty, which means you can not change it or bend the rules, they must be followed exactly. BS 5973, they are recommendations & should be followed at all times, whenever possible.

- Read through and explain the slide on the relevant times to inspect scaffolding, the requirement to do a report of that inspection, although that is explained in more detail later and that this info answers a question in the questionnaire.

- These are the 5 Basic types of Scaffolding which you would be expected to inspect without more experience under this qualification.

- Explain the main component parts of an independent scaffolding, asking the question (what makes a scaffold independent) and explain the answer.

- Explain the main uses of birdcage scaffolding, the reason for its name etc.

- Explain the uses, the pros & cons of putlog, where the name comes from etc.

- Explain the uses, what makes the different types of scaffolding different i. e. number of standards etc., what makes them static / mobile.

- Explain about the different types of system and that there are others, some of the pros & cons of each system and the importance of the user guide of each system before inspecting.

- Explain about alloy towers but again explain about the need to have the particular assembly guide for the type being used and also the importance of an alloy tower course if this is a regular type of scaffolding used not just for erection but inspection also.

- If Kwikstage is a usual type of system used, get them from the picture in their books, to carry out this simple component ID exercise.

- Standard – specifically a 2m standard, which can be seen from the 4 “V” pressings shown. Brace – although we can’t be sure, experience says this is a 3.54 brace for an 8ft. Bay. Always braced from the bottom “V” pressing to just under the top working platform. Transom – in this case a 1.2m transom as can be seen from the 5 board wide working platform. Steelstage – rather than battens, which may be seen from the toeboards being hollow when seen from the back. Ledger – again probably 2.4m long also the same component used for the guardrail, shown only as a single guardrail, which is because it is an old drawing. Universal Jack – actually looks more like an adjustable base & head jack because you can see screw thread both above & below the collar but should always be a universal jack these days. Toeboard – using Steelstage as can be seen from the hollow back, a 1.2m Steelstage, would actually be outside the standards on end toeboard brackets not inside as shown. Guardrail – come in 2 sizes 1.8m (6ft.) & 2.4m (8ft.) as we have said should be double these days, or using Kwikguards / brickguards to close the gap to less than 470mm between guardrail & toeboard.

- This is a picture of the node point on Kwikstage system scaffolding as you can see there are four components fixed to make this node point i.e. Standard (with 2 high v pressings & 2 low v pressings) Transom (t section) which supports and captures the battens / Steelstage & ledgers (tubular section) there are 2 showing in this picture. There is also another low v pressing not visible which may take a fourth component. As you can see, ledgers are fitted to the high v pressings & transoms to the low v pressings.

- This is a picture of a 2 bay Cuplok independent showing the 8 basic components required to erect this type of system scaffolding, it also shows the node point (point of no deflection) where all components in this type of system fit together, the ledgers & transoms have a blade which fits into the lower “cup” (fig 1) and when all the components of each node point are in place the upper “cup” is fastened down (fig 2) and fixed with hammer blows to tighten (fig 3).

- Click for title, and before revealing the components on each mouse click get the delegates to identify them from the bag of fittings and after they have completed the exercise explain each component and their uses from the bag then reveal each one in turn with the pictures following on the next slides.

- Click for title, ask for answers in order, standards, jacks, ledgers, transoms, return transoms, braces, 2.4m Steelstage, 1.2m Steelstage, toeboard brackets and end toeboard brackets and as each answer is given click. All of the above totals would usually be rounded up to the nearest 10 in case of damage or miscalculation, except for the single items. If a design drawing is issued the quantities will normally be exact so erection exactly to the design must be carried out, firstly for safety reasons and secondly because the quantities will follow the design and you may run out of certain materials.

- .

- Click for title, ask for answers in order, standards, jacks, ledgers, transoms, return transoms, braces, 2.4m Steelstage, 1.2m Steelstage, toeboard brackets and end toeboard brackets and as each answer is given click. All of the above totals would usually be rounded up to the nearest 10 in case of damage or miscalculation, except for the single items. If a design drawing is issued the quantities will normally be exact so erection exactly to the design must be carried out, firstly for safety reasons and secondly because the quantities will follow the design and you may run out of certain materials.

- Click for title, ask for answers in order, standards, jacks, ledgers, transoms, return transoms, braces, 2.4m Steelstage, 1.2m Steelstage, toeboard brackets and end toeboard brackets and as each answer is given click. All of the above totals would usually be rounded up to the nearest 10 in case of damage or miscalculation, except for the single items. If a design drawing is issued the quantities will normally be exact so erection exactly to the design must be carried out, firstly for safety reasons and secondly because the quantities will follow the design and you may run out of certain materials.

- Click for title, ask for answers in order, standards, jacks, ledgers, transoms, return transoms, braces, 2.4m Steelstage, 1.2m Steelstage, toeboard brackets and end toeboard brackets and as each answer is given click. All of the above totals would usually be rounded up to the nearest 10 in case of damage or miscalculation, except for the single items. If a design drawing is issued the quantities will normally be exact so erection exactly to the design must be carried out, firstly for safety reasons and secondly because the quantities will follow the design and you may run out of certain materials.

- Click for title, ask for answers in order, standards, jacks, ledgers, transoms, return transoms, braces, 2.4m Steelstage, 1.2m Steelstage, toeboard brackets and end toeboard brackets and as each answer is given click. All of the above totals would usually be rounded up to the nearest 10 in case of damage or miscalculation, except for the single items. If a design drawing is issued the quantities will normally be exact so erection exactly to the design must be carried out, firstly for safety reasons and secondly because the quantities will follow the design and you may run out of certain materials.

- Click for title, ask for answers in order, standards, jacks, ledgers, transoms, return transoms, braces, 2.4m Steelstage, 1.2m Steelstage, toeboard brackets and end toeboard brackets and as each answer is given click. All of the above totals would usually be rounded up to the nearest 10 in case of damage or miscalculation, except for the single items. If a design drawing is issued the quantities will normally be exact so erection exactly to the design must be carried out, firstly for safety reasons and secondly because the quantities will follow the design and you may run out of certain materials.

- Click for title, ask for answers in order, standards, jacks, ledgers, transoms, return transoms, braces, 2.4m Steelstage, 1.2m Steelstage, toeboard brackets and end toeboard brackets and as each answer is given click. All of the above totals would usually be rounded up to the nearest 10 in case of damage or miscalculation, except for the single items. If a design drawing is issued the quantities will normally be exact so erection exactly to the design must be carried out, firstly for safety reasons and secondly because the quantities will follow the design and you may run out of certain materials.

- Click for title, ask for answers in order, standards, jacks, ledgers, transoms, return transoms, braces, 2.4m Steelstage, 1.2m Steelstage, toeboard brackets and end toeboard brackets and as each answer is given click. All of the above totals would usually be rounded up to the nearest 10 in case of damage or miscalculation, except for the single items. If a design drawing is issued the quantities will normally be exact so erection exactly to the design must be carried out, firstly for safety reasons and secondly because the quantities will follow the design and you may run out of certain materials.

- Click for title, ask for answers in order, standards, jacks, ledgers, transoms, return transoms, braces, 2.4m Steelstage, 1.2m Steelstage, toeboard brackets and end toeboard brackets and as each answer is given click. All of the above totals would usually be rounded up to the nearest 10 in case of damage or miscalculation, except for the single items. If a design drawing is issued the quantities will normally be exact so erection exactly to the design must be carried out, firstly for safety reasons and secondly because the quantities will follow the design and you may run out of certain materials.

- Click for title, then click each part in turn and ask for definition of each part as they appear.

- Click for title, then click each part in turn and ask for definition of each part as they appear.

- Click for each point & go through all the above points elaborating where necessary.

- Go through all the above points elaborating where necessary.

- Go through all the above points elaborating where necessary.

- Info on page 19 of book. Explain on whiteboard about fixing diagonally if required.

- Info on page 19 of book. Explain on whiteboard about fixing diagonally if required.

- Info on page 19 of book. Explain on whiteboard about fixing diagonally if required.

- Run through this information but explain that if there is a risk of a fall they should always work behind a guardrail protection whenever possible.