More Related Content More from Anirudh Chaiworaporn More from Anirudh Chaiworaporn (20) 2. http://www.alteich.com/tidbits/t060401.htm:

An estimated 90% of the world's trade today

moves in containers.

One hundred million container loads

crisscross the world's oceans each year in

over 5,000 container ships.

Some 20% of the containers on board

are empty…

http://log.ae/2008/09/01/maximising-space/

2

3. http://www.interasset.com/docs/AssetManagementWP.pdf

Container Usage during its Life-Span

A container can spend on average 56% of its lifespan

either idle or being repositioned while empty.

This represents a non revenue generating part involving

additional costs (such as warehousing and repositioning)

that are assumed either by the shipping or the leasing

company.

Such a cost is part of the leasing rate.

Copyright © 1998-2009, Dr. Jean-Paul Rodrigue, Dept. of Global Studies & Geography, Hofstra University.

For personal or classroom use ONLY

3

4. http://www.interasset.com/docs/AssetManagementWP.pdf

Container Usage during its Life-Span

The lifespan of a container ranges between 10 to 15

years depending on its level of usage and the conditions

it has been exposed to.

A well maintained container not exposed to harsh

conditions can even have a lifespan up to 20 years.

Copyright © 1998-2009, Dr. Jean-Paul Rodrigue, Dept. of Global Studies & Geography, Hofstra University.

For personal or classroom use ONLY

4

5. INNOVATION, what can it bring?

The year 1954.

At that time Philip Morris & Co,

owners of a brand called Marlboro,

was dead last in sales among the

major tobacco companies.

Marlboro makeover---

it’s packaging!

For a 5 year exclusivity Marlboro

was the first brand to be packaged

in the handy “Flip-Top Box.”

Marlboro’s new image paid

huge dividends

Think outside the box ! in attracting smokers.

5 5

6. aluminum and/or …

1958

care free aluminum / iron / galvanized iron / …

WIKI: galvanizing for protection of iron is favored because of its low cost,

the ease of application, and the extended maintenance-free service that it provides.

6

9. Technical innovation, copyrighted design,

exclusive implementation through Patent Application,

taking into account the range of terminal operations:

9

graphics via www.cosmos.be

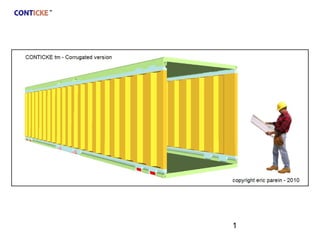

13. Trade Mark

40’ Foldable Standard General Purpose

Shipping Container

(graphics here 12m x 2.44m x 2.70m)

13

© eric parein - 2009

14. the Tunnel

the Door-End and

the Back-End are off

its automatic upright positioning

( the folding principle)

14

© eric parein - 2009

16. the Side Wall upright on Bottom Plate

( the spring here is almost at rest )

16

© eric parein - 2009

17. the Tunnel, its controlled folding or rising

the folding principle - think outside the box, literally!

17

© eric parein - 2009

22. the

straddle

carrier

utilizing existing port and terminal’s equipment

22

25. dry freight – technical issue

(half in length depiction, scaled down Tunnel-Elements, in width and height only)

25

© eric parein - 2009

35. Locking Device (yellow) and Positioning Rod (red)

The locking devices (yellow) are located in the vertical sections

35

© eric parein - 2009

37. moving Conticke’s Door-Ends only

Maximal reduction !

adjust Ends thickness to ½ foot = 80 Door Ends assembled within 40’!

37

© eric parein - 2009

38. Feasibility – Huge Dividends Check ‘Foldable Containers:

a New Perspective on Reducing Container-Repositioning Costs’

38

on ‘http://www.ejtir.tudelft.nl/issues/2001_04/pdf/2001_04_01.pdf

39. From 1/5th, to ‘Complete Empty Volume Reduction’ …

Copyright © 1998-2009, Dr. Jean-Paul Rodrigue, Dept. of Global Studies & Geography, Hofstra University.

For personal or classroom use ONLY

39

40. YES

YES

YES

YES

not enfolded

Scheme from study by the Technical University of Delft - (link on previous slide)

40

42. 1. Other technical option is to enfold from 16 cm higher hinge to also store the two container ends. Less

efficient.

2. Preferably, the back end would be entirely flat outside, to allow more volume inside.

3. Both end parts, as well as the extremities of the green parts, are possibly without the forklift cut outs.

4. Possibly, (some) manipulation or use of the containers do not require the springs.

5. The watertight property is not compulsory for all transported goods or commodities.

Watertight packing or covering the goods inside might even be possible.

6. The plates and the back end are hollow or not. If hollow the container has increased floatation capacity.

Possibly they are ecologically foam-filled, also to offer a temperature barrier.

7. The side walls could be made of a single corrugated plate.

8. Full recycle ability is pursued. Adhering maximal to the Cradle to Cradle philosophy...

If one part is damaged, the other parts remain fully recoupable to further serve.

9. Longer hinges or extra hinge parts in between the shown hinges if required. All measurements are possibly to

be adapted.

10. Most preferably galvanized steel execution, equals longevity. Or, no paint.

11. Outside the great money-saving folding property, longevity further compensates initial manufacturing costs.

12. Outside visual identification of the Conticke happens through its tags all around the door-end, as well

vertically as horizontally. On the front, the top side, as on its two sides. As there is only one door-end per

container assembly, the other parts remain neutral as they are interchangeable.

13. Patent protection is pursued to acquire exclusivity and to easily control the development, manufacture and

exploitation.

14. “In this age of terrorism, the folding container ensures better security since it cannot be so easily used as a

means of smuggling,”

15. Strategically, own specific corner fittings and consecutive own equipment clamps is an option.

42

© eric parein - 2009

43. Thank You for considering:

The environment-friendly key to lower IT costs.

Significantly increasing the TOS appeal.

Eric Parein – CONCEPT LICENSING

43

© eric parein - 2009