13 12 11 Sr

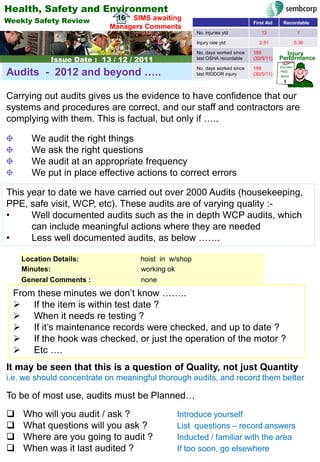

- 1. Health, Safety and Environment Weekly Safety Review 16 SIMS awaiting First Aid Recordable Managers Comments No. injuries ytd 13 1 Injury rate ytd 2.51 0.36 No. days worked since 189 Injury Issue Date : 13 / 12 / 2011 last OSHA recordable (30/5/11) Performance INJURY Audits - 2012 and beyond ….. No. days worked since 189 FREE last RIDDOR injury (30/5/11) WEEK 1 Carrying out audits gives us the evidence to have confidence that our systems and procedures are correct, and our staff and contractors are complying with them. This is factual, but only if ….. We audit the right things We ask the right questions We audit at an appropriate frequency We put in place effective actions to correct errors This year to date we have carried out over 2000 Audits (housekeeping, PPE, safe visit, WCP, etc). These audits are of varying quality :- • Well documented audits such as the in depth WCP audits, which can include meaningful actions where they are needed • Less well documented audits, as below ……. Location Details: hoist in w/shop Minutes: working ok General Comments : none From these minutes we don’t know …….. If the item is within test date ? When it needs re testing ? If it’s maintenance records were checked, and up to date ? If the hook was checked, or just the operation of the motor ? Etc …. It may be seen that this is a question of Quality, not just Quantity i.e. we should concentrate on meaningful thorough audits, and record them better To be of most use, audits must be Planned… Who will you audit / ask ? Introduce yourself What questions will you ask ? List questions – record answers Where are you going to audit ? Inducted / familiar with the area When was it last audited ? If too soon, go elsewhere

- 2. All Employees need to ….. 1. Prepare before you audit 2. Identify positives and good practice when you see them 3. Identify things that need to be corrected (an Action) 4. Write up the audit (Intranet/Safety/Safety Audits) promptly, and include relevant detail 5. If assigning actions, discuss them with your manager first and make them realistic Managers need to ….. Set a realistic audit schedule for your staff Give them time to plan, carry out and then write up audits Check the audits carried out by your team periodically to make sure they are being done, and to review the quality Identify positives and good practice when you see them If quality is an issue, have a 1-2-1 to discuss strengths and weaknesses with the individual auditor Discuss and agree proposed actions when asked for advice Check that actions are completed in a timely manner If you or your team need Auditor training, contact Rebecca Nary on Tel. 2030