UTILISATION OF ELECTRICAL ENERGY

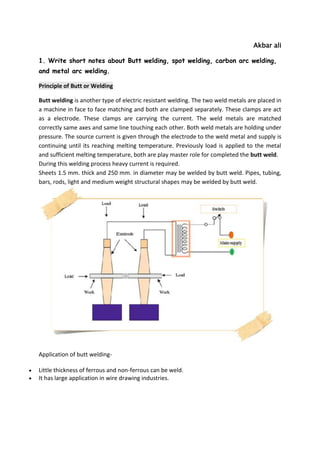

- 1. Akbar ali 1. Write short notes about Butt welding, spot welding, carbon arc welding, and metal arc welding. Principle of Butt or Welding Butt welding is another type of electric resistant welding. The two weld metals are placed in a machine in face to face matching and both are clamped separately. These clamps are act as a electrode. These clamps are carrying the current. The weld metals are matched correctly same axes and same line touching each other. Both weld metals are holding under pressure. The source current is given through the electrode to the weld metal and supply is continuing until its reaching melting temperature. Previously load is applied to the metal and sufficient melting temperature, both are play master role for completed the butt weld. During this welding process heavy current is required. Sheets 1.5 mm. thick and 250 mm. in diameter may be welded by butt weld. Pipes, tubing, bars, rods, light and medium weight structural shapes may be welded by butt weld. Application of butt welding- Little thickness of ferrous and non-ferrous can be weld. It has large application in wire drawing industries.

- 2. The principle of spot welding Spot welding joint is one type of electric resistance welding. Generally joining the sheet to sheet, sheet to rolled sections, wire to wire etc. by this spot weld process. The spot welding is very effectively, which can replace the rivet joints and is very speedy process, this spot welding machine does not need skilled operator, it can be operated by semi-skilled labour. The principle of spot welding is shown in the bellow diagram. In this machine basically having a transformer core (T) which is having a primary winding (PW). This primary winding tapped at a number of points. The secondary winding (SW) has the two ends of a circuit (C) which is connected two arms made of copper or bronze. Each side has a copper electrode, this electrode of spot welding produce the sufficient heat to fuse the joining metal. The lower arm is generally stationary and upper arm is movable (upward and downward). The technical terms are rocker arms or electrode arms. The electrodes of spot welding is cooled by water, the water is passing through the inter looped water line. The essential factor of spot welding- The welding current. The time of current application. The pressure of electrodes. The shape or area of electrodes. The surface condition of welded material. Advantages of spot welding- In this welding process is free from fumes and spatter. Generally it has nothing maintenance or no skilled persons are required for maintenance. No skilled persons are needed to operate the spot welding.

- 3. Welding cost is minimum. Carbon-arc welding The carbon-arc welding is the type of arc welding. Where carbon or graphite are used as a electrode. There are two methods used for produced an arcs, the single-carbon process and another is the twin-carbon process. The main difference is, the twin-carbon arc welding carried electrically independent torch. The carbon-arc welding is invariably carried out with direct current. The heat is produced between carbon electrode and work piece, base metal melts with this heat and additional filler metal can be added where extra metal needed. The essential point of this carbon-arc welding is that the filler rod quite difference from the ordinary filler rod. Because it cannot be connected with current source. The carbon arc welding is suitable for particularly for non-ferrous metals because of the availability of reducing atmosphere around the arc which does not allow the oxidation of the metal to take place. Advantages: Work piece distortion is less. Process is suitable for any kind of joint. Weld heat can be controlled very easily through changing of arc length. Welders are made skilled in short time. It is simple welding process. Big range of metals and their alloys can be welded.

- 4. Metal arc welding In electric arc welding is only a electrical spark, otherwise it is nothing. It is fusion welding process. It is work in a closed electrical circuit in which current flows. If a small gap formed in the circuit then there an electrical spark is occurred, which is called electrical arc. In this spark or arc are contain a huge amount of temperature like 34000C-40000C. Due to this huge temperature, the weld metal can be fuse in arc welding process. Principle of Arc welding In the arc welding the heat is produced through an electrode or arc welding rods. The electric arc is produced between consumable electrode and the work piece. The current is continuously supplied through the consumable electrode and fillet deposited on work piece. Thus the electric arc welding process is carried out. The electrode which is passing the current is made with flux coated, these types of electrode is called bar electrode. The coating flux are melt at the time of welding and deposited upper level of filler metal as a slag, which is removed by chipping or grinding process after normal cooling. The filler metal is called electrode in arc welding practice.

- 5. 2. Describe the Ajax Wyatt (vertical type) type induction furnace and explain its working? Construction Ajax Wyatt furnace consists of a horizontal core which is similar to three phase transformer. It’s innermost core is passed through the vertical crucible which is used as a channel of charge. The core of this furnace in made up of heavy steel. The primary of this is an inductor coil which is wound on the central limb of laminated core and the secondary is a closed loop of molten metal. The Ajax Wyatt furnace is shown in figure 47.15, Operation When an A.C supply is given to the furnace, a varying strong electromagnetic field is produced in the laminated core. The molten metal in the V channel acts as a short circuited secondary coil carrying heavy induced current which generates heat in the charge. As, the V channel resistance is high the heat is produced and distributed evenly due to the convention currents and by stirring action of electromagnetic force. The V channel is always maintained full of metal. As the weight of the metal over the V channel is more, there is no pinch effect. Application This is used for melting non-ferrous metals like zinc, tin, brass etc.

- 6. 3. List the various application of electric heating? Domestic application: Room heaters for heating the building. Immersion heater for water heating. Hot plates for cooking. Geysers. Electric kettles. Electric iron. Electric oven for baking products. Electric toaster. Hot air dryers. Popcorn plant. Industrial application: Melting of metals. Electric welding. Molding of glass for making glass appliances. Baking of insulators. Heat treatment of pointed surfaces. Making of plywood. Molding of plastic components. Enameling of copper conductors. Heat treatment like annealing, tempering, soldering, brazing, cast harderning,etc. *********** 4. Explain about Resistance Heating? It is based on the I2R effect. When current is passed through a resistance element I2R loss takes place which produces heat. There are two methods of resistance heating. (a) Direct Resistance Heating. In this method the material (or charge) to be heated is treated as a resistance and current is passed through it. The charge may be in the form of powder, small solid pieces or liquid. The two electrodes are inserted in the charge and connected to either a.c. or d.c. supply (Fig. 47.2). Obviously, two electrodes will be required in the case of d.c. or single-phase a.c. supply but there would be three electrodes in the case of 3-phase supply. When the charge is in the form of small pieces, a powder of high resistivity material is sprinkled over the surface of the charge to avoid direct short circuit. Heat is produced when current passes through it. This method of heating has high efficiency because the heat is produced in the charge itself.

- 7. (b)Indirect Resistance Heating. In this method of heating, electric current is passed through a resistance element which is placed in an electric oven. Heat produced is proportional to I2R losses in the heating element. The heat so produced is delivered to the charge either by radiation or convection or by a combination of the two. Sometimes, resistance is placed in a cylinder which is surrounded by the charge placed in the jacket as shown in the Fig.47.3. This arrangement provides uniform temperature. Moreover, automatic temperature control can also be provided.

- 8. 5. Explain various losses occur while time of heating? This section describes the various methods and techniques used to quantify the losses from the furnace and the methods to carry out performance assessment of typical furnaces. Heat losses affecting furnace performance Ideally, all heat added to the furnaces should be used to heat the load or stock. In practice, however, a lot of heat is lost in several ways as shown in Figure 11. Flue gas losses: Part of the heat remains in the combustion gases inside the furnace. This loss is also called waste-gas loss or stack loss. Loss from moisture in fuel: Fuel usually contains some moisture and some of the heat is used to evaporate the moisture inside the furnace Loss due to hydrogen in fuel which results in the formation of water Loss through openings in the furnace: Radiation loss occurs when there are openings in the furnace enclosure and these losses can be significant, especially for furnaces operating at temperatures above 540°C. A second loss is through air infiltration because the drafts of furnace stacks/chimneys cause a negative pressure inside the furnace, drawing in air through leaks or cracks or whenever the furnace doors are opened.

- 9. Furnace skin / surface losses, also called wall losses: while temperatures inside the furnace are high, heat is conducted through the roof, floor and walls and emitted to the ambient air once it reaches the furnace skin or surface. Other losses: there are several other ways in which heat is lost from a furnace, although quantifying these is often difficult. Some of these include 1. Stored heat losses: when the furnace is started the furnace structure and insulation is also heated, and this heat only leaves the structure again when the furnace shuts down. Therefore this type of heat loss increases with the number of times the furnace is turned on and off. 2. Material handling losses: the equipment used to move the stock through the furnace, such as conveyor belts, walking beams, bogies etc, also absorb heat. Every time equipment leave the furnace they lose their heat, therefore heat loss increases with the amount of equipment and the frequency by which they enter and leave the furnace . 3. Cooling media losses: water and air are used to cool down equipment, rolls, bearing and rolls, but heat is lost because these media absorb heat. 4. Incomplete combustion losses: heat is lost if combustion is incomplete because unburnt fuel or particles have absorbed heat but this heat has not been put to use. 5. Loss due to formation of scales. ***********

- 10. 6. Explain Temperature Control of Resistance Furnaces or ovens? The temperature of a resistance furnace can be changed by controlling the I2R or V2/R losses. Following different methods are used for the above purpose: (1) Intermittent Switching. In this case, the furnace voltage is switched ON and OFF intermittently. When the voltage supply is switched off, heat production within the surface is stalled and hence its temperature is reduced. When the supply is restored, heat production starts and the furnace temperature begin to increase. Hence, by this simple method, the furnace temperature can be limited between two limits. (2) By Changing the Number of Heating Elements. In this case, the number of heating elements is changed without cutting off the supply to the entire furnace. Smaller the number of heating elements, lesser the heat produced. In the case of a 3-phase circuit, equal number of heating elements is switched off from each phase in order to maintain a balanced load condition. (3) Variation in Circuit Configuration. In the case of 3-phase secondary load, the heating elements give less heat when connected in a star than when connected in delta because in the two cases, voltages across the elements is different . In single-phase circuits, series and parallel grouping of the heating elements causes change in power dissipation resulting in change of furnace temperature. Heat produced is more when all these elements are connected in parallel than when they are connected in series or series-parallel.

- 11. (4)Change of Applied Voltage. (a) Obviously, lesser the magnitude of the voltage applied to the load, lesser the power dissipated and hence, lesser the temperature produced. In the case of a furnace transformer having high voltage primary, the tapping control is kept in the primary winding because the magnitude of the primary current is less. (b) Bucking-Boosting the Secondary Voltage. In this method, the transformer secondary is wound in two sections having unequal number of turns. If the two sections are connected in series s aiding, the secondary voltage is boosted i.e., increased to (E2 + E3) When the two sections are connected in series-opposing the secondary voltage is reduced i.e., there is bucking effect. Consequently, furnace voltage becomes (E2 – E3) and, hence, furnace temperature is reduced. (c) Autotransformer Control. The use of tapped autotransformer used for decreasing the furnace voltage and, hence, temperature of small electric furnaces. The required voltage can be selected with the help of a voltage selector. (d) Series Reactor Voltage. In this case, a heavy-duty core-wounded coil is placed in series with the furnace as and when desired. Due to drop in voltage across the impedance of the coil, the voltage available across the furnace is reduced. With the help of D.P.D.T. switch, high/low, two mode temperature control can be obtained .Since the addition of series coil reduces the power factor, a power capacitor is simultaneously introduced in the circuit for keeping the power factor nearly unity. As seen, the inductor is connected in series, whereas the capacitor is in parallel with the furnace.