Radial Flux Labs Optimised Ev Motor Design

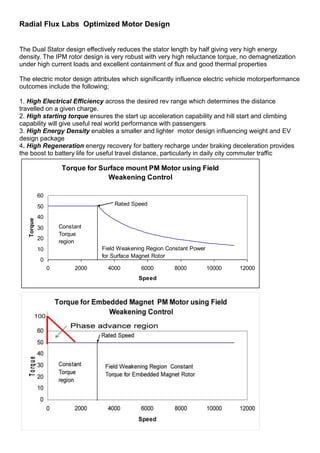

- 1. Radial Flux Labs Optimized Motor Design The Dual Stator design effectively reduces the stator length by half giving very high energy density. The IPM rotor design is very robust with very high reluctance torque, no demagnetization under high current loads and excellent containment of flux and good thermal properties The electric motor design attributes which significantly influence electric vehicle motorperformance outcomes include the following; 1. High Electrical Efficiency across the desired rev range which determines the distance travelled on a given charge. 2. High starting torque ensures the start up acceleration capability and hill start and climbing capability will give useful real world performance with passengers 3. High Energy Density enables a smaller and lighter motor design influencing weight and EV design package 4. High Regeneration energy recovery for battery recharge under braking deceleration provides the boost to battery life for useful travel distance, particularly in daily city commuter traffic Torque for Surface mount PM Motor using Field Weakening Control 60 50 Rated Speed 40 Torque 30 Constant Torque 20 region 10 Field Weakening Region Constant Power for Surface Magnet Rotor 0 0 2000 4000 6000 8000 10000 12000 Speed

- 2. Saliency A high saliency in a motor is the key to enabling high reluctance torque and so take advantage of field weakening and Phase Advance For the following reasons the RFL design achieves very high saliency.: In surface magnet motors the Iq and Id are the same and when these motors are run under field weakening mode, the torque drops away as the speed is increased, giving constant power. In motors with buried magnets and high saliency (such as the RFL) the Iq can be much higher than Id. In this case by utilizing field weakening the Iq torque (Reluctance Torque) can be made to add to the Id torque (Permanent Magnet Torque) thus helping to maintaining torque as the speed is increased. Reluctance torque is from the Id current not the Iq current and is available only over half of the cycle therefore Saliency with a rating of higher than 2 is needed for the motor to be able to achieve this reluctance torque effect. Phase Advance enables a doubling of the starting torque without additional current drain. The higher the saliency the greater this effect is. At a saliency of greater than 2.5 it is possible to maintain constant torque and output power from the motor when run in field weakening mode.. The RFL design has a saliency of 2.79 and is able to maintain approximately constant torque under field weakening mode. Field weakening is a motor control technique that allows a motor to run faster than its rated speed. Using this control method should provide at least 1.5 times the rated speed, with embedded or internal magnet rotor designs. (IPM) Spinning the motor up to its rated speed is referred to as operating in the “constant-torque region,” where the motor’s available torque is constant as the speed is varied . See graph 2a below for the RFDS torque profile Higher torque in the higher speed range from the reluctance torque available from the RFL design gives significantly improved overtaking torque. This is not possible from surface mount designs Reluctance Torque and Field Weakening The RFL design has embedded magnets and an overlapping concentrated winding. This arrangement has high reluctance torque. It has a high salience factor of 2.79 giving high efficiency under heavy overloads. The Fractional Slot PM motors have no reluctance torque and suffer from loss of efficiency under high current loads. This effect is clearly evident in Fig 1 below at torques over the rated torque of 40 Nm. It can be seen that at torques over 40 Nm that the efficiencies start to diverge with the RFL design staying up and the Kelly efficiency dropping away. This reflects the high reluctance torque of the RFL design. Iron Losses The RFL design has very high energy density yet has lower pole numbers than conventional PM motor designs and will fit into the same space as the fractional slot designs without their high iron losses. Iron losses are proportional to the square of the frequency. The RFL’s lower running frequency from the lower pole number results in lower stator core losses. This is especially evident at lower loads and at no load conditions such as downhill running when there is typically still battery drain. The RFL design reduces this level of battery drain compared to other designs Rotor and Magnet Losses The RFL design has a conventional overlapping- concentrated winding arrangement. As a result the rotor is not subject to large rotor eddy current losses resulting from the 7th harmonics like the fractional slot machines. The result is a motor with lower losses at high current loads, such as starting torque and hill climbing. US Department of Energy analysis into the best design of motor for EV’s which concluded that a key design attribute is ( high saliency allowing Controller driven filed weakening to enable optimization of the motor size (power) ,