Circle Slash Rev1

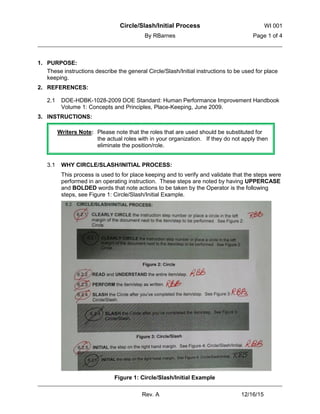

- 1. Circle/Slash/Initial Process WI 001 By RBarnes Page 1 of 4 Rev. A 12/16/15 1. PURPOSE: These instructions describe the general Circle/Slash/Initial instructions to be used for place keeping. 2. REFERENCES: DOE-HDBK-1028-2009 DOE Standard: Human Performance Improvement Handbook2.1 Volume 1: Concepts and Principles, Place-Keeping, June 2009. 3. INSTRUCTIONS: WHY CIRCLE/SLASH/INITIAL PROCESS:3.1 This process is used to for place keeping and to verify and validate that the steps were performed in an operating instruction. These steps are noted by having UPPERCASE and BOLDED words that note actions to be taken by the Operator is the following steps, see Figure 1: Circle/Slash/Initial Example. Figure 1: Circle/Slash/Initial Example Writers Note: Please note that the roles that are used should be substituted for the actual roles with in your organization. If they do not apply then eliminate the position/role.

- 2. Circle/Slash/Initial Process WI 001 By RBarnes Page 2 of 4 Rev. A 12/16/15 Circle/Slash is used so steps are not accidentally omitted or repeated. Initialing the step states which Operator has completed and signed off on the step. This process also addresses when suspending a step or handing off the Operating Instruction prior to finishing to another Operator. CIRCLE/SLASH/INITIAL PROCESS:3.2 3.2.1 CLEARLY CIRCLE the instruction step number or place a circle in the left margin of the document next to the item/step to be performed. See Figure 2: Circle. Figure 2: Circle 3.2.2 READ and UNDERSTAND the entire item/step. 3.2.3 PERFORM the item/step as written. 3.2.4 SLASH the Circle after you’ve completed the item/step. See Figure 3: Circle/Slash. Figure 3: Circle/Slash 3.2.5 INITIAL the step on the right hand margin. See Figure 4: Circle/Slash/Initial. Figure 4: Circle/Slash/Initial NOTE: Do not slash continuous steps – only one item (step) at a time.

- 3. Circle/Slash/Initial Process WI 001 By RBarnes Page 3 of 4 Rev. A 12/16/15 SUSPENDING OR CONTINUATION BY ANOTHER OPERATOR:3.3 3.3.1 When suspending the Operational Instruction or not finishing a step the step number is CIRCLED and text is UNDERLINED. In the left hand margin WRITE ‘COMPLETE THIS STEP” and INITIAL. It is permissible to USE colored adhesive page markers (such as Post-it Notes ®) to help trace progress through the instruction or to denote reference sections. Use this step when you are passing an Operational Instruction to another Operator to be completed. 3.3.2 When resuming an activity that has been SUSPENDED or PASSED from one Operator to another, CONFIRM that Precautions and Limitations conditions and Requirements are met and that any required approvals are obtained before proceeding. COMPLETED Operating Instructions are to be SUBMITTED to the Manager. WRITE3.4 comments on any issues or problems encountered. 4. RECORDS: Completed Operating Instructions are to be submitted to the Manager.4.1 Retain the most recent review signature page in a local file. Older copies are4.2 shredded. 5. CHANGE MANAGEMENT: Responsibility for Procedure5.1 Address all questions on this procedure to the Manager. The Manager will be responsible for engaging the appropriate subject matter experts (SMEs) in developing proposed revisions. Quality Assurance must approve the revisions prior to publishing. Revision History5.2 Revision history to include revision number, date, details of changes, and initials of the Manager signifying revision approval. Rev. A 12/16/15 – Final. 6. SIGN-OFF AND REVIEW: Not required for this procedure.6.1 7. ATTACHMENTS: Training.7.1

- 4. Circle/Slash/Initial Process WI 001 By RBarnes Page 4 of 4 Rev. A 12/16/15 ATTACHMENT 7.1 Training/Confirmation Page 1) Review the steps with the trainee. Have the trainee perform the Circle/Slash/Initial after each noted step. 2) Upon Completion, have Trainee SIGN here: ____________________. 3) This can be used as a training record. Writers Note: Depending on your organization a work instruction should be able to be used for training. A simple attachment can be added to document and record the training.