Poultry times of india july issue

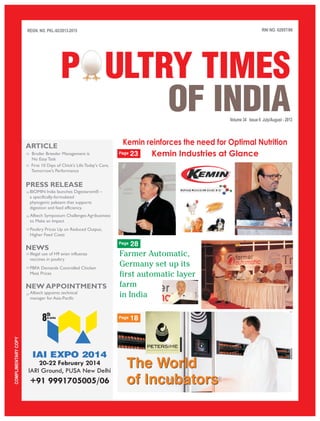

- 1. RNI NO. 02957/96 Volume 34 Issue 6 July/August - 2013 REGN. NO. PKL-92/2013-2015 COMPLIMENTARYCOPY P ULTRY TIMES OF INDIA IAI EXPO 2014 20-22 February 2014 IARI Ground, PUSA New Delhi th 8in series PRESS RELEASE NEWS ARTICLE +91 9991705005/06 ›› ›› ›› ›› ›› ›› NEW APPOINTMENTS ›› Broiler Breeder Management is No Easy Task First 10 Days of Chick's Life:Today's Care, Tomorrow's Performance BIOMIN India launches Digestarom® – a specifically-formulated phytogenic palatant that supports digestion and feed efficiency. Alltech Symposium Challenges Agribusiness to Make an Impact Poultry Prices Up on Reduced Output, Higher Feed Costs ›› Illegal use of H9 avian influenza vaccines in poultry PBFA Demands Controlled Chicken Meat Prices Alltech appoints technical manager for Asia-Pacific Kemin reinforces the need for Optimal Nutrition Kemin Industries at Glance The World of Incubators The World of Incubators Farmer Automatic, Germany set up its first automatic layer farm in India 23 28 18 Page Page Page

- 2. 2 Office/Works: Vill. Kishora, Opp. Devi Lal Park (G.T. Road), Near Govt. Primary School, Teh. & Distt. Sonepat (Hr.) Phone: 0130 2111614 | Telefax: 0130 2111615 | Email: bsantil@chaudharyagro.com Contact: Mahabir Singh Antil Mob: 09215212614, 09416012614 Balraj Singh Antil Mob: 09215214520, 09416014520 CHAUDHARY AGRO INDUSTRIES C HeeraFeed

- 3. Editorial CONTENTS Advertisement High moisture levels at harvest, humidity in environment, inappropriate drying techniques and faulty storage practices caused usually high amount of poor quality corn as well as decrease the life of feed mill infrastructure especially silos. Silos are susceptible for corrosion if proper moisture management is not carried out. High temperature and availability of moisture provide suitable conditions for corrosion and deterioration of silos. Maintenance of silos by proper monitoring and vigilance is prime need of the time. We have to consider this issue seriously because feed industry is growing at very fast pace and output of the mills will surely be increase in near future. Installations of new feed mills and expansion of existing production lines must addressthis issue properly to improve efficiency and life of silos. Preventive maintenance on a tower silo helps ensure proper feed storage and is necessary for safety issue as well as to preserve the quality of tower silo. Proper maintenance will results into many years of trouble free feed storage. A 20 x 60 oxygen limited silo holds about $94000 of shelled corn. Considering the value of corn itself feed millers need to know that their feed storage system is in the best possible condition. Silos may look fine from outer inspection but corrosive reactions due to moisture may exacerbate the silo and decreases its life. One should conduct an inspection of the inside of the tower silo when it is empty ensure proper working of all drains, bottoms, inlets and outlets. This exercise is looking tedious, time taking and expensive and we need to look at the alternative technologies which reduce labor and cost. Some novel molecules which absorb considerable amount of moisture without affecting the quality of grain can be mixed properly with grains and protect silos and grains from wet spoilage. From the Pen of Chief Editor Editorial & Advertisements may not be reproduced Without the written consent of the publishers. Whilst every care is taken to ensure the accuracy of the contents of Poultry Times of India the publishers do not accept any responsibility or liability for the material. Office : 923, Sector-9, Urban Estate, Karnal 132 001 (Haryana) Tel.: + 91 (184) 4033326/327, 2202174/75 Fax : + 91 (184) 2231050 E-mail: Website :info@pixie.co.in | www.pixie.co.in Pixie Consulting Solutions Ltd. Karnal Printed at : Jaiswal Printing Press, Chaura Bazar, Karnal Published at : 821, Sector-13, Urban Estate, Karnal 132 001 (Haryana)c : Vishal Gupta Dr. Ibne Ali, M.V.Sc Jawahar Khurana Kuldeep Singh Ashwani Verma Chairman & Editor in Chief vishal@pixie.co.in Co-editor iaiexpo@pixie.co.in Marketing Manager marketing@pixie.co.in Assistant Content Manager poultry@pixie.co.in Graphic Designer design@pixie.co.in Our Team 29-30 News 31 Egg Rates 33 Events Calender NEED OF PROPER MAINTENANCE OF SILOS 24 New Appointments 4 Broiler Breeder Management is No Easy Task 8 First 10 Days of Chick's Life: Today's Care, Tomorrow's Performance 12 Epidemic of Resistant Bugs in Poultry Industry and Search of New Antibiotic 16 BIOMIN India launches Digestarom® – a specifically-formulated phytogenic palatant that supports digestion and feed efficiency. 18 The World of Incubators 20 Alltech Symposium Challenges Agribusiness to Make an Impact 22 Poultry Prices Up on Reduced Output, Higher Feed Costs 23 Kemin reinforces the need for Optimal Nutrition 26 General Body Meeting of Poultry Breeders Association 28 Farmer Automatic, Germany set up its first automatic layer farm in India ! Andritz Feed & Biofuel 21 ! Bovian 13 ! ChaudharyAgroIndustries 02 ! DSM 11 ! IAIExpo2012 36 ! IAINutrition Forum 27 ! IAIBreeding Forum 06 ! IAIForum Automation & BioenergyConference 24 ! IMVTechnologies 32 ! IndianHerbs Overseas 15, 35 ! ISRMAXAsia2013 05 ! Kemin 17 ! Natural Remedies 34 ! Vamso BiotecPvt.Ltd. 09 ! Venky 25 ! ZeusBiotech 22 ! ZydusAnimal HealthLtd. 07

- 4. Article 04 Feed intake and photostimulation are the key factors for good production of fertilised eggs, according to Tom Tabler (Extension Professor), Chris McDaniel (Professor), Jessica Wells (Extension Instructor) and Haitham M. Yakout (Visiting Research Professor) of the Poultry Science Department at Mississippi State University. Broiler breeder genetics are constantly changing as the poultry industry continues to shift more to processed items to meet increasing consumer demands for these products. Strains with the potential for high breast-meat yield in a feed- efficient manner now have the majority of the US market. Genetic improvement over the past 50 years has been nothing short of remarkable. In fact, the six-fold improvement in carcass yield of 2001 broilers fed a 2001 diet compared to 1957 broilers fed a 1957 diet was 85 to 90 per cent due to genetics, and only 10 to 15 per cent due to nutritional changes (Havenstein et al., 2003). However, this efficient growth and high meat yield in the broiler means that a lot is demanded of broiler breeders. Unfortunately, efficient growth in the broiler and reproductive fitness in the breeder are negatively related production traits (Siegel and Dunning ton, 1985). As a result, effective management of a commercial broiler breeder flock is a compromise. The continued genetic advancements in feed efficiency, rapid growth, and high breast-meat yield in the broiler requires constant modifications to the management and feeding of broiler breeders to prevent overweight birds and the associated negative impacts on egg numbers, fertility and reproductiveperformance. Bodyweight gain must be limited throughout the life of breeder birds by controlling feed intake to minimise reproductive problems in the adult bird (Richards et al., 2010). This presents breeder managers and broiler breeder growers with what is commonly known as the 'broiler breeder paradox' (Decuypere et al., 2006); that is, the difficult task of managing a breeder bird so that it retains all the important broiler production traits by strictly controlling its feed intake and body weight gain to prevent decreased egg production andpoor reproductiveefficiency. TheGoalisFertilised Eggs The main goal of broiler breeder management is producing eggs. Eggs ultimately determine the number of broiler chicks per hen housed. But the only good broiler breeder egg is a fertilised egg (McDaniel, 2011). A non-fertile broiler breeder egg is basically a table egg that holds little value for the breeder manager. If egg production numbers or mating activity is low, it is likely that the number of chicks per hen housed will be less than desirable. While it is true that integrators are in the business of selling broiler meat and not eggs, you have to have a fertilised egg before you can have a broiler chick, and eventually broiler Broiler Breeder Management is No Easy Task meattosell. Achieving a fertilised hatching egg is more difficult than you might think. The external factors that can affect egg production are numerous. Bird age, flock management practices and specific feed ingredients, formulations and allocations can affect the oviduct, the egg itself and semen quality. In turn, these affect egg production numbers and reproductive efficiency. Understanding ovarian function of the chicken and its interaction with nutritional status, age and genetic strain is critical to the production of fertile eggs with a high hatching probability (Renemaetal., 2008). The interaction between nutritional and reproductive traits is complex and constantly shifting as genetic advancements continue to be made (Renema et al., 2007). Managing modern broiler breeder strains is made more difficult because these birds cannot adequately self- regulate feed intake during the growth and development stage. This increases the difficulty associated with achieving an optimal body weight and composition needed to support efficient egg and chick production by the hen (Richards et al., 2010). To assist integrators with managing the changing genetic landscape, primary breeders provide guidelines that target feeding levels, diet compositions and body weights that best suit individual genetic strains.The key to maximising egg production is to provide just enough feed at the right times.Too much or too little feed intake will result in decreased egg production. In general, the best performing breeder flocks closely follow primary breeder recommendations for bodyweights, photostimulation, diet composition andfeed allocation. Feed Intake Female broiler breeders require a minimum cumulative nutrient intake before photostimulation to sustain subsequent egg production and fertility during the production cycle (Walsh and Brake, 1997).The same may be true for male broiler breeders to sustain subsequent reproductive performance (de Reviers and Seigneurin, 1990). Although numerous factors affect egg production and mating activity, nutrient intake is certainly high on the list. Also important is the underlying relationship between energy status and the physiological processes that require energy, such as maintenance, growth and reproduction (Richards, 2010). Included in broiler breeder management is the strict control of feed allowance during both rearing and breeding phases to limit bodyweight gains and reduce the incidence of overweightbirds. Correct feed allocation and proper body weight management are essential to maximising the potential of any breeder flock, regardless of genetic strain. Although birds in controlled feeding programs take longer to reach sexual maturity (Leeson and Summers, 1982), the added value associated with increased egg production, increased fertility, improved hatchability, improved egg quality, and reduced mortality far outweigh the delayed sexual maturity and starting of lay (Bruggeman et al., 1999). However, even with controlled feeding programs it is still very easy to over-feed broiler breeders. Therefore, regularly monitoring and recording body weight and uniformity are critical management tools, especially during the period between15 weeksof ageandphotostimulation. In addition, care must be taken not to stimulate a flock with too much feed at the wrong time. Feed management benefits reproductive efficiency in broiler breeder females by controlling follicle development (Robinson, 2002). Pullets that enter the breeder house overweight tend to have excessive follicular development that can lead to oviductal prolapse, increased number of double- yolk eggs, egg yolk peritonitis (presence of egg yolk in the abdominal cavity), erratic oviposition (laying outside the normal laying time) and laying more than one egg per day (often with poor quality shells) (Stanley, 2003). Overweight hens may have poor fertility due to sperm transport problems in the oviduct.They also may become too large to matesuccessfully. Feed management after peak of lay is also critical. Mistakes can have negative consequences for the remainder of the lay cycle. A number of factors may affect timing and amount of feed reduction post-peak (Aviagen, 2013): ! Body weight and body weight change from thestart of production ! Dailyegg production ! Dailyegg weightand egg weighttrend ! Eggmasstrend ! Health status of the flock and feathering condition ! Ambient temperature ! Feedenergy andproteinlevels ! Feedtexture ! Feed quantity consumed at peak (energy intake) ! Flock history (rearing and pre-peak performance) ! Changes in feed clean-uptime ! Feathercover Too much nutrient intake after peak can result in overweight birds and a faster drop in production and fertility as the birds age (Meijerhof, 2011). Proper feed management in the breeder flock during and after peak helps prevent excessively heavy birds that may lay poorly or show very low fertility as the flock ages. Breeder managers often struggle with when to start cutting feed back after peak, especially if the birds are still laying eggs at a high level. However, waiting too long increases

- 5. International Sugar, Rice, Maize & Agriculture Expo Hall 5-6, IMPACT Exhibition and Convention Center, Bangkok, Thailand www.isrmaxasia.net Focused approach on the entire value chain from pre-harvest to post-harvest 15/16/17 August 2013 Organizers MUYANG THONG THANI For Stall Booking +91 9991705003, 9991705002 rice@pixie.co.in, sugar@pixie.co.in 923, Sector-9, Urban Estate, Karnal - 132001 (Haryana) Fax: 0184 2231050 | Email: info@pixie.co.in www.isrmaxasia.net 5

- 6. the risk that birds may become overweight as egg production gradually declines in the weeks after peak. Photostimulation Photostimulation, or daylength perception, is just as important to breeder managers and growers as nutrient intake. The actual age to increase daylength from short (8 hours) to long (≥11 hours) depends on the average flock body weight and flock uniformity. However, in most cases, primary breeders recommend that photostimulation not occur before 20 to 21 weeks.Flocks that arebelow target weightor non- uniform (CV greater than 10 per cent) may need todelayphotostimulationbyaweekormore. Photostimulating a flock too soon will make the feeding programme even more difficult to manage and result in a sexually uneven flock. All birds will be receiving the same feed allotment, but sexually mature birds will have to split their feed nutrients three ways - some for maintenance, some for growth and some for egg production. The non- layerswillonlyhavetosplittheirfeednutrientstwo ways (some for maintenance and the rest for growth), allowing them to divert additional nutrients to unwanted weight gain and body fat. Maintaining high egg numbers and fertility throughout the production cycle depends on reaching the desired target weight and flock uniformityatphotostimulation. Photostimulation sets up a series of events that ultimately results in eggs. As daylength increases, thebrainrespondsbyproducinghormonesthat,in turn,traveltotheovarywheretheycausefolliclesto develop. When the mix and amount of hormones is right, the follicle ovulates an ovum (yolk) that can then be fertilized before traveling down the oviduct where albumen and shell are formed around the yolk (Robinson, 2002; McDaniel, 2011). For hens, the complete process of egg formation, after ovulation of the egg yolk, takes a little longer than 24 hours. You may have noticed that hens usually lay for several days in a row and then pause for a day or two. This happens because of the relationship between the time of day hormones are released and the length of time it takes for an egg to form. The number of eggs a hen lays on consecutive days before pausing is called her sequence. The rate of follicle maturation and egg formation determines the sequence length; hens with slow follicle maturation and egg formation rates lay in short sequences (two to three days), while hens with faster rates lay in long sequences. Sequence length changes throughout the production cycle, with the longest sequences occurring at peak production somewherearound30to35weeksofage. Hens that have their feed intake strictly controlled produce more eggs because they lay longer sequences, persist in lay longer, lay fewer abnormal eggs and have fewer multiple ovulationsinasingle day (Gibson et al., 2008). IAI Breeding Forum international animal industry expo 8thin series 21 February 2014 IARI Ground, PUSA Campus, New Delhi For more information +91 9991705005/06, 9812082121 poultry@pixie.co.in, vishal@pixie.co.in Organizer www.iaiexpo.com Government of India, Ministry of Agriculture notified that some poultry farmers in the country are using spurious Avian Influenza vaccines in poultry under some other names. The vaccine had been tested by government and it was found that it contain antigen of H9 Avian Influenza virus. As per National Action Plan on Avian Influenza, Government of India has not permitted any use of Avian Influenza vaccines in the country. According to government this is a serious issue and can spread the virus in the clean flocks as well because this virus undergoes antigenic shift very frequently and low pathogenic H9 strainmight be mutatedtohighlypathogenic strain. Government asks poultry farmers not to use such vaccines as it is illegal and might aggravate the problem of frequent bird flu outbreaks in the country. Under this notification Andhra Pradesh Animal husbandry department take immediate action and instruct the field staff to create more awareness and to adopt bio security measures. The poultry, which was considered as a backyard proposition in the early 60's has now been transformed into a strong agro based commercial activity having tremendous employability and income generation potential contributing nearly 0.7% of the national GDP and about 10% of the Livestock GDP. India produces about 65 billion eggs and 2 million tons broiler meat annually. This mammoth industry is already facing dual crisis of increasing feed costs and almost stagnant product prices. In such situation use of these fraudulent practices by some ignorant people reduces faith of stake holders and otherinvestorswhichwillfurtherdeterioratethecondition. In this period of crisis government & poultry industry should come forward and take some bold initiatives and work together for possible wayout. Fear of Bird Flu outbreak: Illegal use of H9 avian influenza vaccines in poultry NEWS Article 06

- 7. 7

- 8. Article 08 First 10 Days of Chick's Life: Today's Care, Tomorrow's Performance Dr AK Jain, Head – Training & Development, Zydus Animal Health Limited, Ahmedabad Whether broiler or layer, first 7 – 10 days of chick's life are crucial to its future performance. In the body of the chick, the digestive organs develop in the first week and thereafter musculoskeletal tissue mass increases. The intestine is almost sterile initially and needs the normal microflora to develop. But pathogens pose threat and multiply faster in a stress condition. The immune system is yet to develop. Therefore, the focus has to be to hatch sound & healthy chicks with a good initial weight. Taking extensive care in initial 10 days is vital, as healthy beginning of chick decides the future performance. In order to keep chicks healthy particularly during first 10 days, the following challenges pose themajor threat: 1. Management challenges 2. Nutritional challenges 3. Infectious or pathogenic challenges. 4. Challenges due to non-specific or metabolic disorders Management challenges & measures · Prefer good quality, genetically sound chicks from a reliable source. Chicks having uniform size are easier to manage in later life. · Feeding and watering within 24 hours of hatching · Transportation: Suffocation and dehydration are common problems faced during transportation, causing early chick mortality. Care should be taken while keeping chicks in the boxes. Use of electrolytes (e.g. C - Lyte) can help to reduce it. Chicks should notbestarved. · Prefer morning time for chicks' arrival, so thatwehaveentireday for close monitoring. · Litter material: Litter material plays a very important role in deep litter system. It helps to maintain temperature and to absorb the moisture. The bedding should be a minimum of 4 inches in depth. The bedding material should be chosen carefully. It should not be uncomfortable to thechicks at any time. · Brooding: Brooding is the backbone for poultry farming. Proper brooding is vital for bird's future and production. Count the chicks before placing in the brooder. Brooding affects the body weight and feed conversion. Maintain proper temperatureas per guidelines, keeping the age and weather conditions in view. High or low brooding temperatureshavetheir own disadvantages. · Space: 3 – 4 square inches of space per chick is the minimum floor space required. Overcrowding causes excessive dampness in the litter leading to lot of complications including coccidiosis and other infections. It may increase mortality and reduce growth. · Feeders and drinkers: Regular feeders should be provided after 3-4 days. Initially it is advisable to spread the feed on paper. Cleandrinkers should beused. NutritionalChallenges; Deficiency of certain key vitamins and minerals can lead to deficiency syndromes. Therefore, provide nutritious balanced feed to chicks. The first feed should be provided to chicks 3 hours after the arrival of chicks. Starter feed should be given for first 10 days. Preferably sieved crumbs or mini pellets should be given. In case, mash feed is to be given, ensure a coarse uniform particle size. Minimize the use of fine particles or powder form. Pathogenic Challenges: Omphalitis&Yolk Sac Infection: Omphalitis may be defined technically as an inflammation of the navel. The term refers to improper closure of the navel (navel ill; mushy chick disease). Since yolk sac is close to navel in birds, it is invariably involved with omphalitis causing yolksac infection. Immediately after hatching, approximately 20% of the chick's weight comprises of yolk material. Yolk sac infection is one of the commonest causes of high chick mortality. The major pathogen responsible is E. coli. The other pathogens include Pseudomonas, Klebsiella, Bacillus cereus and Staphylococcus etc. The pathogens enter through the unhealed navel. The disease often spreads due to poor hygiene and faulty management at hatchery. Egg shell contamination by fecal material is the major cause of infection. Number of chicks are found dead in the boxes on arrival from the hatchery. The peak mortality time is first 4 days. Chicks are often wet and mushy with an offensive odour. Abdomen is distended with discoloration around the navel. To minimize yolk-sac infection, strict hygiene plays vital role at hatchery and farm level. The preferred treatment for all E.coli infections includes flumequin (e.g. Zydaquin) and amikacin injection (e.g. Amidac). Other antibiotics can be given based on the need. Antibiotic treatment should be given for not less 4-5days. Aspergillosis: Also known as 'brooder pneumonia', it is a fungal disease caused by Aspergillus. Newly hatched chicks are highly susceptible to aspergillosis. Infected chicks show very rapid and difficult breathing. Contaminated poultry litter is the major source of infection. Sometimes feed also contains spores of aspergillus which could be inhaled by chicks to produce aspergillosis. Daily cleaning and disinfection of feed and water utensils helps to reduce the occurrence of aspergillosis. Hygiene at hatchery level plays the vital role. Fumigation of eggs at hatchery level is recommended. Pullorum Disease: It is a highly contagious, egg-transmitted disease, caused by gram negative bacterium Salmonella pullorum. It spreadsfroman infected mother hen through the eggs to the newly hatched chicks. Many chicks are found dead in shells only. The affected chicks develop white viscous droppings, that's why it is called bacillary white diarrhoea. Probiotics (e.g. Improval Gold) help to reduce pathogenic load in the intestine. Use of antibiotics like Flumequin (e.g. Zydaquin) and amikacin injection (e.g. Amidac) is recommended to treat Pullorum in chicks. Strict biosecurity both at hatchery and farm level is the key to minimize the chances of infection. Terminal disinfection (e.g. Use of Glufort) is recommendedtoprevent theinfection at farm. Mycoplasmosis: Mainly transmitted through hatching eggs, Mycoplasmosis or CRD is of great economic importance. It affects younger birds more severely than mature birds. Many times mycoplasmosis is complicated by E.coli resulting in CCRD. CRD is mainly characterized by abnormal respiratory sounds, coughing and nasal discharge. Tylosin phosphate granules (e.g. Winmyco) is recommended for prevention of CRD. On the other hand,Tylosin injection (e.g. CRDnil injection) is the most preferred antibiotic to treat CRD. Viral Diseases: Adenovirus infections: Transmitted vertically through egg, adenoviruses are the non-enveloped viruses. . They can cause respiratory disease, diarrhoea, poor growth & poor feed conversion in chickens. The infection of Adenoviruses can be reduced by strict biosecurity measures.

- 9. 9

- 10. Article 10 Infectious Bronchitis: Caused by a coronavirus, Infectious Bronchitis is a highly contagious disease and more common in young chicks. Many times, other pathogens also invade which include E.coli, Mycoplasma & Haemophilus. Affected chickens will be chirping, with a watery discharge from the eyes and nostrils, accompanied with laboured breathing (gasping). The IB virus spreads by air, people and fomites (virus-contaminated substances). For prevention, IB H-120 live vaccine is recommended to the day-old chick. Alternatively, combined IB H120 + ND live vaccine can be used on 3rd to 5th day. For the treatment of secondary bacterial infections, antibiotics like flumequin (e.g. Zydaquin) and amikacin injection (e.g. Amidac) are recommended. The intensity can be reduced through proper brooder management. Biosecurity alsohelpstoreducetheincidences. NewcastleDisease: Caused by avian paramyxovirus (enveloped virus), ND is one of the most dreaded and highly contagious viral disease of poultry. It can affect birds of any age, although young ones are more susceptible. The disease transmits rapidly via airborne droplets s p r e a d b y t h e c o u g h i n g o r sneezing of infected b i r d s . T h e incubation period of 3 -5 days. The disease in young chickens begins with difficult breathing, gasping and sneezing. This phase continues for 10 to 14 days and may be followed by nervous symptoms which include paralysis of one or both the wings and legs or the twisting of neck toone side knownas torticollis. Non-specific diseases: Reduced blood glucose level: Chicks that are hatched early or from small eggs may have reduced blood glucose level when taken from hatchery. During transportation, the chicks may be without feed for 24 -48 hours, which may cause reduced glucose level. Use of C-Lyte containing dextrose helps in elevating the blood glucose level. Gout: Gout is a multifactorial disease of chicks. The mistakes committed in management at farm level is the major cause e.g. Simple dehydration due to lack of water, or inadequate number of drinkers can lead to an outbreak of gout in the flock. Many times it is due to the infection of nephropathogenic IB virus. There is urate deposit on the surface of kidneys and then other visceral organs. The birds die from kidney failure. IB H120 vaccine (live) is recommended on day-1 to prevent nephropathogenic IB strains in young chicks. Provide plenty of drinking water to chicks. Care should be taken to use cool water during summers in particular. Herbal anti-gout medicines (like Nephroclean) are recommended to treatgout inbirds. Ascites: All these factors result in imbalance between oxygen supply and demand, thus causing ascites. Anti-oxidants such as vitamin E & Selenium (e.g. Supermune WSP) are recommended to reduce mortality in ascites. Nephroclean can also be used to treatascites. Summary: Chicks are very delicate birds. They need special care particularly during first 10 days of life. Lesser the stress on chicks, better the growth, more the profits. Therefore, understanding the challenges during this period is vital to minimize risks and maximizeprofits. For further information: M: 9974051265 (akjain@zydusahl.com) Says Dr G. Ranjith Reddy, who used this ignorance to his firm's advantage at an event recently VINCENT KING We are all enamoured by colourful rainbows in the sky but very few make it to that pot of gold at the end. Meet Dr. G Ranjith Reddy, MD of Rohini Minerals Pvt. Ltd, who recently participated in the Microsoft Complete Boss Challenge and catapulted his company to the country's top three. With around 2,500 CEO,s spread across seven Indian cities, each company had to go through rigorous tasks to win the top honour. “Three were different parameters for each industry. My company was judged on three levels: Promoter' back ground, parameters of the company, and financials. What gave us the edge, is the fact that since we are from the poultry industry, not many know the challenges of delivering quality products to the end consumer”, Dr. Reddy said, duly thanking 'No one knows about poultry partner Dr. A.Tirupathi Reddy, breeding farmers and everyone in the firm. Poultry is a very big industry and no one realizes this when they eat chicken. We select the female and the male lines, and we , maintain the generation of every chicken.These facts impressed the Microsoft”, he adds. Now, the three winners will be supported by Microsoft, Linked In Money Control, Web Chutney, DOOR, and CRISIL SME Ratings in areas of technology, talent, knowledge , and etc. for the next fiveyears. NEWS

- 11. 11

- 12. Article 12 Introduction: Discovery of antimicrobial agents became a transformative moment in human history, beginning with the discovery of penicillin in 1928 by Alexander Fleming's. Antibiotics were easily accepted as wonder drugs and “magic bullets,” and the services they offered seemed infinite.Bacterial diseases in poultry are of great economic importance worldwide due to the monetary losses incurred following infections.However, the emergence of multi antibiotic resistant bacteria is one of the most critical problems of modern medicine. Resistance particularly multidrug resistance to antimicrobials is an emerging problem in Enterobacteriaceae, Mycoplasma and many more commonly prevalent pathogens for developing and developed countries. Resistant microorganisms have emerged as a result of improper use of antibiotics in human health as well as in agricultural practices. In the poultry industry low level antibiotics are administrated as growth promoters. Over the time these low doses of antimicrobials confer the ability of microorganisms to evolve mechanisms of defense, therefore, making them less susceptible to the effect of the drug and contributing to treatment failure (Khachatourians, 1998). Concerns about development of antimicrobial resistance and about transference of antibiotic resistance genes from animal to human microbiota, have led to withdraw approval for antibiotics as growth promoters in theEuropean Union sinceJanuary 1, 2006 (Castanon, 2007). Earlier in 1986 Sweden ban all growth- promoting antibiotics, whereas Denmark in 1995 and 1998ban the use of avoparcinand virginiamycin. In 1997 European Union (EU) banned the use of avoparcinand in 1999 the other four antibiotics used for growth promotion like bacitracin (a polypeptide), spiramycin, Tylosin (macrolides), and virginiamycin (a streptogramin combination) were restricted. Many of the authors feel that these bans were imposed may be because of consumer and political opinion, and a scientific concern that resistance selected in animals might be transmitted to humans posing threat to human health (Casewell, 2003).But experience in Sweden as quoted by Wierup, (2001)had shown that the bans might have adverse consequences for animal health and welfare, and economic consequences for farmers.Some of the workers also suggested that human health is unlikely to benefit and that it might even be adversely affected(Acaret al., 2000 and Phillips, 1999).Studying carefully the scanty published literature of events in Europe since the EU ban showed that these concerns were well supported and need tobe undertaken. EPIDEMIC OF RESISTANT BUGS IN POULTRY INDUSTRY AND SEARCH OF NEW ANTIBIOTIC Tarun kumar, Naveen Sharma, Praveen Kumar Bovian healthcare Pvt. Ltd, SSR Corporate Park, Faridabad-121003 The ban has resulted in the complete removal of thebanned compounds as growth promoters in many of the developed countries.With the ban of antibiotics in Denmark where about 105 metric tonnes of antibiotics were used for growth promotion in 1996, the usage fell to nil by 2000(DANMAP, 2000). With the banreduction of resistance to avoparcin, macrolides and virginiamycin among enterococci was observed infood-animal faeces, in Denmark and elsewhere,although vancomycin-resistant Enterococcus faecium has persisted in samples from Danish broilers and pork (Heueret al., 2002; Boel and Andersen 2002). So it may be hypothesizedthat the pool of antibiotic resistance genes in animal faecal enterococci has not completely diminished even with the implication of antibiotic ban. With the use of all these antibiotics resistance also showed its emergence. In one recent study (Álvarez-Fernándezet al., 2012) it was observed that all the Salmonellastrains isolated from poultry in spain were multi-resistant (resistant to 3–13 antimicrobials). The average number of resistances per strain increased from 3.98 in 1993 to 5.00 in 2006.An increase in the incidence of resistance was observed between 1993 and 2006 for cephalothin, enrofloxacin,and tetracycline (Fig. 2) Fig. 1: Percentage of Salmonella isolates resistant to each antibiotic tested. Why weneed new antibiotic Even with more appropriate prescribing and antibiotic usage, it seems likely that antibacterial resistance will continue to accumulate in many pathogens and settings, especially in hospitals/ poultry farms etc. posing problems in treating bacterial infections in poultry. There is remarkable variation in resistance of Salmonella from chickens and turkeys to a wide range of antimicrobialagents, possession of conjugativeor co-transmissible plasmids encoding resistance is often a major factor in dissemination of resistance. A dominant clone that carries resistance genes may be the major determinant of resistance patterns. For example, occurrence of the multi-resistant S.Typhimurium DT104 may be responsible for a speci? c pattern of resistance. Class I integrons appear to be important in the acquisition and spread of genes that encode antimicrobial resistance in many serovars of Salmonella frompoultry(Gyles,2008). Re s i s t a n c e t o f l u o ro q u i n o l o n e s f o r campylobacteriosishave been reviewed by Zhang et al. (2003) and stated that resistance is most commonly due to mutations in the quinolone resistancedetermining region (QRDR) regions of gyrA, with high levels of resistance to cipro? oxacin associated with the Thre-86-Ile mutation and intermediate levels associated with the Asp-90-Asn or the Thr-86-Lys mutation. A functional ef? ux pump is required for the gyrA mutations to confer resistance; over-expression of the ef? ux pump is not required for high-level resistance.The fact that a single mutation in gyrA can confer highlevel resistanceto ? uorquinolones

- 13. 13

- 14. Article 14 IAI Aquaculture Expo 2014th 8in Series 20-22 February, IARI Ground, PUSA Road, New Delhi +91 9991705005, iaiexpo@pixie.co.in | poultry@pixie.co.in www.iaiexpo.com +91 9034005126 indicates that such resistance may occur readily (Moore et al., 2006; van Bovenet al., 2003).Avian pathogenic E.coli responsible for respiratory/ septicemic diseases in chickens and turkeys requiregood antibiotics to treat these infections.Resistance of these strains to antimicrobials is therefore important in the selection of agents for treatment.Zhao et al. (2005) reported that resistance to quinolones like nalidixic acid was associated with mutations in gyrA, gyrB and parC, and with up-regulation of the multi-drug resistance pump encoded by acrAB. Plasmid-mediated quinolone resistance has also been detected at low prevalence and involves Qnr proteins that interact with topoisomerase, a quinolone-acetylating enzyme, a n d a Q e p p u m p ( Y u e e t a l . , 2008).Enterobacteriaceae resistant to third- generation cephalosporinsresistance often arises through mutational hyper-production of chromosomal AmpCß-lactamases in Enterobacterspp. In Indian scenario it is well documented that multiple antibiotic resistance pattern is prevalent in the poultry sector making most of the disease outbreaksunmanageable for poultry consultants/ practitioners. In 2012, Kumar et al. stated that multiple drug resistance patterns in Haryana making Salmonella infection difficult to treat in broilers and breeders. In the study antibiotics, namely chloramphenicol, amikacin, gentamicin, cephotaxime and cephadroxil, were used.Tamulyet al. (2008)found that out of 30 Salmonella isolates frompoultry 28 were resistant to all the 15 antibiotics used including levofloxacin, gentamicin, chloramphenicol etc.Enrofloxacin was the most effective antibiotic against E. coli infection in earlier days but its indiscriminate usage in poultryleads to fluoroquinolone resistancein zoonotic Gram negative bacilli as reported by Oteoet al., (2005). Akondet al., (2009) found that the E.coli isolated from poultry in Bangladesh found to have multiple drug resistancepatterns against the most commonly used antibiotics. In a very recentstudy from Pantnagar, North India (Joshi et al., 2012) workers reported multiple drug resistance in 52.63% E. coli isolates with highest degree of resistance to Cephalexin and Enrofloxacin. So there is no doubt that next epidemic in Poultry will be of resistant bugs or maybe we are already facing ittoday. It is well understood that antibiotics have revolutionized Veterinary medicine allow totreat number of fatal infections that may lead to severe economic losses to the famers and ultimately industry. But with the development of resistance to number of existing antibiotics it become difficult to treat number of disease outbreaks. No antibiotic escapes all resistance and if any one did this then it would shift the microbial ecology in favour of some more resilient opportunist pathogens.Livermore (2004) stated that there should be sound reasons to doubt whether reductions in antibiotic use can be achieved or maintained at a suf? cient degree to substantially reverse growing resistance. Cessation of use, as with growth promoters, is not an option for therapeutic drugs, and the objectives of reducing usage and selection pressure are counter-poised by number of social and economic factorsespecially in India. With detailed studying and reviewing various aspects of antibiotic resistance it is not accepted that small improvements or reductions in antibiotic usage can tremendously decrease the increasing resistanceproblem(Gillespie, 2001). So antibiotic development remains vital if man is to keep ahead of resistant bugs, and it is known that despite press hype some new agents do continue to be developed and marketed.The most important fact is that one should be clear about the judicious use of antibiotics. So the need of new antibiotic in veterinary sector especially in poultry medicine is very clear as the disadvantages with the use of existing resistant antibiotics are many more in terms of financial loss, secondary infections and public health concern. The intentions of using new developed antibiotics in poultry may vary, but deleterious effects will be more if we stave off the use of new developed antibiotics and continue to use old resistantantibiotics. Poultry Feed Prices Remain Unchanged NDIA - Despite a downtrend in the prices of its key ingredients, poultry feed prices remained unchanged thisweek. Aditya Mishra, a commodity expert, told that prices of a few ingredients have come down but it hasn't made any major impact on the cost of production. Demand for feed is steady in the market and feed products may continue to rule without alteration for thenextfew days, hesaid. In the physical market, soyameal dropped by Rs 500 and soldatRs 34,400atonne. Bajra dropped by Rs 100 to Rs 1,460 a quintal, DCP was at Rs 35 a kg, MBM eased by Rs 200 a quintal and sold at Rs 35,300 while maize went down byRs100 toRs15,100 a quintal. Mustard De-oiled cake dropped by Rs 100 and sold at Rs 14,900 a tonne, DRB quoted at Rs 11,000 a tonne while rice bran oil went down by Re 1 and ruled at Rs 53/kg. Broiler concentrate feed quoted at Rs 2,050 for a 50-kg bag while Broiler starter mash was at Rs 1,550. Pre-lay mash sold at Rs 1,040 while layer grower mash quoted at Rs 980. Layer concentrate 25 per cent was Rs 1,490 while layer concentrate 35 per cent wentfor Rs1,175. Meanwhile, a downtrend was witnessed in the poultry products market on reduced offtake. Egg decreased by 18 paise and sold at Rs 2.96. Broiler dropped by Rs 8 and quoted at Rs 78/kg, while chick went for Rs 11, Re 1down frompreviouslevel.

- 15. 15

- 16. Press Release 16 Digestarom® – the phytogenic product line of BIOMIN – was launched across India through a series of events hosted in Hyderabad, Panipat and Ooty.These events brought together close to 250 industry delegates. In addition to serving as key knowledge-transfer meetings, they also provided the opportunity to introduce Digestarom®, the poultry-specific phytogenic solution from BIOMIN that has been specifically formulated to support digestion and feed efficiency in poultry. With 30 years of experience in animal health and nutrition, and with more than 400 invitro and invivo trials conducted with Digestarom®, BIOMIN has grown its global network of collaborations with institutes to over 100. Several trials with major poultry producers in India have shown that Digestarom® significantly contributes to improvements in FCR, egg production, egg quality, nutrient sparing effect and reductionof ammonia. BIOMIN kicked off the launch of Digestarom® at the poultry hub of India – Hyderabad on 16th April, hosting the event at the Novotel Airport Hotel. Leading industry figures from Andhra Pradesh, Maharashtra and Gujarat attended the event, and several independent experts in the field of poultry were invited to present on key issueschallenging theindustry. The event was opened by Dr. SujitKulkarni, Sales Director of BIOMIN India, who warmly welcomed the delegates and introduced the global business activities of BIOMIN as well as the company's India-specific focus. This was followed by a presentation from Dr. Ramakoti Reddy, Principal Scientist ofAvian Health Laboratory, PDP Hyderabad who highlighted gut immunity and the importance of the GI tract as key functions of immunity in poultry. Echoing that point, Ms.Ines Rodrigues, Technical Manager with BIOMIN Singapore, then presented on the role that phytogenics can play in improving the performance of poultry. Focusing on the benefits that have been proven with Digestarom®, Ms. Rodrigues explained how the defined mode of action of this specific BIOMIN India launches Digestarom® – a specifically-formulated phytogenic palatant that supports digestion and feed efficiency. phytogenic solution can improve poultry performance through exertion of combined aromatic and biological properties. “Digestarom® is able to up-regulate the transcription factor Nrf2, responsible for both anti-inflammatory and anti-oxidative activities within the body, thereby increasing nutrient digestibility and improving feed efficiency” explainedMs. Rodrigues. She then went on to highlight the nutrient-sparing effect of Digestarom®, supported by multiple trial data generated globally from BIOMIN, as well as the ability to reduce ammonia emissions which can have significant application potential with the increasinguseof ECshedswithinIndia. “We are seeing very exciting opportunity for Digestarom® application within the Indian poultry industry” explained Dr.Sujit. “Despite the tough economic conditions being faced by the producers, we are seeing that application of Digestarom® is effective at improving feed efficiency, supporting an improved health status of the bird and even has the capability for nutrient sparing evaluation, further allowing offset of costswithin theformulation exercise”. The Hyderabad event came to an end with a Q&A session, and finally a special vote of thanks was given by Mr. Subramaniam, Director of Tara Enterprises and the exclusive distributor of BIOMIN for Andhra Pradesh. Further thanks was offered to the delegates by the local representatives of BIOMIN in Andhra Pradesh – Mr. Ramakrishna, Technical Sales Manager based in Hyderabad, and Mr. Krishna Reddy, Technical SalesExecutivefor CoastalAPregion. Next stop on the Digestarom® launch roadshow was Panipat in Haryana on 17th April. Close to 80 delegates joined this event at Nirulas Hotel, including several key industry personnel from East India. Following a similar format as the Hyderabad event, independent specialists were invited by BIOMIN to address key issues facing the industry. Dr. Pawan Kumar, Program Manager of US Soya Export Council for North and East India presented on “Soya – the present status and future challenges” Dr. Kumar highlighted the importance of soya in poultry feed and shared extremely useful information concerning present soya production, exports, domestic consumption and future trends. This was followed by Ms.Ines Rodrigues again presenting on Phytogenic applications and the specific benefits that can be achieved through the strategic application of Digestarom® Poultry. Ines shared some very recent data that has been generated through extensive commercial trials within India that has shown very good improvement in FCR, egg production, egg quality and ammonia reduction. All the delegates from the north and east India appreciated this event and there were some lively interaction during thediscussions. A special vote of thanks was given to the delegates in Panipat by Mr. Manoj Garg, Director of MG Marketing and the exclusive distributor of BIOMIN in North India. The north delegates were thanked by Mr. Arvind Sharma, Technical Sales Manager for BIOMIN in North India, and for the East delegation, the thanks was offered from Mr. Neeraj Singh, Technical Sales Manager for BIOMIN in EastIndia. The final stop on the week-long tour led to Ooty, a beautiful hill station in Tamil Nadu, where Hotel Gem Park was chosen as the venue. More than 60 delegates from Tamil Nadu, Karnataka and Kerala gathered for the event on 19th April. This launch event of Digestarom® also served as the opening session for the Front Runners 2 event – a programme designed specifically to address challenges being faced by the industry and potential solutions to overcome these. A full review of Front Runners 2 will be given in the coming weeks. A vote of thanks in Ooty was given by Mr. Krishnan Sekar, Director of Sri Amman Enterprises and exclusive distributor for BIOMIN in Tamil Nadu, Karnataka and Kerala. Mr. Rajan, Regional Sales Manager for BIOMIN in Tamil Nadu thanked the delegates from Tamil Nadu and Kerala,and Mr. Rajesh,Technical Sales Manager for BIOMIN in Karnataka thanked his respective delegates for their support and attendance. BIOMIN would like to thank all delegates for having attended these events, and also look forward to continual support of the India poultry industry through more of these highly interactive knowledge-transfer events.Moreexciting news of BIOMIN's events in India will be released next month. Dr.SujitKulkarni, Sales Director of BIOMIN India, delivers his welcome speech Dr.Pawan Kumar, Program Manager of US Soya Export Council for North and East India, delivers his presentation, “Soya – the present status and future challenges” Ms. Ines Rodrigues, Technical Manager of BIOMIN Singapore, with staffof BIOMIN India, and Mr. Manoj Garg, Director of MG Marketing

- 17. 17

- 18. The World of Incubators The World of IncubatorsPetersime is the world leading supplier of incubators, hatchery equipment, project services and turnkey hatcheries. Our headquarters in Olsene, Belgium (40,000 m²) include production units, an R&D department, an in-house hatchery and a Customer Centre. Petersime is part of the TBG Europe, which groups companies that are active in the agro-industry. TBG has three main activities: egg handling, hatcheries and fruit, flower and vegetable handling. Petersime belongs to the hatchery branch of TBG. OUR MISSION We aim to strengthen our position as the world leader in the development, production, export and service of incubators and hatcheries, with the view to maximize our client's return on investment. Our mission consists of identifying the exact needs of our clients to define a tailor- made solution and then implement it to make the hatchery more bio-secure, more efficient and more cost effective. Ourproductsand services Incubators In 2010, Petersime launched a new range of state- of-the art single-stage incubators: the S-line.It is designed to optimize hatchery performance by increasing chick quality and quantity. In addition, it reduces energy, maintenance and labour costs. The new S-line provides the long- awaited answer to hatcheries wishing to maximizetheir economic return. S-line incubators are equipped with Petersime's patented technology guaranteeing a constant interaction between the embryo and its incubator e n v i r o n m e n t : E m b r y o - R e s p o n s e Incubation™.By on-line diagnosis of the real embryo temperature, actual CO2 output, egg weight loss, etc. the system constantly and interactively adapts the incubation parameters to create the optimal environment for each specific batch of eggs. Scientific research and extensive field trials have proven that chick quality and hatchability as well as post-hatch performance largely benefit from this active control of bio-response parameters during incubation. Hatchery equipment Besides incubators, Petersime provides a whole range of equipment for hatcheries: HVAC equipment, trays, trolleys, baskets, automation equipment, washing machines, hatchery doors, etc. Petersime recently launched Eagle Eye™,a revolutionary software package that allows hatchery managers to monitor and control their entirehatchery from one single PC. It provides an integrated solution for all of the key parameters and settings in the hatchery: incubators, room conditions, cooling water temperatures, parameters related to air handling, etc.This allows hatchery managers to reduce their labour cost but also to react immediately if an abnormal condition should occur. Turnkeyhatcheries We design, deliver, and install your complete hatchery and provide support over the lifetime of the hatchery. Petersime has more than 35 years of experience in designing turnkey hatcheries. We have already installed several turnkey hatcheries over the world. And more than 6,000 hatchery layoutdrawings havebeen made byour experts. Services OurService Department provides: - 24/7 helpdesk assistance from technical and incubation experts, - Documentation in13languages, - Acomprehensive Incubation Guide, - Freesoftwareupgrades, - Anextensivespareparts e-shop, - Hatcherytraining courses, - Service packs for maximum hatchery efficiency. Petersime has a modern Customer Service Centre with a showroom and training facilities at the headquarters. Moreover, an increasing number of local distributors have Certified Field Service Engineers and spare parts warehouses that can offer a fast solution to the problem in the local language. 18 CoverStory

- 19. Cover Story 19 poultry and hatchery industries are no exception to this global trend.Increasingcompetition in the poultry market and pressure on prices are driving hatcheries to maximize their production. Here at Petersime we view such a challenge as a good opportunity for improving the use of resources, such as energy and raw materials, in the most efficient way. A concrete example of our philosophy is our new range of single-stage incubators, the S-line. Our S-line provides higher chick output by ensuring a bio-secured environment, higher hatch performance, and high uniformity of day-old chicks, resulting in lower feed conversion ratios and increasing the efficiency in the meat processing chain. What's more, maintenance, labour and energy costs are reduced to a minimum. This way, the S-line is exactly what our customers need to keep their competitive position in the increasingly global and integrated poultrysector. People who contact us want a competitive initial capital investment and they expect a guaranteed return on their investment for many years to come. That's why we provide long-lasting solutions: an incubator can last 25-35 years and our equipment is designed to have a long life without worries. We select components and materials that are suited for intense use and are highly resistantto wearandtear. We're determined to be close to our customers and it's necessary to become a local player in developing countries like Russia, Brazil, India and China, where poultry companies are growing much faster than elsewhere. For example, we already are a local player in Brazil thanks to our History The origins of Petersime NV date back to the year 1912, when Mr Petersime invented the very first electric incubator in theUnited States. In the 1920s, the first models of this incubator were producedin the US and exported to Europe. In 1949, an agreement was concluded between the American exporter and Mr Bohez from Olsene, who started producing the incubators under license. 1949 thus saw the establishment of the Belgian company Petersime nv as we know it today. The year 1968 marked the end of this license agreement as well as the starting point of Petersime's own developments in Belgium. Numerous technical innovations lead to a dramatic increase of market recognition. The name “Petersime” was kept and soon became a symbol of leadership in the European markets and in the Middle East. In 1984, the company was taken over by an international investment group, an event followed by strong growth and increasing export, due to exploration of new markets. Continuous research investments led to the launch of Petersime's patented Embryo- Response Incubation™ technology in 2000: a system that constantly and interactively adapts the incubation parameters to create the optimum environment for each specific batch of eggs. One decade later, in 2010, the S-line was launched: state-of-the-art single-stage setters and hatchers, with a capacity of 14,112 to 115,200 chicken, turkey or duck eggs. The new product range immediately proved an enormous success in the market. Ourfocus Globalization is increasingly affecting our lives in every way possible, whether we like it or not.The

- 20. Press Release 20 [LEXINGTON, Ky.] –The Alltech 29th Annual International Symposium came to a close today, challenging delegates to take a glimpse into the future, search out opportunities to make an impact in the agribusiness industry and give the farmer of tomorrow a competitive advantage in the marketplace. Speaking to more than 2,300 delegates from 72 countries, Rebecca Timmons¸ global director of applications research and quality for Alltech, kicked off the closing session highlighting the latest applications for algae in livestock and human nutrition. While most of the attention on algae has focused primarily on it being a source for biofuel, microalgae contain large quantities of high quality eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA) that can bring additional nutritional improvements to feeds and food. Currently, the most common sources for DHA or “good fat” are fish meal and fish oil. However,Timmons said these products can often be inconsistent, unsustainable, unavailable, poor quality and unsafe. At Alltech's Algae production facility in Alltech Symposium Challenges Agribusiness to Make an Impact Winchester, Ky., Alltech SP-1 was recently developed to provide a consistent source of algae with a wide range of benefits for a variety of species as well as improvements for both ends of the value chain. Besides seeing an increase in immunity, a decrease in mortality and increased litter size in their herds, producers who utilize feeds with this type of algae will also be able to further brand their products as value-added DHA Omega-3enriched for consumers. “It's going to be two-fold; you're going to have those benefits to the animals as well as through the enriched product to consumers. This means you will be improving your return while creating a healthier population of both humans and animals all at the same time,”Timmons said. “We can reallychange the way wefeed the world, so we are not just looking at feeding the world but feeding theminabetterway.” Dr. Patrick Wall, University College Dublin, Ireland, expanded upon Timmons' presentation, stressing the importance of food safety in feeding today's growing population. The former veterinarian, medical doctor, businessman and European Food Safety Authority chairman said the curtain hasn't fallen on food scares and that every day a chronology of food scares and recalls show up in themedia. “Your jobs are so important. If something goes wrong in the food chain, the repercussions are huge. Everything an animal eats - so do we,” Wall said. “It takes millions of dollars and years to build a brand, but can take a few seconds to destroy it.” Wall said the problem with the food chain is that that we have convinced the consumer that it's a straight line from farm to fork; however, there is a major disconnect between the final consumer and modern agricultural practices with issues such as a rising population, diverting food to fuel, global food trade, downward pressure on price and inconsistent country regulations. Wall said every agricultural corporation needs to develop a fully integrated risk-based system by choosing trusted suppliers, managing a well-trained staff, implementing a stringent quality control and regulatory system, using the latest in composite testing, being proactive with consumers and the media, and developing a safe feed culture at the leadershiplevel. “We have the fundamental goal to provide safe, nutritious food. We are in the human health business. Doctors and nurses are in the sickness business,” Wall said. “What is our most valuable asset? It's not your farm, your stock or shares. It's About Alltech: Founded in 1980 by Dr. Pearse Lyons, Alltech improves the health and performance of animals, plants and people through natural nutrition and scientific innovation. With more than 3000 employees in 128 countries, the company has developed a strong regional presence in Europe, North America, Latin America, the Middle-East, Africa and Asia. For further information, visit www.alltech.com. For media assets,visit www.alltech.com/press. Alltech is the proud title sponsor of the Alltech FEI World Equestrian Games™ 2014 in Normandy. For more information about these prestigious global championships, visit www.alltechfeiweg2014-normandy.com.

- 21. 21

- 22. Press Release 22 your health and the health of your friends and family.Youarein thehuman healthbusiness.” Dr. Mark Lyons, vice president of corporate affairs at Alltech also stressed the importance of food safety as he shared the company's vision for helping expand agricultural production in China. According to Lyons, food security is seen as “the potential Achilles' heel of China” and is too big of an issue toignorepublicly. China's five-year plan focuses on making farms larger, more efficient and more traceable. For example, half of the world's pigs livein China and from those 50 million sows, 20 pigs per sow are born alive per year. This equals an annual production of one billion pigs per year. However, due to preweaning mortality, only 600 million actually go to market. The 400 million lost is three times the size of U.S. pig production. In China, one more pig per sow per year would meanone milliontonsof feed saved. “What is Alltech's five-year plan? We want to be a foreign brand with a Chinese heart,” Lyons said. “We want to firmly establish market leadership, partner with the government and leading feed, production and food companies, and give our customersacompetitiveadvantage.” Founder and president of Alltech, Dr. Pearse Lyons wrapped up Symposium, challenging the delegates to help the farmer of tomorrow and to use the resources provided to them at this year's event. “Are you going to fly or are you going to soar? Willyou flourish?” Dr. Lyons asked. “You need to leave here today and say, 'I may not rule the world, but I can have an impact on feeding the world's growing population.'” The Symposium's 175 contributors, 20 sessions and 22 discussion dinners focused on how agribusiness can meet the challenge to produce enough food to feed three billion new urban dwellers, or nine billion people in total by 2050. Poultry Prices Up on Reduced Output, Higher Feed Costs INDIA - A cut in production combined with a rebound in demand and rising feed prices have taken poultryand egg prices to a new high. The poultry industry was reeling under excess supply and low demand, leading to a crash in prices. But a harsh summer has resulted in an increase in chicken mortality across north India and Andhra Pradesh while farmers in other regionsslowedproductiontobring down loss. Poultry prices have now zoomed toRs 140-200 per kg in Kerala, which is predominantly dependent on supplies from neighbouring states. In May, prices were in the range of Rs 70-80 per kg. "There is a demand-supply gap now as production has come down. An increase in the cost of production due to high feed prices has also contributed to the rise in prices," said VK Mohan, general manager, Suguna Poultry Farms. In Tamil Nadu, prices have nearly doubled to Rs 110 per kg in the space of two months. With the arrival of the monsoon, demand has risen in western states. Trawling has been banned in Kerala and Karnataka, which has led to a decline in fish catch. This has led an increase in chicken consumption. In north India, which is still in the grip of summer, chicken shortage and rising feed cost have pushed up the prices. Prices have moved up from Rs 60 per kg in the first week of May to aroundRs85 perkg now. "Soya prices have doubled toRs 36-40 per kg in two years while maize prices continue to remain around Rs 13-14 per kg blowing up the cost of production. Production has also fallen by around 30 per c e n t , " s a i d R a m e s h ChanderKhatri, secretary of Poultry Federation of India. T h e decline in the rupee's v a l u e has inflated the prices of medicines given to chicken. "Almost 90 per cent of such medicines are imported," said Ram Reddy, president of Andhra Pradesh Poultry Breeders Association. Egg prices are now inching towards Rs 4 apiece after a 20 per cent cut in production when prices slid below Rs 3 last month. With egg prices ruling below the production cost of Rs 3.20 for most of the time last year, the sector has suffered heavy l o s s . T h e l o s s i n Namakkal in Tamil Nadu, the hub of egg production, would come to around Rs 240 crore, according to Dr P V Senthil, secretary of Livestock and Agri F a r m e r s T r a d e Association. "Retail prices are around Rs 3.80 per egg while the farm gate price is Rs 3.45, which means farmers are making a profit now. But this has to be sustained for a long time for farmers to recover from last year's loss," he said. Meanwhile, the government has failed to get Oman lift the ban on Indian egg imports. The two consecutive bans were imposed after incidences of bird flu in Karnataka and Bihar fromlastOctober.

- 23. Kemin reinforces the need for Optimal Nutrition Chennai, India – June 26, 2013 Profitability is the roadmap to successful business. Having focused on increasing production the efficiency of poultry production has reached an optimum. The feed prices are increasing at a tremendous rate and therefore out of a poultry farmers' control. Over the past five decades, Kemin has earned the reputation of being a total nutrition provider. Having extensive knowledge in the field of nutrition, Kemin has conceptualized a new theme called “Optimal Nutrition”. Optimal Nutrition is the roadmap for poultry farmers to increase nutrient utilization by the bird without compromising on bird performance therefore increasing profitability. It is the process by which the farmer can increase his profitability by controlling things that are under his control. Optimal Nutrition focuses on the three facets of the birds' digestion – Breakdown & Absorption of nutrition, Gut Health and Efficiency. By focusing on all the facets, we provide a holistic support for the bird to efficiently achieve its genetic potential. In order to increase awareness among poultry farmers and consultants on the benefits of Optimal Nutrition and the need for focus on nutrition to enhance profitability, Kemin conducted two Kemin Kontact programs at Coimbatore and Bangalore on 24th and 25th of June 2013 and will be conducting more such events across the country in the near future. The main focus of these programs was to encourage the industry to redirect the industry to focus on the nutrient wastage that result in loss in profitability. During his discourse, Dr. Chris Nelson, PhD, now President and CEO of Kemin, had enthralled the audience with his powerful insight about the dynamic changes around the world that have resulted in drastic changes in agriculture and feed availability. Talking further, Dr. Chris Nelson, stressed upon the need to focus on the adaptability to the changing environment in order to ensure continual survival. Taking it further from Dr. Nelson, Mr. K.P. Philip, President, Kemin Industries South Asia P Ltd, captivated the audience with his insight about the amount of nutrient wastage in our Industry. He reiterated that the prices of chicken have not kept pace with rise in price of feed costs and therefore using Optimal Nutrition was significant. As he explained the Kemin, founded in 1961 by R.W & Mary Nelson, was and still is family effort based on developing innovative products and delivering outstanding services. Today, R.W & Mary work alongside their son and company president Dr. Chris Nelson at the global headquarters inDesMonies, Iowa. Kemin Agrifoods South Asia Pvt ltd is 100% subsidiary of its US Parent Kemin Industries. Kemin has completed 50 years of its existence in 2011 and has established a very strong presence in all the continents of the world. In the past five decades, Kemin Industries has grown into a global company that provides innovative ingredients to various segments including Animal Nutrition, Human health, Pet healthy, crop sciences, Pharmaceuticals and beauty industry. Kemin is focused in achieving its vision of touching and improving the quality of life of half the population of the world with its product and services and is currently able to reach 1.5 billion people across the world on daily basis. Kemin has committed and invested in an advanced research and production facility in India early on and built its first plant in Gummidipoondi in Chennai in 2000. The plant was expanded in 2011 and the production of organic minerals commenced in India. Currently Kemin India is the only subsidiary of Kemin, which is locally producing organic minerals other than the parent company intheUSA. Kemin South Asia produces all its products in India under stringent quality control measures and is certified with IS0 9000, HACCP,GFSI etc. The research Centre in India is well equipped and has employed numerous top scientists and is currently doing research in the fields of Biochemistry, Microbiology, Bio technology etc. Kemin India has modern animal research facilities and has tied up with many leading veterinary university in the region and has done many scientific publications and filed global patents for its products. Kemin has supported the Poultry, Dairy and Aqua industry through its strong technical services, laboratory services and engineering services. Using its global presence and awarenessKeminhas done extensivestudy in all the fields it is present in and constantly challenged the industry practices and introduced novel and path breaking technologies to increase the return on investmentsof its customers. Kemin will continue its focus in adding value to its customer business in the coming years and through its “Total Nutrition” approach and is committed to provide safety, health and efficiency for the animals and the consumers and though its capable technical and laboratory support. It strives to elevate the customers quality consciousness and input quality consistently. Kemin's goal is to be the leader in the animal nutrition and in the health business by offering superior products and services in the industry weserve. For media inquiries, please contact: manasi.v@kemin.com Kemin Industries at Glance Press Release 23 Dr. Chris Nelson, PhD, now President and CEO of Kemin Mr. K.P. Philip, President, Kemin Industries South Asia different nutritional available to the bird, he stress upon the amount of gross energy that is wasted in the feaces. Indicating one of the many lapses in nutrient utilization, Mr. Philip showed how the proteases and the NSPases failed to completely Poultry Delegation at Kemin Kontact

- 24. digest the nutrients available in the feed. He highlighted that currently, different additives were used to achieve digestibility of different nutrients. However, birds require a unique Hyper-Enzyme system to ensure complete digestion and absorption of all the nutrients. Highlighting the significance of healthy gut for preventing of disease incidence and better nutrient utilization, he shared experimental data and statistics to indicate the difference in performances. IAI Farm Automation & Bioenergy Conference international animal industry expo 8thin series 20 February 2014 IARI Ground, PUSA Campus, New Delhi For more information +91 9991705005/06, 9812082121 poultry@pixie.co.in, vishal@pixie.co.in Organizer www.iaiexpo.com IAI Farm Automation & Bioenergy Conference lobal animal health and nutrition company, Alltech has appointed Dr Tugrul Durali as Asia-Pacific technical manager for Alltech's Mycotoxin Management Team. Based in Sydney, Durali will provide technical support to the company's local and regional accounts, focusing on Alltech's On- Farmprogram. Durali started his professional career as an intern in 2001 at one of the biggest egg and poultry meat producers in Turkey focusing on aflatoxicosis in layer hens, then joining the Turkish Armed Force where he graduated as a veterinarian lieutenant from the Army Veterinarian College. After returning to civil life, Durali received training on turkey breeder health, management and artificial insemination from a leading Israeli company specialising in thepoultrybreederfield in theMiddle East. Durali later worked as a poultry veterinarian at another company, focusing on gut health and mycotoxicosis on broiler and breeder productions, and then moved to Australia to join a leading poultry producer as a technical services manager. His interests in improvement of poultry welfare with nutrition and particularly antibiotic free production led him to establish research trials, and he played a major role in the establishment of the company's free range broilerproduction. Alltech's Mycotoxin Management program was launched in early 2012 in order to help producers in their control of mycotoxins through a combination of mycotoxin management programs and technologies. Alltech appoints technical manager for Asia-Pacific NEWAPPOINTMENTS Press Release 24 The Kemin Seminars provided a neutral ground for healthy discussion on the raising feed costs, optimal nutrition and techniques t o i m p r ov e p r o f i t a b i l i t y w i t h o u t compromising on bird performance. Poultry Press with Kemin Team at Kemin Industries South Asia Pvt. Ltd. in Chennai Dr. Samraj Jeyachandran Senior Vice President, Kemin Industries South Asia Pvt. Ltd.

- 25. 25

- 26. Press Release 26 OFFICE BEARERS: 1 DR.G.RANJIT REDDY PRESIDENT MANAGING DIRECTOR S.R HATCHERIES (P) LTD., 2 MR.V. HARSHAVARDHAN REDDY VICE PRESIDENT MANAGING DIRECTOR LAKSHMI VENKAT FARMS LTD 3 MR. G. RAMESH BABU GENERAL SECRETARY MANAGING DIRECTOR DIAMOND HATCHERIES PVT. LTD. 4 MR.C.MADHUSUDHAN RAO JOINT SECRETARY MANAGING DIRECTOR JANAKI FEEDS PVT LTD 5 MR. K.S. REDDY TREASURER MANAGING DIRECTOR SAI KRUPA HATCHERIES PVT.LTD. EXECUTIVE COMMITTEE MEMBERS: 6 MR. D. RAM REDDY MEMBER MANAGING DIRECTOR SNEHA FARMS (P) LTD. 7 MR. M. DAMODAR REDDY MEMBER MANAGING DIRECTOR CRYSTAL HATCHERIES PVT. LTD. 8 MR. D. RAGHAVA RAO MEMBER MANAGING DIRECTOR KOHINOOR HATCHERIES PVT LTD 9 MR. JAMES AMALANATHAN MEMBER GENERAL MANAGER SUGUNA FOODS LTD., 10 MR.K.ASHOK REDDY MEMBER MANAGING DIRECTOR SAURI BREEDING FARMS PVT LTD., 11 MR. P. RAMA RAO MEMBER DIRECTOR SIRI BREEDERS PVT. LTD. SPECIAL INVITEES 1 MR.K.G. ANAND GENERAL MANAGER VENKATESWARA HATCHERIES PVT LTD 2 MR. S. BALASUBRAMANYAM GENERAL MANAGER – (INT) VENKATESWARA HATCHERIES PVT.LTD. 3 MR. K V S SUBBA RAJU ZONAL CHAIRMAN NATIONAL EGG COORDINATION COMMITTEE 4 MR. D. SUDHAKAR PRESIDENT A .P. POULTRY FEDERATION The annual General Body Meeting of Poultry Breeders Association(A.P) was held on 15/6/2013 at Hotel Blue Fox,Banjara Hills, Hyderabad. The Meeting was presided by Mr.D.Ram Reddy President of the Association. The meeting was attended by as many as 80 members. President in his welcome speech has made a remark stating that the unprecedented increase in the prices of essential ingredients of poultry feed i.e. Soya meal and Maize has put the industry into crisis. Thus there is imbalance between the marketing cost and the output cost. He further made an appeal to all the members the need for unity and also to chalk out measures to restore economic viability and accelerate future growth of industry. Later on President took up the agenda items and requested the General Secretary Mr.G.Ramesh Babu to present the annual secretary report. Mr.K.S.Reddy Treasurer of the Association was also to present the treasurer report for the year 2012-2013 . Both have presented their respective reportstothehouse. President took up the election agenda and nominated Mr.K.G.Anand and Mr.K.V.S.Subba Raju as the returning officers and requested to conduct the election for 11 executive committee posts for the year2013-2015. The members have unanimously elected the Executive committee members who in turn have elected office bearers. The list of of office bearers, executive committee members and the special invitees for the term 2013-15, functional effective from 16/6/2013 areas follows: The newly elected president and his team took over the charge. In his concluding remarks he sought the co-operation of all the members as the coming two years is crucial for the new team and needs hard work to fulfill the aspirations of the members. He also thanked the outgoing presidentand his teamfor their good work. NAME OF THE ORGANISATION M/s. SHATHAVAHANA BREE. & HAT. P. LTD. Mr. G. RAJESHWARRAO M/s. SAVITHA HATCHERIES PVT. LTD., Mr.V.DHANAMJAYAREDDY M/s. SHASHIKALA HATCHERIES PVT LTD. MR.V. NARSIMHAREDDY M/s. SINGH POULTRY PVT. LTD., Mr. HARBANSSINGH M/s. SIRI BREEDERS PVT. LTD., Mr. P. RAMARAO/ Mr.HARSHAVARDHAN M/S. SNEHA FARMS PVT. LTD., Mr. D. RAMIREDDY M/s.VARUN BREEDING FARM. Mr. A. GOPALREDDY M/s. DENDI AGRO FARMS PVT. LTD. Mr. D. RAMIREDDY M/s. SOMANATH POULTRY GROWER FARM Mr. A. SRINIVAS M/s. SREE LAKSHMI HATCHERIES PVT. LTD., Mr.V.YADAGIRIREDDY M/s. SLR HATCHERIES PVT. LTD. Mr.V.VIJAYABHASKARREDDY M/s. SRI LAKSHMI POULTRY BREEDER FARM Mr. M. LAKSHMINARAYANA M/s. S.R. HATCHERIES PVT. LTD., Dr. G.RANJITH REDDY, Dr. A. TIRUPATHI REDDY M/s. SRI RAMANA HATCHERIES PVT. LTD., Mr. K.MOHANREDDY M/s. PUNNAMI HATCHERIES Mr. K. ABHILASH REDDY M/s. SRIVEN HATCHERIES MR.P.V. KRISHNAREDDY M/s. SRIVENKATESHWARA BR.FARM & HAT Mr. NUCHE MALESH M/s. SRIVENKATESWARA FARMS & FEEDS Mr. P. SATYANARAYANAREDDY M/s. SriVINAYAKA HATCHERIES Mr. S.VENKAT REDDY M/s. S.S.A. HATCHERIES PVT. LTD., Mr. S. CHAITANYA M/s. S. S. HATCHERIES Mr. S. NAGESWAR M/s. STANDARD BREEDERS PVT. LTD. Mr.VENE GOPAL M/s. STANEX BREEDING FARMS PVT LTD Mrs. K. BHAGAWANREDDY M/s. SUGUNA POULTRY FARM LTD., MR.V.VENKATARAMANA M/s. SUMANTH BREEDERS Mr. N. SRINIVAS M/s. TIRUMALA BREEDERS PVT. LTD., Mr. P. RAMAKRISHNA M/s. TIRUMA HATCHERIES PVT. LTD. Mr. VENUGOPAL M/s.VENKATADRI BREEDERS Mr. B. SRINIVAS M/s.VENKATESHWARAHATCHERISPVTLTD., Mr. K.G. ANAND M/s.VENKATESHWARAHATCHERISPVTLTD., Mr. S. BALASUBRAMANYAM General Body Meeting of Poultry Breeders Association

- 27. International platform to discuss the nutritional issues faced by Indian Poultry Industry st 21 Feb 2014 Alternate Feed Resources Feed Storage Feed Milling Solutions Layer Nutrition Mycotoxin Prevalence Broiler Nutrition Principle Sponsor Organizer Pixie Consulting Solutions Ltd. IAI Nutrition Forum IARI Ground, PUSA Campus New Delhi INDIA Profitability n Concurre t Event t interna ional mania al industry expo IAI Expo 2 br y 20-2 Fe uar 2014, AR u A I I Gro nd, PUS , w l Ne De hi www.iaiexpo.com For more details contact: +91 9991705621 | marketing@pixie.co.in 27