Melden

Teilen

Downloaden Sie, um offline zu lesen

Empfohlen

1-1 Influence of Multi Extrusion Die Process on Mechanical and Chemical Behav...

1-1 Influence of Multi Extrusion Die Process on Mechanical and Chemical Behav...Ahmed Ibrahim Razooqi

Weitere ähnliche Inhalte

Andere mochten auch

Andere mochten auch (9)

Ähnlich wie SCC Research Guide

1-1 Influence of Multi Extrusion Die Process on Mechanical and Chemical Behav...

1-1 Influence of Multi Extrusion Die Process on Mechanical and Chemical Behav...Ahmed Ibrahim Razooqi

Evaluating Concrete Quality using Nondestructive In-situ Testing Methods

Evaluating Concrete Quality using Nondestructive In-situ Testing MethodsKhalid Abdel Naser Abdel Rahim

Ähnlich wie SCC Research Guide (20)

A fracture mechanics based method for prediction of

A fracture mechanics based method for prediction of

Pullout test as a nondestructive test method in structural engineering

Pullout test as a nondestructive test method in structural engineering

Pullout test as nondestructive test method in structural engineering

Pullout test as nondestructive test method in structural engineering

Fracture mechanics-based method for prediction of cracking

Fracture mechanics-based method for prediction of cracking

1-1 Influence of Multi Extrusion Die Process on Mechanical and Chemical Behav...

1-1 Influence of Multi Extrusion Die Process on Mechanical and Chemical Behav...

The Effects of Copper Addition on the compression behavior of Al-Ca Alloy

The Effects of Copper Addition on the compression behavior of Al-Ca Alloy

Correlation between the Interface Width and the Adhesion Strength of Copper F...

Correlation between the Interface Width and the Adhesion Strength of Copper F...

Fluid Dynamic Simulation and Experimental Study of Honeycomb Seal Structures ...

Fluid Dynamic Simulation and Experimental Study of Honeycomb Seal Structures ...

Evaluating Concrete Quality using Nondestructive In-situ Testing Methods

Evaluating Concrete Quality using Nondestructive In-situ Testing Methods

Study and Experimental Modelling of Welding Parameters on Hardness of Hot Air...

Study and Experimental Modelling of Welding Parameters on Hardness of Hot Air...

Approach to simultaneous improvement of strength, ductility

Approach to simultaneous improvement of strength, ductility

SCC Research Guide

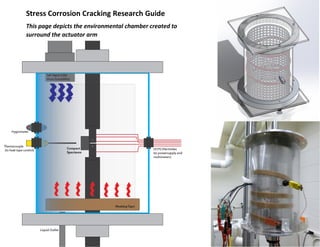

- 1. Stress Corrosion Cracking Research Guide This page depicts the environmental chamber created to surround the actuator arm

- 2. The load chain and CT specimens were designed to meet ASTM E647 Crack growth was measured using the direct current potential drop (DCPD) method to circumvent temperature and corrosion affecting the strain gauges U-bend samples were also tested to examine the effects of residual stress rather than applied stress U-bend surface SCC over 17 days U-bend test sample Compact Tension sample

- 3. Stress Corrosion Cracking Research Results This graph shows varying SCC rates dependent on environmental and material factors. Increased temperature had a large effect on SCC acceleration This graph shows SCC pitting rates dependent on environmental and material factors. There was an upper threshold to pitting initiation due to ion consumption from neighboring pits